Patents

Literature

63results about How to "Fully milled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

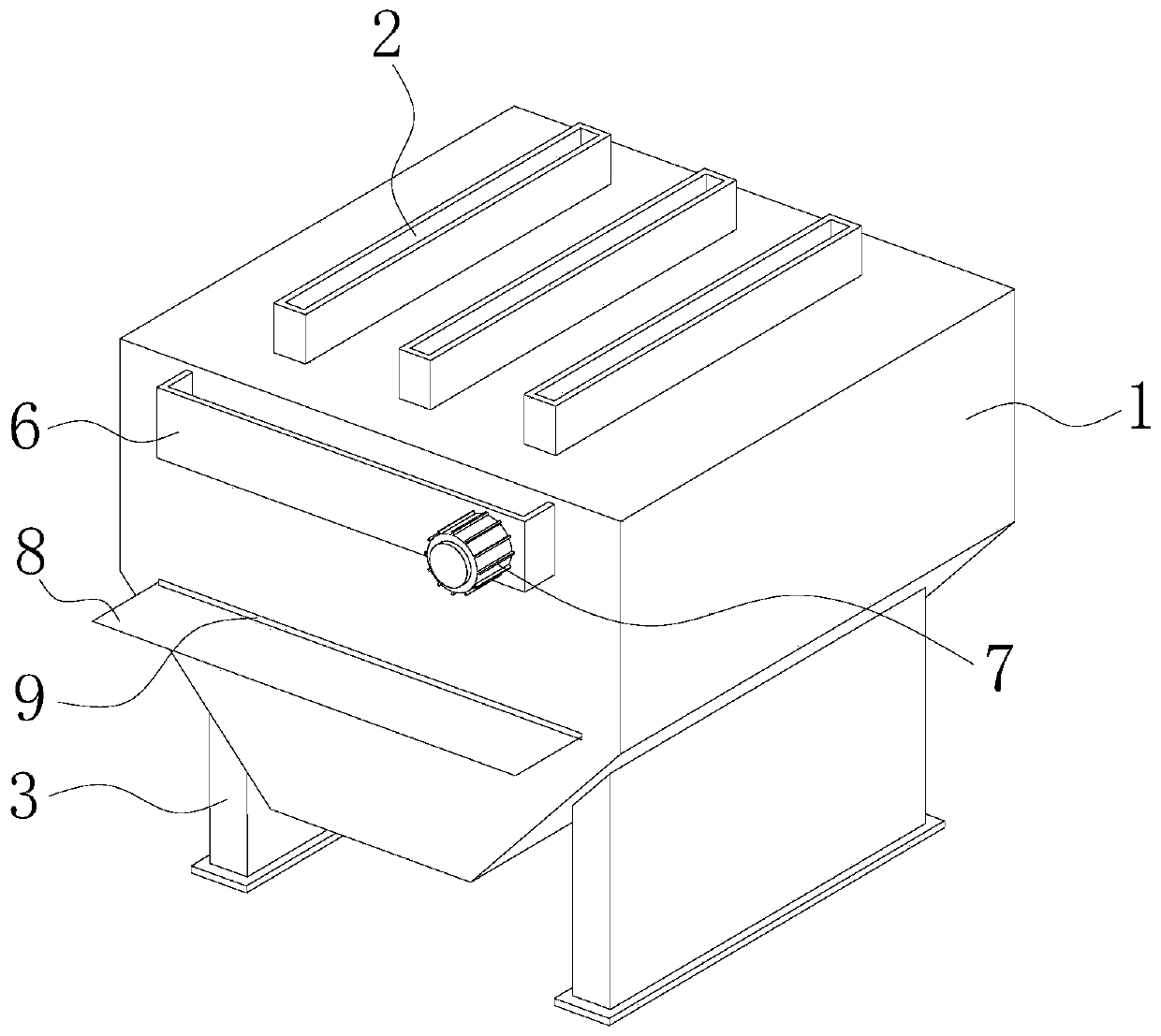

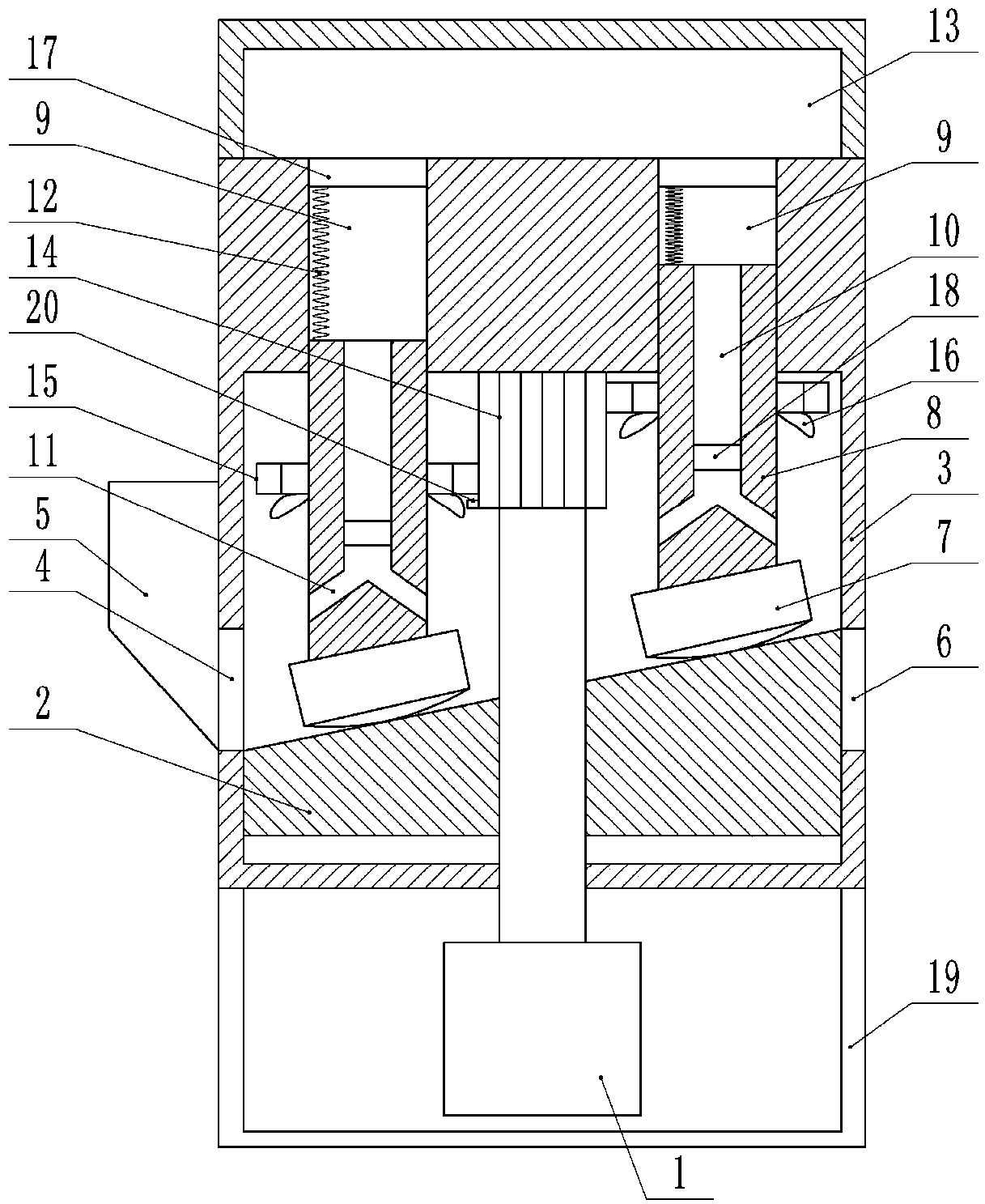

Traditional Chinese medicine powder grinding device with filtration screening function

InactiveCN109092469AEffective crushing effectConvenient millingCocoaGrain treatmentsMotor driveFiltration

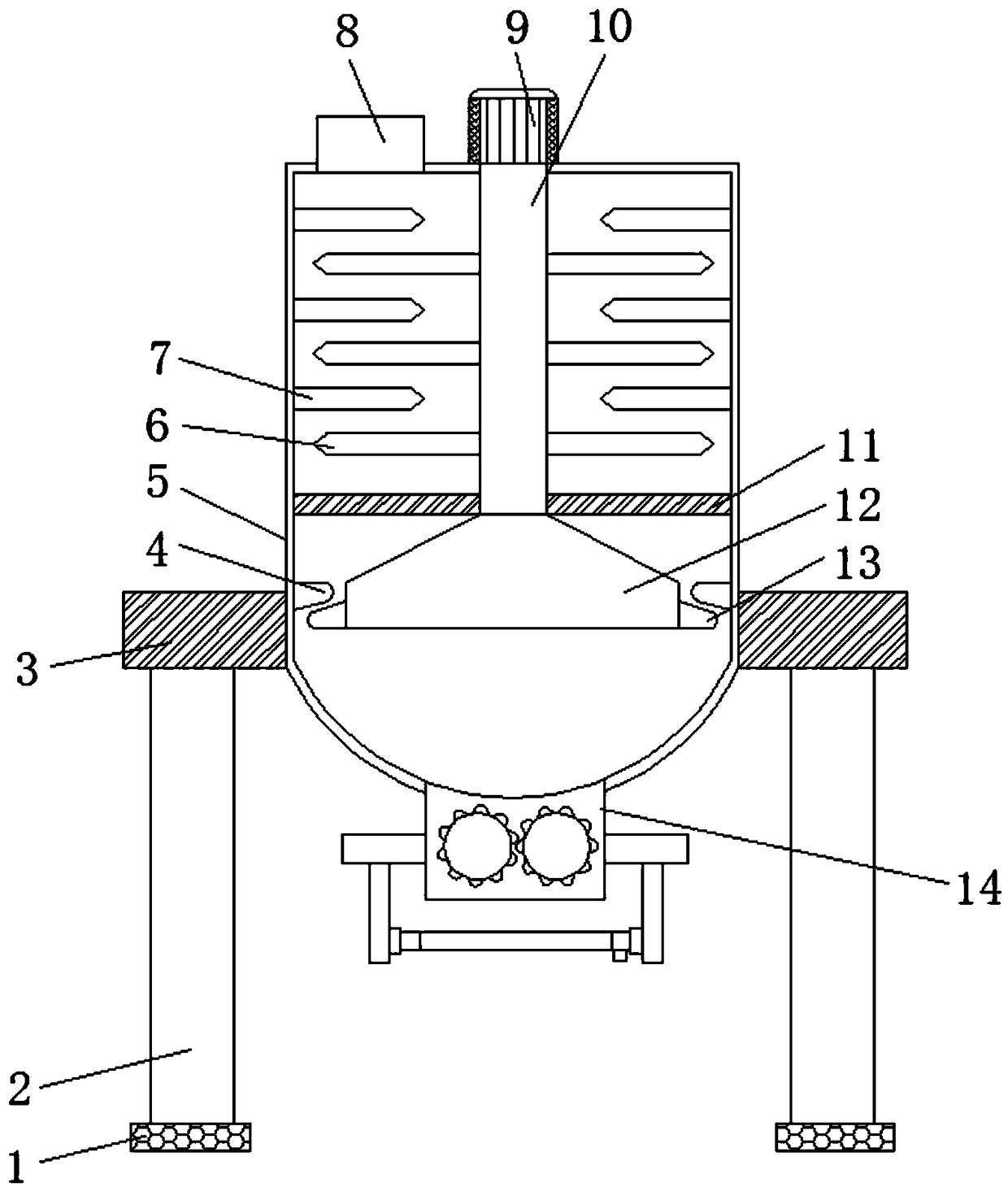

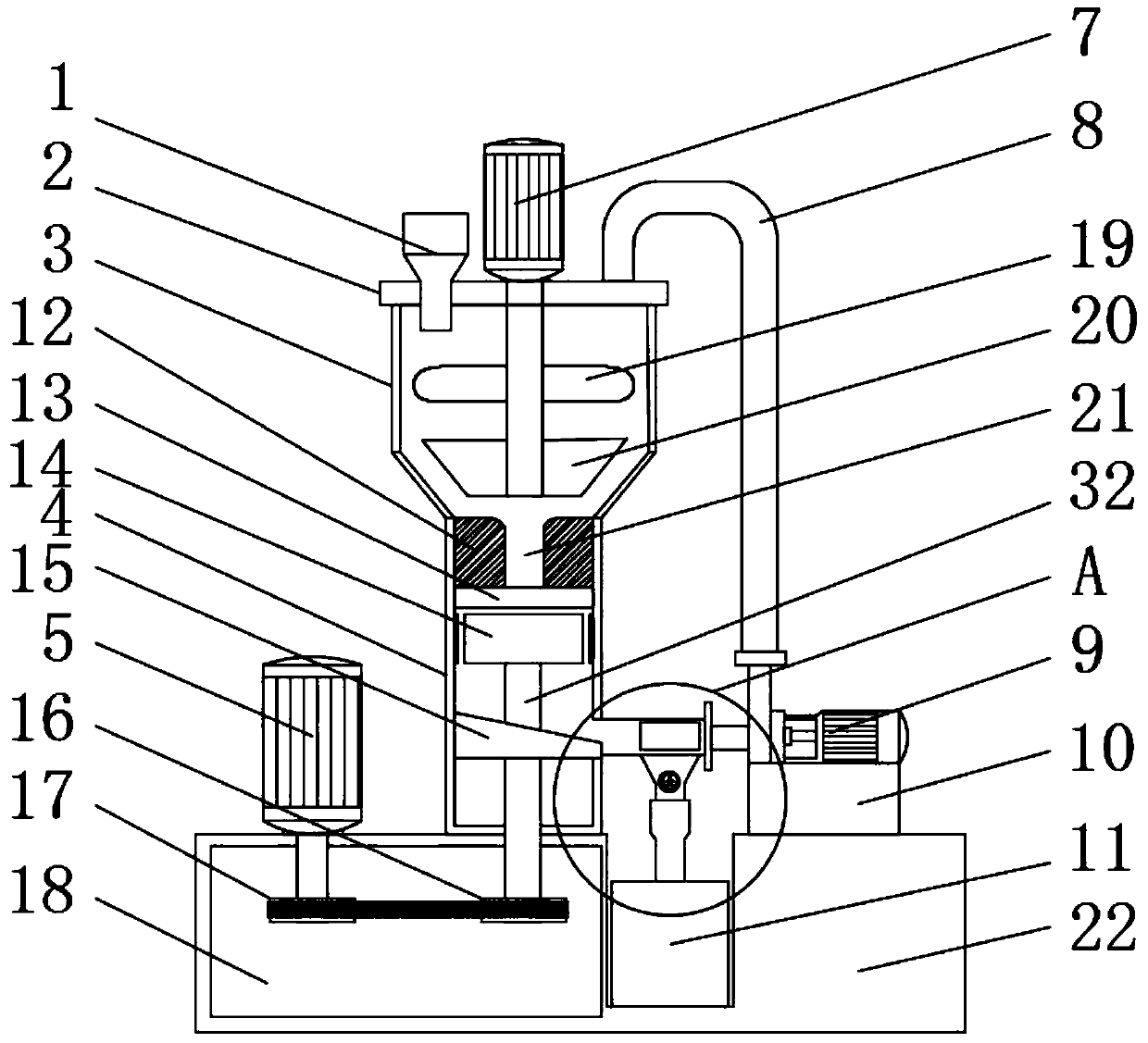

The invention discloses a traditional Chinese medicine powder grinding device with a filtration screening function. The traditional Chinese medicine powder grinding device comprises a supporting table; a first through hole is formed in the outer wall of the center of the top of the supporting table, and a crushing box is connected to the inner wall of the first through hole through bolts; and a first rotating motor is connected to the outer wall of the center of the top of the crushing box through bolts, and an output shaft of the first rotating motor is connected with a vertically-arranged first rotating shaft through bolts. According to the traditional Chinese medicine powder grinding device with the filtration screening function, a conical plate is arranged, a second annular grinding plate is arranged on the circumferential outer wall of the conical plate, a first annular grinding plate arranged on the inner wall of the crushing box is combined, thus broken traditional Chinese medicines are crushed when passing through the two annular grinding plates, and the effect of primary crushing is achieved; and the primarily crushed traditional Chinese medicines fall into a discharge pipe, a second rotating motor drives a grinding gear to rotate, and thus the traditional Chinese medicines are fully ground into powder finally.

Owner:天马(安徽)国药科技股份有限公司

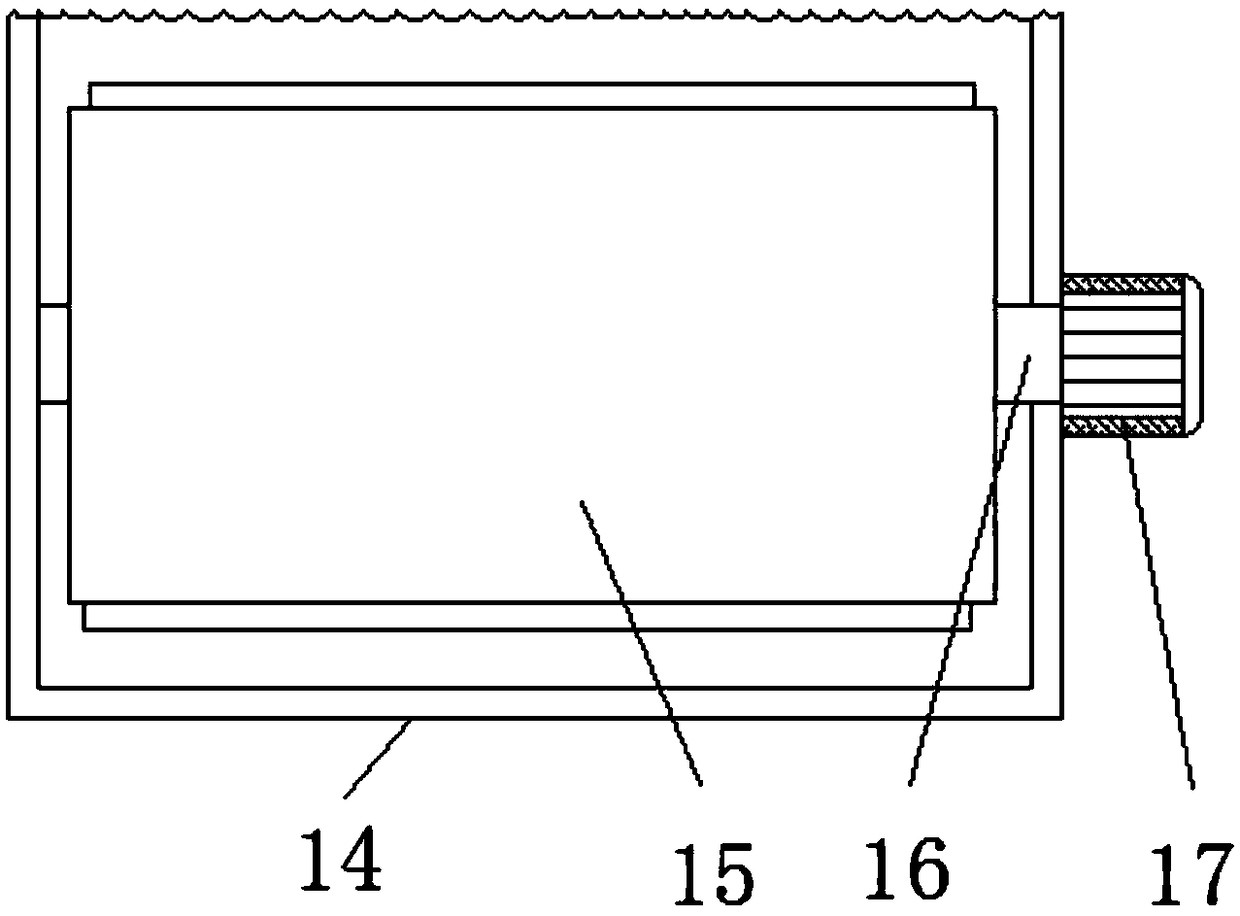

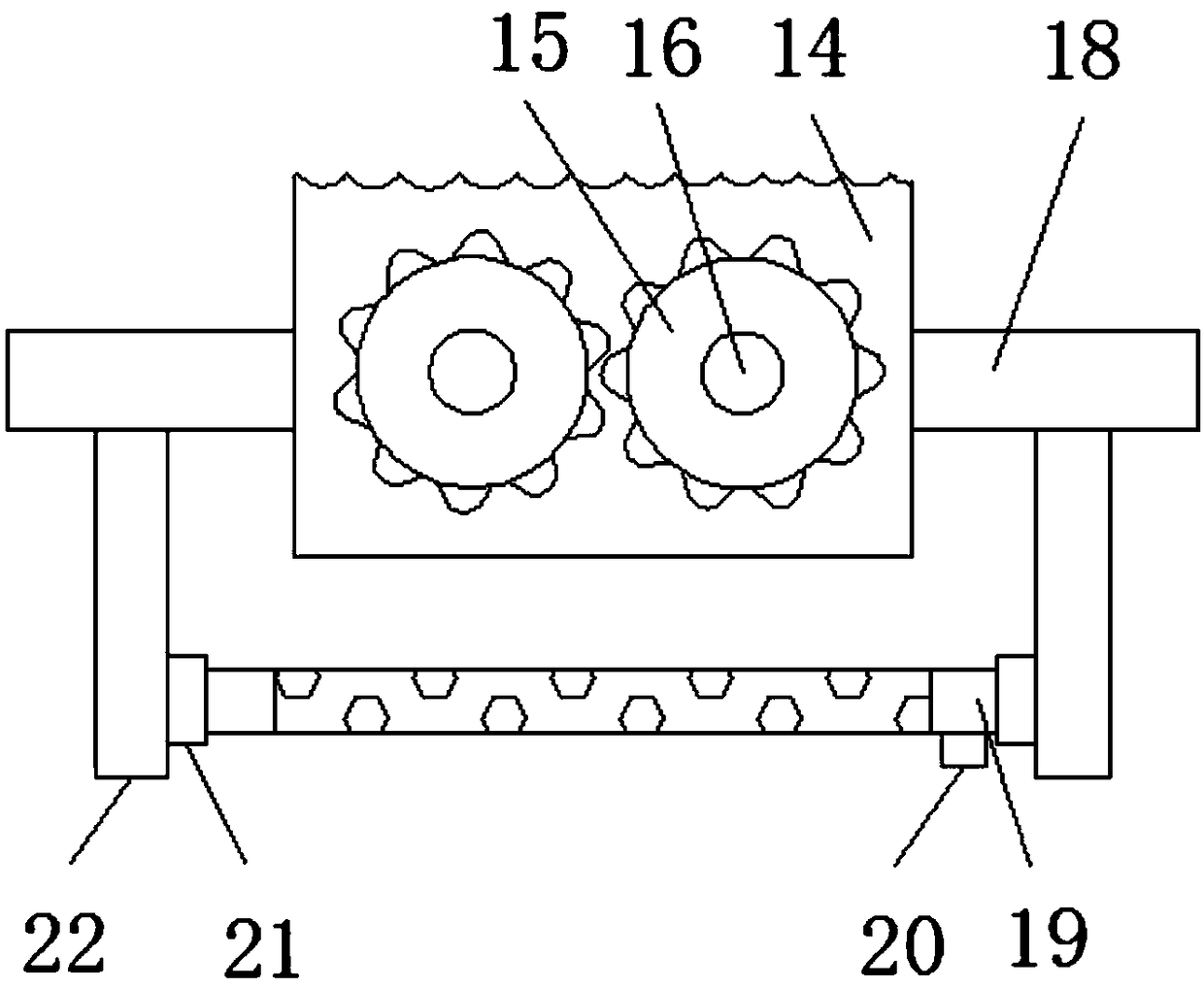

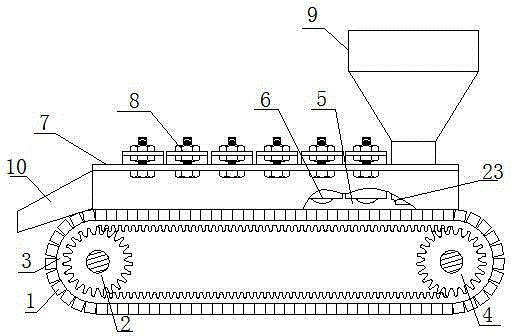

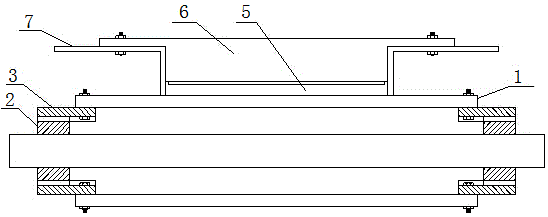

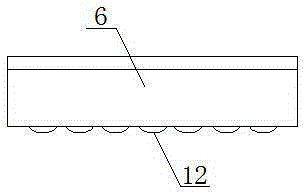

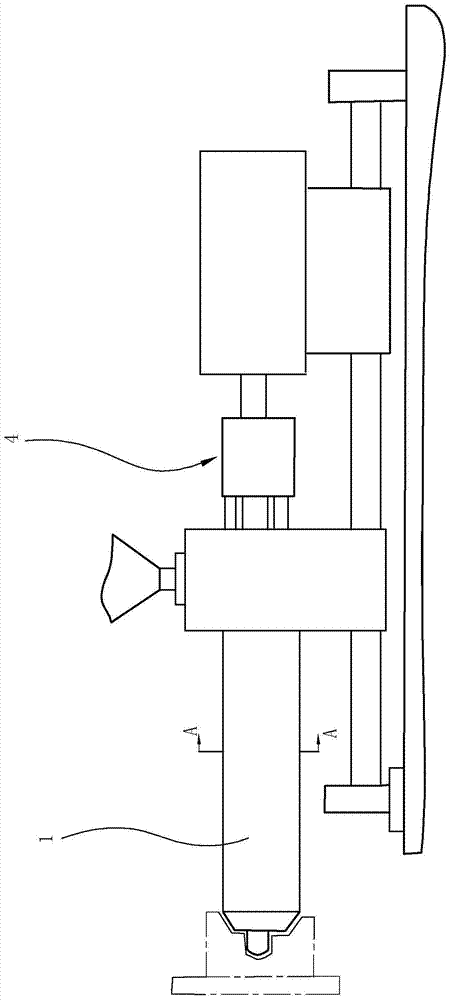

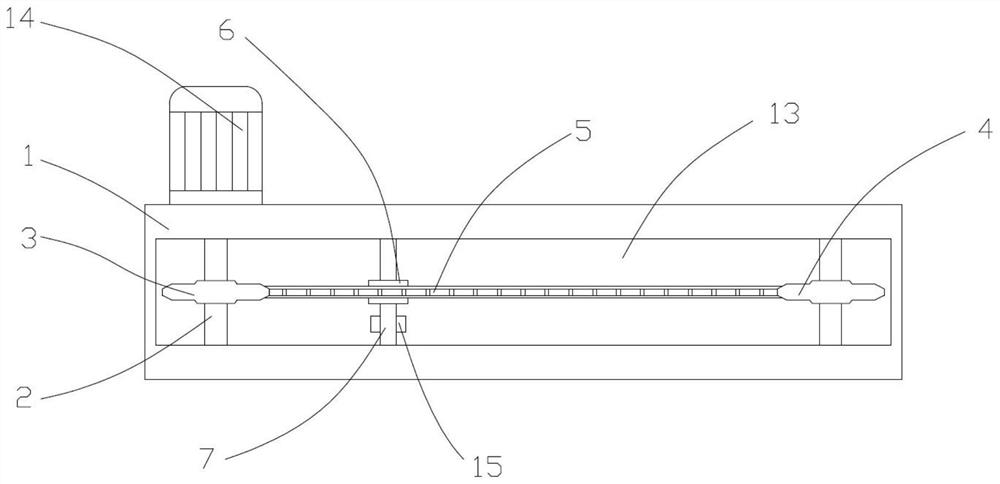

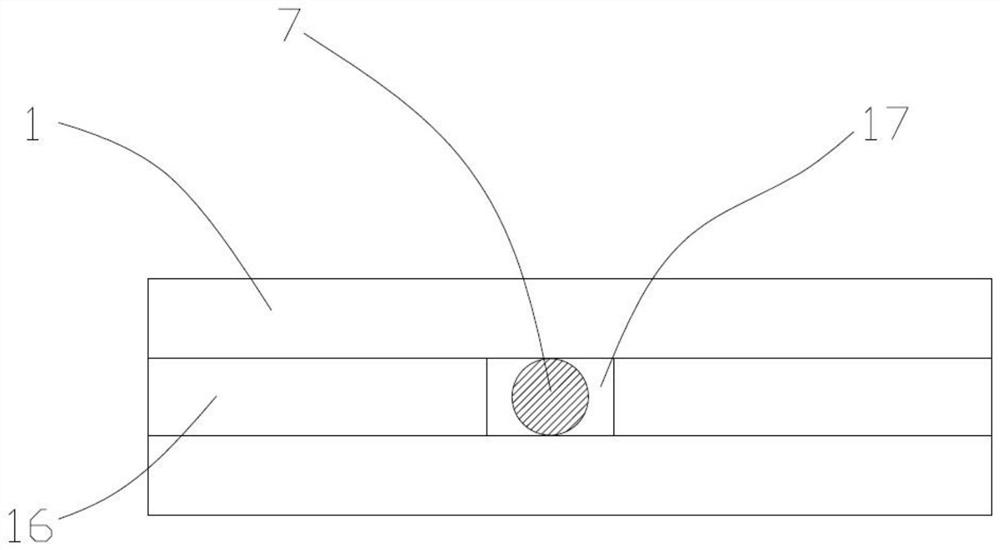

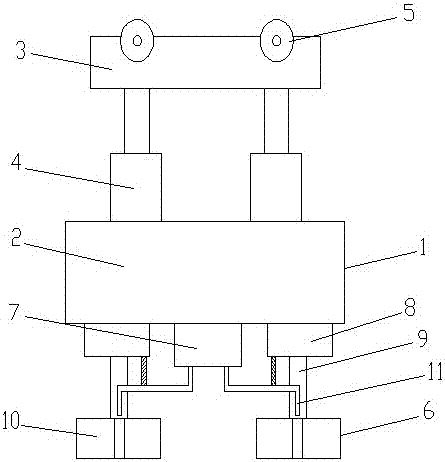

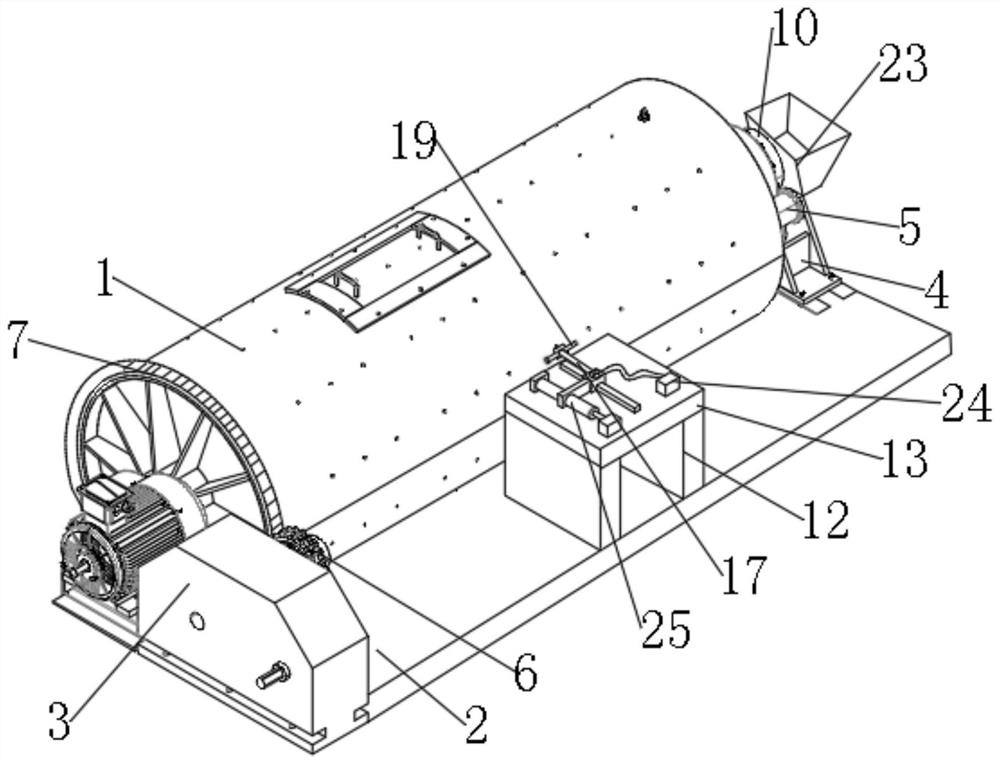

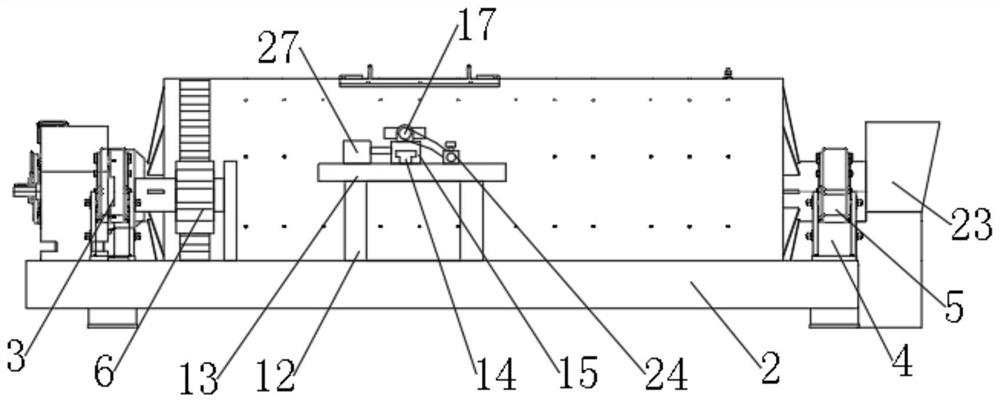

Crawler type rice mill

ActiveCN105251567AReduce impactReduce broken rice rateGrain treatmentsAgricultural engineeringEngineering

The invention discloses a crawler type rice mill. The crawler type rice mill comprises a hopper, a discharging barrel, a rack and a conveying mechanism, wherein rice knives are mounted on the rack, the conveying mechanism comprises a driving wheel, a driven wheel and a conveyor belt matched with the driving wheel and the driven wheel, the hopper is communicated with one end of a rice milling channel through a feeding opening, the discharging barrel is communicated with the other end of the rice milling channel, a plurality of milling strips are mounted on the conveyor belt, the milling strips are transversely and densely arranged on the conveyor belt, the rice milling channel is formed between the milling strips and the rice knives, the sides, opposite to the rice knives, of the milling strips are milling surfaces, and clearances allowing rice grains to rotate are arranged between the adjacent rice knives. The crawler type rice mill is high in milling efficiency, low in electricity consumption, high in rate of remained germs and low in rice crushing rate, and is durable.

Owner:彭才贵

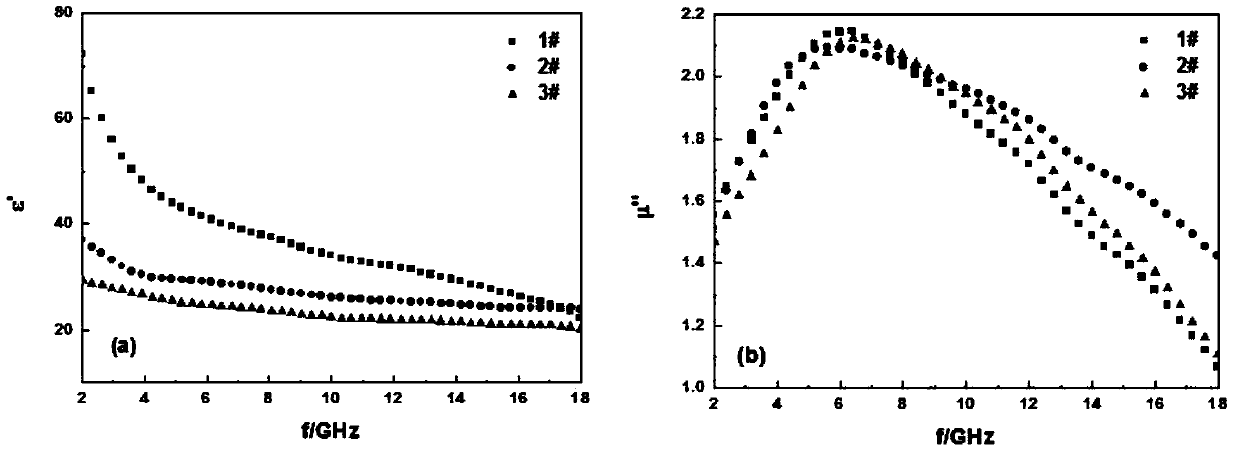

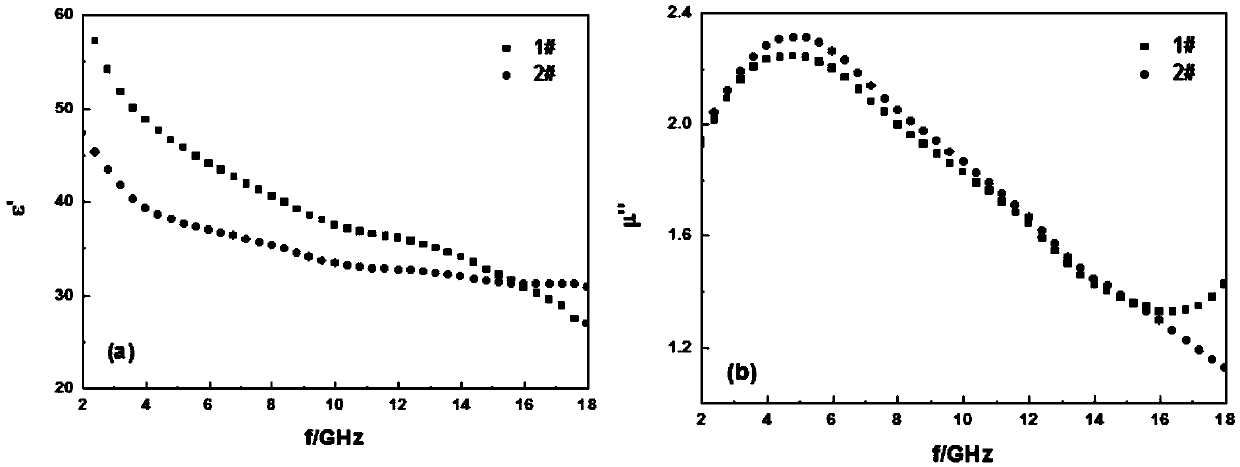

Modification method for electromagnetic parameters of carbonyl iron powder

InactiveCN105502517AHigh dielectric constantLow dielectric constantIron carbonylsDielectricNon destructive

The invention relates to a modification method for electromagnetic parameters of carbonyl iron powder and belongs to the field of absorbent preparation. The technical problem that the dielectric constant and the magnetic parameter of a carbonyl iron powder absorbent prepared through an existing preparation method are mismatched at a high mixing amount is solved. The preparation method includes the steps that firstly, the untreated carbonyl iron powder is treated according to a ball milling method through metal pots and ball milling balls so that the purposes of increasing the specific surface area, changing the micro-shape and then adjusting the electromagnetic parameters can be achieved; then, a passive film is generated on the surface of the carbonyl iron powder through a metal passivation chemical technology so that the dielectric constant of the carbonyl iron powder can be effectively reduced; finally, relatively-uniform phosphatized micron-size carbonyl iron powder particles are obtained by grinding the dried carbonyl iron powder in a non-destructive mode. By testing the electromagnetic parameters of the carbonyl iron powder, it is found that the real part of the dielectric constant of the treated carbonyl iron powder is significantly reduced, and the magnetic loss is kept unchanged basically, so that the purposes of parameter matching and parameter modification are achieved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

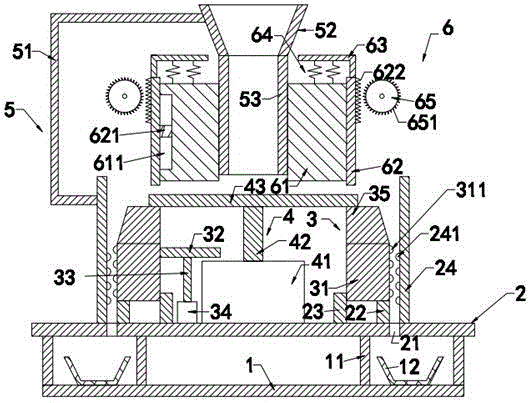

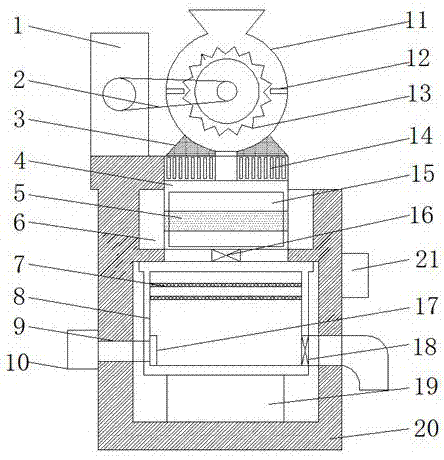

Medicine grinding device dedicated to general surgery department

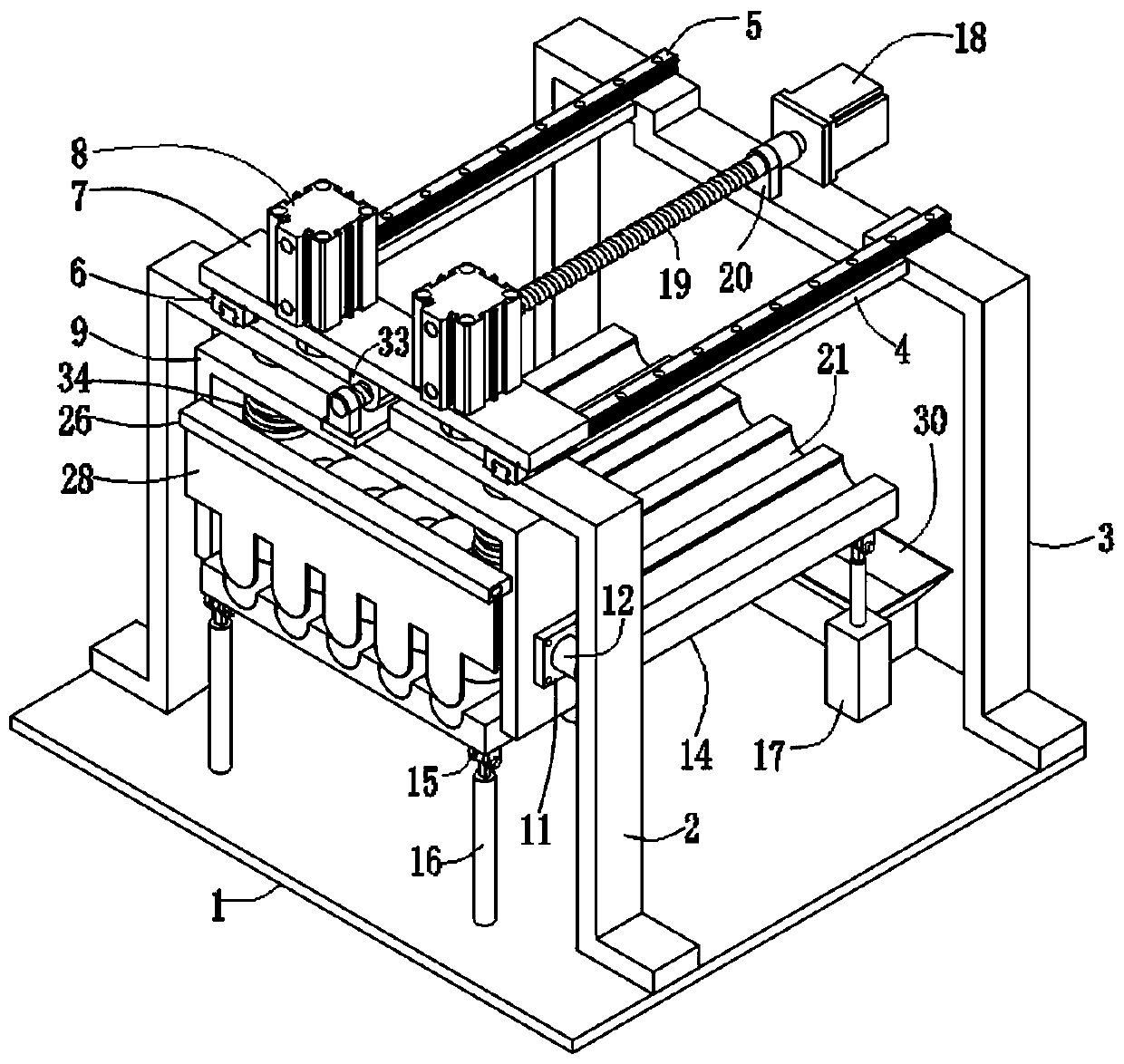

The invention discloses a medicine grinding device dedicated to a general surgery department. The medicine grinding device comprises a bottom plate, a supporting plate, a rotating device, a motor device, a feeding device and a grinding device, wherein first supporting rods and material receiving boxes are arranged on the bottom plate; a first through hole, a first supporting ring, a locating ring and a first grinding ring are arranged on the supporting plate; the rotating device comprises a second grinding ring, a material pouring ring, a gear, a first rotating shaft and a first motor; the motor device comprises a second motor, a second rotating shaft and a rotary disc; the feeding device comprises a first bracket, a feed hopper and a feeding tube; and the grinding device comprises a third grinding ring, a baffle ring, a second bracket, springs and rotating wheels. According to the medicine grinding device, medicine can be fully grinded, the grinding effect is relatively good, patients can conveniently take medicine, the noise is relatively low, the rest of patients is not influenced, the medicine can be directly grinded, an additional plane is not required to be found, and the utilization convenience is improved.

Owner:QINGDAO MUNICIPAL HOSPITAL

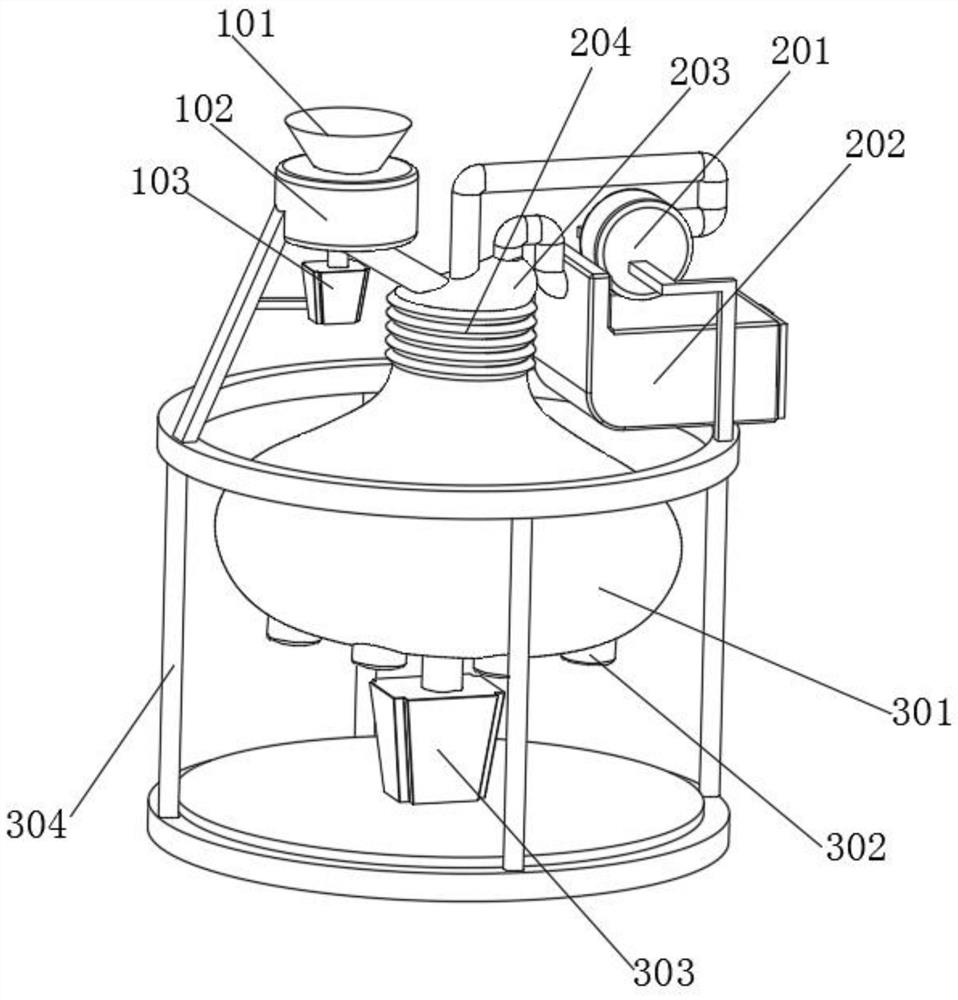

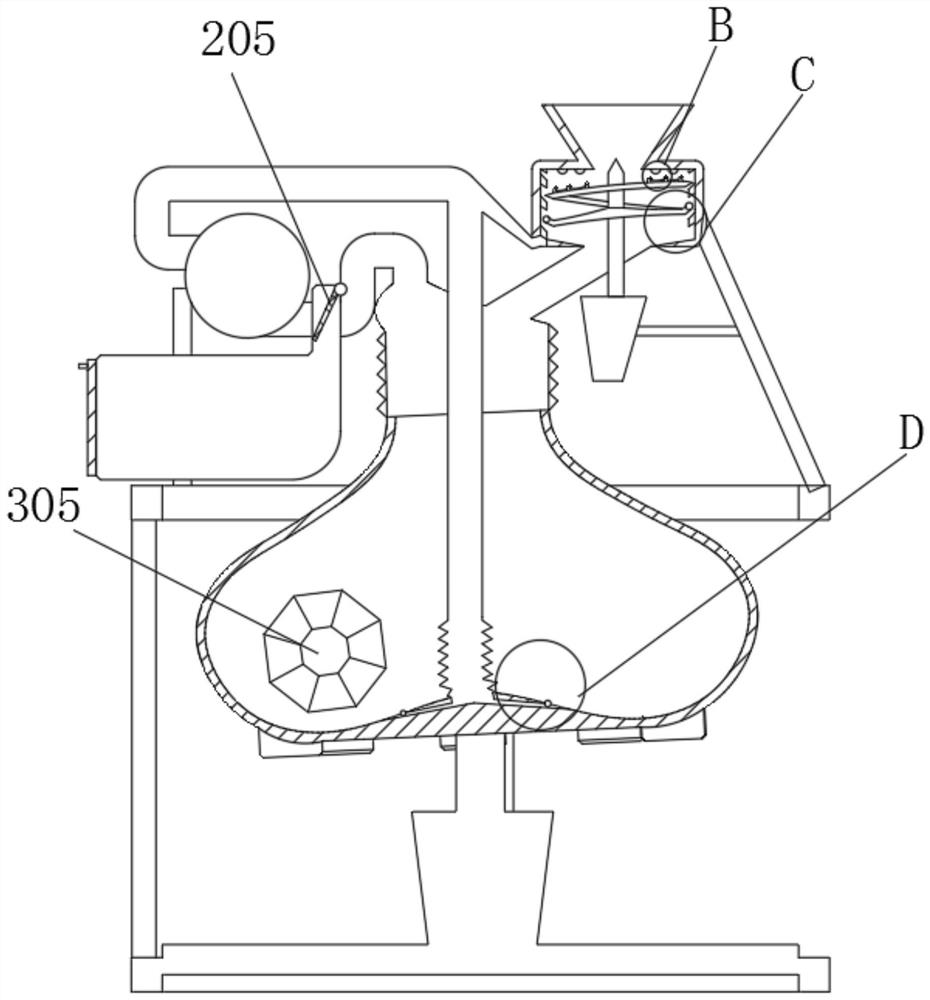

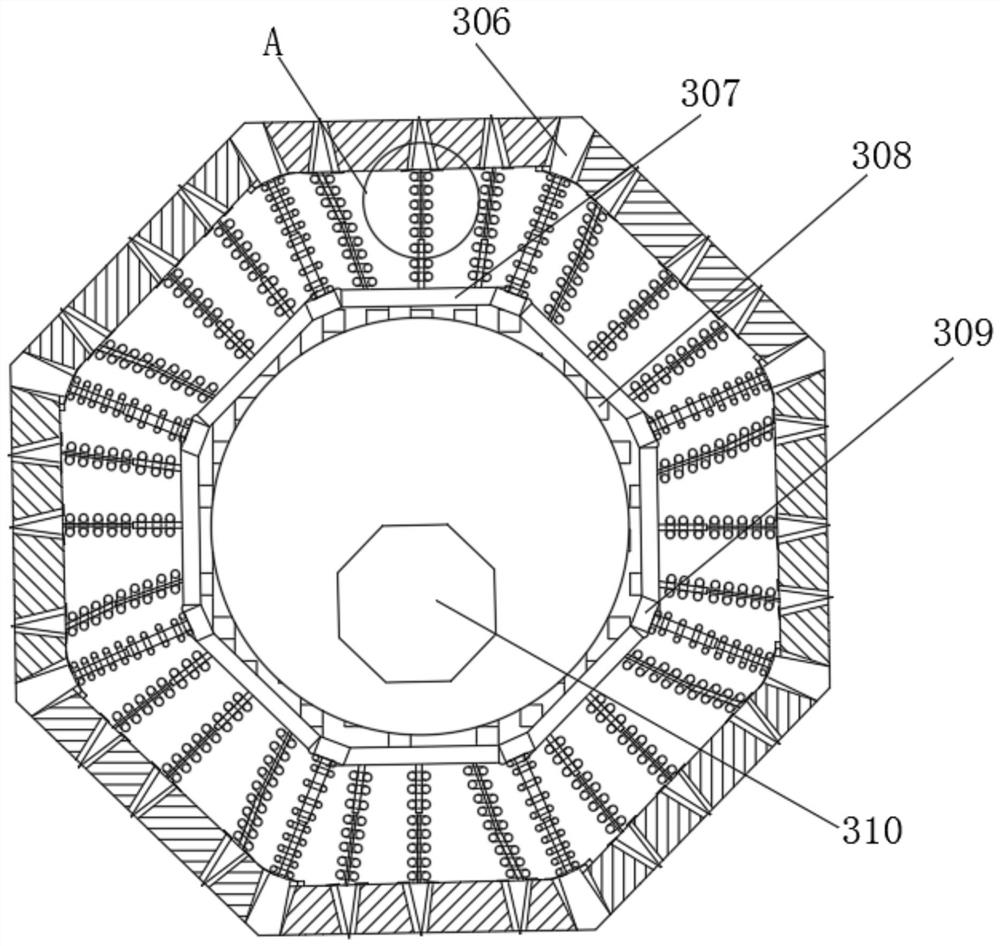

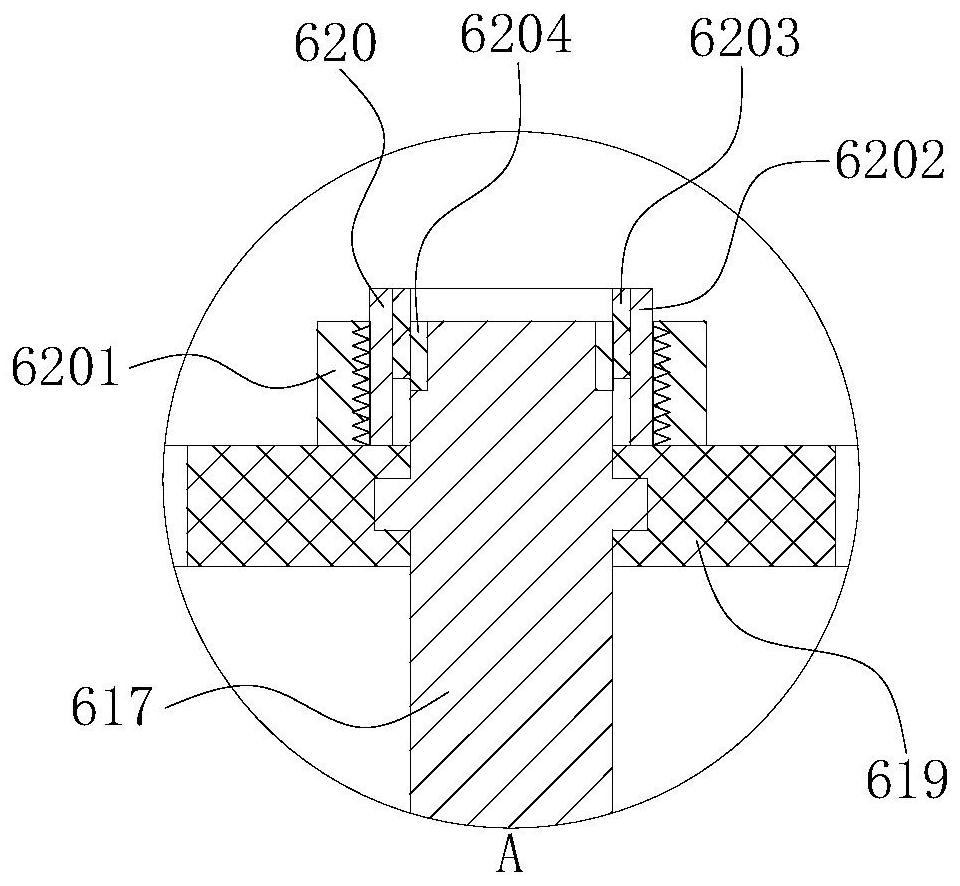

Amplitude type scorpion grinding device

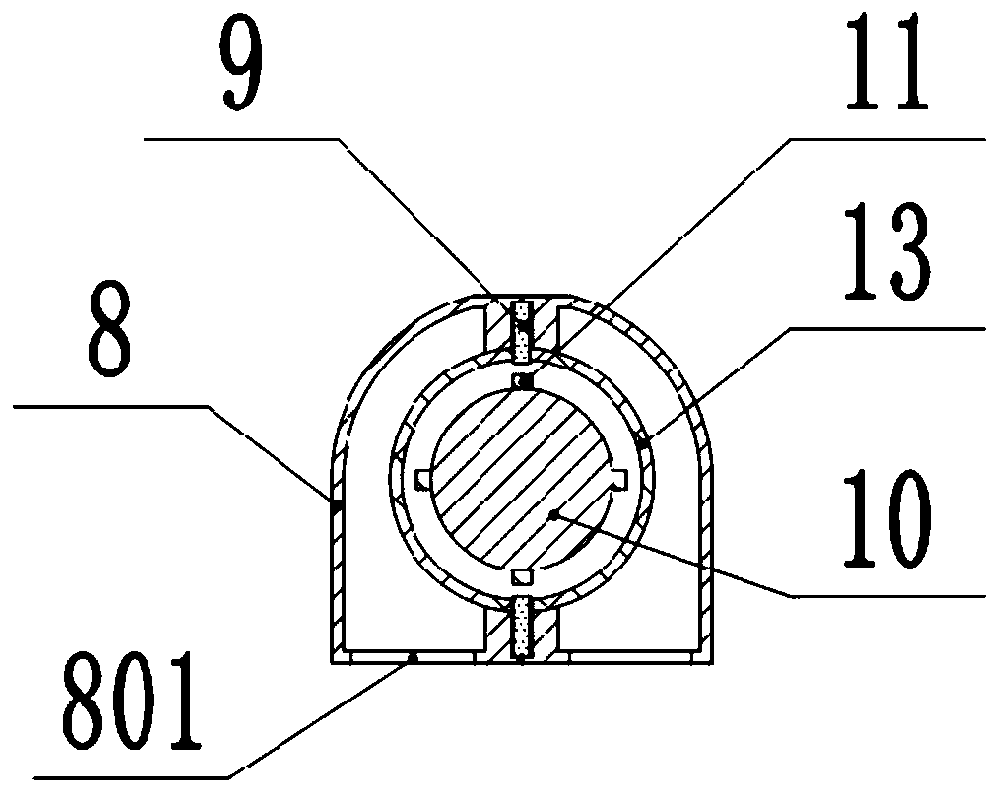

ActiveCN112427122AEnsure crushing efficiencyImprove work efficiencyGrain treatmentsEngineeringPhysics

The invention discloses an amplitude type scorpion grinding device. The amplitude type scorpion grinding device comprises an extruding and smashing mechanism used for smashing scorpion shells, a circulating collecting mechanism used for blowing cleaning and collecting and a magnetic grinding mechanism used for grinding the scorpion shells in an amplitude mode. A supporting frame is arranged in themagnetic grinding mechanism, and a support A is welded to the top of the supporting frame. The outer wall of the magnetic grinding mechanism is fixedly connected with the extruding and smashing mechanism through the arranged supporting frame and the support A. A support B is welded to the right end, away from the support A, of the top of the supporting frame. The magnetic grinding mechanism is fixedly connected with the circulating collecting mechanism through the arranged supporting frame and the support B. A first screw rod rotates clockwise to move scorpions upwards continuously, an extruding block is a small slope from low to high, the extruding block and a semicircular block are staggered to smash the relatively large scorpions, the scorpions are smashed repeatedly to the needed size, the scorpions of different sizes can be smashed, and the scorpion smashing efficiency is ensured.

Owner:周茂正

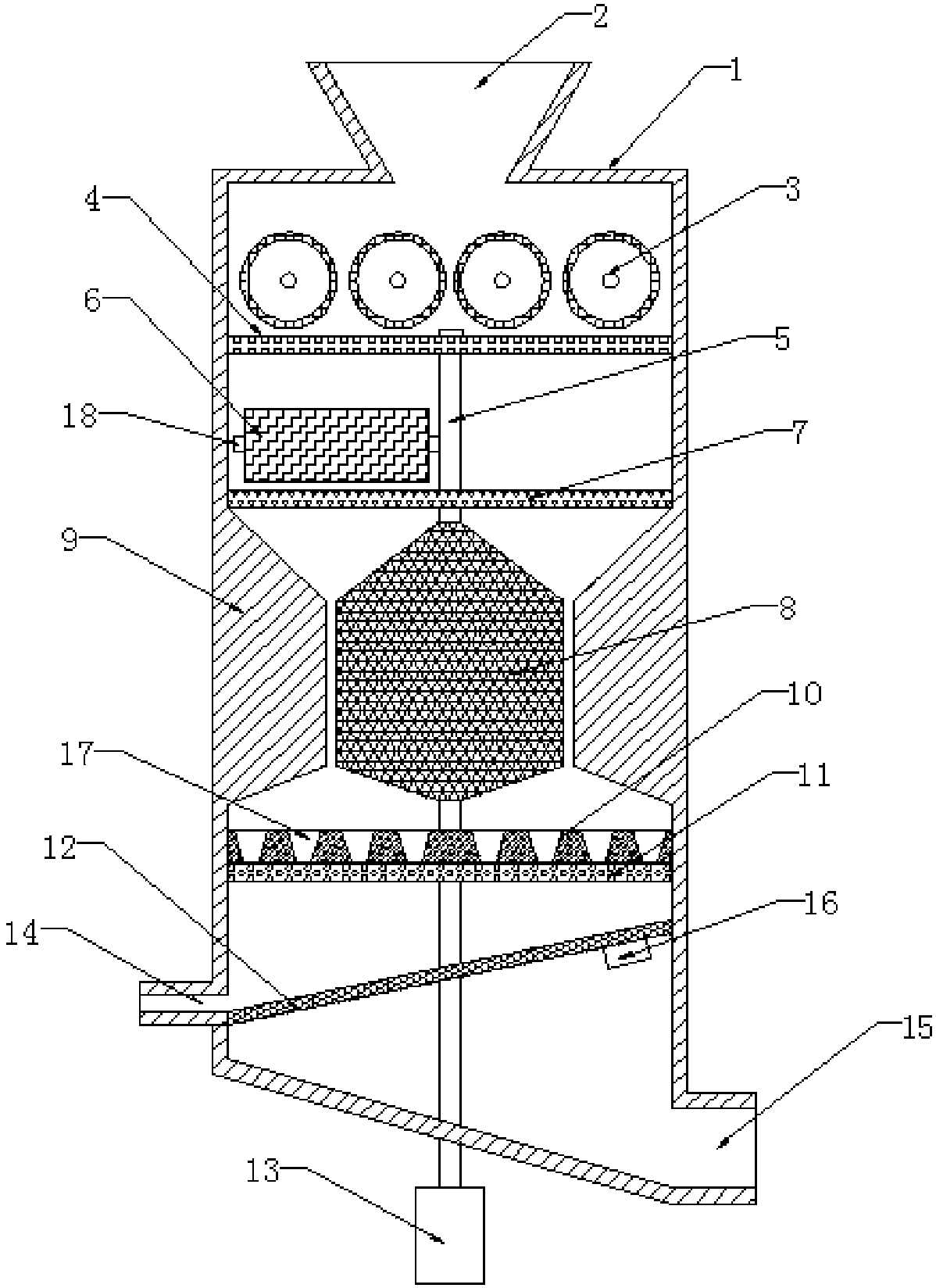

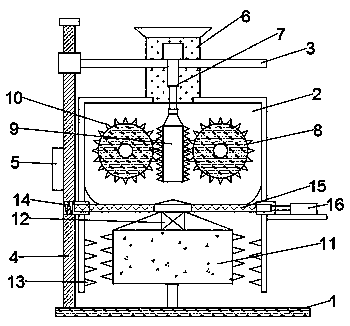

Efficient automatic powder grinding device

InactiveCN109718895AIncrease the number of grindsQuality assuranceCocoaGrain treatmentsEngineeringMillstone

The invention provides an efficient automatic powder grinding device. The efficient automatic powder grinding device comprises a box body, a crushing roller, a grinding roller, a second sieve plate, agrinding column and a grinding disc; a feeding hole is formed in the top of the box body, the upper part of the interior of the box body is provided with the crushing roller, and a first sieve plateis arranged at the position 5-10 cm below the crushing roller; a vertical rotating shaft is arranged in the box body; a supporting rod, the grinding column and the grinding disc are sequentially arranged on the rotating shaft from top to bottom, the rolling roller sleeves the supporting rod, and the second sieve plate is arranged at the position 10 cm below the grinding roller, and grinding bulgesmatched with the grinding column for use are arranged on the side wall of the box body; a plurality of abrasive holes are uniformly distributed in the millstone, and a third sieve plate matched withthe grinding disc is arranged below the grinding disc; and a fourth sieve plate which is obliquely arranged relative to the horizontal plane is arranged below the third sieve plate. The efficient automatic grinding device is provided with the multi-stage grinding structure, so that the grinding effect is good, and the efficiency is high.

Owner:新昌县永益包装有限公司

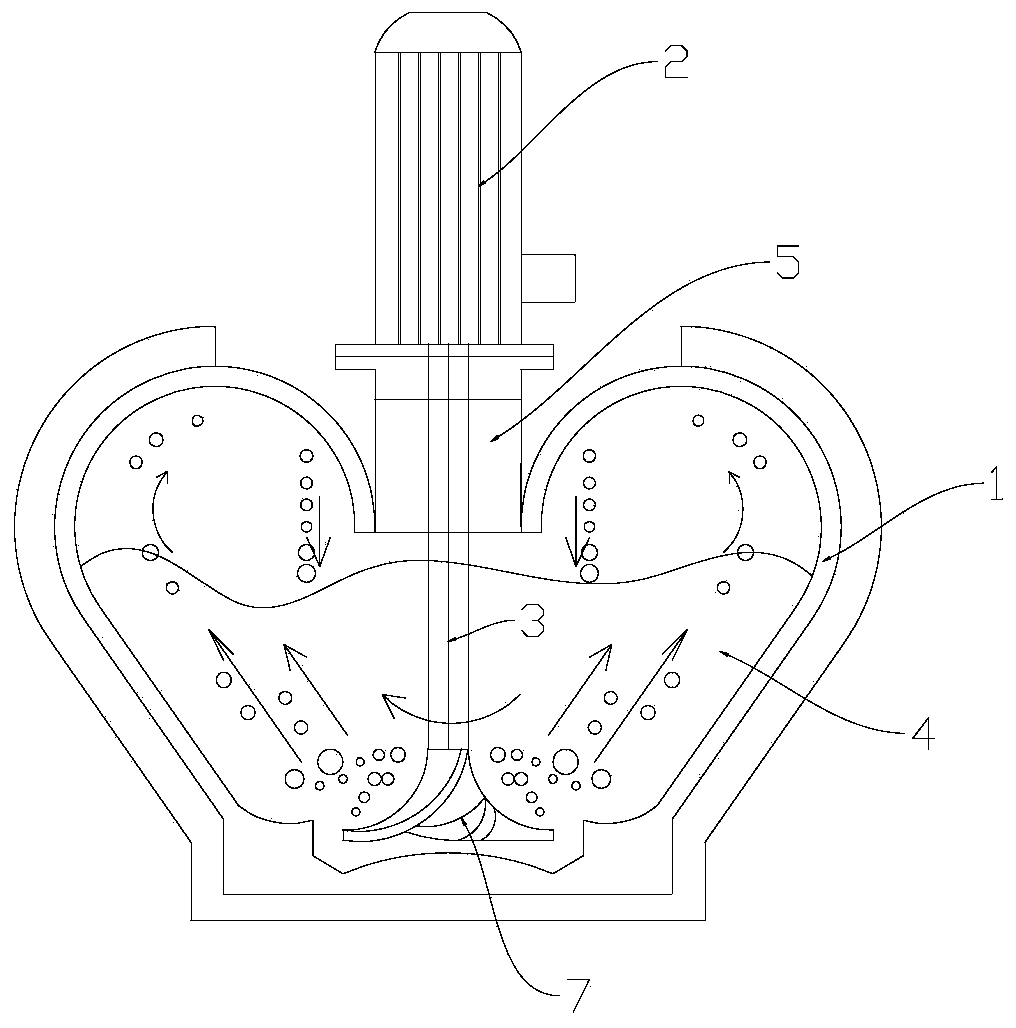

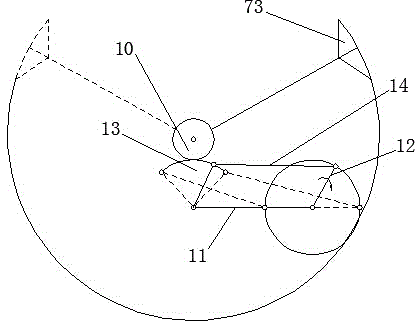

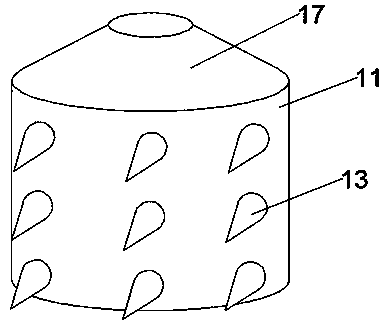

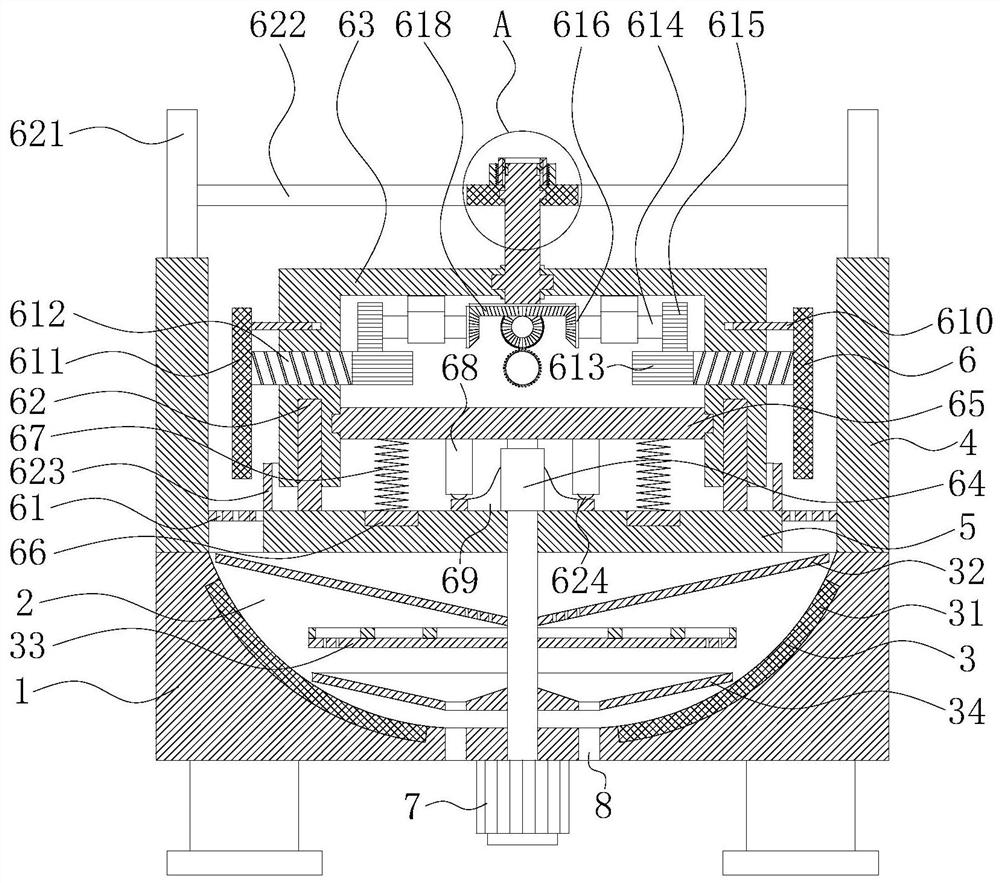

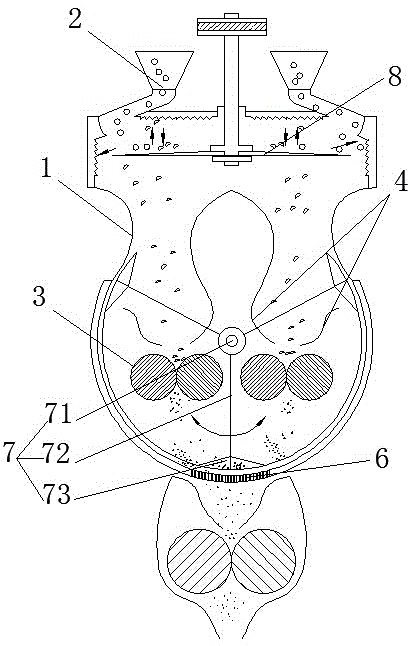

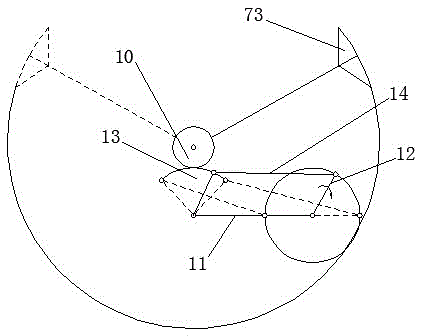

Parabolic grinding device

The invention relates to the technical field of grinding devices and discloses a parabolic grinding device comprising a grinding chamber, a motor and a rotary shaft. The grinding chamber is provided with a grinding cavity. The grinding cavity is provided with a parabolic wall face in a parabolic shape. The grinding cavity is filled with a granular grinding medium. The motor is arranged at the topof the grinding chamber. An output shaft of the motor is connected with the rotary shaft. The rotary shaft extends into the grinding cavity. Blades are evenly distributed at the lower end of the rotary shaft around the circumferential direction of the rotary shaft. Blade faces of the blades are curved faces warping upwards by a preset angle. A receiving disc and the blades warping upwards by the preset angle are arranged at the bottom of the grinding chamber, after materials are scattered to the receiving disc, the rotary shaft drives the receiving disc to rotate, the materials are thrown up by the blades, after thrown, the materials pass through the peach-shaped grinding cavity and are thrown back to the receiving disc along the outer wall of the grinding cavity, thus circular grinding ofthe materials is formed in the grinding cavity, and fuller grinding is achieved.

Owner:四川瑞驰拓维机械制造有限公司

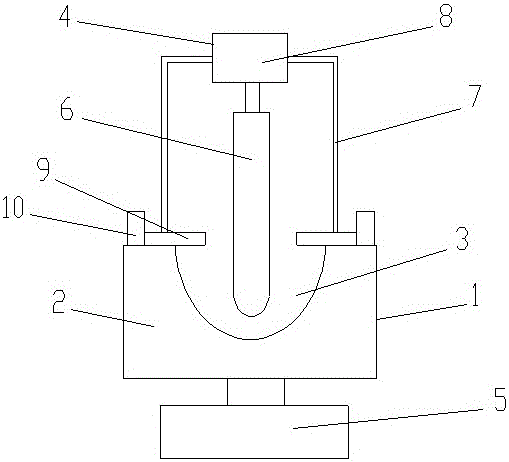

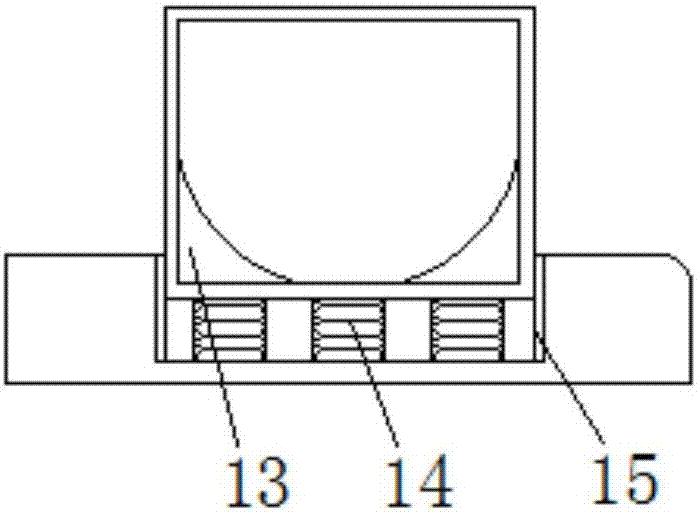

Powder material grinding device

The invention discloses a powder material grinding device. The powder material grinding device comprises a grinding device body. A grinding table is arranged at the lower end of the grinding device body. A U-shaped grinding groove is formed in the center of the grinding table. A rotation mechanism and a vibration mechanism are arranged at the bottom end of the grinding table. A muller rod is arranged at the upper end of the grinding device body and fixed to the upper end of the grinding table through an installing support. The upper end of the muller rod is connected with a lifting mechanism. The lower end of the muller rod is vertically downwards guided into the U-shaped grinding groove of the grinding table. Movable sealing plates are further arranged at the two ends of the grinding table. The corresponding two ends of the movable sealing plates are connected with moving mechanisms. The movable sealing plates are two symmetrically-arranged semicircular sealing plate bodies. Through the above manner, powder materials can be sufficiently ground through the powder material grinding device, and the powder material fineness degree is improved; and meanwhile, the grinding device has a vibration function, and powder at the upper end of the grinding groove can be continuously shaken down to be continuously ground.

Owner:WUXI KUAKE MICRONUTRIENT

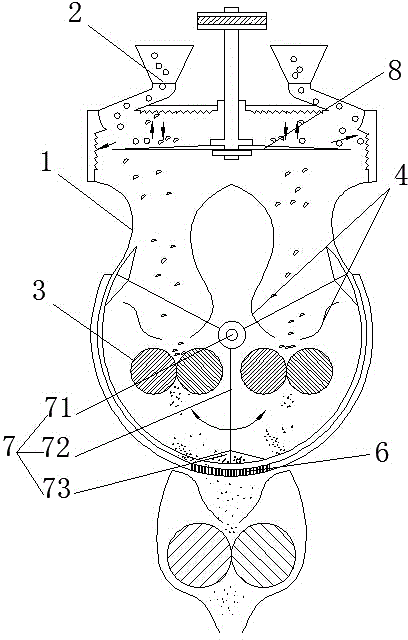

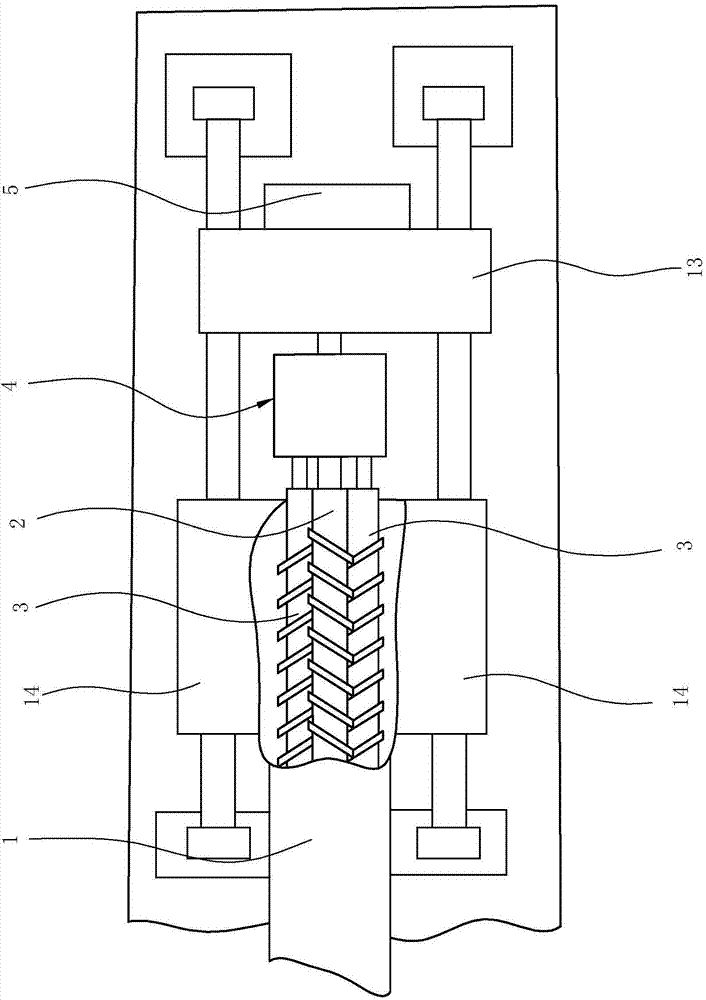

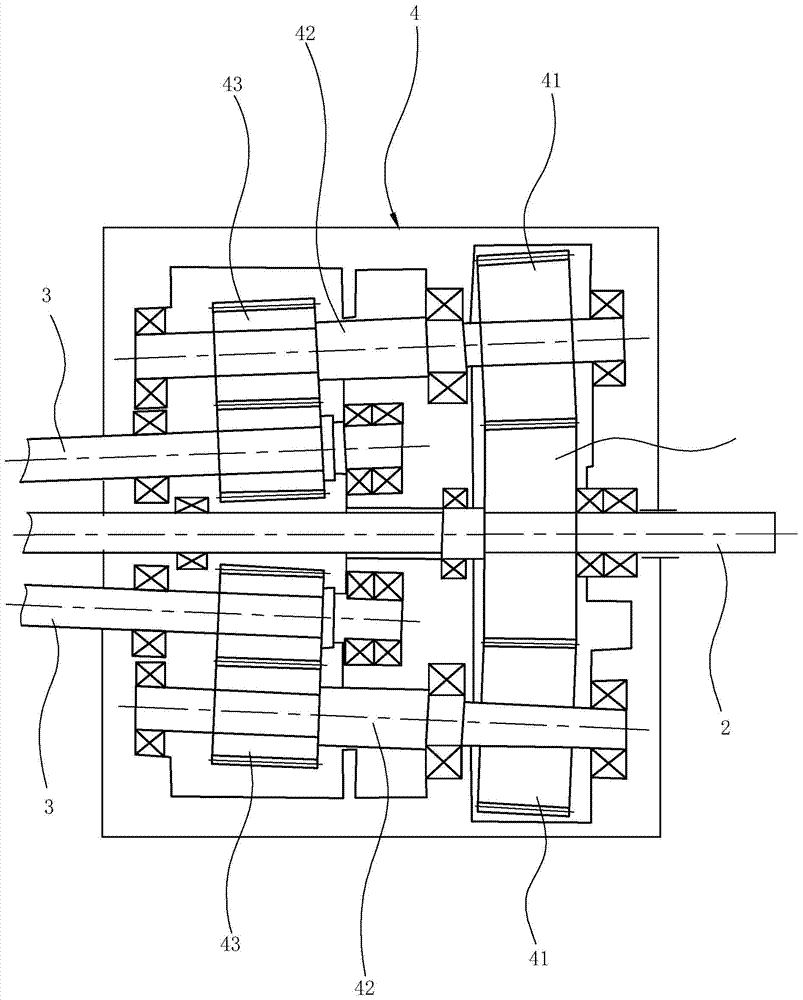

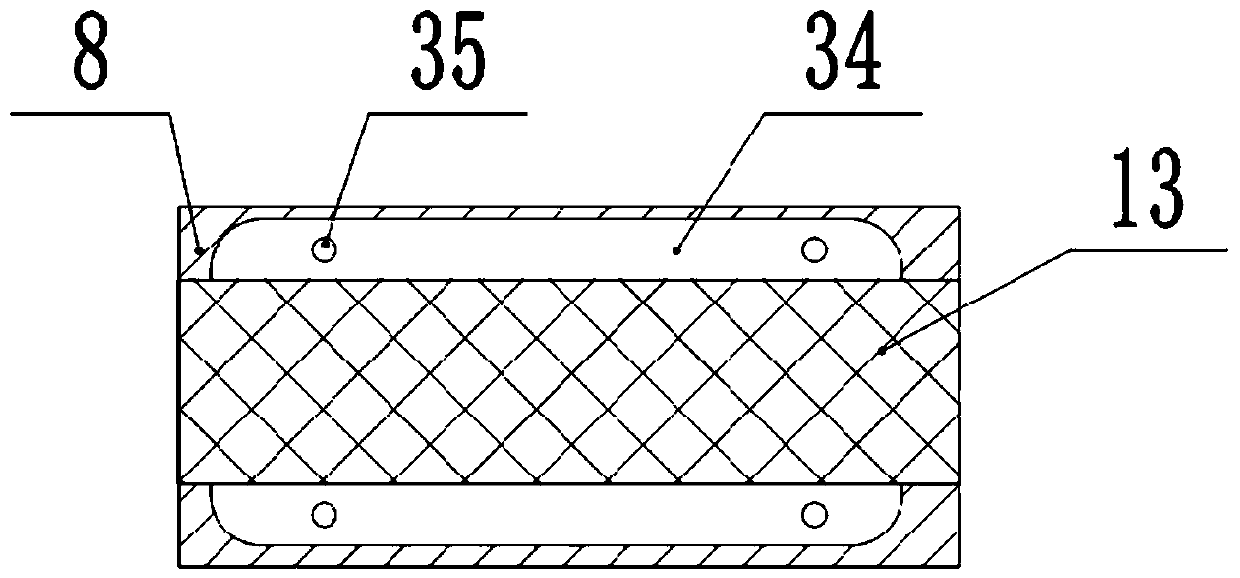

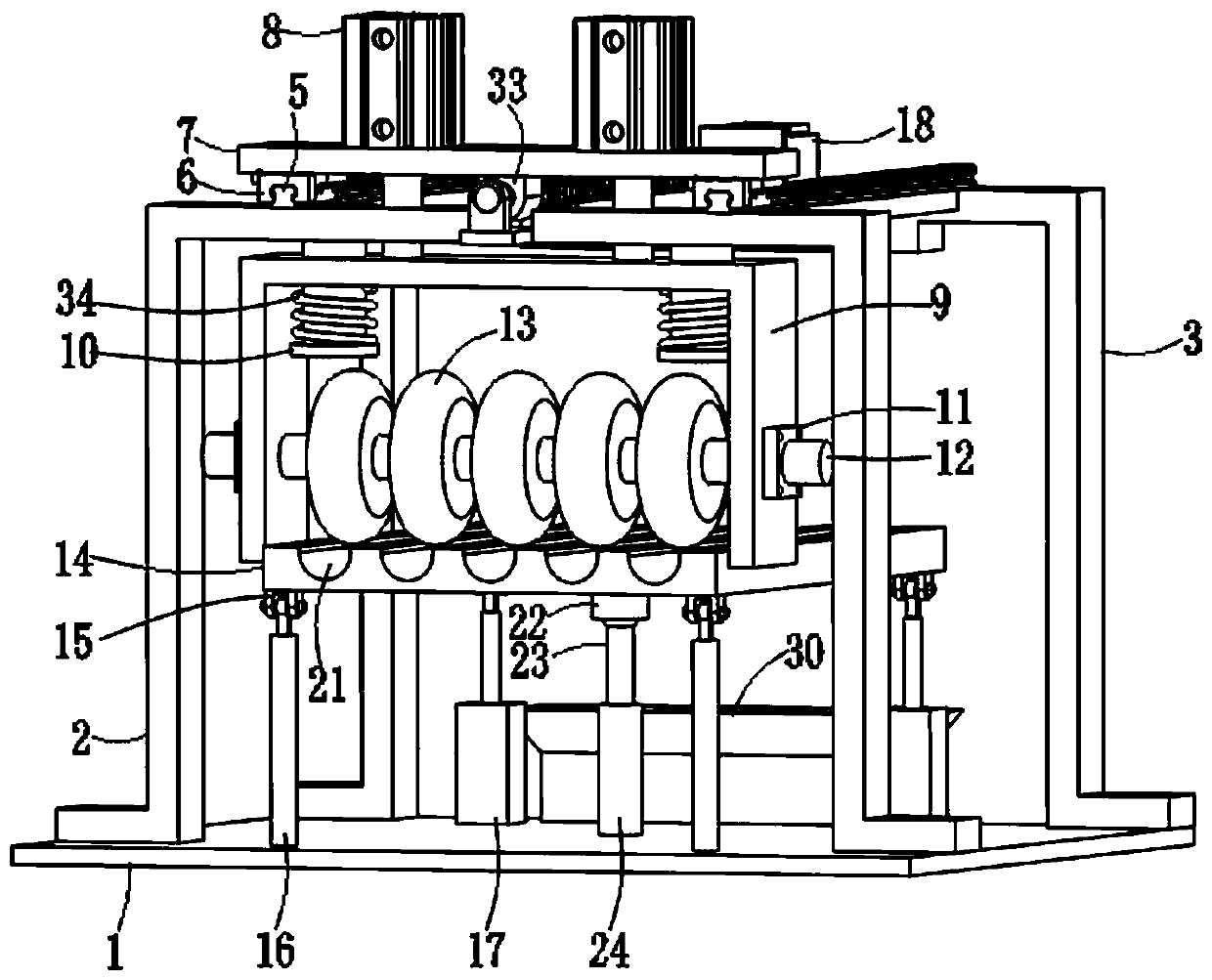

Circulating type powder grinding device

The invention discloses a circulating type powder grinding device which comprises a body provided with a powder grinding chamber, hoppers arranged on the upper part of the body, and grinding mechanisms; the grinding mechanisms comprise a coarse grinding mechanism and a fine grinding mechanism, wherein the coarse grinding mechanism is arranged inside the powder grinding chamber of the body, the bottom of the body is provided with a filtering device with mesh pores, and the fine grinding mechanism is arranged below the filtering device. The circulating type powder grinding device also comprises a debris recovery mechanism which is used for transporting debris on the filtering device and with the particle size greater than the mesh pores to the upward side of the coarse grinding mechanism; the coarse grinding mechanism comprises two pairs of mutually symmetrically arranged roller mechanisms, wherein the interior of the body is provided with guide plates for respectively guiding raw materials to the upward sides of corresponding rollers; the fine grinding mechanism comprises a group of paired-arrangement columnar rollers, wherein a gap between the adjacent columnar rollers is adjustable; the fine grinding mechanism also comprises elastic tensioning devices each for adjusting the gap between the adjacent columnar rollers. The circulating type powder grinding device has the characteristics of full grinding, low energy consumption, and simple control.

Owner:ZHEJIANG UNIV OF TECH

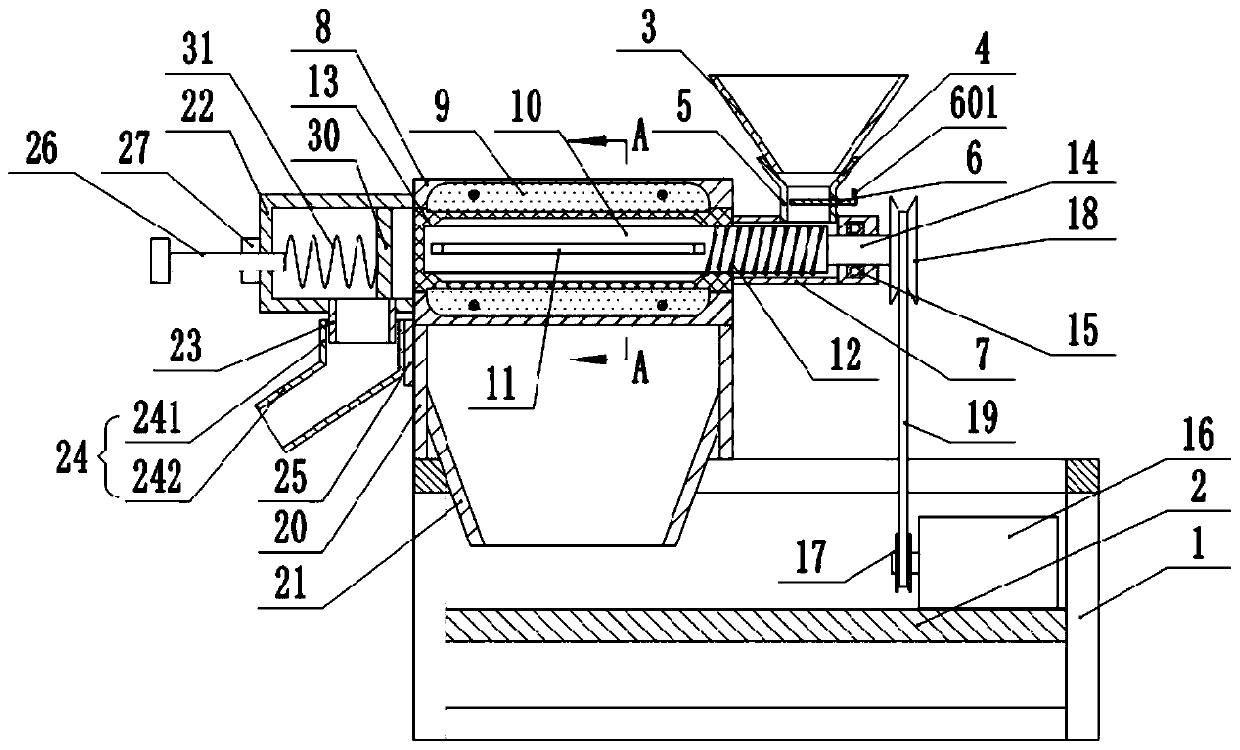

Glue injection device for injection molding machine

The invention discloses a glue injection device for an injection molding machine. The glue injection device comprises a plastifying part, wherein the plastifying part comprises a material barrel and screw rods arranged in the material barrel; the glue injection device for the injection molding machine is characterized in that three screw rods are arranged in the material barrel and are arranged triangularly or in a linearly parallel manner, and the inner wall of the material barrel is tangent with the outer trajectory formed by rotation of three screw rods. According to the glue injection device for the injection molding machine, three screw rods are adopted to forcibly convey the material, screw ridges and screw grooves of each screw rod have speed difference, so that the material can be fully extruded, ground and mixed and has good self-cleaning property and good calendaring effect, the quality of products is improved, and the single energy consumption and the processing cost are reduced.

Owner:阮祺

High-stability aluminum-base composite heat radiating material for LED

The invention relates to a lamp heat radiating material, in particular to a high-stability aluminum-base composite heat radiating material for an LED and a production method thereof. The heat radiating material is produced through the following raw materials in parts by weight: 70 to 72 parts of aluminum, 14 to 16 parts of aluminium nitride, 4 to 6 parts of cryolite powder, 15 to 18 parts of cellulose, 0.4 to 0.6 part of titanium sulfate, 3 to 5 parts of sodium fluosilicate, 8 to 10 parts of graphite, 1 to 2 parts of ferrous chloride, 0.5 to 0.6 part of citric acid, 2 to 5 parts of mineral oil, 2 to 3 parts of potassium alum, 6 to 8 parts of sodium silicate and 4 to 5 parts of auxiliaries. The heat radiating material integrates the advantages of the components such as aluminum, aluminum nitride, cellulose and auxiliaries and has a good heat conduction property and a good insulation property; after being processed by citric acid dilute solution in an immersing manner, the surface properties of the cellulose and the titanium sulfate are improved; all raw materials are ground in the mixed dilute solution of potassium alum and sodium silicate, so that the sintering effect of the heat radiating material is good, the sintering time is shortened, the surface of a finished product is unlikely to fracture, the stability is good, the heat conduction coefficient is high, the LED lamp can be effectively protected, and the service life of the lamp can be greatly prolonged.

Owner:YANYANG LAMP SET TIANCHANG CITY

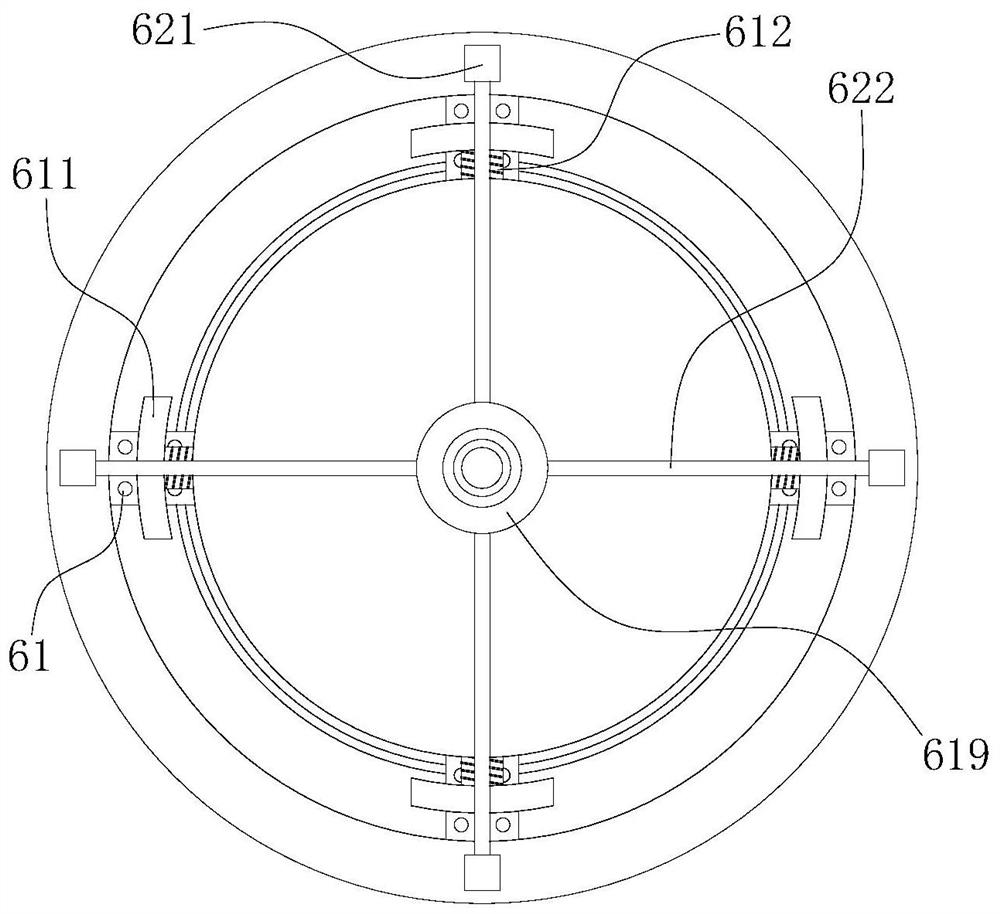

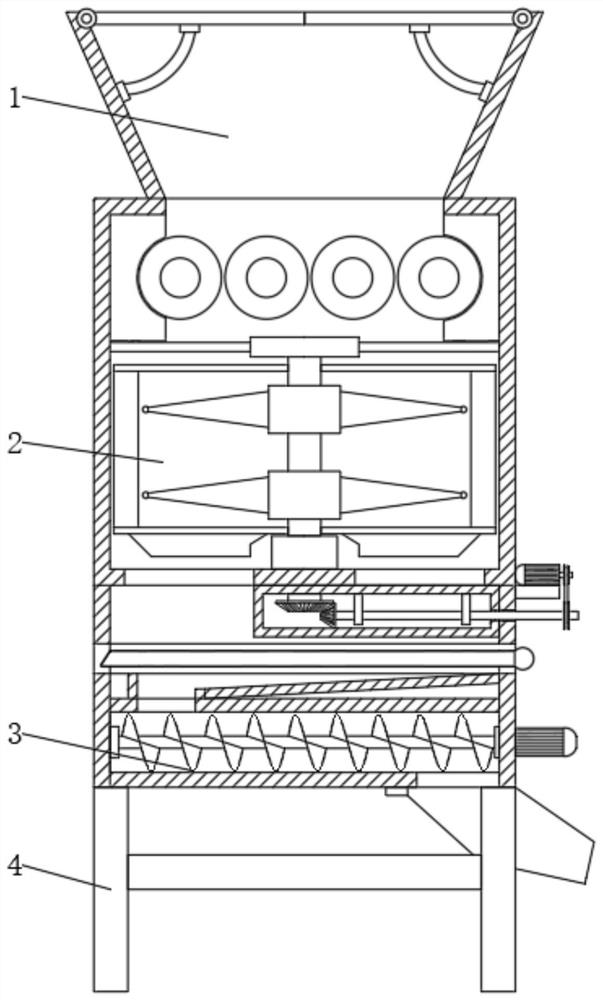

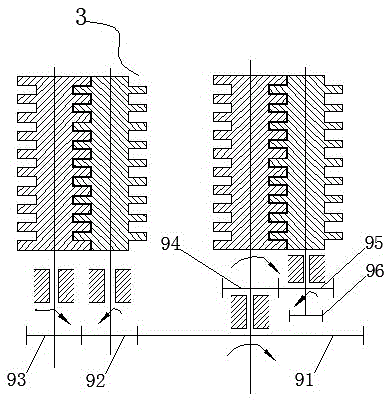

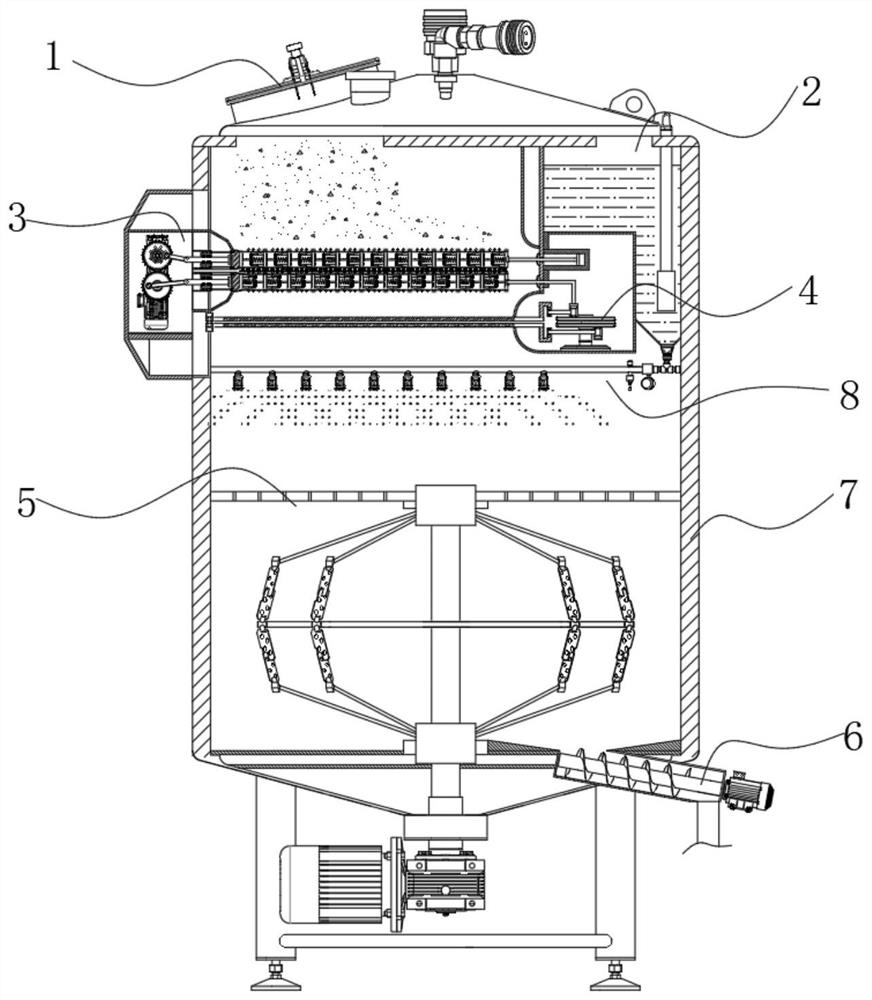

Grain processing rice milling device

InactiveCN111298867AIncrease frictionAffect normal dischargeGrain huskingGrain polishingMilling cutterAgricultural engineering

The invention belongs to the technical field of rice processing devices, and particularly discloses a grain processing rice milling device. The grain processing rice milling device comprises a feedingmechanism, a rice milling mechanism, a rice discharging mechanism, a bran discharging mechanism and a transmission mechanism, wherein the feeding mechanism comprises a conveying box and a feeding hopper, and the feeding hopper communicates with the conveying box; the rice milling mechanism comprises a mounting box and a milling roller, a spiral blade is arranged on the portion, located in the conveying box, of the milling roller, a sieve and a milling cutter are arranged in the mounting box, and a gap is formed between the sieve and the milling roller; the rice discharging mechanism comprisesa rice discharging box, a material blocking plate is arranged in the rice discharging box in a sliding fit mode, a discharging opening is formed in the bottom of the rice discharging box, an adjusting screw is arranged at the end, away from the mounting box, of the rice discharging box, an elastic piece is arranged between the adjusting screw and the material blocking plate, and the material blocking plate can block the discharging opening when the elastic piece is in a natural state. The rice yield can be increased, and the amount of unpeeled rice contained in rice grains is reduced.

Owner:重庆穗花食为天粮油有限公司

Single-driving hydraulic roller pressing sand machine

InactiveCN108940541AAchieve protectionQuick filterSievingScreeningGranularityPulp and paper industry

The invention discloses a single-driving hydraulic roller pressing sand machine, and belongs to the technical field of sand making equipment. The problems that in the gravel smashing process, hydraulic rollers are out of synchronization, and gravel is prone to nonuniform distribution, and the final grain size granularity of gravel is affected are solved. The machine comprises a conveying belt, a smashing box, a hydraulic roller and braking sawteeth; the smashing box is arranged above the conveying belt, a supporting stand column is fixedly welded to the left side of the smashing box, a supporting transverse rod is connected to the upper end of the supporting stand column, a feeding pipe is arranged in the middle of the upper surface of the smashing box, and communicates with the smashing box, the hydraulic roller is arranged in the smashing box, and the breaking sawteeth are arranged on the outer surface of the hydraulic roller. The machine has the efficient gravel smashing capacity, and the gravel granularity uniformity is ensured.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

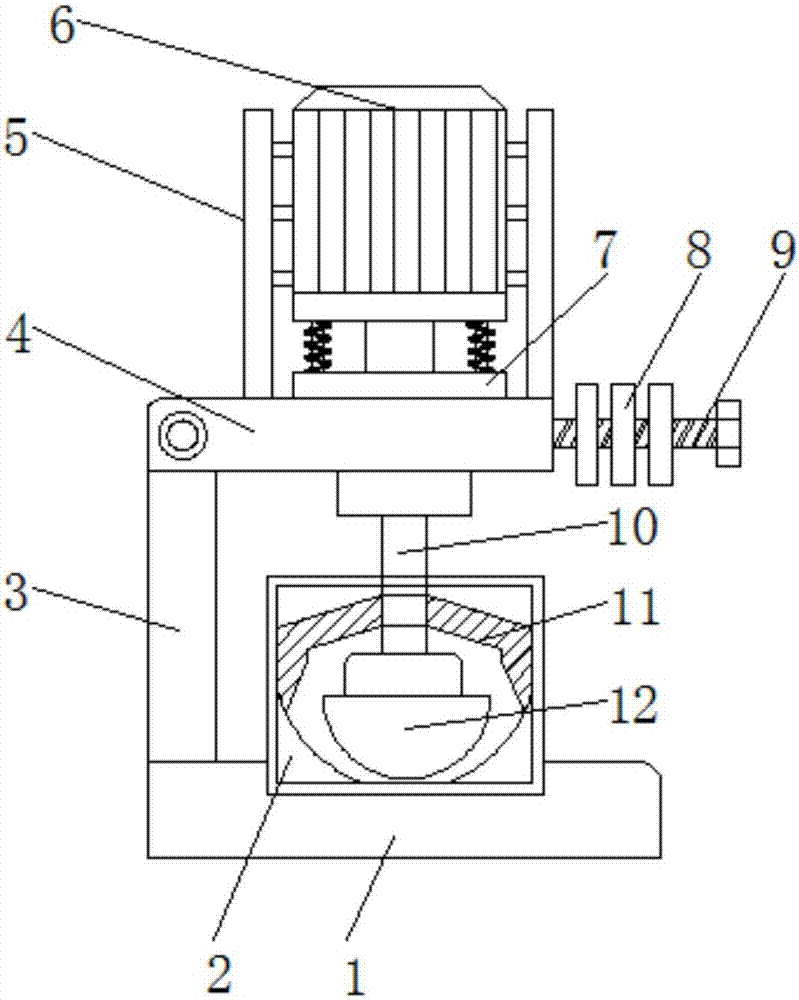

Novel massive material grinding device

InactiveCN107413486AGrind evenlyFully milledShaking/oscillating/vibrating mixersTransportation and packagingHardnessEngineering

The invention discloses a novel massive material grinding device which comprises a grinding base. A grinding bin is embedded in the center position of the top of the grinding base through a fixing groove. A vibration spring is connected between the bottom of the grinding bin and the fixing groove. Arc corners are welded to the four corner positions of the interior of the grinding bin. One side of the grinding base is rotationally connected with a motor bottom plate through a supporting frame. A grinding motor is fixed to the motor bottom plate through a motor fixing frame. The bottom of the grinding motor is connected with the motor bottom plate through a shock absorber. The grinding motor is in transmission connection with a motor rotating shaft through a speed reducer. A discharging frame and a grinding head are welded to the part, located in the grinding bin, of the bottom of the motor rotating shaft. According to the novel massive material grinding device, a loading stud is arranged firstly, loading blocks can be increased according to different hardness of materials needing to be ground, and therefore the novel massive material grinding device can be suitable for grinding materials of different hardness.

Owner:CHENGDU ZHONGFU LIXIANG TECH

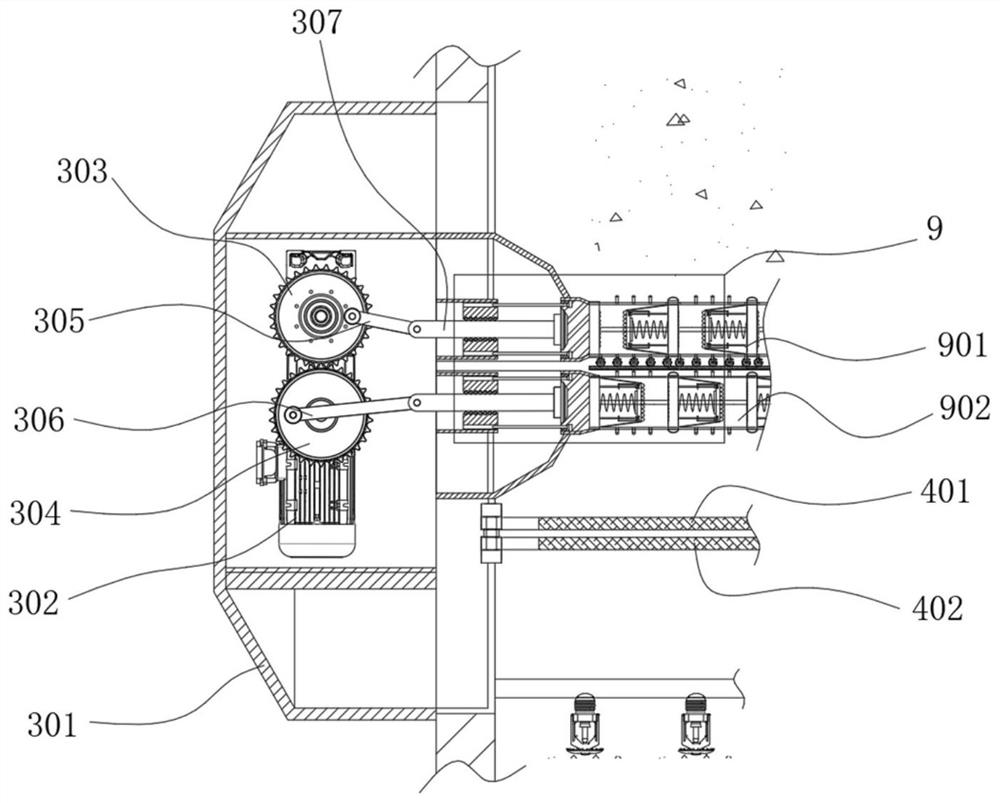

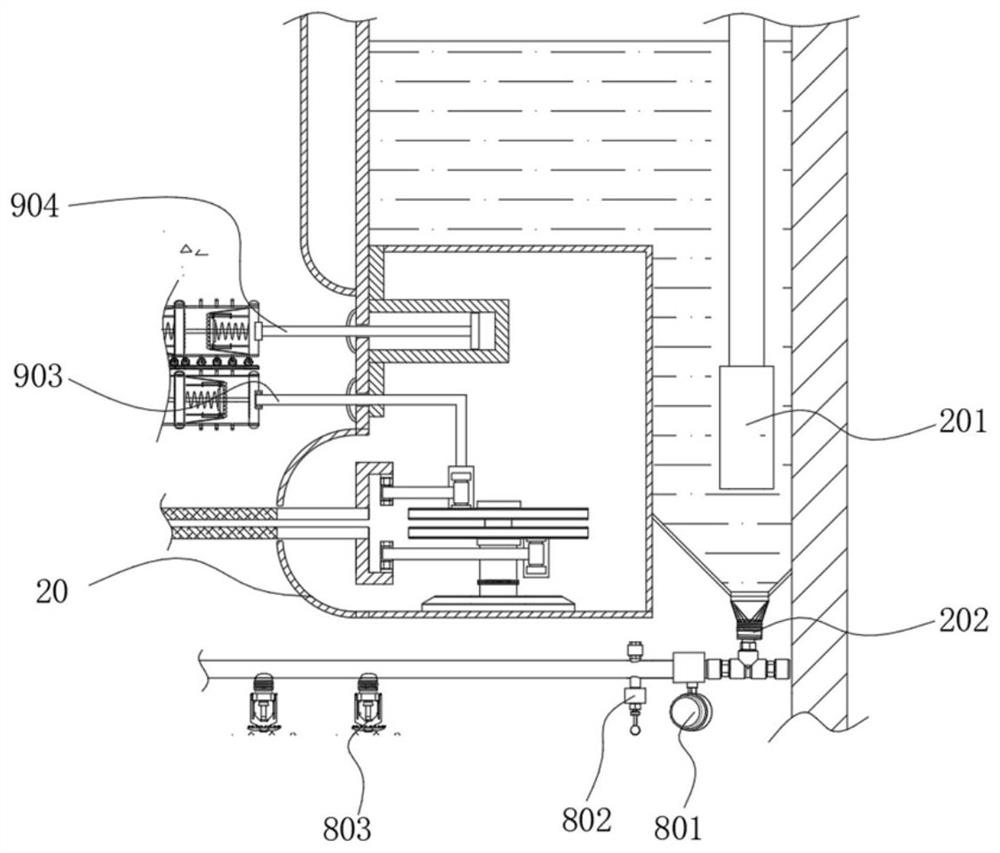

Clamping jaw for magnesium pressing system

The invention provides a clamping jaw for a magnesium pressing system, relates to the technical field of magnesium pressing, and solves the problems, in the prior art, that the efficiency of manuallyextruding and grinding a magnesium block during pretreatment is low, and meanwhile, the metal powder generated in a grinding process has strong pollution and great harm to a human body. The clamping jaw for the magnesium pressing system comprises a transmission assembly. The transmission assembly comprises a primary gear and a secondary gear which are arranged on a hanging bracket. A transmissionchain is arranged between the primary gear and the secondary gear. A chain clamp is arranged at the lower part of the chain in a sleeving manner. The lower part of the chain clamp is connected to a transmission roller. The clamping jaw for the magnesium pressing system further comprises a magnesium pressing assembly. The magnesium pressing assembly comprises a main oil cylinder, a fixing support,a side oil cylinder, a trapezoidal pressing block, and a square pressing block. A fixing clamp is connected to a piston rod of the main oil cylinder. An opening is formed in one end of the metal fixing clamp. A fixing part is arranged at the opening of the metal fixing clamp. A threaded hole is formed in the fixing part.

Owner:江苏盛鑫气动液压设备有限公司

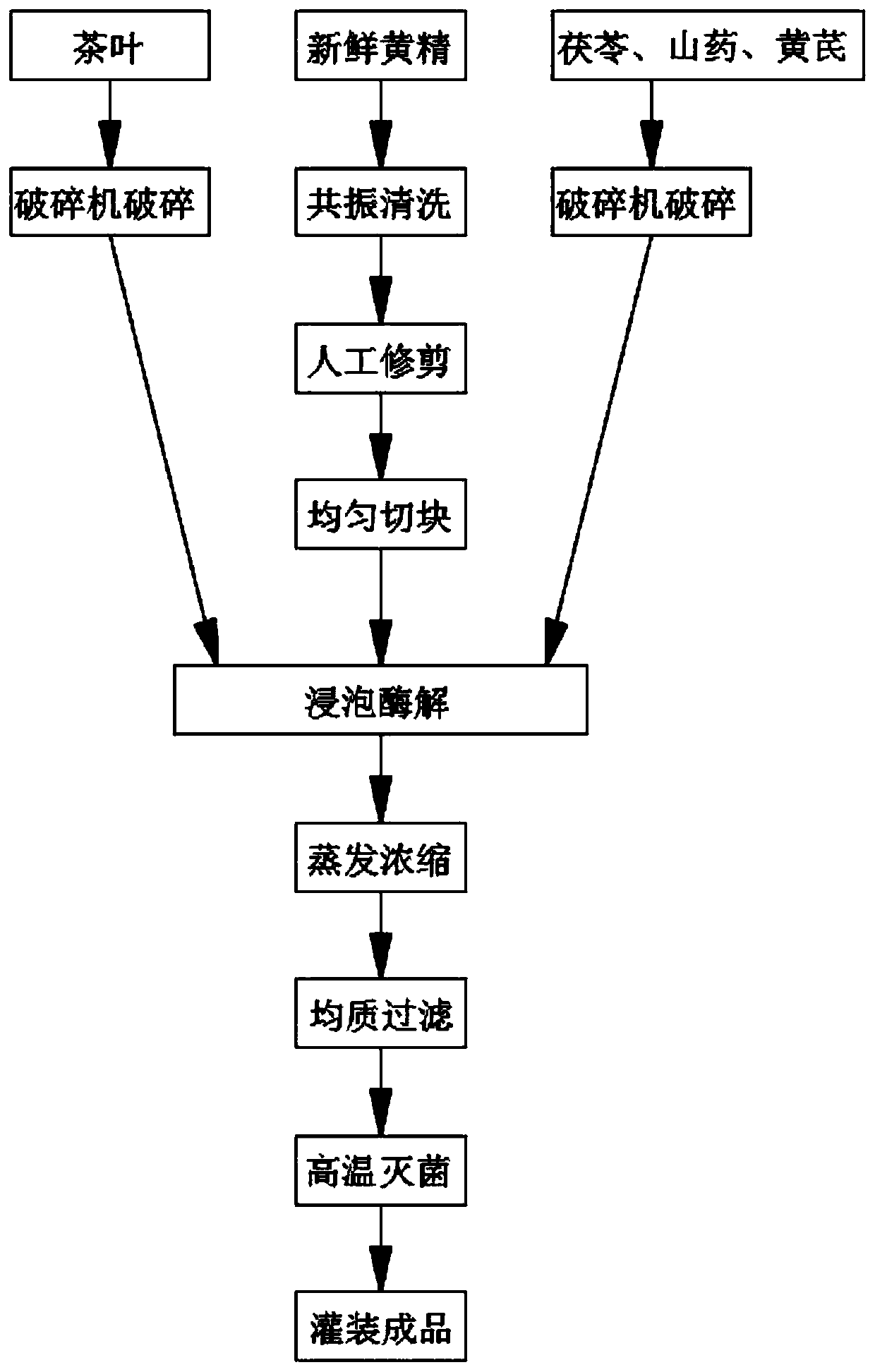

Processing technology for instant rhizoma polygonati tea beverage

InactiveCN110800837AWith health functionGood for healthPre-extraction tea treatmentRadix Astragali seu HedysariProcess engineering

The invention discloses a processing technology for an instant rhizoma polygonati tea beverage. The instant rhizoma polygonati tea beverage is prepared by taking fresh rhizoma polygonati and tea as main raw materials, so that the beverage has a health care function. In addition, the rhizoma polygonati is compounded with the tea, radix astragali, rhizoma dioscoreae and poria, and an own mount numbing effect of the rhizoma polygonati is completely eliminated. The fresh rhizoma polygonati is directly used as the raw material, a technology of "steaming and drying in the sun" is simplified, so thata production technology is convenient and quick, and production efficiency is greatly improved. By use of colloid homogenizing equipment used for homogenizing rhizoma polygonati concentrated juices,the rhizoma polygonati concentrated juices are more sufficiently grinded, and a homogenizing effect is good. A circulating pump machine pumps out the rhizoma polygonati concentrated juices containingsolid particulates, then, the rhizoma polygonati concentrated juices are returned to a mixing box through a return pipe to be continuously grinded and homogenized, so that an extremely small quantityof solid particulates is in the presence in the rhizoma polygonati concentrated juices, and the quality of the rhizoma polygonati concentrated juices is improved. Since a filtering plate is installedin a filtering pipe, a space occupied by equipment is reduced, and in addition, production cost is lowered.

Owner:敬山(上海)实业有限公司

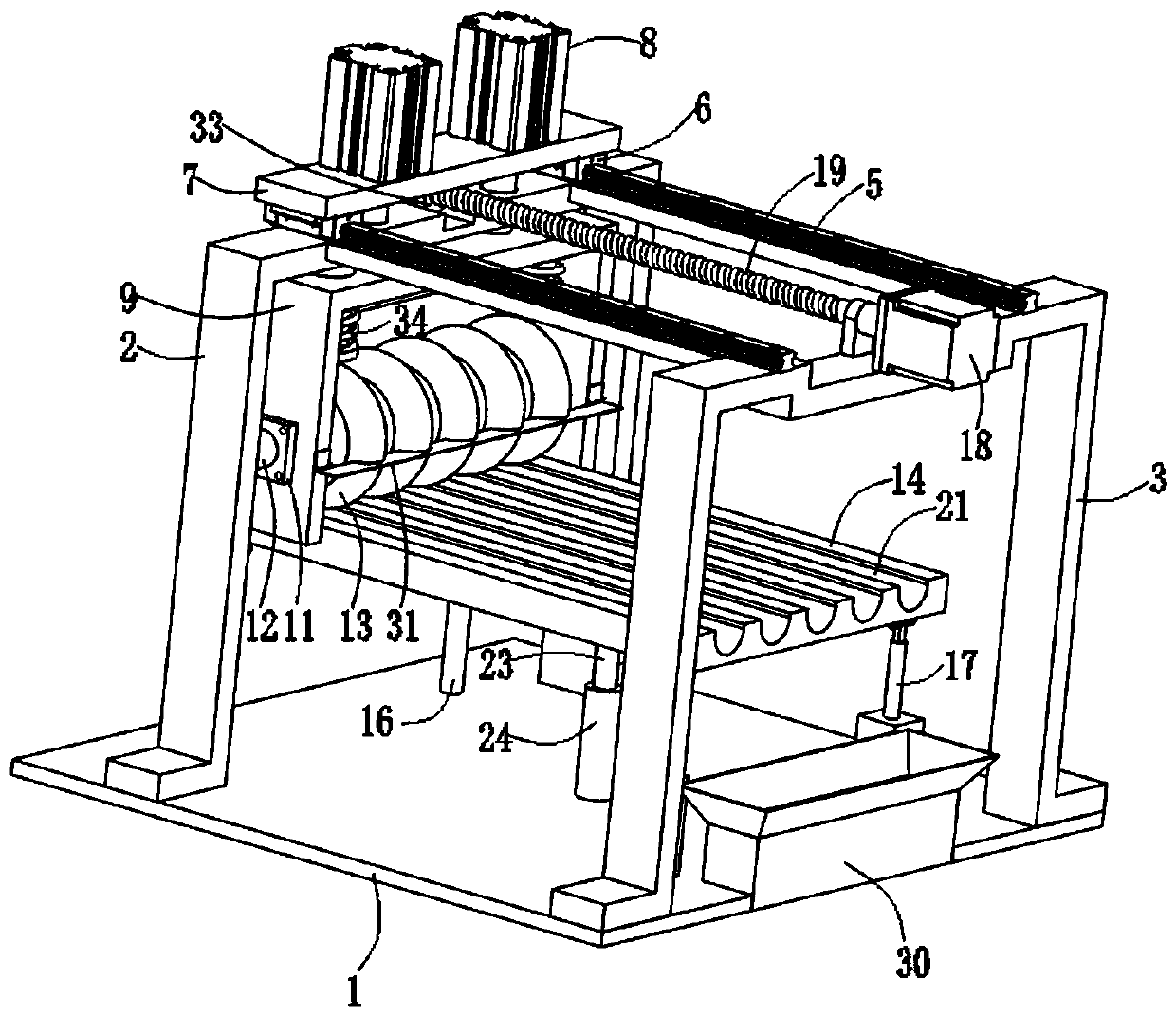

Multifunctional medicine grinding and crushing device for pharmacology

InactiveCN111589516ATime-consuming and laborious to solveImprove work efficiencyGrain treatmentsManual medicineStructural engineering

The invention discloses a multifunctional medicine grinding and crushing device for pharmacology. The multifunctional medicine grinding and crushing device comprises a bottom plate, the left side andthe right side of the upper surface of the bottom plate are welded with a first support and a second support correspondingly, a connecting plate is jointly and fixedly connected between the first support and the second support, a sliding rail is installed on the connecting plate, a sliding block is installed on the sliding rail, a first flat plate is mounted on the sliding block, and a first air cylinder is fixedly connected to the first flat plate. According to the multifunctional medicine grinding and crushing device for the pharmacology, through the arrangement of a crushing roller, a medicine crushing disc and a medicine crushing rail, efficient grinding and crushing of medicine can be achieved, under the action of a roller scraping plate and an arc-shaped bayonet, the medicine adhering to the crushing roller can be scraped away, and therefore sufficient grinding and crushing of the medicine can be achieved; the problem that manual medicine crushing wastes time and labor is solved,the working efficiency of medicine crushing is remarkably improved, the cleanness of the medicine crushing disc is kept while automatic medicine collection of the device is achieved, and the device is simple and practical in overall structure.

Owner:王飞飞

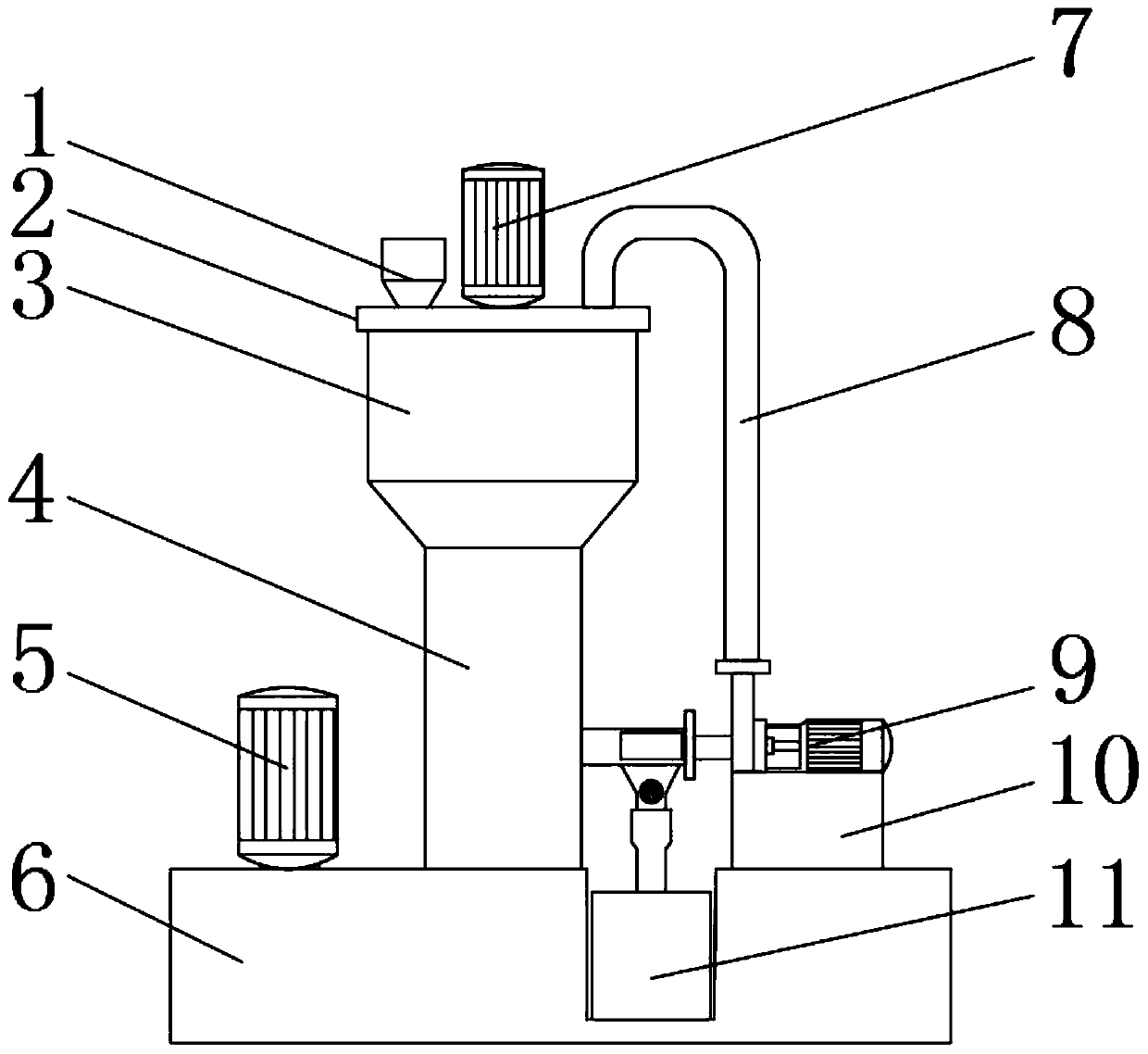

Automatic flour mill

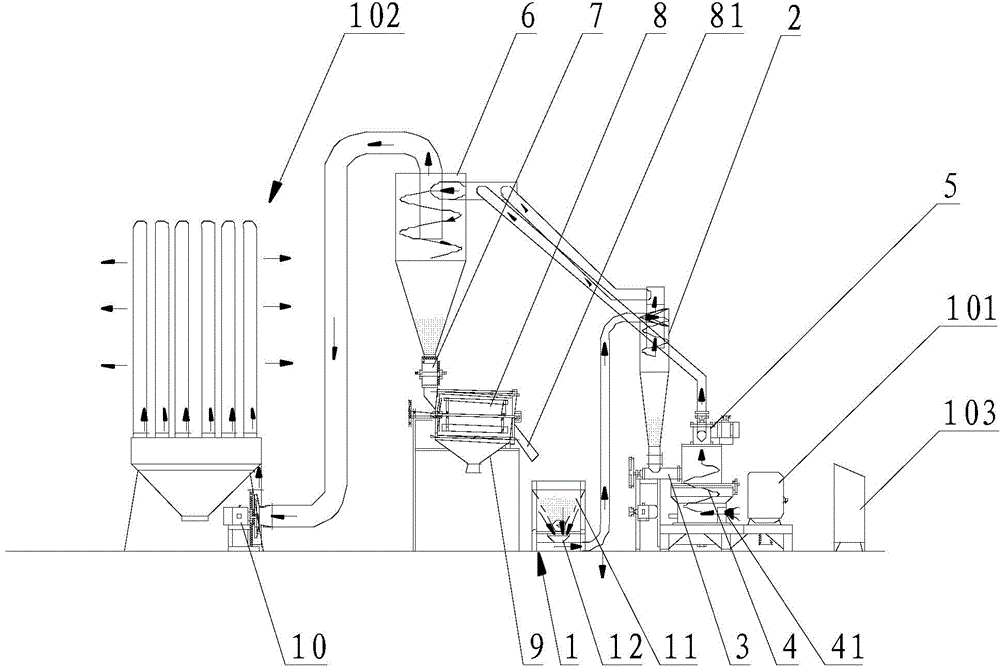

InactiveCN104858035AEfficient separationEffective movementGrain treatmentsEngineeringMechanical engineering

The invention relates to an automatic flour mill. The automatic flour mill comprises a feed mechanism, a first gas / solid separator, a material guiding device, a mill, a classifier, a second gas / solid separator, a closed-air aspirator, a sieving machine, a discharging mechanism, a draught fan and a main motor, wherein an outlet of the feed mechanism is communicated with an inlet of the first gas / solid separator through a pipeline, and an outlet of the first gas / solid separator is communicated with an inlet of the material guiding device; an outlet of the material guiding device is communicated with an inlet of the mill, an outlet of the mill is communicated with an inlet of the classifier, an outlet of the classifier is communicated with an inlet of the second gas / solid separator through a pipeline, and the closed-air aspirator is arranged at the outlet of the second gas / solid separator; the main motor is electrically connected with the first gas / solid separator, the mill, the classifier, the second gas / solid separator, the closed-air aspirator, the sieving machine and the draught fan. The automatic flour mill disclosed by the invention has the advantage that the milling is sufficient, safe and stable.

Owner:福建省邵武德龙机械制造有限公司

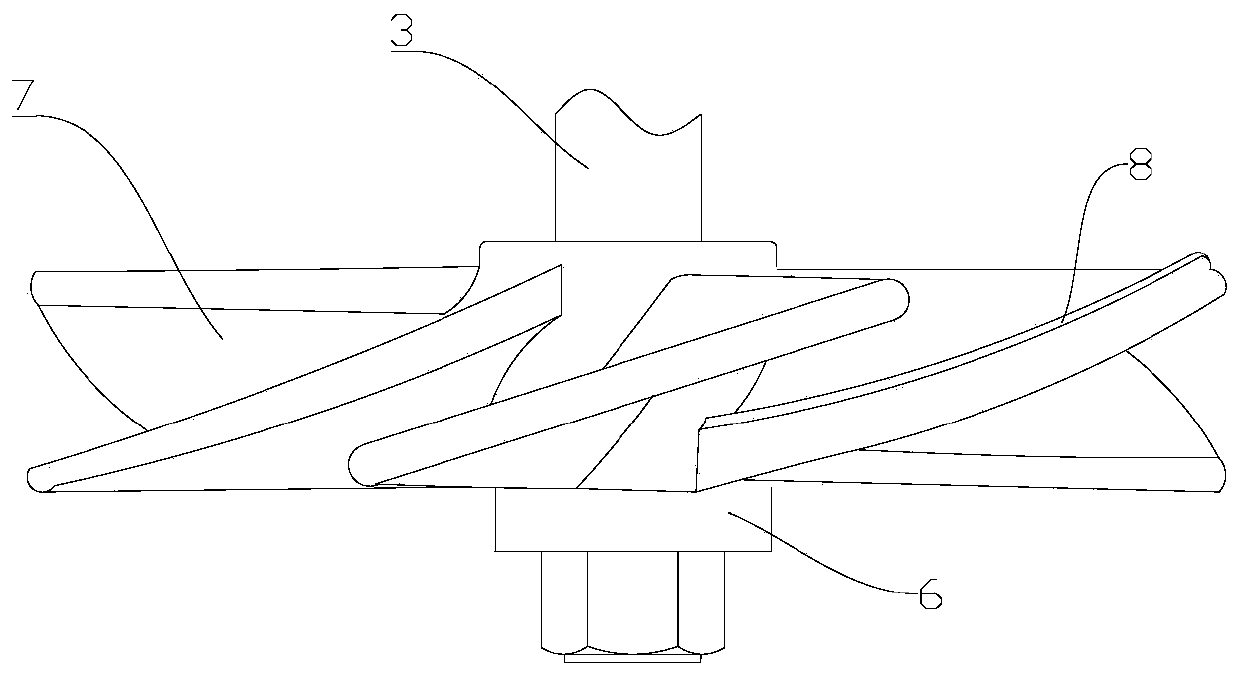

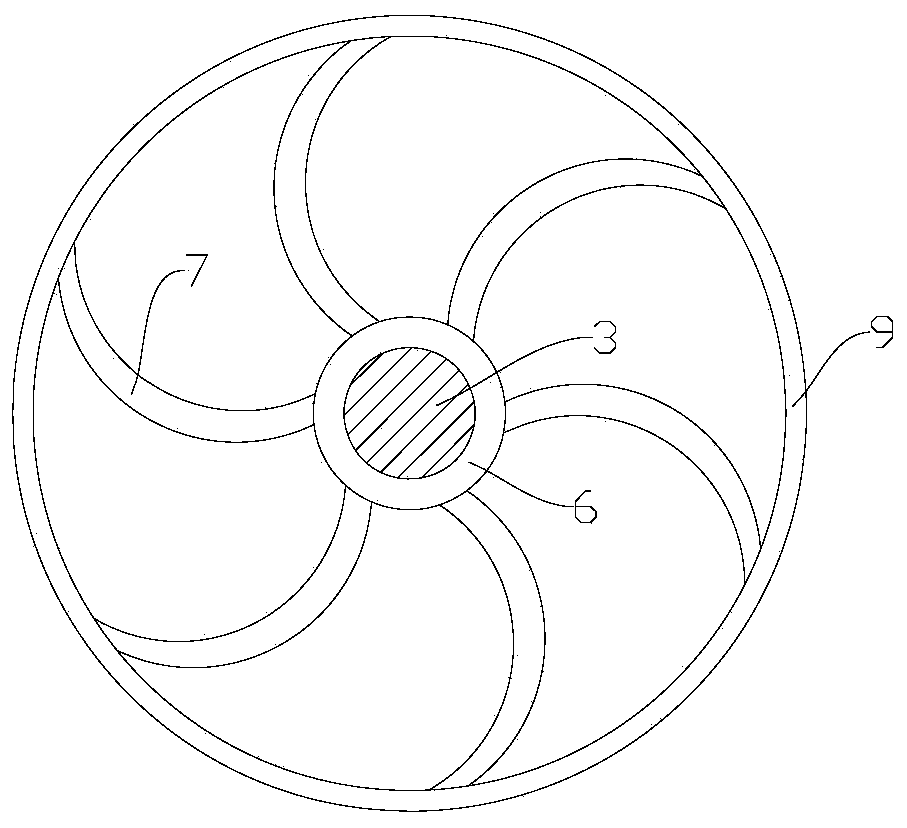

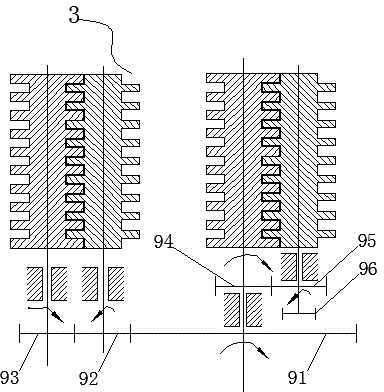

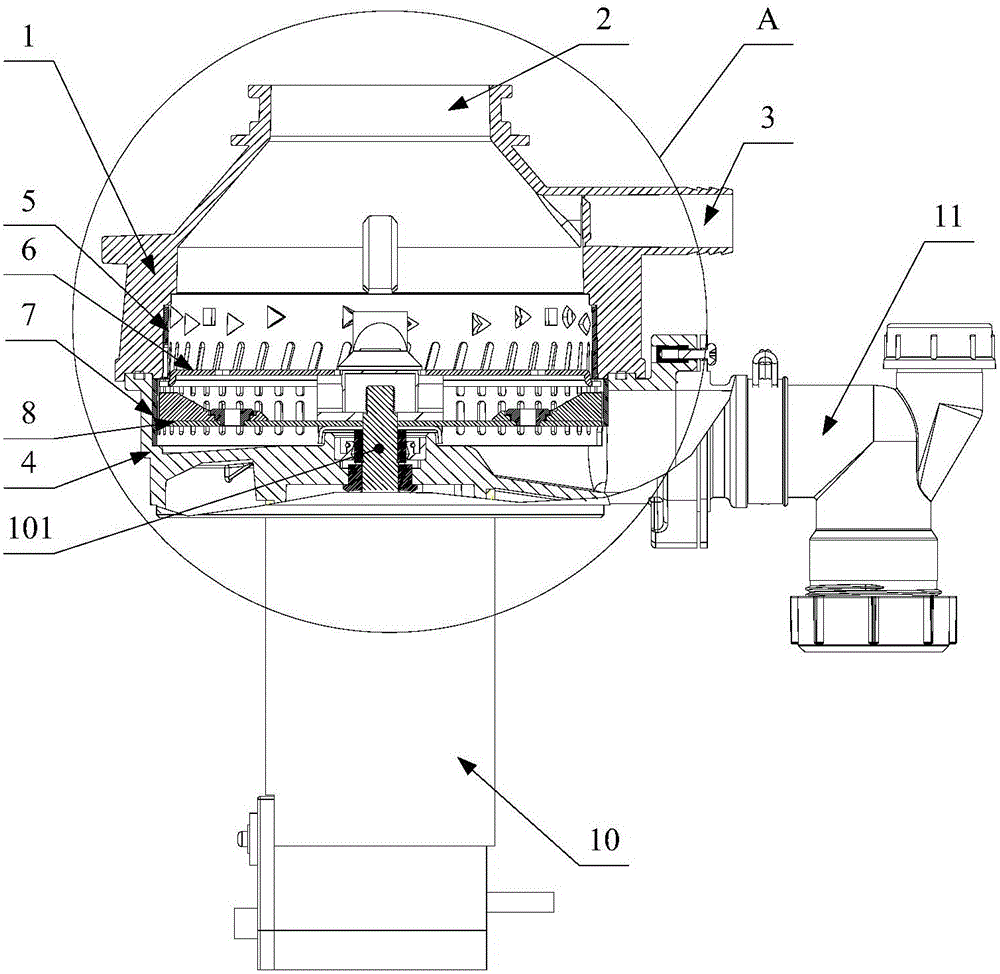

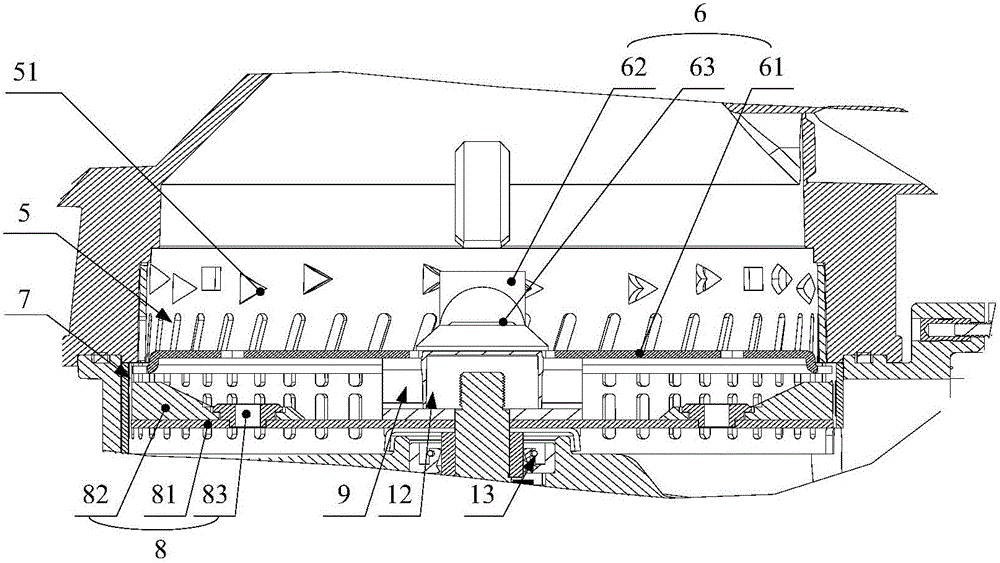

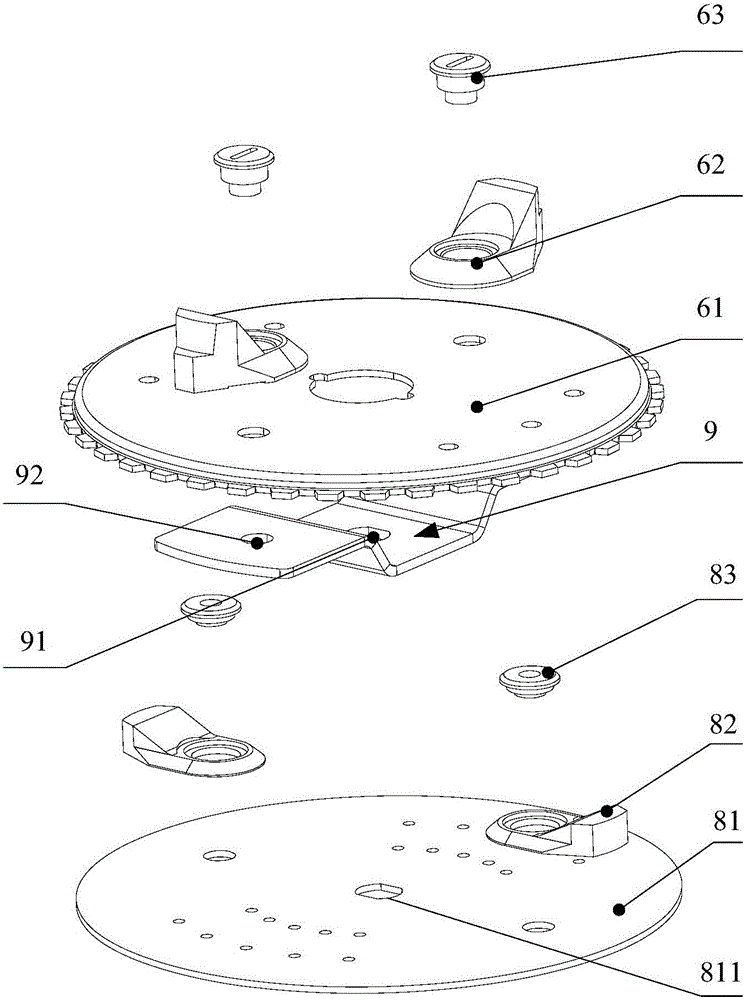

Food waste disposer and grinding mechanism thereof

ActiveCN105689065AImprove grinding finenessFully cutDomestic plumbingGrain treatmentsSewerageMotor shaft

Owner:GREE ELECTRIC APPLIANCES INC

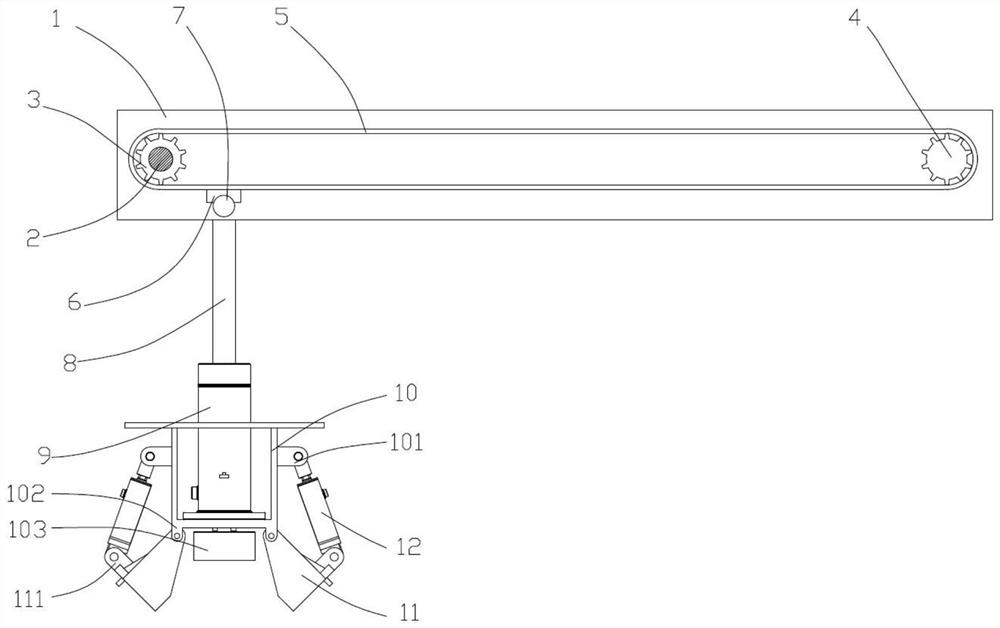

Hanging type travelling powder grinding machine

The invention discloses a hanging type travelling powder grinding machine. The hanging type travelling powder grinding machine comprises a powder grinding machine body, wherein a shifting seat body is arranged at the lower end of the powder grinding machine body; a shifting advancing mechanism is mounted at the upper end of the shifting seat body; a hydraulic supporting rod body is connected between the shifting advancing mechanism and the shifting seat body; a plurality of grinding mechanisms are mounted at the lower end of the shifting seat body; and the grinding mechanism consists of an air-blowing air blower, a rotary motor body, a rotary shaft rod and a grinding disc. In this way, the hanging type travelling powder grinding machine can be hung upside down for grinding powder, so that powder fineness is improved; and the grinding mechanism on the powder grinding machine body further can blow the powder through the air-blowing air blower, so that the powder is sufficiently grinded by the grinding mechanism.

Owner:WUXI KUAKE MICRONUTRIENT

Daily fertilization treatment device for agricultural planting

ActiveCN111886990AThe effect of low grindingFull drying effectFertiliser distributersDrying gas arrangementsAgricultural engineeringElectric machinery

The invention belongs to the technical field of agricultural planting, and particularly relates to a daily fertilization treatment device for agricultural planting. The daily fertilization treatment device comprises a base, wherein an accommodating cavity is formed in the base; a drying mechanism is arranged in the accommodating cavity; an annular support tube is vertically and fixedly arranged onthe top surface of the base around the accommodating cavity; a wear-resistant material covers the inner side wall of the support tube; a round separation plate is horizontally and fixedly arranged onthe bottom of the support tube; a grinding mechanism is arranged on the separation plate; a motor is vertically and fixedly arranged on the bottom surface of the base; an output shaft of the motor vertically penetrates through the middle of the base and the middle of the separation plate and extends into the support tube. When the daily fertilization treatment device is used for drying organic fertilizers, the contact time of organic fertilizer particles and hot air in the accommodating cavity is prolonged, so that the sufficient drying effect is achieved on the organic fertilizer particles;the fertilizers can be ground into spherical fine particles; the surface area of the fertilizer particles is increased; the grinding effect is improved; and the organic fertilizer raw materials with great sizes can also be sufficiently ground and dried.

Owner:WEIFANG UNIVERSITY

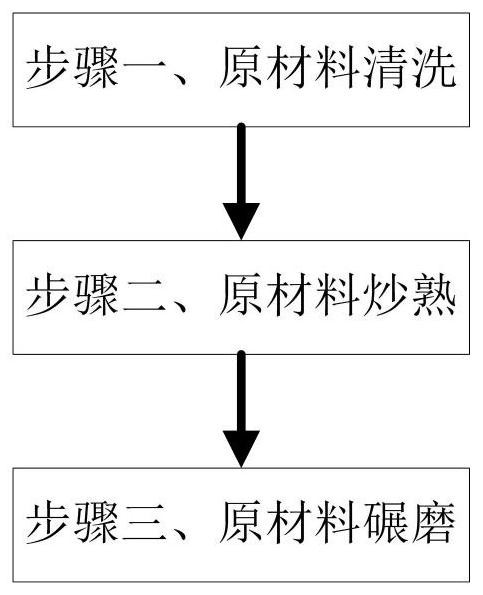

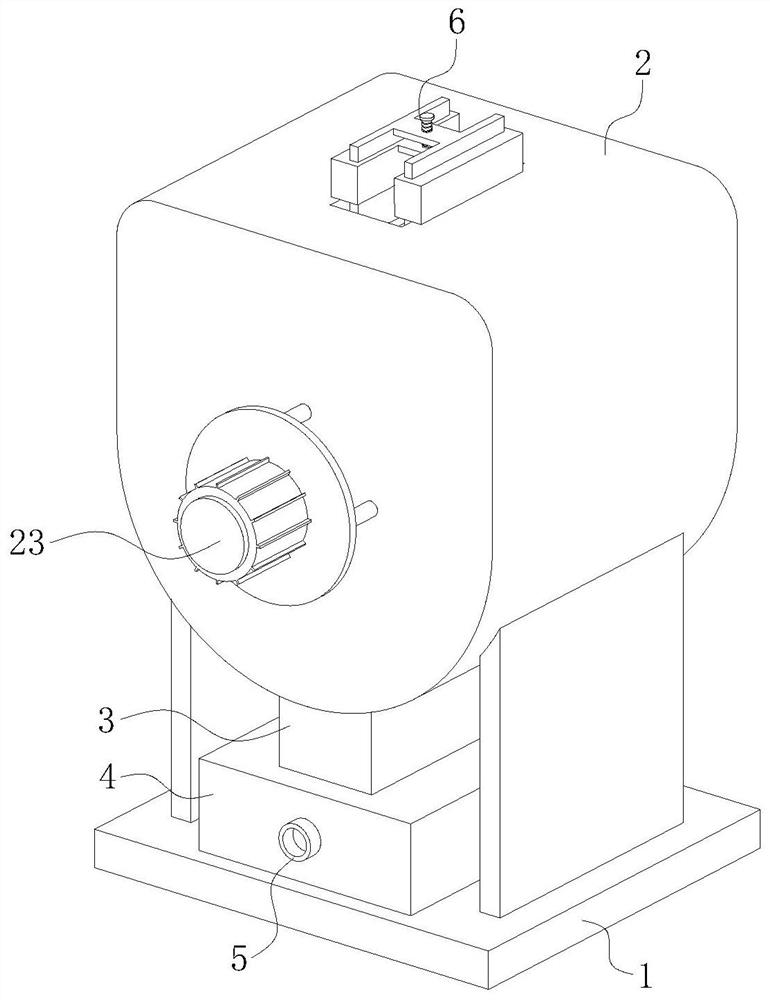

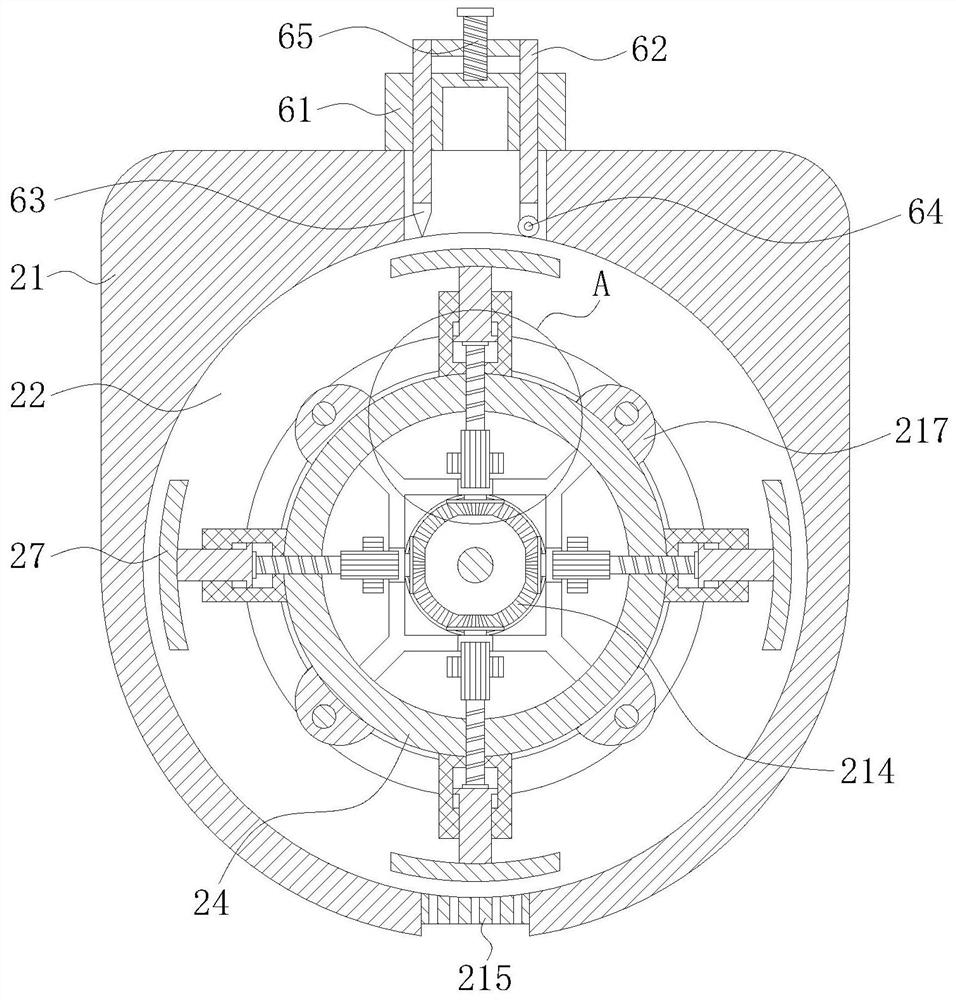

Preparation method of coarse cereal meal replacement powder

PendingCN111802570AFully milledEnsure direct contactGrain treatmentsFood scienceMeal replacementProcess engineering

The invention belongs to the technical field of food processing, and particularly relates to a preparation method of a coarse cereal meal replacement powder. The method comprises the following steps:step 1, raw material cleaning: cleaning raw materials, removing impurities, and carrying out air drying for later use; step 2, raw material stir-frying: stir-frying the raw materials until the raw materials are cooked for later use; and step 3, raw material grinding: adding the raw materials into a coarse cereal meal replacement powder making device, and processing the raw materials into powder. The coarse cereal meal replacement powder making device comprises a bottom plate, a grinding mechanism is fixedly installed on the bottom plate, a sealed channel is installed on the bottom face of thegrinding mechanism, a storage box is installed on the bottom plate, and a discharging pipe is arranged on the side wall of the storage box. According to the coarse cereal grinding device, the distancebetween the friction plate and the side wall of the cavity can be adjusted, the device guarantees that coarse cereals of different particle sizes can be fully ground, the device can guarantee that the friction plate makes direct contact with the coarse cereals in the grinding process, and the grinding effect is improved; and meanwhile, two-way grinding of coarse cereals is achieved, and the device guarantees that the ground coarse cereal powder is in a spherical shape in the microcosmic state.

Owner:张纪彬

Flying-dust-free production and manufacturing equipment for PVC grinding powder

InactiveCN112549360ATo achieve the purpose of dust-free grindingTo achieve the effect of isolationElectric machineryEngineering

The invention discloses flying-dust-free production and manufacturing equipment for PVC grinding powder. The flying-dust-free production and manufacturing equipment comprises a grinding mechanism, a powder grinding mechanism, an output mechanism and a supporting frame. The top of the supporting frame is fixedly connected with the bottom of the output mechanism, the top of the output mechanism is fixedly connected with the bottom of the powder grinding mechanism, the top of the powder grinding mechanism is fixedly connected with the bottom of the grinding mechanism, the inner top of a feeding hopper is hinged to one side of a dust-free plate through a hinge, and the bottom of the dust-free plate is fixedly connected with the top of a spring strip. According to the flying-dust-free production and manufacturing equipment for the PVC grinding powder, by arranging the grinding mechanism, PVC materials enter a grinding shell through the feeding hopper, a first motor is started, four grindingrollers rotate under cooperation of gears to flatten and grind PVC passing through the four grinding rollers, and the purpose of dust-free powder grinding can be effectively achieved; and meanwhile,the dust-free plate can enable the feeding port of the feeding hopper to directly fall off when feeding is needed and return to the original position when no material enters the feeding port, and theisolation effect is achieved.

Owner:德清江明新材料有限公司

Efficient and environment-friendly powder manufacturing apparatus for bio-material processing

A high-efficiency and environment-friendly powder-making equipment for processing biological raw materials, the high-efficiency and environment-friendly powder-making equipment for processing biological raw materials includes a base plate, a positioning device located above the base plate, a frame device arranged on the positioning device, and a housing Concentrating devices in the frame device, and roller devices located on the left and right sides of the concentrating device. The invention can realize sufficient grinding of biomass raw materials, and the grinding efficiency is high, and at the same time, it can promote the continuous shaking and mixing of biomass above the concentrating plate, and then can realize uniform grinding of biomass, which is beneficial to the biomass after grinding Burn fully.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

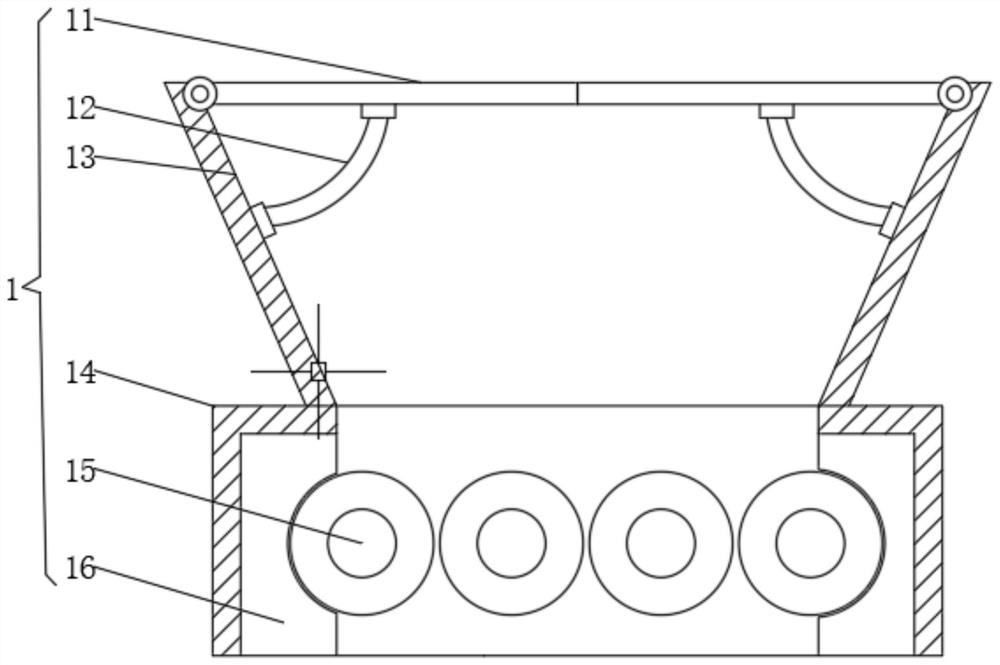

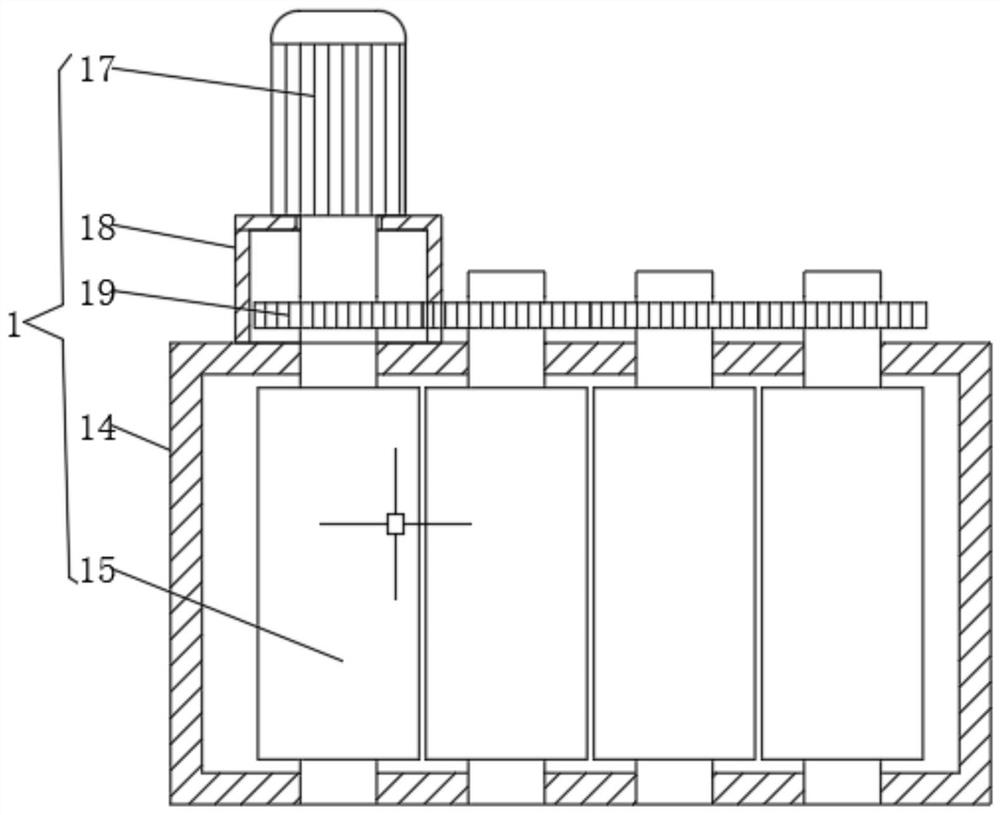

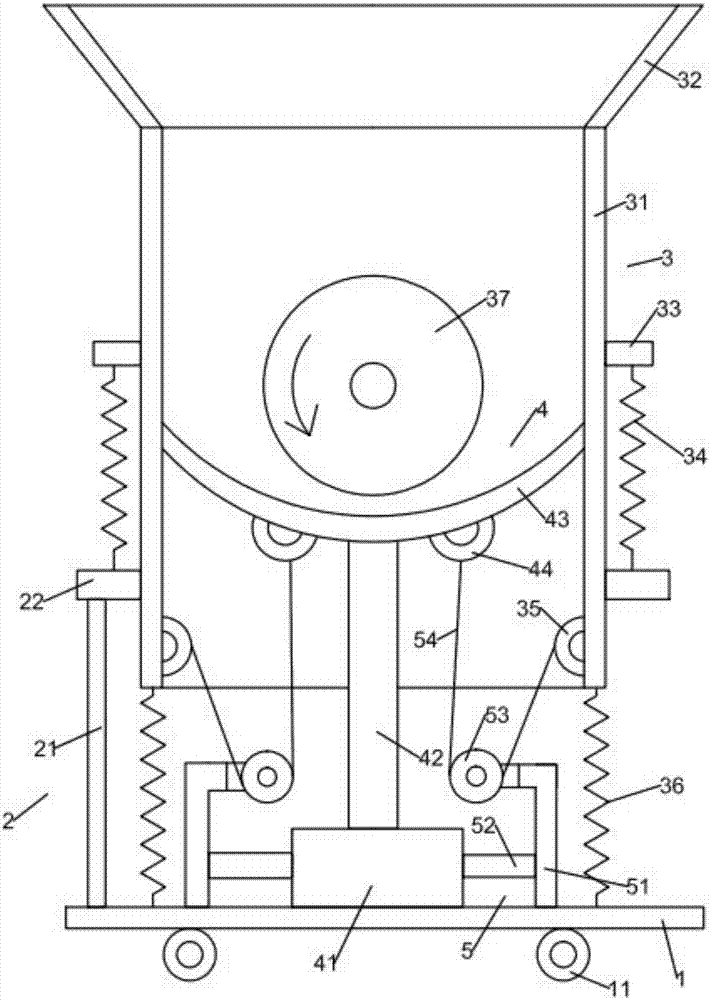

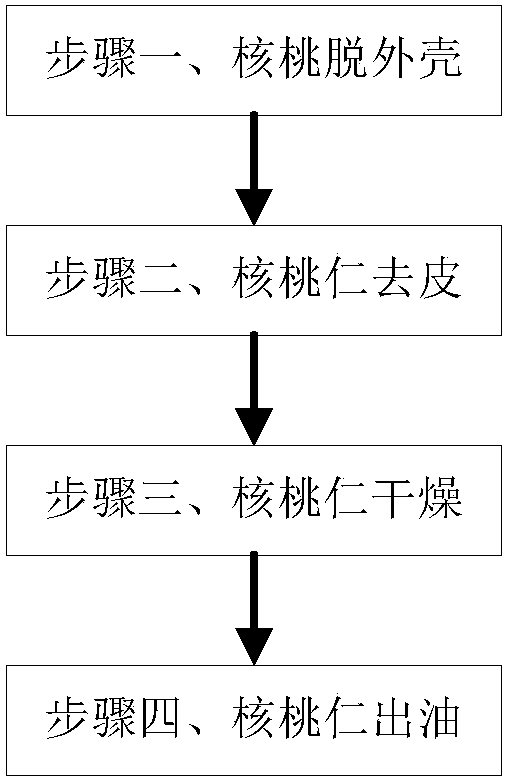

Health-care walnut vegetable oil preparation and processing technology

ActiveCN111454769ACrushed fullyFully milledFatty-oils/fats productionEdible oils/fatsWalnut NutVegetable oil

The invention belongs to the technical field of walnut oil processing, and particularly relates to a health-care walnut vegetable oil preparation and processing technology, which comprises the following steps: 1, walnut shell removal: removing hard shells on the outer layers of the walnuts, and collecting walnut kernels; 2, walnut kernel peeling: soaking walnut kernels in water, heating the water,taking out the walnut kernels, and peeling the walnut kernels; 3, walnut kernel drying: drying the peeled walnut kernels to remove moisture on the surfaces of the walnut kernels; step 4, walnut kernel oil extraction: squeezing the dried walnut kernels to extract oil, and collecting the residues, wherein the process of squeezing out oil in the step 4 is completed by adopting a walnut oil preparation and processing device in a matching manner. The walnut oil is prepared by adopting the preparation and processing technology of the health-care walnut vegetable oil provided by the invention, walnut kernels can be fully crushed and ground, the oil yield of the walnut kernels is improved, and the waste of raw materials is reduced; the surface of the compression roller can be in direct contact with walnut kernels, and the compression roller is prevented from being stuck.

Owner:HEZE ZHONGHEJIANYUAN BIOLOGY TECH CO LTD

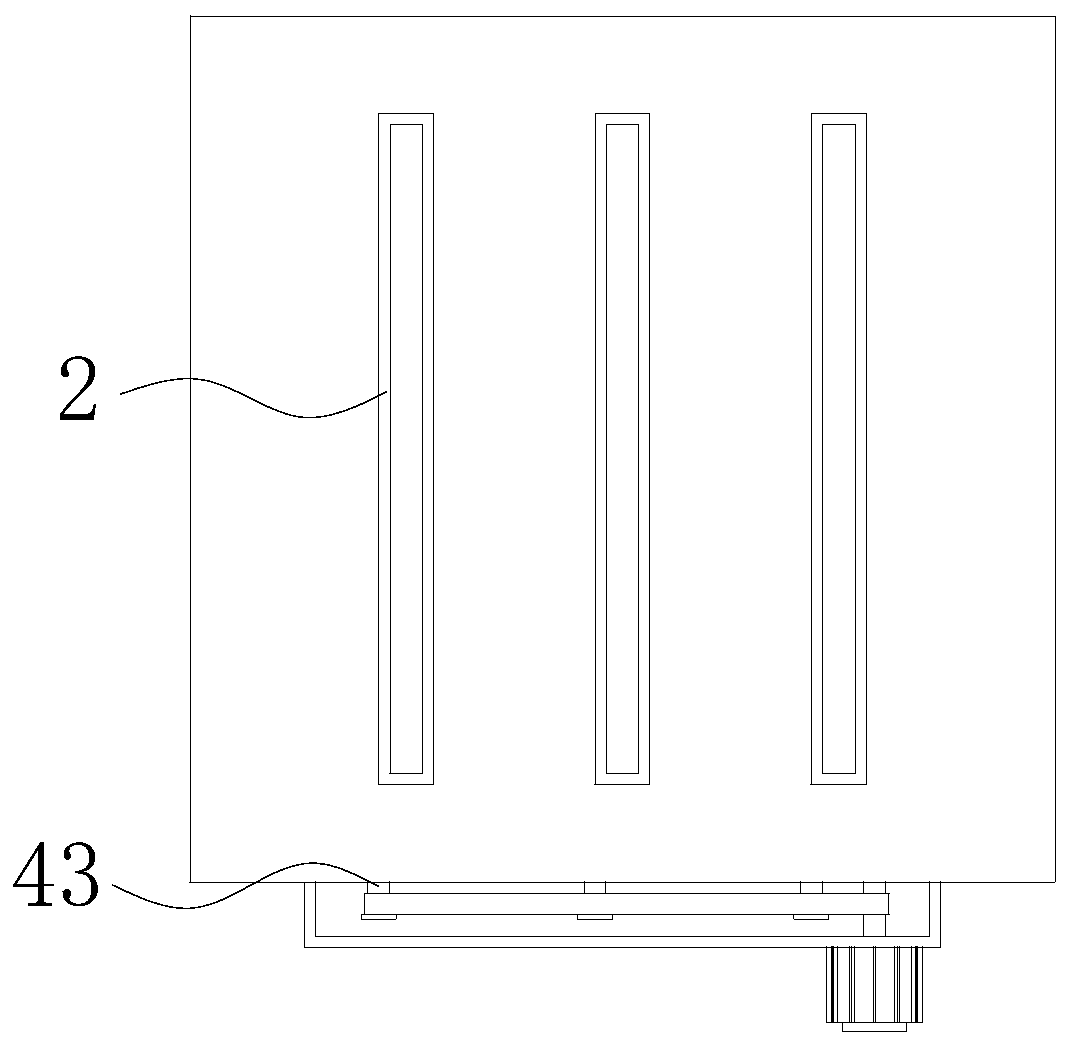

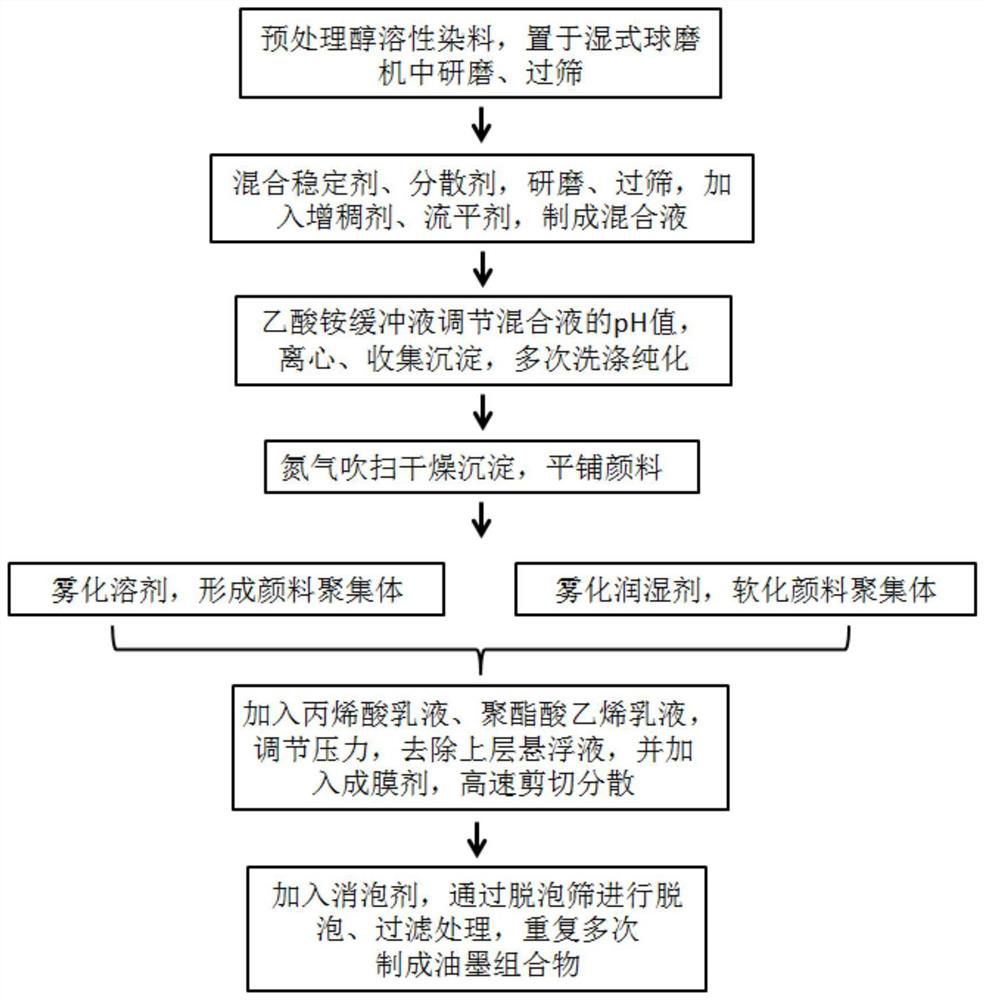

Neutral erasable ink composition and preparation method thereof

The invention discloses a neutral erasable ink composition and a preparation method thereof, and belongs to the technical field of ink preparation. The neutral erasable ink composition comprises the following raw materials: 2-10% of an alcohol-soluble dye, 25-35% of a film forming agent, 0.5-1% of a lubricant, 0.5-1% of a surfactant, 0.5-1% of a stabilizer, 1-2% of a thickener, 10-15% of a dispersant, 30-45% of a solvent, 0.5-1% of a leveling agent, and 0.05-0.5% of an antifoaming agent. The preparation method comprises the following preparation steps of: pretreating a color-based pigment; adding auxiliary materials, performing mixing, ball-milling and dispersing; preparing a pigment aggregate in the form of an atomized solvent and a wetting agent, and softening the pigment aggregate; carrying out high-speed shearing to realize de-aggregation and pre-dispersion to obtain sub-nano-scale particles; and performing defoaming and filtering. The ink has good writing performance; no obvious trace exists on the back face of writing paper; and handwriting can be erased easily through a common eraser.

Owner:闫西安

Cement grinding device

The invention discloses a cement grinding device, which comprises a first motor, a belt, a support frame, a grinding chamber, a rotating rod, a second motor, a filter screen, a screen box, a pneumatic telescopic rod, an air pump, a crushing chamber, a fixed knife, Moving knife, heating device, milling rod, first solenoid valve, push plate, second solenoid valve, vibration motor, bracket and control panel, the bottom of the bracket is fixed with a vibration motor by a detachable structure, and a screen box is arranged on the vibration motor , There are through holes on the bottom of both sides of the screen box, the vibration motor is used to drive the screen box to vibrate, the cement is screened, the cement is screened by the filter screen, and the cement with the best cement activity is selected, and the pneumatic telescopic rod is driven by the air pump. The telescopic rod and push rod push the cement out of the screening box. This device is easy to operate, protects human health, protects the environment, and fully grinds. The cement produced can maximize the activity of cement and increase the storage time of cement.

Owner:石雪芳

Circulating milling device

The invention discloses a circulating type powder grinding device which comprises a body provided with a powder grinding chamber, hoppers arranged on the upper part of the body, and grinding mechanisms; the grinding mechanisms comprise a coarse grinding mechanism and a fine grinding mechanism, wherein the coarse grinding mechanism is arranged inside the powder grinding chamber of the body, the bottom of the body is provided with a filtering device with mesh pores, and the fine grinding mechanism is arranged below the filtering device. The circulating type powder grinding device also comprises a debris recovery mechanism which is used for transporting debris on the filtering device and with the particle size greater than the mesh pores to the upward side of the coarse grinding mechanism; the coarse grinding mechanism comprises two pairs of mutually symmetrically arranged roller mechanisms, wherein the interior of the body is provided with guide plates for respectively guiding raw materials to the upward sides of corresponding rollers; the fine grinding mechanism comprises a group of paired-arrangement columnar rollers, wherein a gap between the adjacent columnar rollers is adjustable; the fine grinding mechanism also comprises elastic tensioning devices each for adjusting the gap between the adjacent columnar rollers. The circulating type powder grinding device has the characteristics of full grinding, low energy consumption, and simple control.

Owner:ZHEJIANG UNIV OF TECH

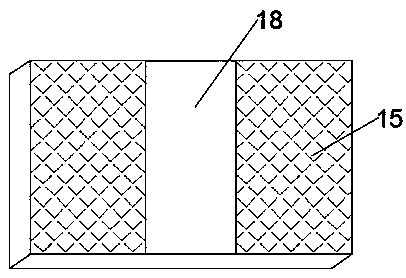

Novel mixing equipment for interior decoration material production

ActiveCN112221403ALess prone to damageFully milledDispersed particle filtrationTransportation and packagingEngineeringWater spray

The invention discloses novel mixing equipment for interior decoration material production. The equipment comprises a stirring tank, a feed inlet, an elastic grinding assembly, a stirring device and adischarge box, the elastic grinding assembly is transversely and fixedly connected with the side wall of the upper end of the stirring tank, a dislocation diffusion assembly is additionally arrangedbelow the elastic grinding assembly, the elastic grinding assembly drives the dislocation diffusion assembly to operate, the elastic grinding assembly grinds raw material crystal particles of the device, the raw material crystal particles are evenly diffused through the dislocation diffusion assembly, a water tank is further arranged on the right side of the elastic grinding assembly and the rightside of the dislocation diffusion assembly, and a water spraying device is installed below the dislocation diffusion assembly. A stirring device is arranged below the water spraying device, and a discharging box is installed at the lower right end of the stirring device.

Owner:HUNAN IND POLYTECHNIC

Cereal husk sifting device

InactiveCN108620156AAvoid enteringFully peeled and dustedGrain huskingGrain polishingHuskEngineering

The invention belongs to the technical field of food processing equipment, and in particular discloses a cereal husk sifting device. The cereal husk sifting device comprises a husk sifting box and atleast one set of dust sucking mechanism; a motor is arranged at the bottom of the husk sifting box; an abrasive disc is arranged at the upper part of an output shaft; the dust sucking mechanisms comprise vertical pipes, first one-way valves, second one-way valves, push rods and pressing blocks; the vertical pipes are vertically and fixedly connected with one side of the husk sifting box; springs are connected between the upper end surfaces of the push rods and the upper parts of the vertical pipes; air sucking pipelines are arranged in the push rods; the first one-way valves are arranged at the upper parts of the vertical pipes; air sucking holes are formed in the lower parts of the push rods; the second one-way valves are arranged at the lower parts of the air sucking pipelines; the husksifting box is provided with a feed port and a discharge port; and the lowest part of the feed port and the lowest part of the discharge port are flush with the lowest part of an inclined surface of the abrasive disc. The cereal husk sifting device is mainly used for sifting husks of unhusked rice, and solves the problem of influence on the rice eating by bad dust and unhusked rice husk treatmenteffect in the husk sifting operation of unhusked rice after primary milling.

Owner:凤冈县万福食品有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com