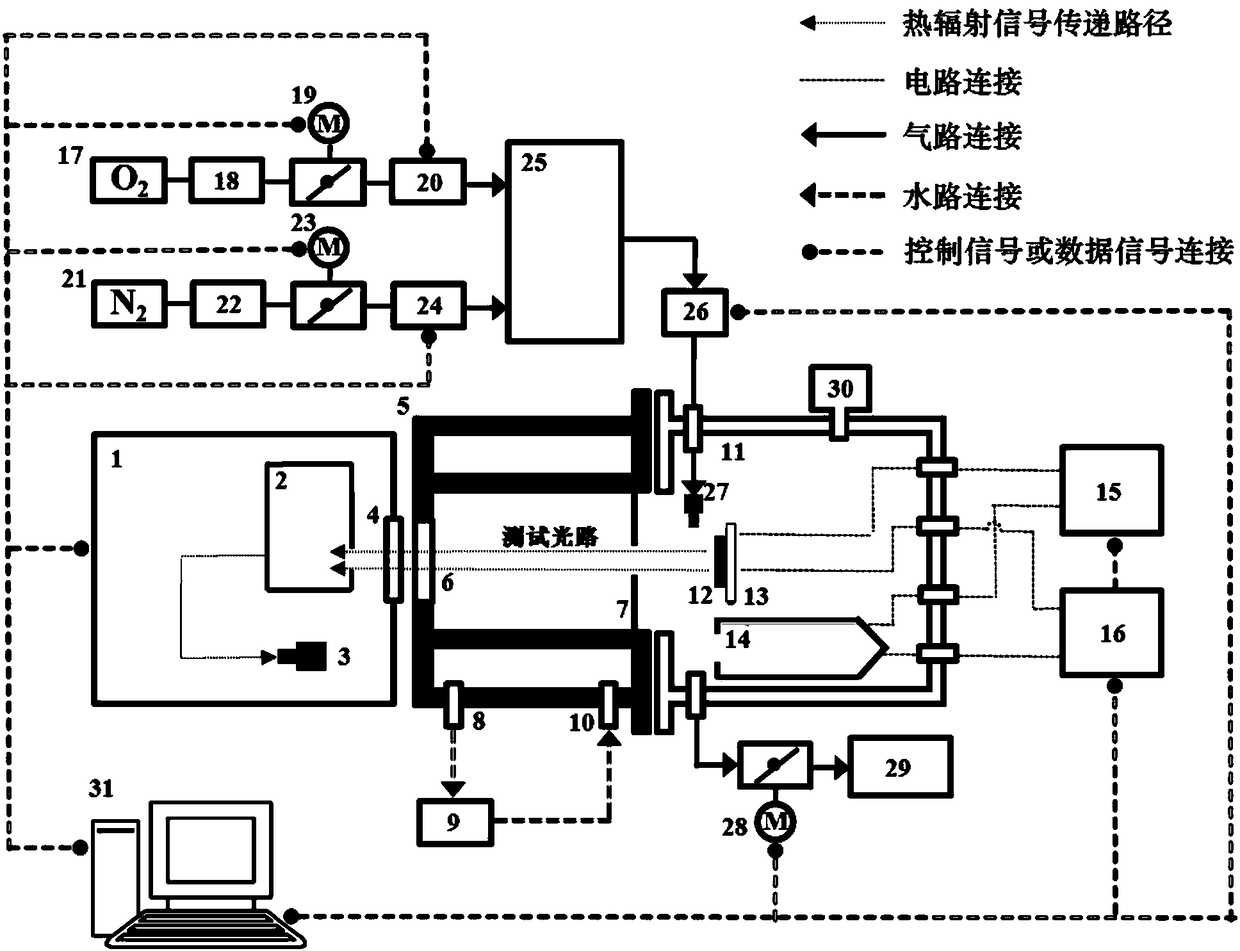

Variable oxygen partial pressure environment high temperature heat radiation performance test device, and method

A testing device and oxygen partial pressure technology, applied in the direction of thermal development of materials, can solve the problems of testing, the inability to complete the high temperature thermal radiation coefficient of materials, etc., and achieve the effect of ensuring the accuracy of temperature control, ensuring accurate testing, and inhibiting convective heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

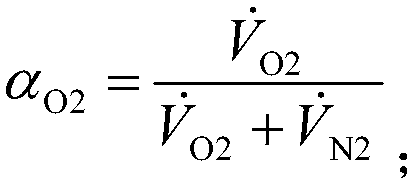

[0067] The following uses quartz fiber reinforced phenolic heat-resistant composite materials at a temperature of 1000°C and an oxygen partial pressure of 2.1×10 2 The heat radiation coefficient test under the condition of Pa is taken as an example to further illustrate the high temperature heat radiation performance test method in a variable oxygen partial pressure environment provided by the present invention. The test is carried out in the following steps:

[0068] Step 1: The computer 31 controls the first electronically controlled butterfly valve 19, the second electronically controlled butterfly valve 23 is closed, the third electronically controlled butterfly valve 28 is fully opened, the vacuum pump 29 is turned on, and the water-cooled optical tip 5 and the sample / blackbody heating furnace 11 are discharged All the air in the enclosed space and the gas mixing device 25 and the gas heating device 26, until the absolute pressure of the gas displayed by the electronic va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com