Hot water pot steam heating system

A technology of heating system and hot water tank, which is applied in the field of hot water tank steam heating system, which can solve the problem of low water temperature control accuracy in the hot water tank, failure to meet the production requirements of water temperature, and inability to accurately reflect the temperature of the hot water tank outlet, etc. problems, to achieve the effect of reliable structure, convenient installation, and guaranteed temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

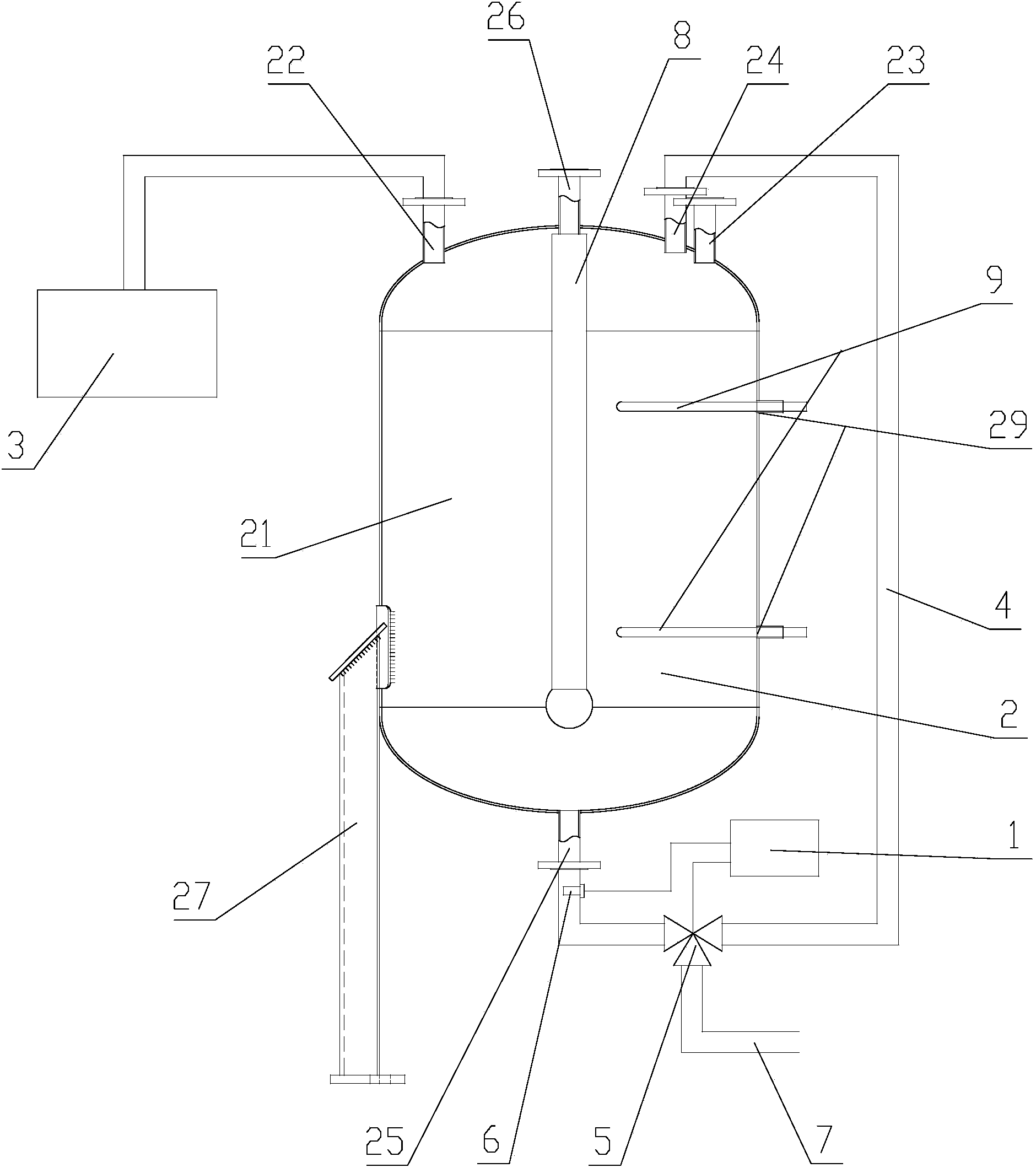

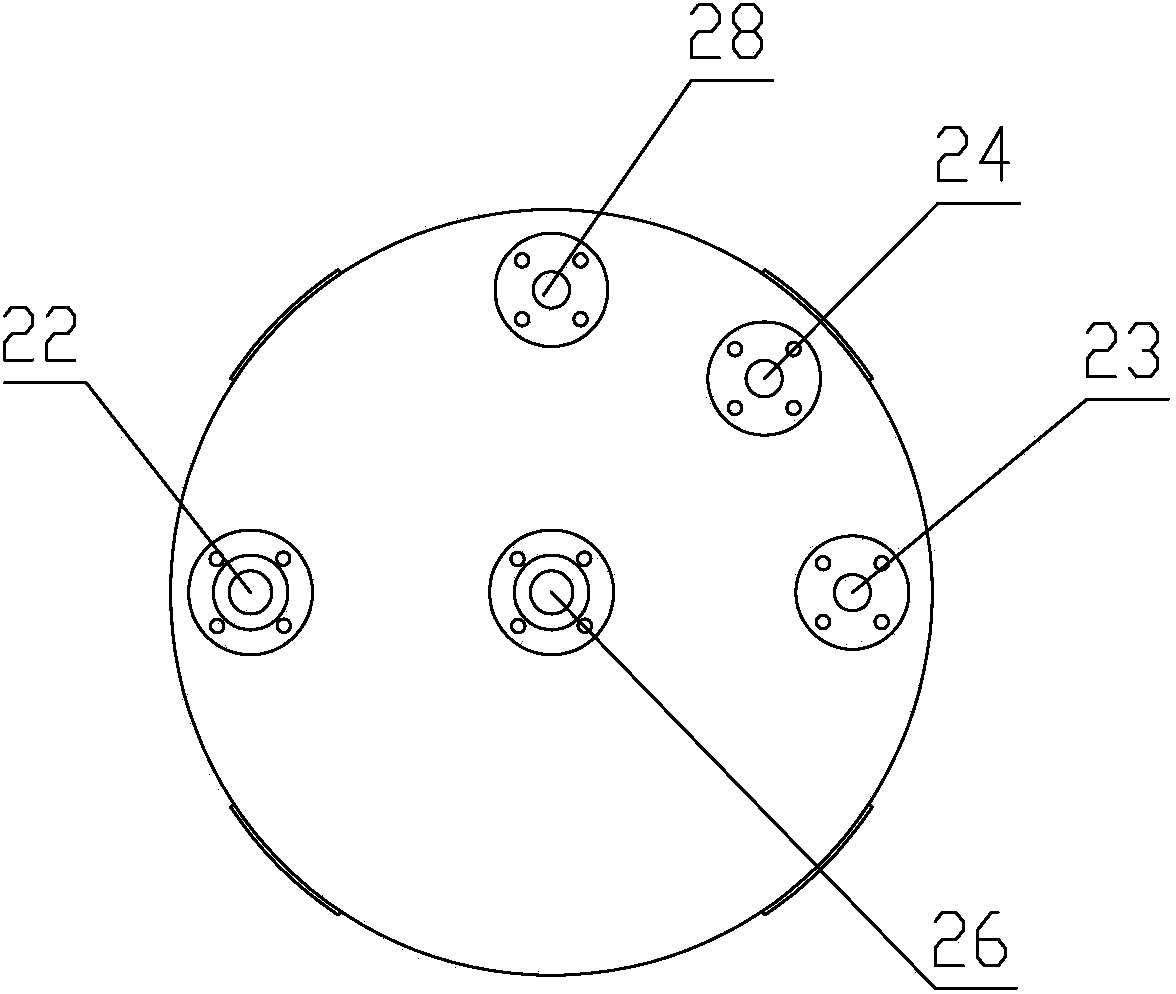

[0033] figure 1 It is a structural schematic diagram of the hot water tank steam heating system provided in this embodiment. figure 2 It is the top view of the hot water tank of this embodiment. As shown in the figure, the hot water tank steam heating system includes a controller 1 , a hot water tank 2 and a steam supply device 3 connected to the hot water tank 2 . Hot water tank 2 comprises tank body 21, as figure 2 As shown, a steam inlet 22 , a cold water inlet 23 and a hot water return port 24 are arranged on the top of the tank body 21 , and a hot water outlet 25 is arranged on the bottom of the tank body 21 . The steam inlet 22 is connected to the steam supply device 3 , and the hot water outlet 25 is connected to the hot water return port 24 through the hot water return pipeline 4 . A reversing valve 5 is arranged on the hot water return line 4, the input end of the reversing valve 5 is connected to the hot water outlet 25 through the temperature sensor 6, and the ...

Embodiment 2

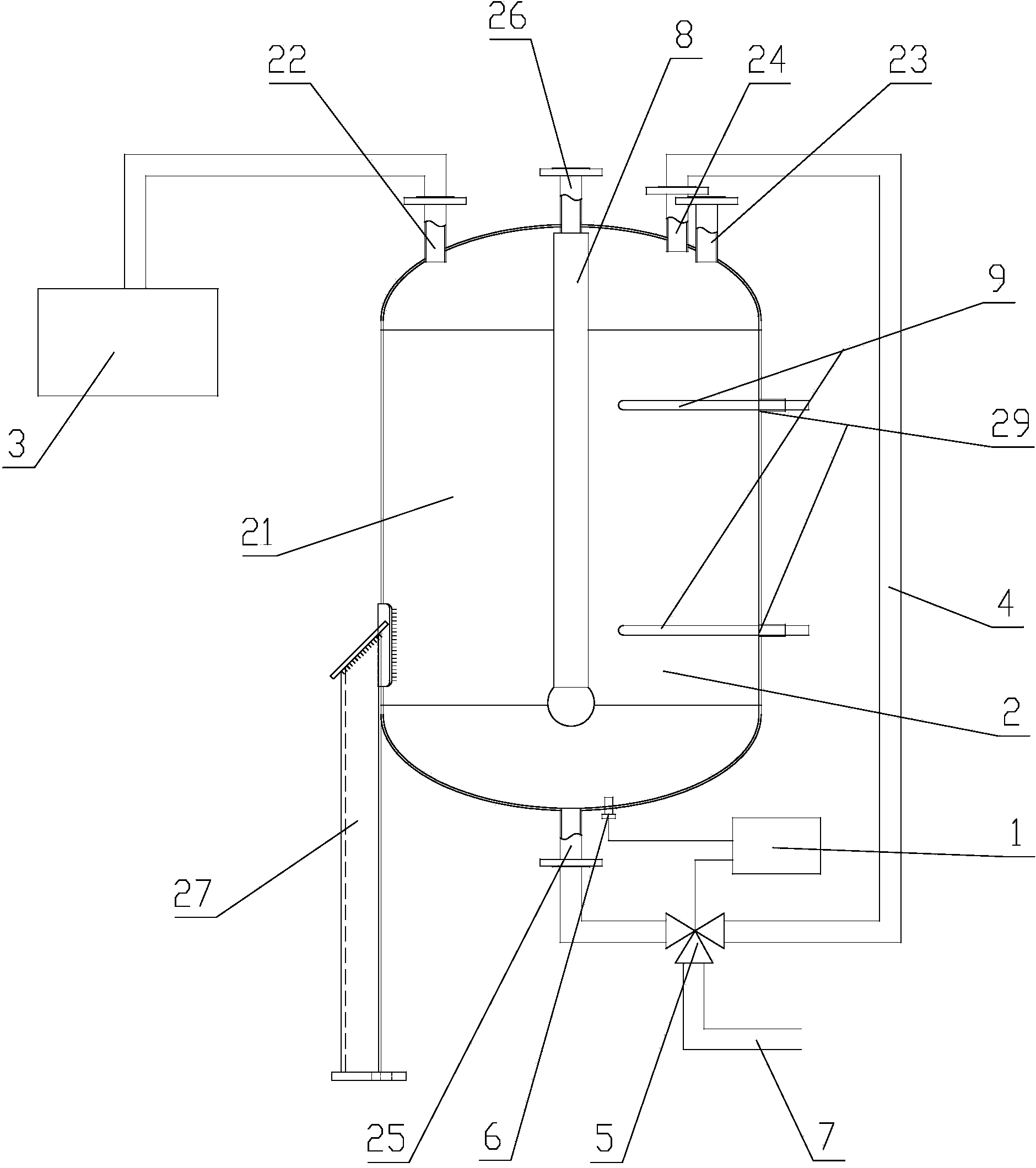

[0041] image 3 It is a structural schematic diagram of the hot water tank steam heating system provided in this embodiment. As shown in the figure, the basic structure of the hot water tank steam heating system of this embodiment is the same as that of the first embodiment, including a controller 1 , a hot water tank 2 and a steam supply device 3 connected to the hot water tank 2 . The hot water tank 2 includes a tank body 21 , a steam inlet 22 , a cold water inlet 23 and a hot water return port 24 are arranged on the top of the tank body 21 , and a hot water outlet 25 is arranged on the bottom of the tank body 21 . The steam inlet 22 is connected to the steam supply device 3 , and the hot water outlet 25 is connected to the hot water return port 24 through the hot water return pipeline 4 . A reversing valve 5 is arranged on the hot water return pipeline 4 , and two output ends of the reversing valve 5 are respectively connected to the hot water return port 24 and the hot wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com