Foaming heat preserving material and production method thereof

A technology of thermal insulation material and production method, applied in the field of foam thermal insulation materials, can solve the problems of solid waste pollution and environmental pollution, and achieve the effects of low price, stable operation and high flue gas desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

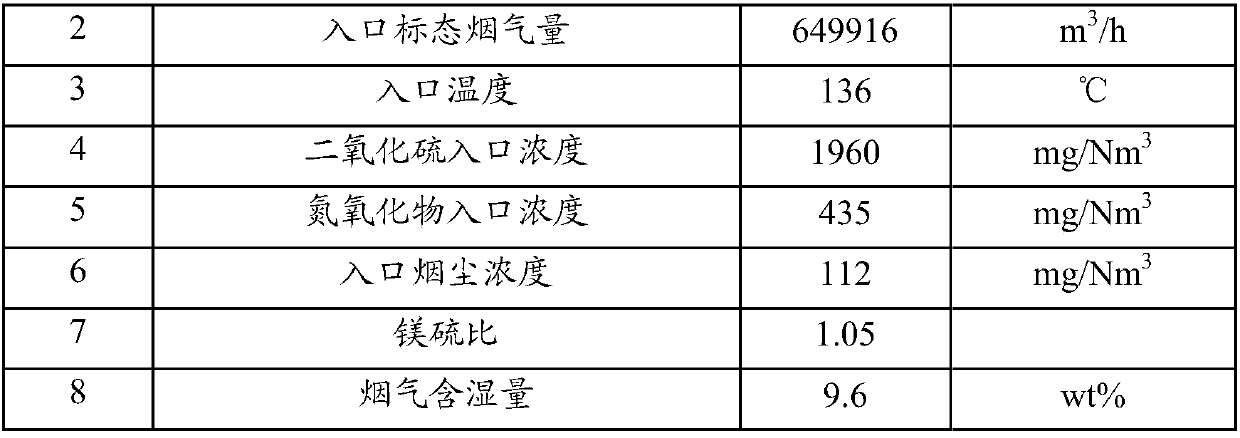

[0067] Add magnesium oxide powder to alkaline wastewater to make flue gas absorbent, and send it to desulfurization tower. The flue gas (with an oxygen content of 18vol%) enters the desulfurization tower, and after passing through three absorption spray layers, the sulfur dioxide gas is fully absorbed by the flue gas absorbent. After the flue gas absorbent absorbs sulfur dioxide, it forms an absorption product containing magnesium sulfate (at a temperature of 30°C and a density of 1.2t / m 3 ), and then enter the slurry circulation tank in the lower part of the desulfurization tower. The slurry in the upper part of the slurry circulation tank in the tower is sent to the three absorption spray layers respectively, and the circulation volume of the three accounts for 50vt% of the total output. The pH of the slurry in the lower part of the slurry circulation tank in the tower is discharged after reaching 6.5, and is used as the flue gas absorption slurry. The flue gas is demisted...

Embodiment 1

[0073] The flue gas absorption slurry that preparation example 1 gained, collect the steel slag (specific surface area is 500m3) from steel mill 2 / kg), the fly ash from the coal-fired boiler and additives were mixed and stirred for 30 minutes to obtain a mixed slurry. Then, while stirring at a high speed, add hydrogen peroxide, and continue stirring for 5 seconds to obtain a foaming material. Immediately inject the foaming material into the mold for foaming, and perform initial curing for 8 hours at a temperature of 30°C and a humidity of 60% after the injection molding is completed. After demoulding, it is cut into required specifications, and then naturally cured outdoors for 15 days to obtain foamed insulation materials, which are then sent to packaging machines for packaging. See Table 3 for recipes. See Table 4 for performance test results.

[0074] Table 3. Foam insulation material formula

[0075] Material name

fly a...

Embodiment 2

[0079] Except adopting the prescription of Table 5, all the other conditions are identical with embodiment 1. See Table 6 for performance test results.

[0080] Table 5. Formula of foam insulation material

[0081] Material name

magnesium oxide

additive

Specifications (kg)

70

45

40

25

5

1

[0082] Table 6. Properties of foam insulation materials

[0083] Water absorption / %

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com