Electromagnetic oven

A technology of induction cooker and furnace body, applied in the field of induction cooker, which can solve the problems of reduced service life, reduced service life, burnt pots and panels, etc., and achieves the effects of reducing temperature resistance requirements, reducing production costs, and ensuring temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

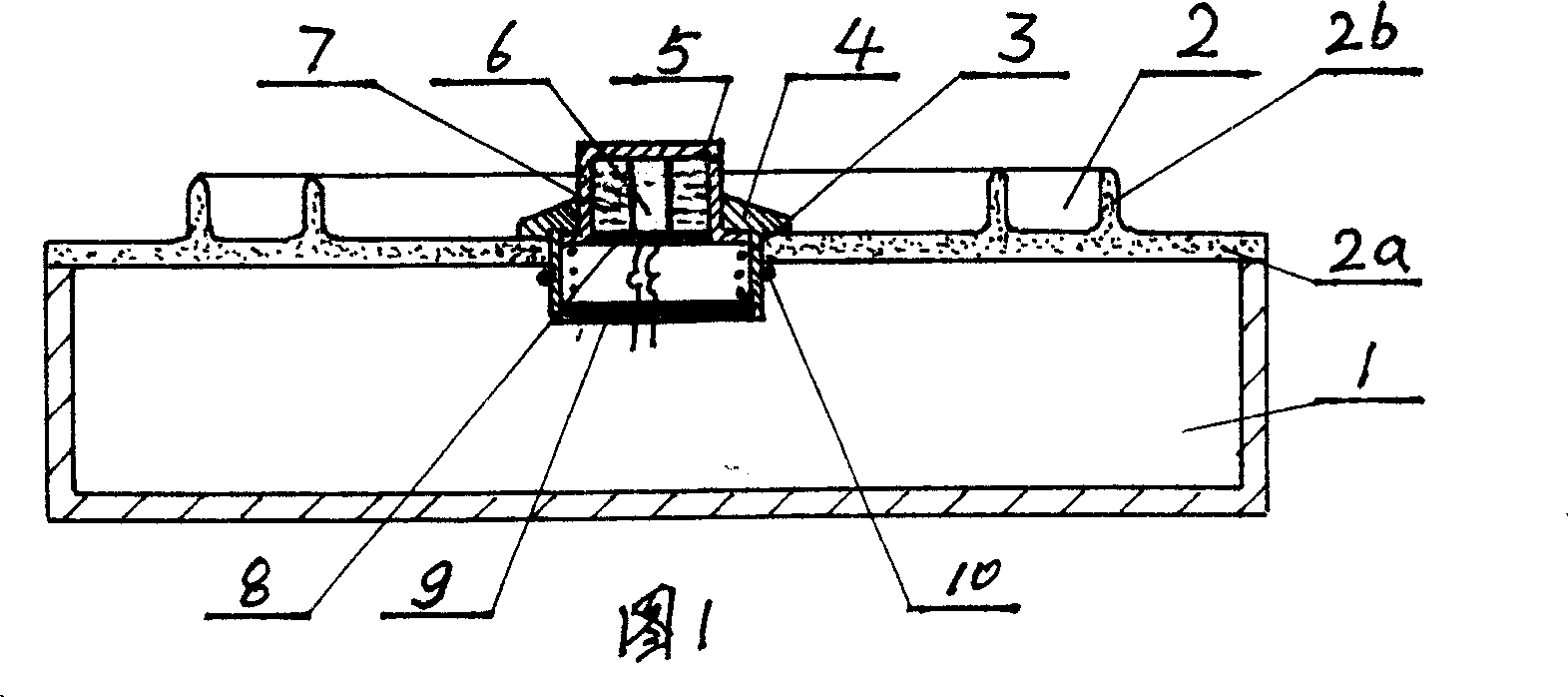

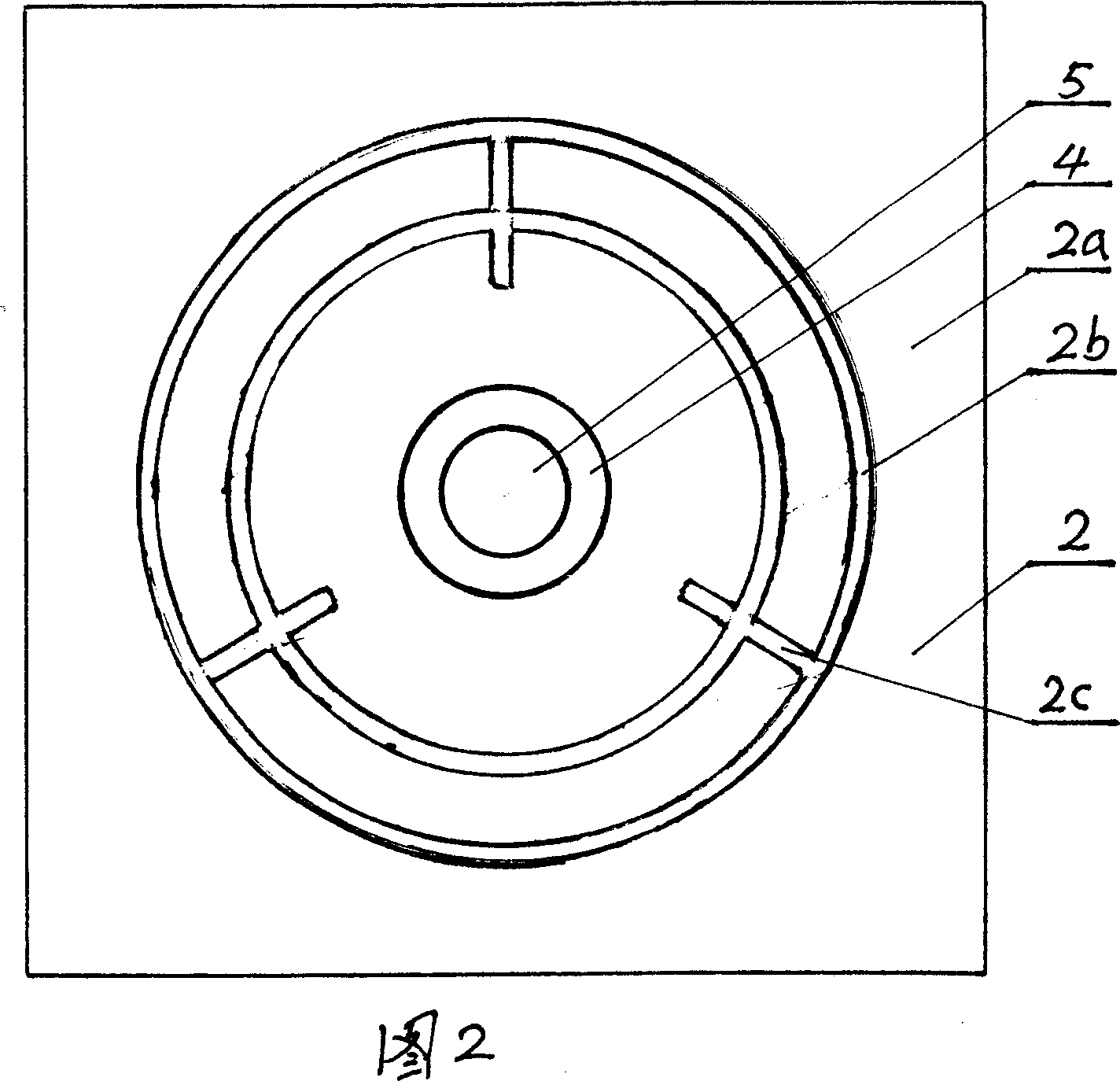

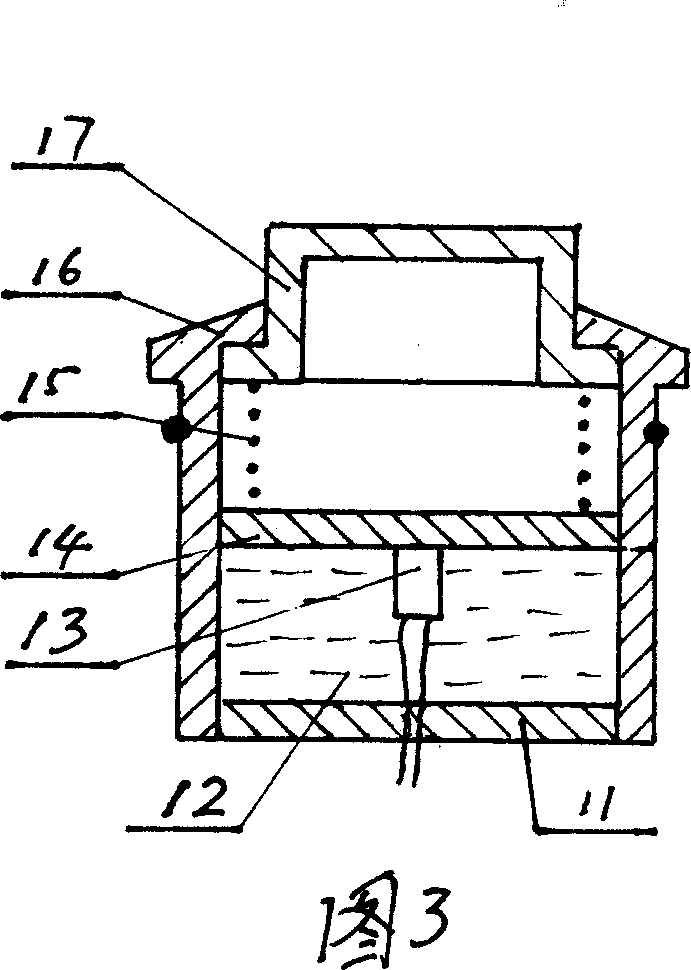

[0021] As shown in Fig. 1 and Fig. 2, a panel (2) is installed on the body of furnace (1), for the view can show the invention point of the present invention more clearly, omit in Fig. 1 and be installed in the body of furnace (1) The panel (2) consists of a panel body (2a), 2 closed concentric raised rings (2b) and 3 raised ribs (2c) designed on the panel body (2a), the 2 The height of the concentric raised ring (2b) is the same as the height of the three raised ribs (2c), and the temperature sensor body (4) installed on the panel body (2a) in the raised ring (2b) passes through the fixing device (10) fixing, the fixing device (10) is the structural form of snap ring, also can use the structural form of screw thread, in the endoporus of this temperature sensing probe device body (4), be equipped with temperature sensing cap (5), temperature sensing The cap (5) is in the form of a closed upper end and surrounding wall, and an open lower end, which can slide relative to the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com