Closed cycle spray drying and solvent recovery system

A closed-circuit circulation and recovery system technology, which is applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of limiting the range of use of the drying system, wasting production costs of products, and not suitable for viscosity atomization, etc., to achieve cleaning Easy to disassemble and install, easy to clean, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

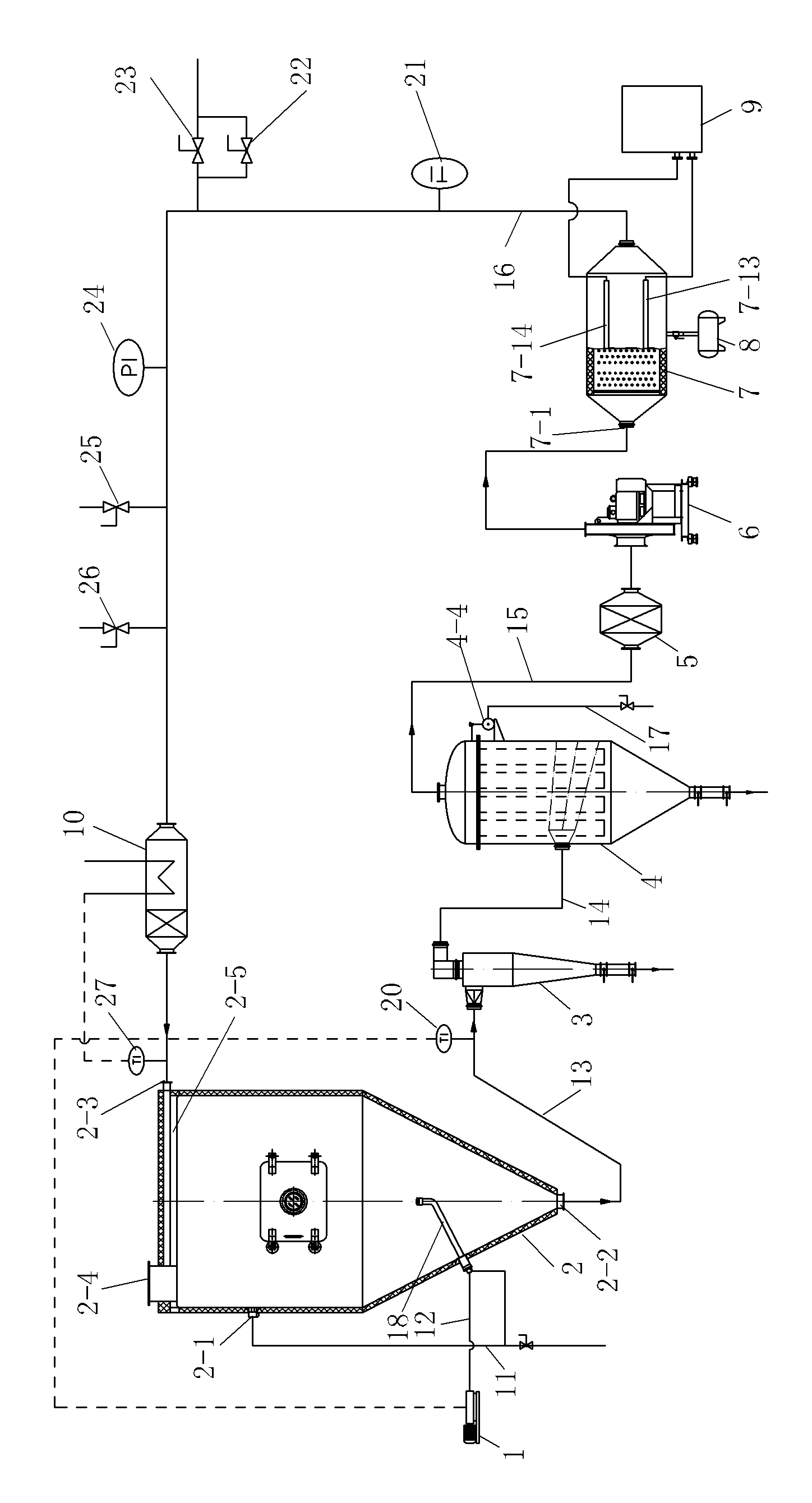

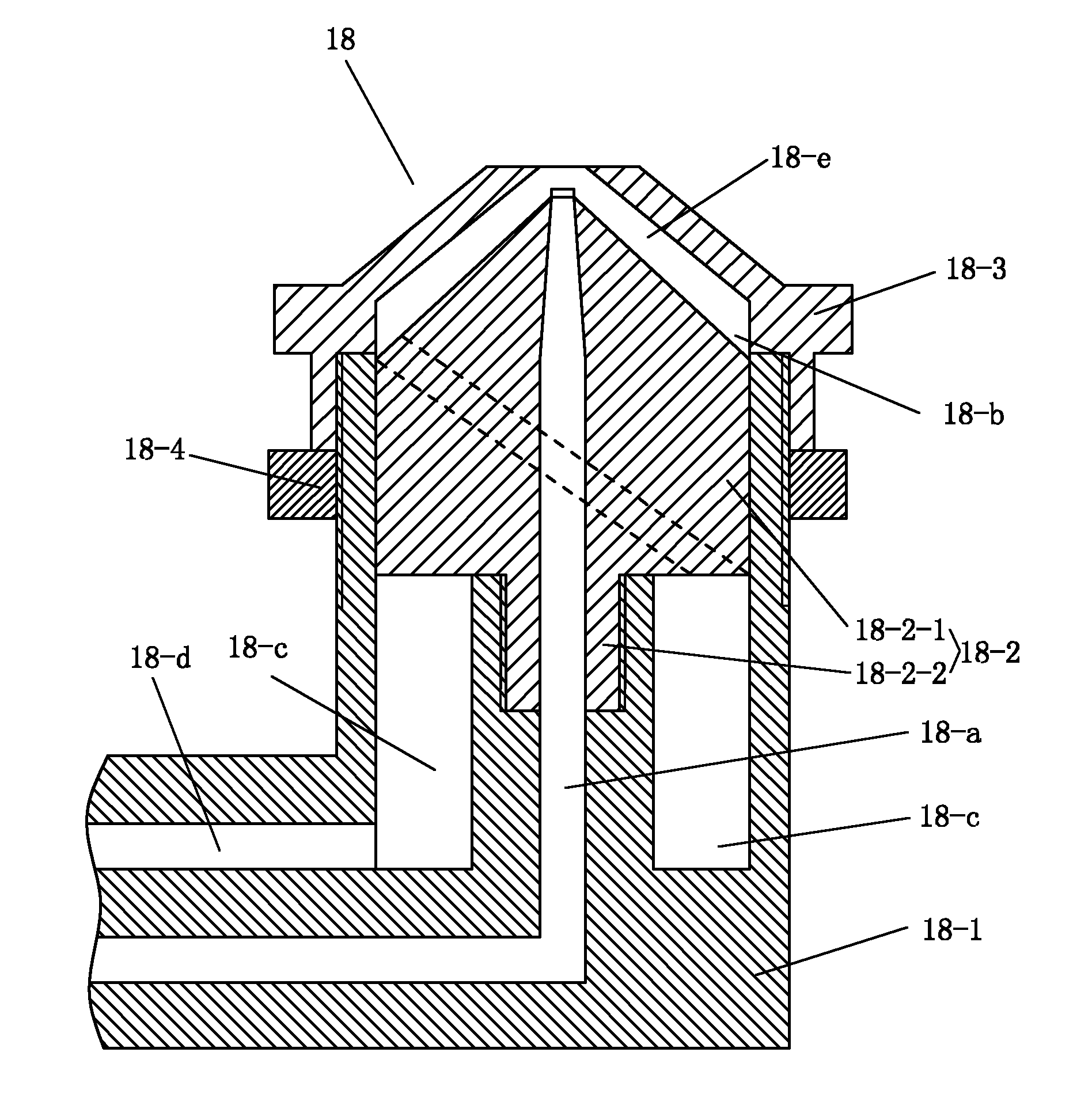

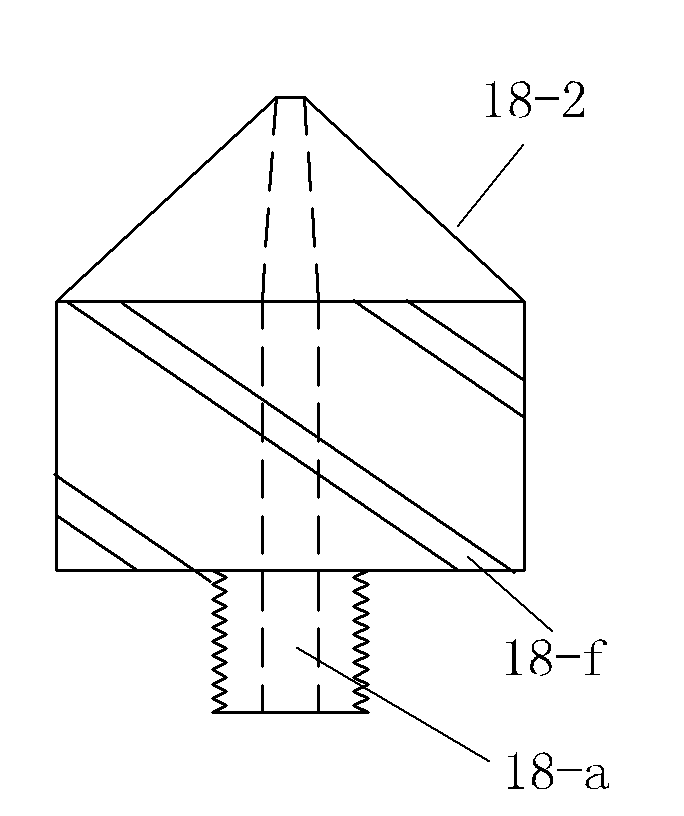

[0027] See figure 1 , the present embodiment includes a feed pump 1, a spray drying tower 2, a dust remover, a three-stage filter 5, a closed fan 6, a condenser 7, a heater 10, and the dust remover includes a cyclone dust collector 3 and a bag filter 4 . The upper part of the tower body of the spray drying tower 2 is provided with an air hammer 2-1, and the lower part of the tower body is provided with an air-flow sprayer 18, and the feed pump 1 is connected with the feed port of the air-flow sprayer 18 through a feed pipe 12, and No. 1 Nitrogen gas supply pipe 11 is connected with the feeding port of air hammer 2-1 and airflow sprayer 18 respectively by two branch pipes. The air outlet at the bottom of the spray drying tower 2 is connected with the air inlet of the cyclone dust collector 3 by No. 1 pipeline 13, and the air outlet of the cyclone dust collector 3 is connected with the air inlet of the bag filter 4 by No. 2 pipeline 14, The air outlet of the bag filter 4 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com