Centrifugal Pump Comprising a Spiral Housing

a centrifugal pump and spiral housing technology, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of damage to electronic components, inability to avoid liquid or vapor passing, etc., and achieve the effect of reducing the overall space required for centrifugal pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

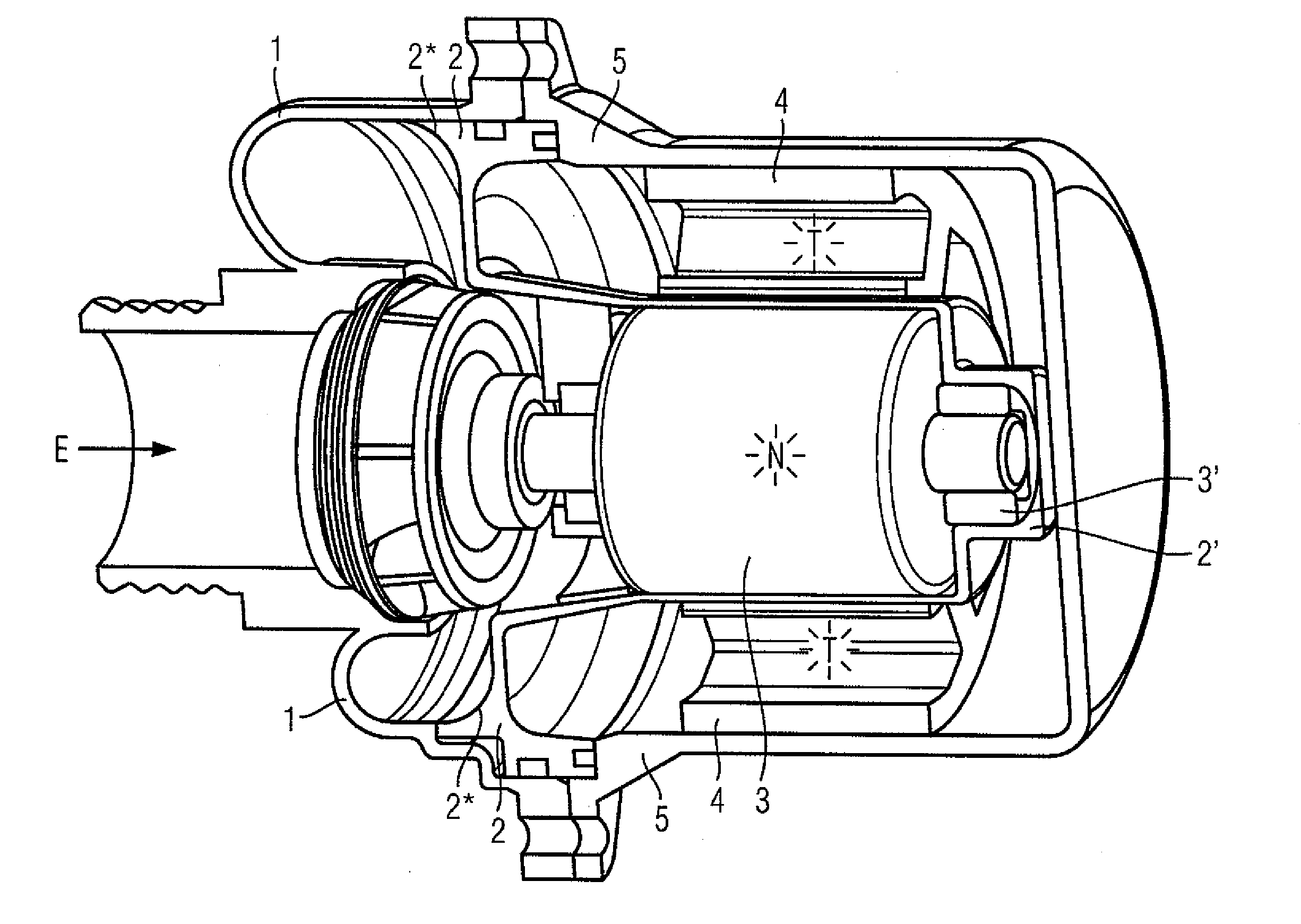

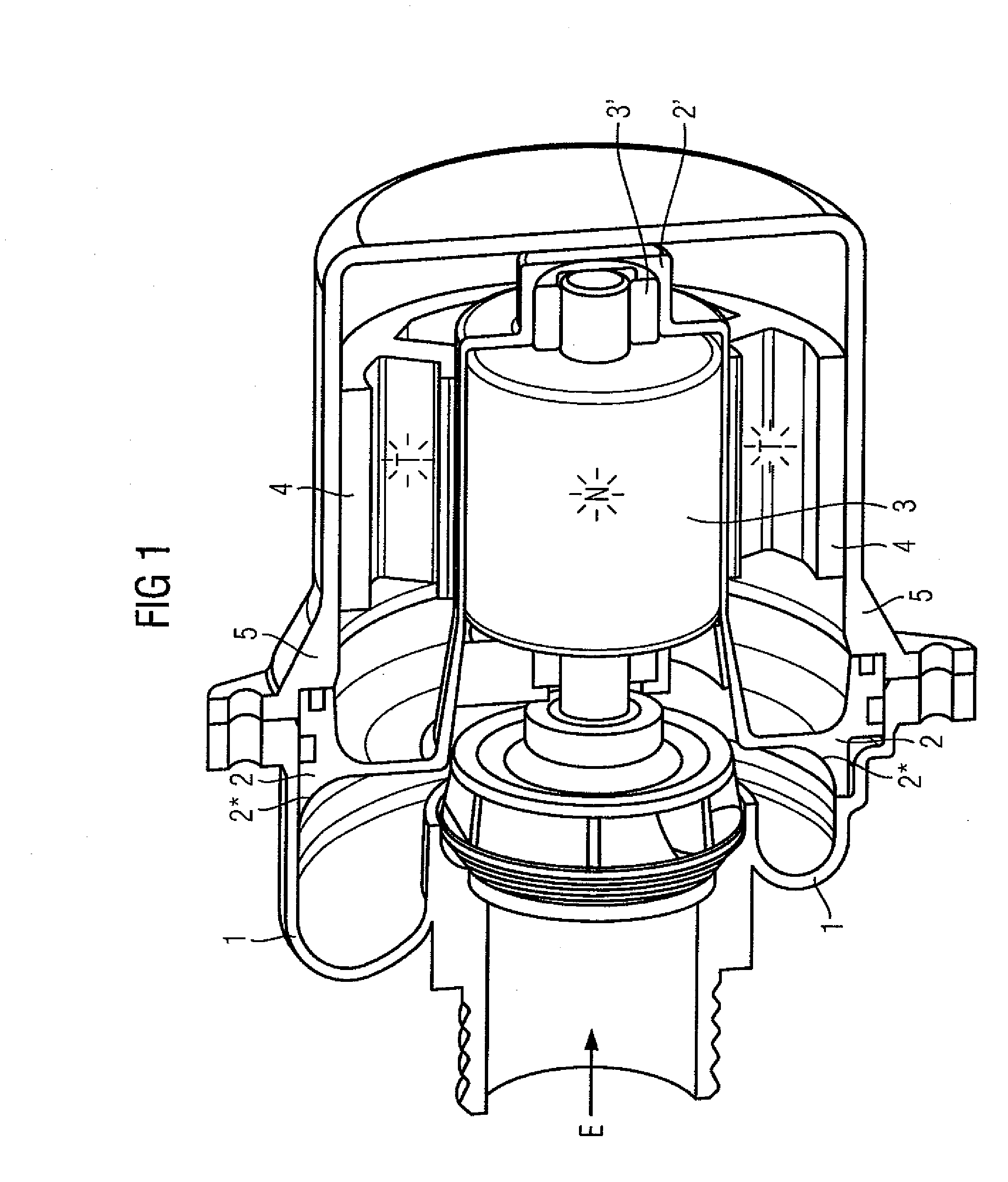

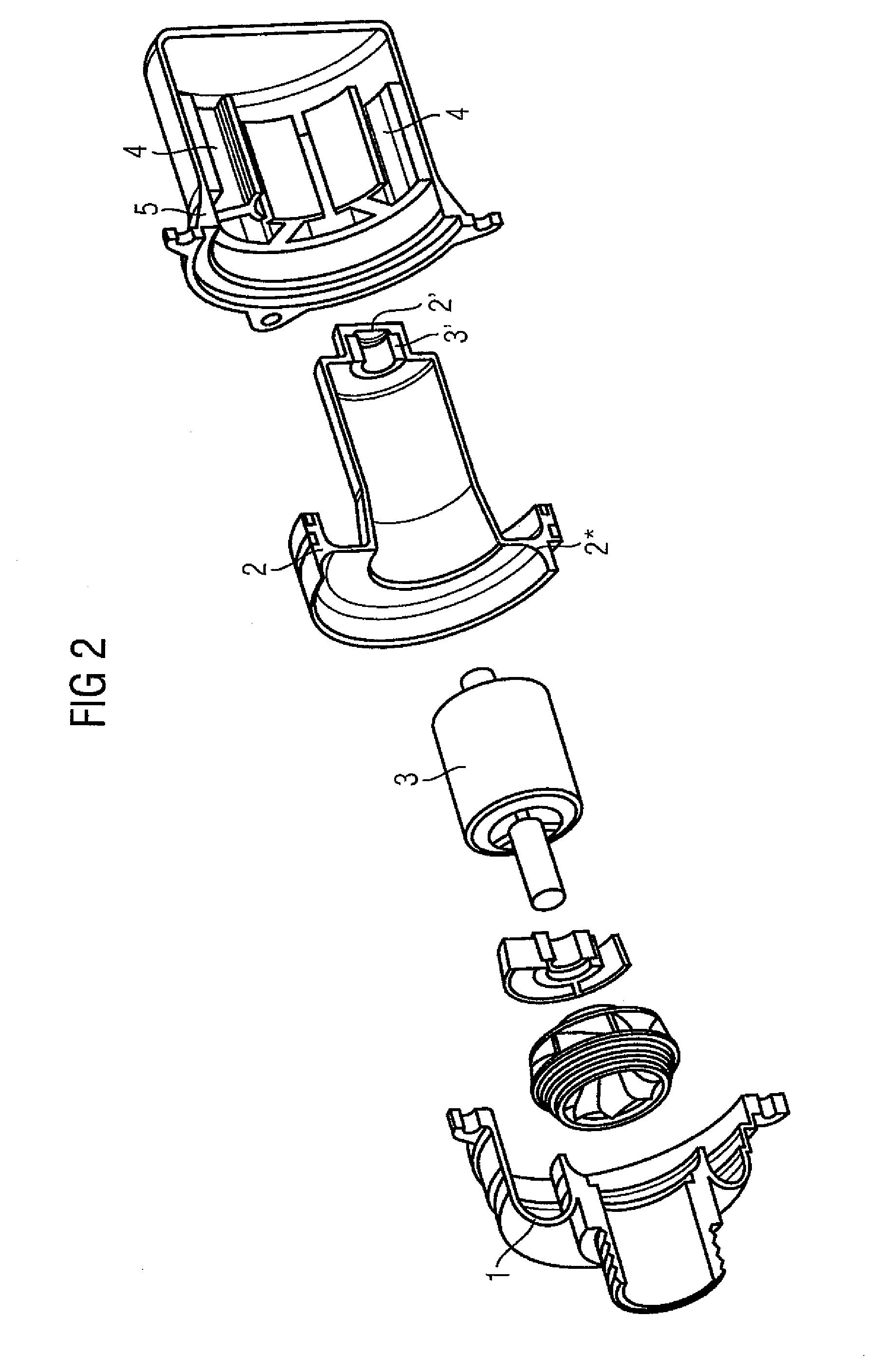

[0014]FIG. 1 is a centrifugal pump in longitudinal section. It comprises a spiral housing, which comprises a first housing part 1 and a second housing part 2. A central area of the second housing part 2 is of a continuous cup-shaped design to accommodate the rotor 3 situated in a wet chamber N. In the cup-shaped base part 2′ the second housing part 2 has a bearing 3′ for the rotatable mounting of the rotor 3. A stator 4 is arranged in a dry chamber T externally surrounding the second housing part 2 in the area of the rotor 3. The dry chamber T is sealed from the surroundings by a housing 5. The outer area of the second housing part 2 has an outline 2* of curved longitudinal section perpendicular to the direction of flow of the medium flowing in from the inlet E. The medium flowing in is represented by a bold arrow. The curved outline 2* serves to optimize the flow conditions inside the spiral housing. Any ingress of liquid or vapor from the wet chamber N into the dry chamber T is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com