Method for purifying aluminum-silicon-iron alloy through low-temperature remelting, centrifugal separation and grading

A centrifugal separation and ferroalloy technology, applied in the field of smelting, can solve problems such as inability to carry out efficient and large-scale practical applications, and achieve the effect of great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

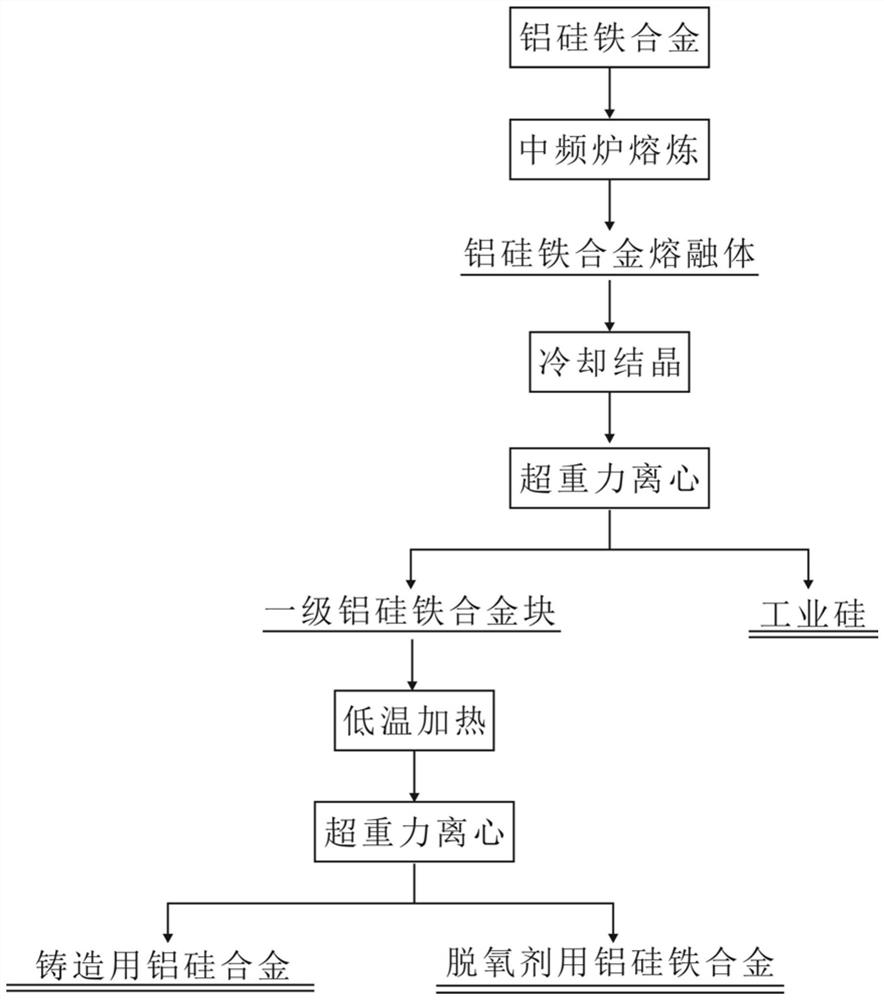

[0029] A method for low-temperature remelting, centrifugal separation, and graded purification of Al-Si-Fe alloys, the process flow chart of which is as follows figure 2 shown, including the following steps:

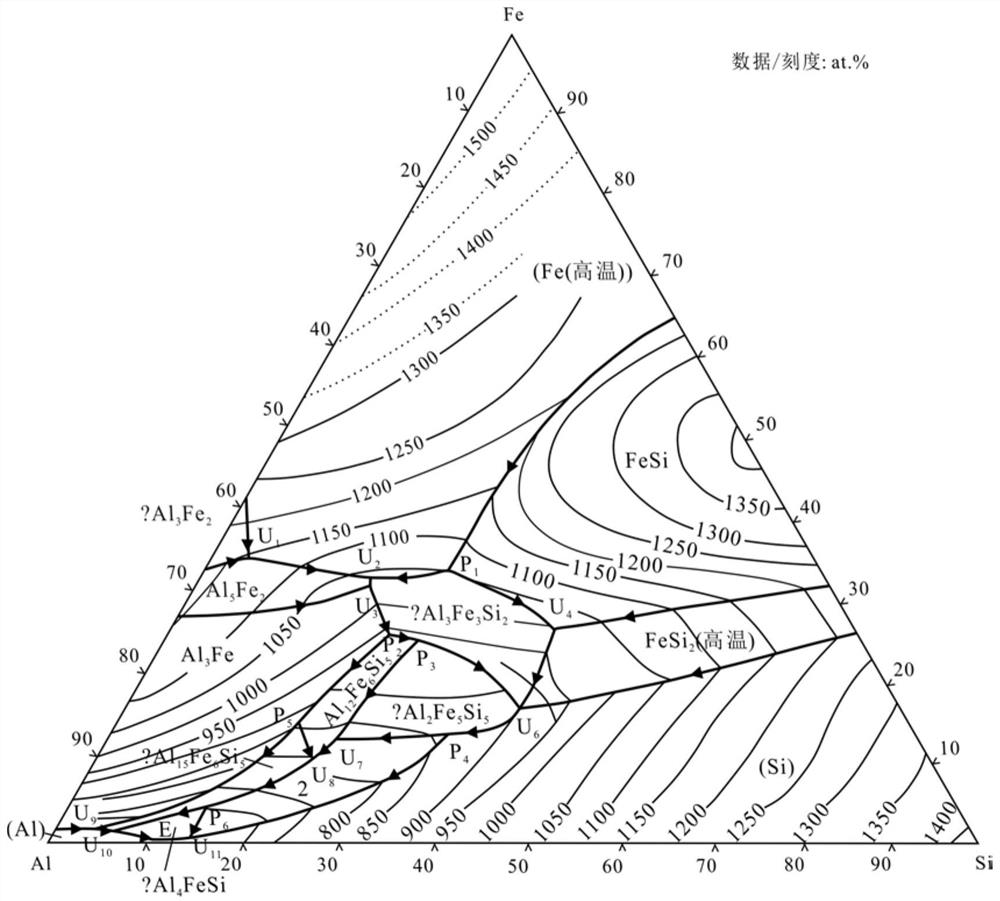

[0030] Put 100kg of Al-Si-Fe alloy into an intermediate frequency furnace for high-temperature smelting, the temperature of the molten material is 1400-1600°C, the mass fraction of Al in the Al-Si-Fe alloy composition is 53.21%, the mass fraction of Si is 42.50%, and the mass fraction of Fe is 2.45%. Aluminum-silicon-iron alloy melt; put the alloy melt into the supergravity centrifugal device with heating device, then cool down to 900℃ at 2°C / min, keep it at this temperature for 180min, start the centrifuge, the supergravity coefficient is 212g, and separate The time is 10 minutes. Under the action of supergravity, the melt is separated through the porous filter plate. After the melt is cooled and solidified, 16.25kg of industrial silicon is obtained. Such as figure 1...

Embodiment 2

[0033] A method for low-temperature remelting, centrifugal separation, and graded purification of Al-Si-Fe alloys, the process flow chart of which is as follows figure 2 shown, including the following steps:

[0034] Put 100kg of Al-Si-Fe alloy into an intermediate frequency furnace for high-temperature smelting, the temperature of the molten material is 1400-1600°C, the mass fraction of Al in the Al-Si-Fe alloy composition is 53.21%, the mass fraction of Si is 42.50%, and the mass fraction of Fe is 2.45%. Aluminum-silicon-iron alloy melt; put the alloy melt into a supergravity centrifugal device with a heating device, then cool down to 950℃ at 3°C / min, keep warm at this temperature for 60min, start the centrifuge, the supergravity coefficient is 212g, and separate The time is 10 minutes. Under the action of supergravity, the melt is separated through the porous filter plate. After the melt is cooled and solidified, 11.02kg of industrial silicon is obtained. Such as figure ...

Embodiment 3

[0037] A method for low-temperature remelting, centrifugal separation, and graded purification of Al-Si-Fe alloys, the process flow chart of which is as follows figure 2 shown, including the following steps:

[0038] Put 100kg of Al-Si-Fe alloy into an intermediate frequency furnace for high-temperature smelting, the melting temperature is 1400-1600°C, the mass fraction of Al in the composition of Al-Si-Fe alloy is 53.46%, the mass fraction of Si is 39.43%, and the mass fraction of Fe is 5.20%. Aluminum-silicon-iron alloy melt; put the alloy melt into the supergravity centrifugal device with heating device, then cool down to 900℃ at 2°C / min, keep it at this temperature for 180min, start the centrifuge, the supergravity coefficient is 212g, and separate The time is 10 minutes. Under the action of supergravity, the melt is separated through a porous filter plate. After the melt is cooled and solidified, 18.10 kg of industrial silicon is obtained. Such as figure 1 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com