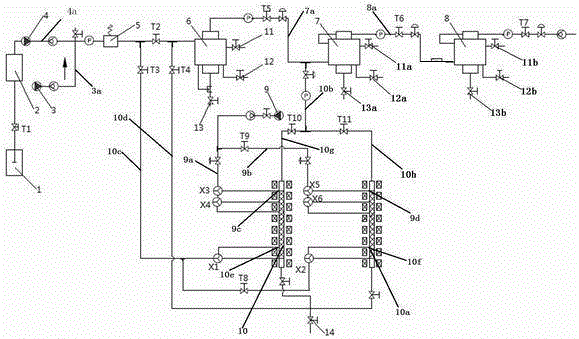

Supercritical fluid extraction, rectification and chromatography preparation device and control method thereof

A technology for supercritical fluid and preparation device, applied in the field of chromatography devices, can solve the problem of high cost consumption, and achieve the effects of reducing labor intensity, saving labor costs, and ensuring safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

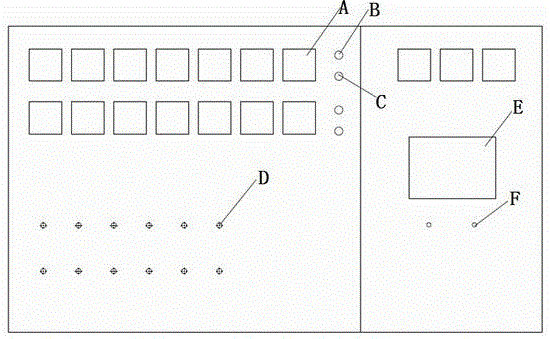

Method used

Image

Examples

Embodiment 1

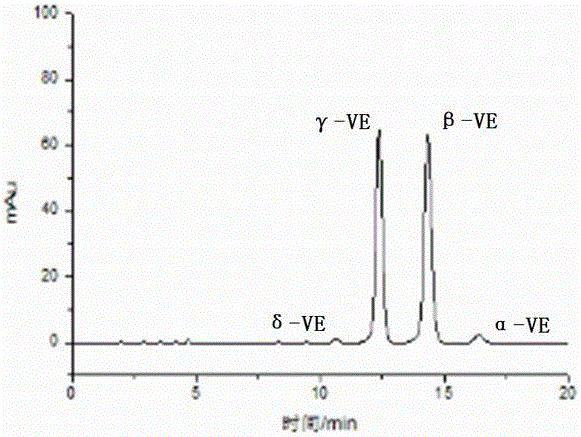

[0052] The raw material is the deodorized distillate of soybean oil, which has been methylated, and the natural vitamin E content is 6.27%.

[0053] The single-column mode of the rectification tower is used to open the first stop valve T1, the third stop valve T3, the tenth stop valve T10, the sixth stop valve T6, and the seventh stop valve T7 to form the flow direction of the liquid path; the soybean oil deodorization distillate is obtained by Feed pump 9 is transported to the first rectification tower 10 through the first feed branch pipe 9a, the first feed inlet 9c, rectification sample and supercritical CO 2 Dissolved, the dissolved part is subjected to rectification treatment on the sample through the temperature gradient of the rectification tower, and then the first CO at the upper end of the first rectification tower 10 2 The output branch pipe 10g, the rectifying tower pipeline 10b, enter the first separation kettle 7 and the second separation kettle 8 in turn, and di...

Embodiment 2

[0059] The raw material is fish oil, which has been ethyl-esterified, and the content of EPA and DHA is 30%.

[0060] The conditions of supercritical fluid distillation are as follows: temperature gradient of rectification tower (from bottom to top): 40-90°C; first separation tank: 45°C; second separation tank: 45°C; feeding port: feeding port in Section 3; Feeding speed: 1mL / min; CO 2 Flow rate: 100mL / min; pressure: 15MPa, keep for 5h.

[0061] Supercritical fluid chromatography conditions are as follows: Chromatographic column packing: silica gel (300-400 mesh); extraction kettle, first separation kettle, 2 temperature: 40°C; extraction kettle, first separation kettle pressure: 15MPa; second separation kettle pressure: 1 MPa; CO 2 Flow rate: 100mL / min, hold for 30min, enrich EPA and DHA.

[0062] After product analysis, the natural vitamin E content increased from 30% to 96%, and the recovery rate was 90.44%.

[0063] The invention has the advantages of no reagent consum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com