Tail gas treatment device of high-temperature sintering furnace for graphite production

A technology for high-temperature sintering and tail gas treatment, which is applied in water/sewage treatment, flotation water/sewage treatment, neutralization water/sewage treatment, etc. It can solve complex components, unstable tail gas composition, and non-environmentally friendly exhaust methods, etc. problems, to achieve the effects of increasing acidity and alkalinity, saving tail gas treatment costs, and ensuring long-term recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

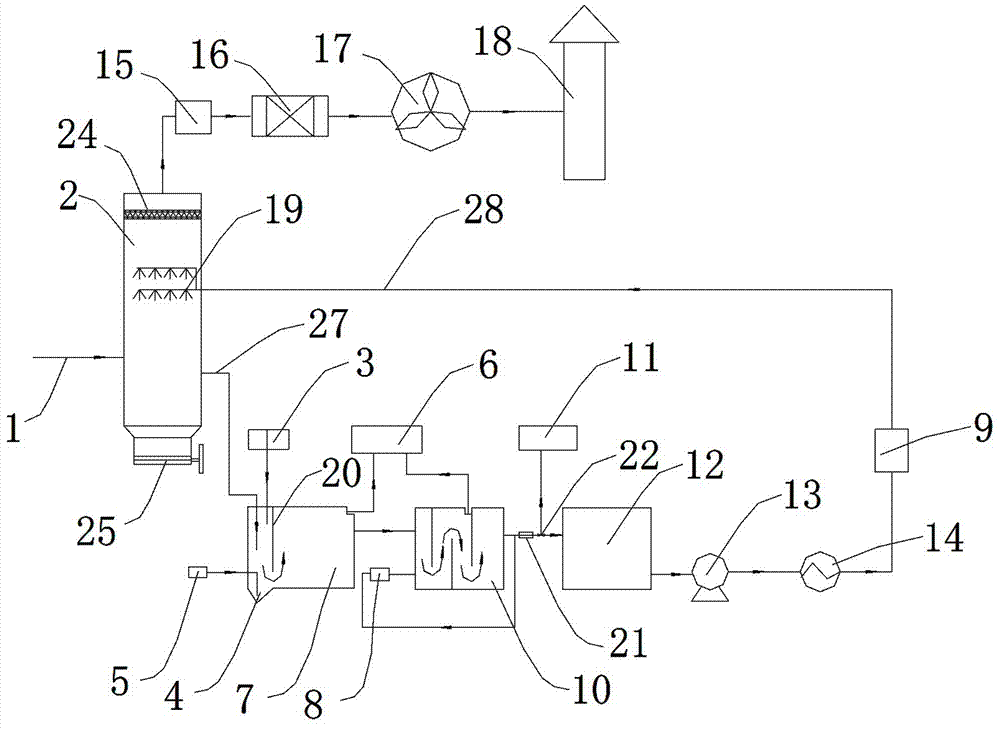

[0028] Such as figure 1 As shown, the high-temperature sintering furnace tail gas treatment device for graphite production includes a spray tower 2, and the spray tower 2 is provided with an inlet pipe 1 through which flue gas enters, and the side wall of the spray tower 2 is provided with a discharge The liquid outlet pipe 27 of the cooling liquid and the liquid spray pipe 28 for transporting the cooling liquid. The liquid outlet pipe 27 is located below the liquid spray pipe 28. In this embodiment, the cooling liquid is industrial standard water, and the gas coming in from the air inlet pipe 1 The composition is complex, mainly containing gasified asphalt and sulfide, in which the asphalt condenses to form a greasy liquid, part of the sulfide is soluble in water, and the other part is insoluble in water, and the water-insoluble sulfide condenses to form solid sulfide, which is then mixed with asphalt Among them, the condensed greasy substance accumulates on the side wall and...

Embodiment 2

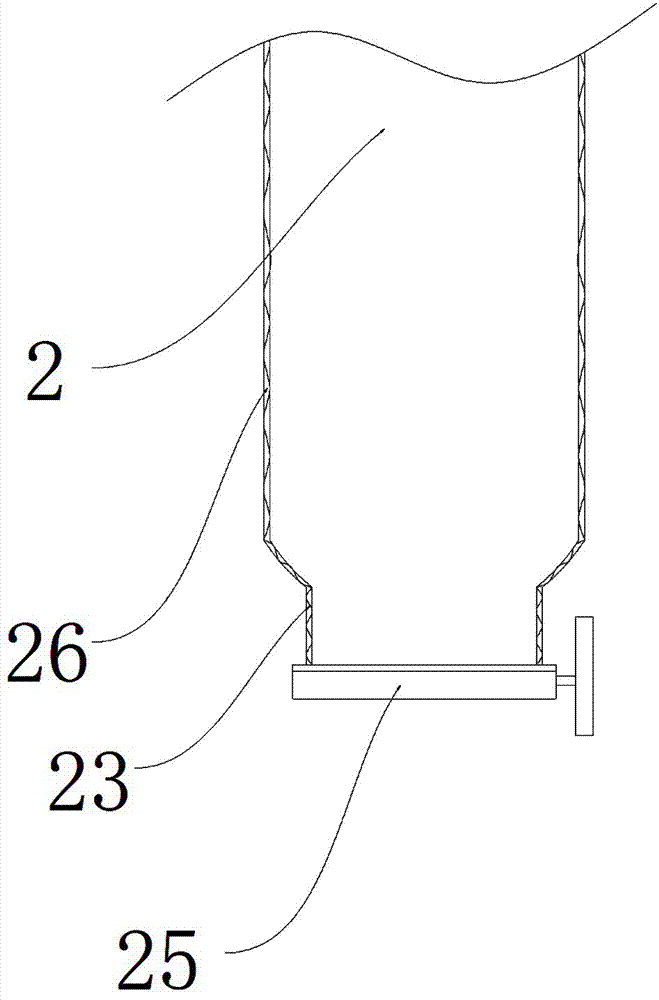

[0034] The structure of this embodiment is basically the same as that of Embodiment 1, the only difference is that the heating device is different. In this implementation, the heating device is a water heating device, and the water heating device is heated by steam. The tower 2 is provided with an air inlet communicating with the heating chamber 26 and an air outlet communicating with the heating chamber 26. In this embodiment, the temperature of the water is high-temperature water of 70-90 degrees Celsius. When it is necessary to open the blanking valve At 25:00, high-temperature water is introduced a few minutes earlier, and the high-temperature water transfers heat energy to the inner wall of the spray tower. The oily liquid softens at this temperature, and its viscosity is greatly reduced. The spray tower 2 can be quickly discharged, and because the spray tower 2 has a temperature of 70~90°C, the greasy liquid in contact with the spray tower 2 can be quickly softened and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com