Load frequency response test system and method for hydraulic cylinder

A frequency response test, frequency response technology, applied in fluid pressure actuation system test, machine/structural component test, measurement device and other directions, can solve the problem of test result influence, failure to achieve the test purpose, etc., and achieve a high degree of automation , The effect of accurate test and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, not limitation to protection scope:

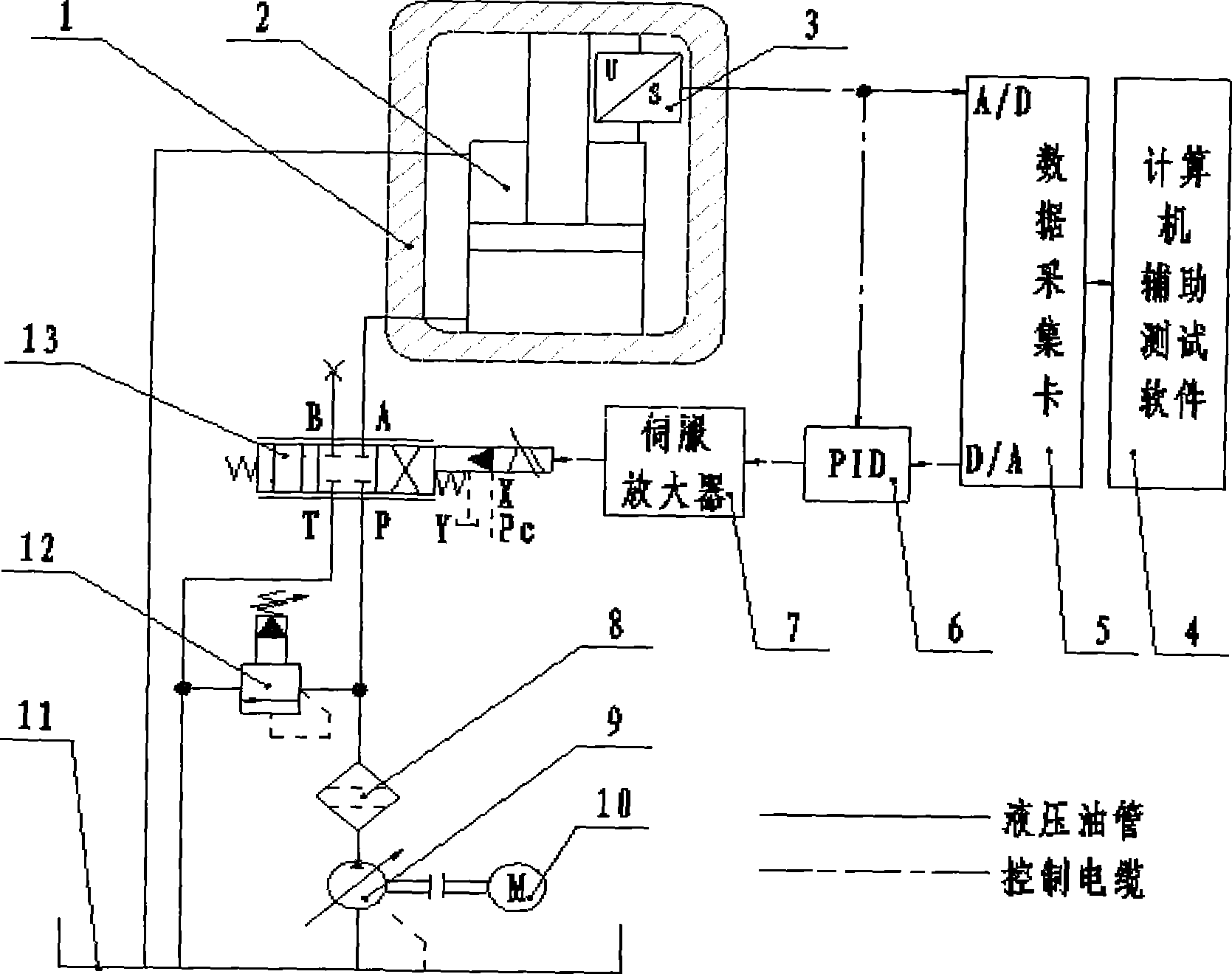

[0039] A test system and test method for measuring the load frequency response of a hydraulic cylinder, the test system is as follows figure 1 As shown: the oil pump 9 is coaxially connected with the motor 10, the oil suction port of the oil pump 9 communicates with the oil tank 11, the oil outlet port of the oil pump 9 communicates with the P port of the electro-hydraulic servo valve 13 through the filter 8, and the A port of the electro-hydraulic servo valve 13 The port communicates with the rodless chamber of the tested hydraulic cylinder 2, and the B port of the electro-hydraulic servo valve 13 is closed; the rod chamber of the tested hydraulic cylinder 2 and the T port of the electro-hydraulic servo valve 13 communicate with the oil tank 11; An electromagnetic overflow valve 12 is connected between the P port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com