Patents

Literature

103results about How to "Improve grinding fineness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

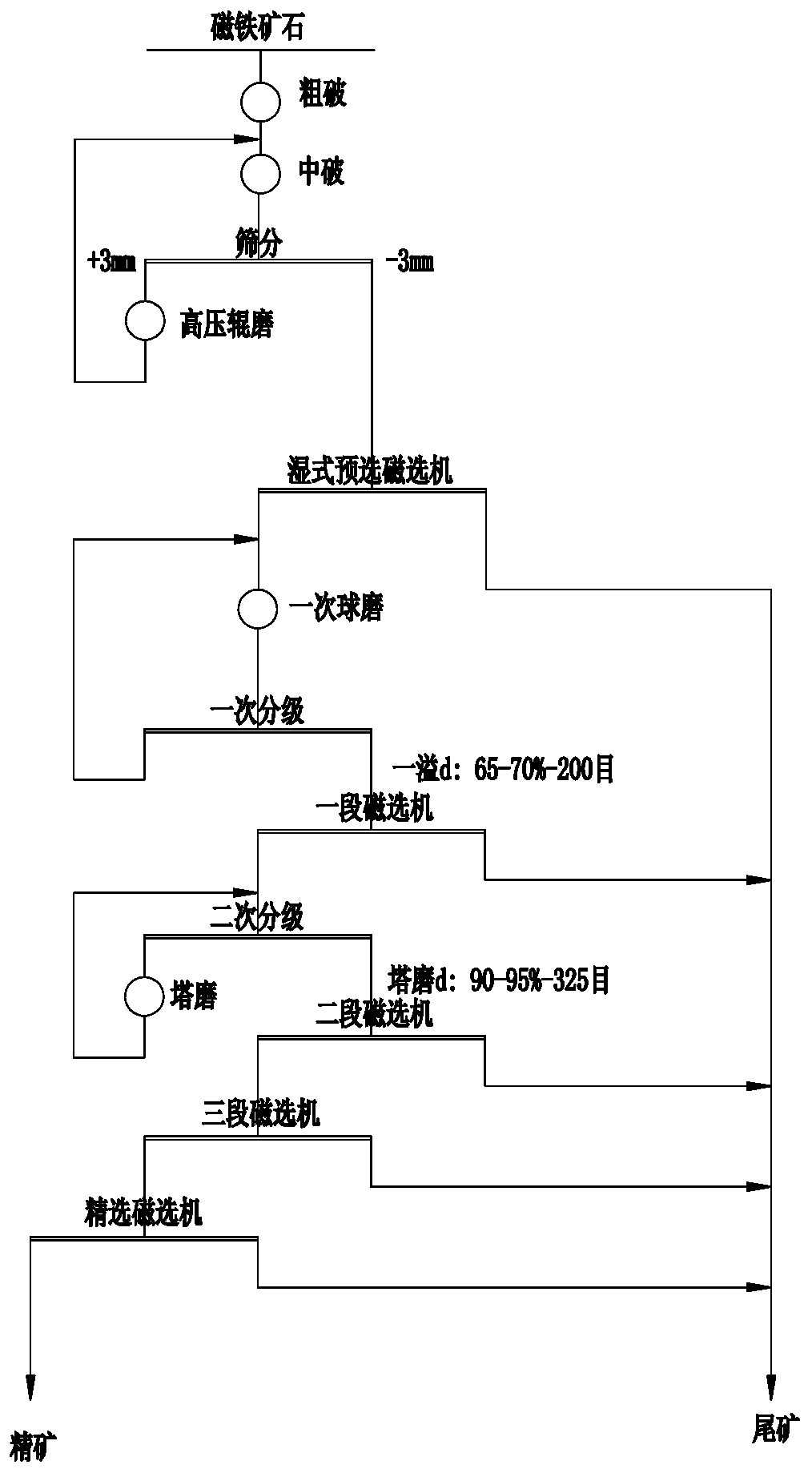

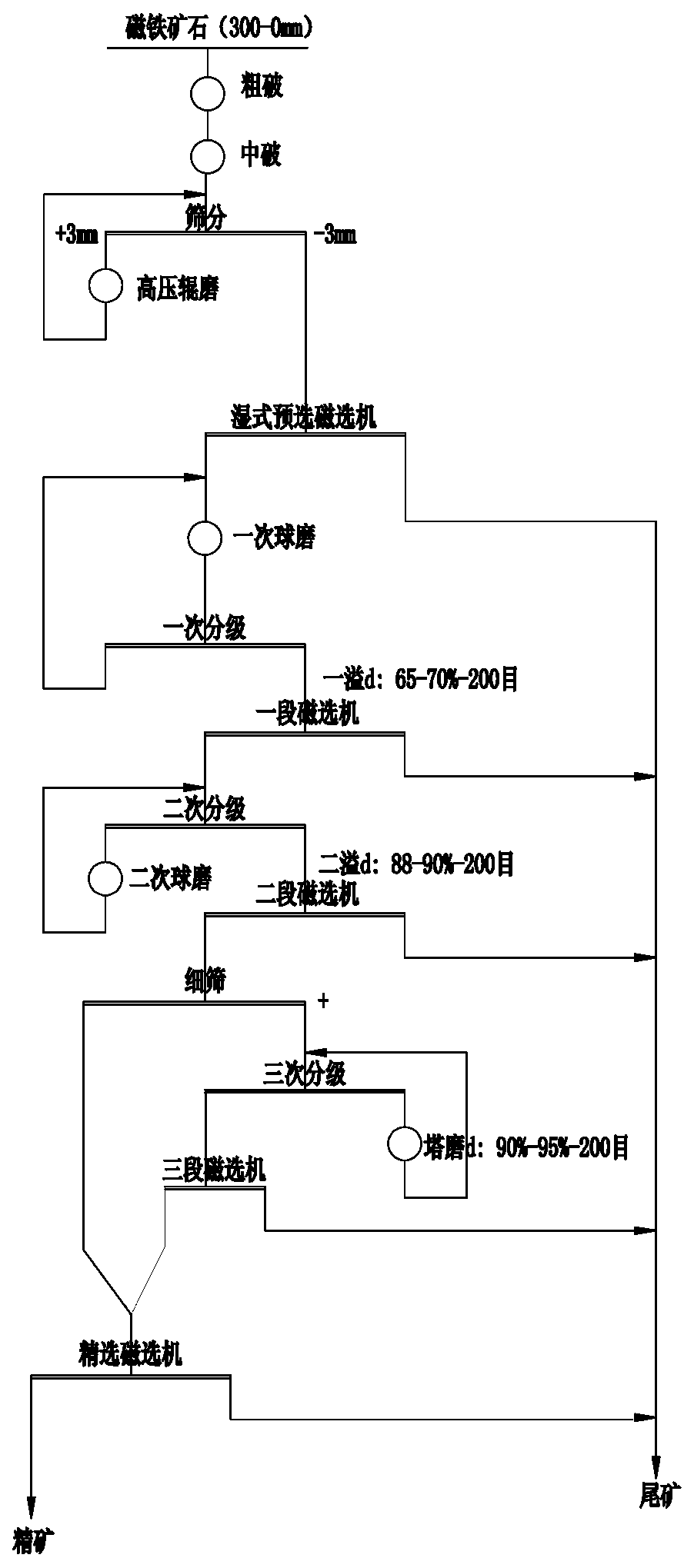

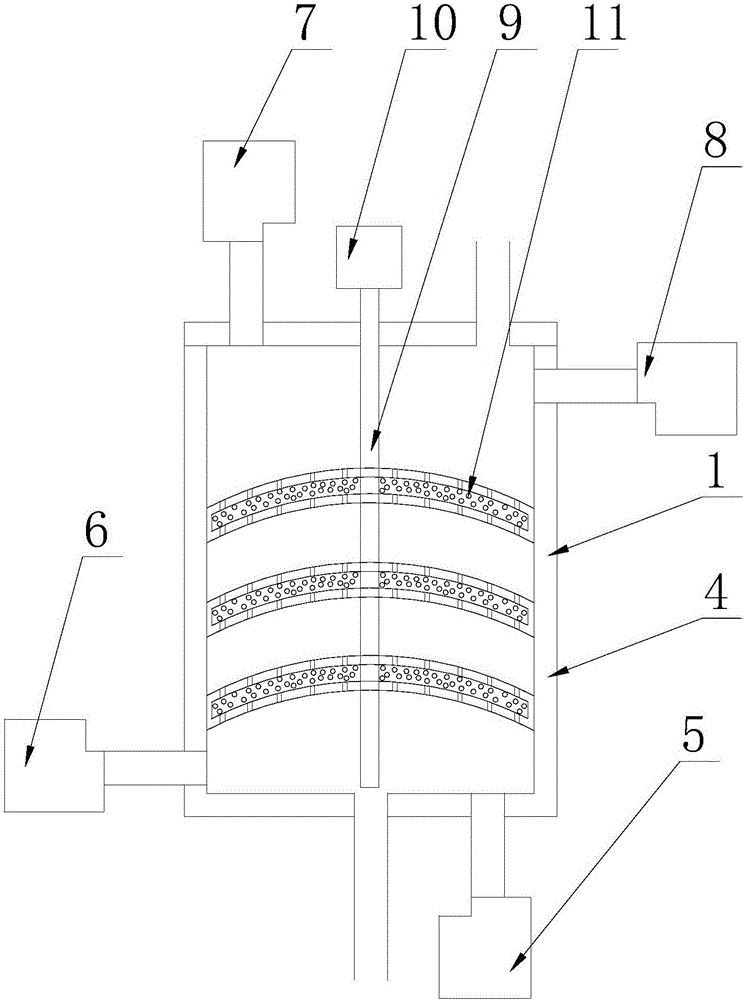

Magnetite high-pressure roller mill-wet type preconcentration-stage grinding-tower mill magnetic separation technology

The invention relates to a magnetite high-pressure roller mill-wet type preconcentration-stage grinding-tower mill magnetic separation technology. The magnetite high-pressure roller mill-wet type preconcentration-stage grinding-tower mill magnetic separation technology comprises rough breaking operation and intermediate breaking operation and is characterized in that products obtained by the intermediate breaking operation are subjected to the following operations in sequence: closed-loop high-pressure roller mill-sieving operation formed by a high-pressure roller mill and sieving equipment, wet type preconcentration magnetic separation operation, one-stage closed-loop ore grinding operation, second-stage closed-loop ore grinding operation formed by secondary cyclone grading and a second-stage tower mill and continuous three-stage magnetic separation operation, so that final concentrate with the grade being 67%-67.8% and the yield being 38%-41% and integrated tailings with the grade being 8.5%-9.5% and the yield being 62%-59% are obtained. The magnetite high-pressure roller mill-wet type preconcentration-stage grinding-tower mill magnetic separation technology has the advantages that a high-pressure roller mill is used for preconcentration, so that the size of particles fed into the mill is reduced, and the grade of crude ore and the fineness of grinding are improved; the second-stage closed-loop ore grinding operation formed by the cyclone and the tower mill is adopted; the fine screening-regrinding operation is omitted; the fifth-stage magnetic operation is reduced; the technology process is simplified; and the beneficiation cost is reduced.

Owner:ANSTEEL GRP MINING CO LTD

Cement production method

ActiveCN103214198ASimple manufacturing methodImprove the mixing effectClinker productionExhaust valveSlag

The invention discloses a cement production method, relating to the technical field of cement production. The cement production method disclosed by the invention comprises the following steps of: pre-grinding slag to form superfine slag powder for later use; proportioning cement clinker, gypsum and limestone and grinding in a ball mill; feeding grinded fine powder into an air conveying inclined groove at the tail part of the mill, and mixing the fine powder with the superfine slag powder; conveying the mixed material by using a pneumatic hoister, and feeding formed mixed powder into a small storage cabin; and opening a feeding valve and an exhaust valve of a cabin pump, so that the mixed powder in the small storage cabin enters the pump body, when the weight of the mixed powder in the pump body is up to a pre-set value, closing the feeding valve and the exhaust valve, opening a fluidizing valve and a conveying valve after delaying for 8s, and feeding the mixed powder into a finished product storeroom after sufficiently and uniformly mixing through a conveying pipeline. Compared with the prior art, the cement production method disclosed by the invention has the advantages that the method is simple and easy; the production efficiency is high; the mixing effect is better; activity of mixed materials is sufficiently excited; the mixed materials are high in admixture amount; the production cost is low; and produced cement is high in intensity, steady in quality and high in yield.

Owner:GUANGXI YUFENG CEMENT +1

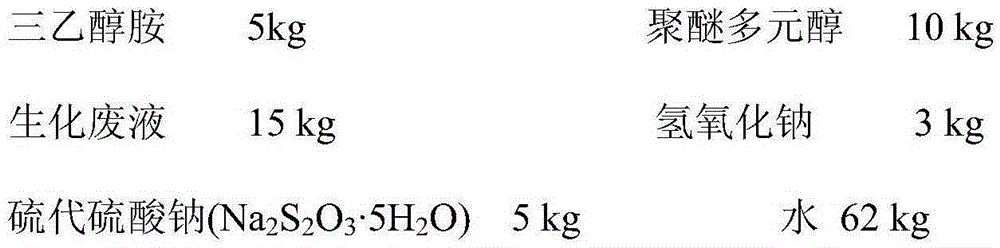

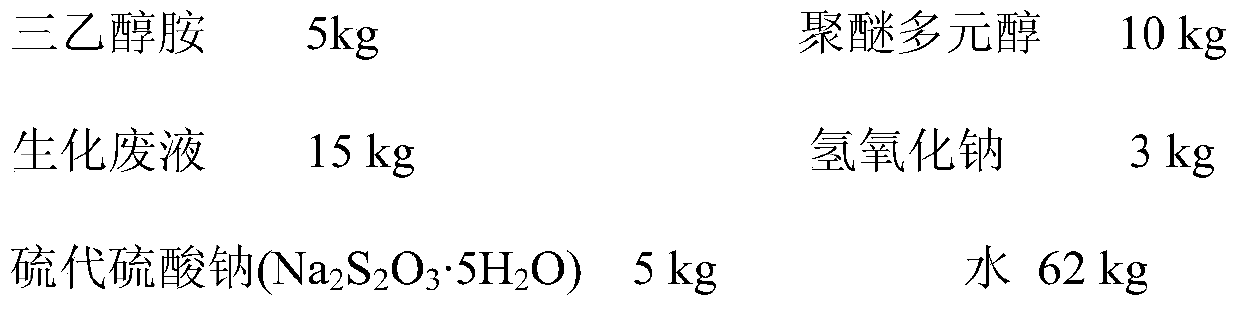

Cement grinding aid

The invention provides a cement grinding aid. The cement grinding aid comprises raw materials as follows: triethanolamine, polyether polyol, sodium hydroxide, sodium thiosulfate and a biochemical waste liquid, wherein the biochemical waste liquid is one of or a mixture of a waste liquid produced during production of industrial sodium gluconate and a waste liquid produced during production of an industrial itaconic acid product. The cement grinding aid can optimize the cement grain composition, activate the early strength of cement, improve the powder grinding efficiency of the cement and reduce energy consumption.

Owner:ZHANGQIU HUAMING CEMENT

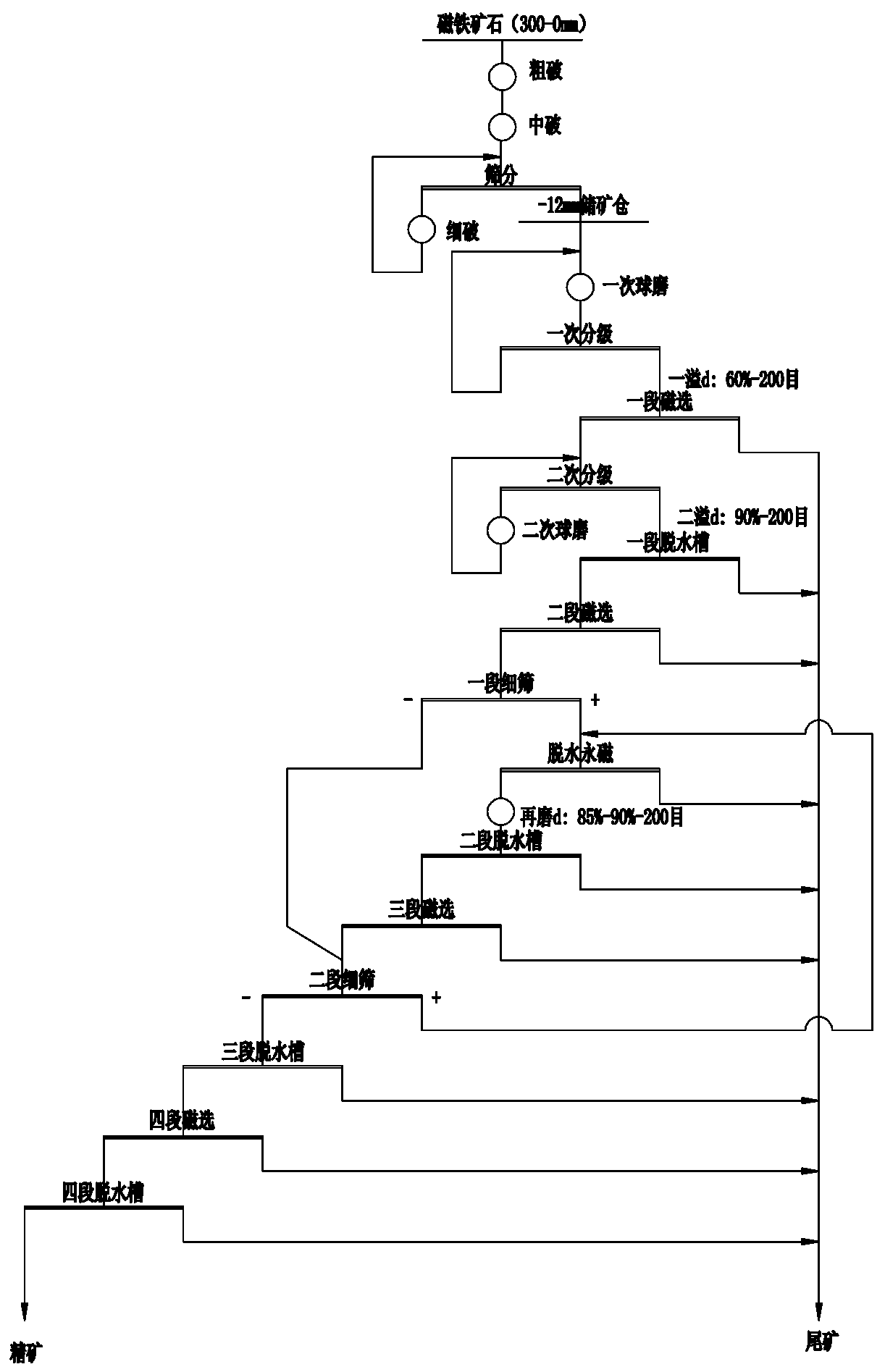

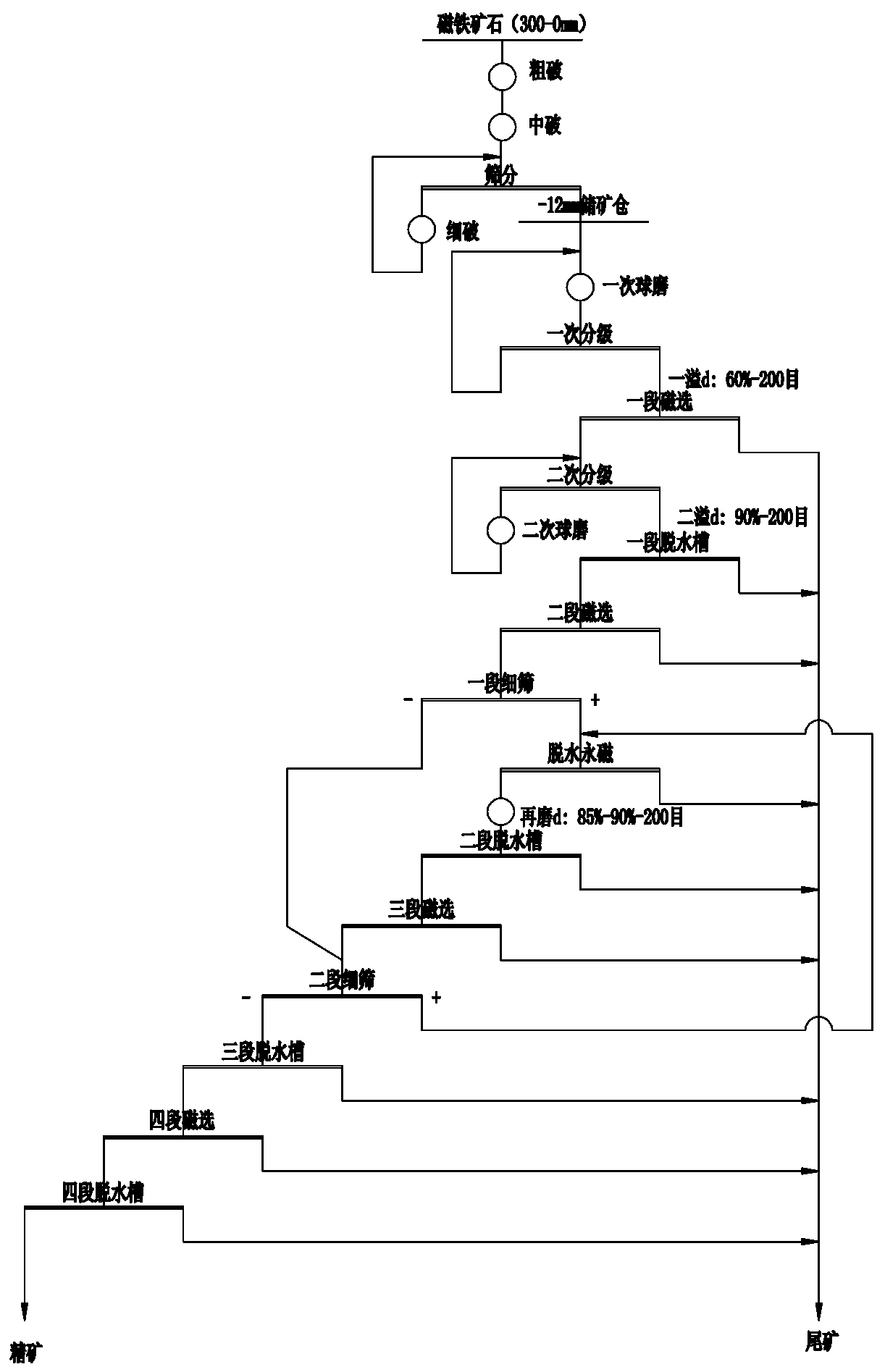

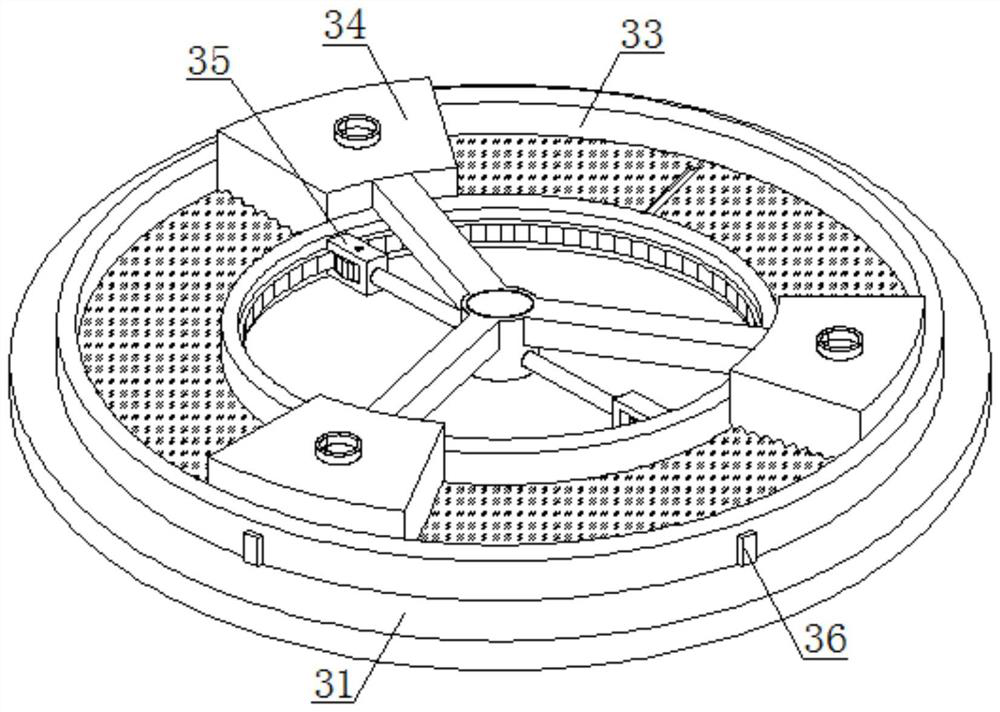

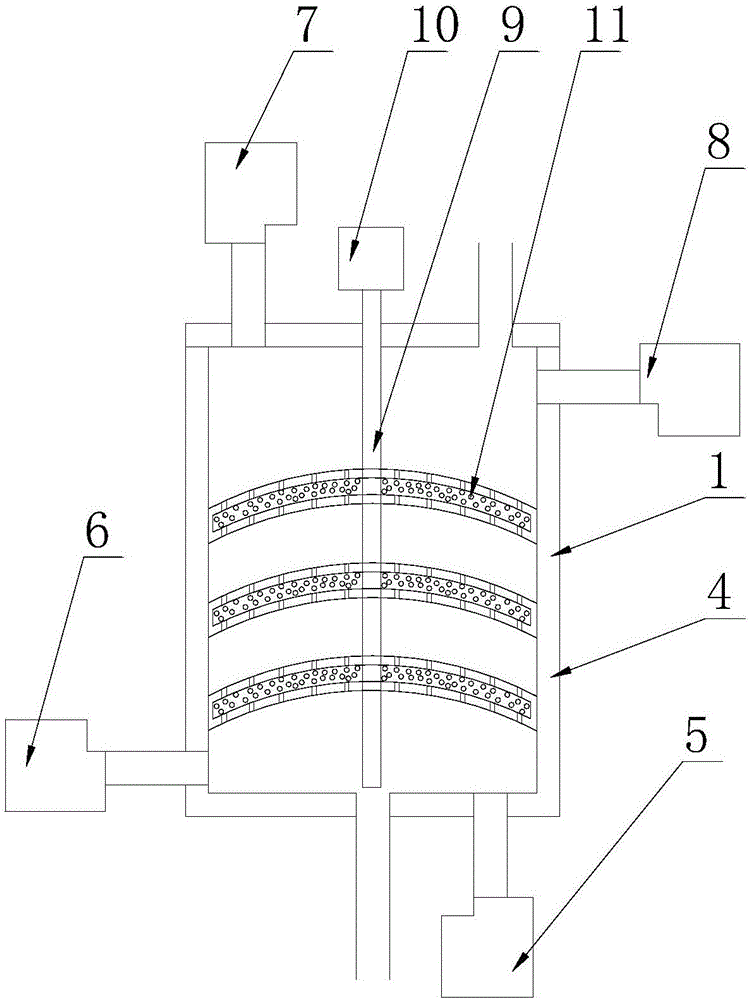

Magnetite high compression rolling wet pre-concentration-stage grinding-fine screen tower rolling magnetic separation process

The invention relates to a magnetite high compression rolling wet pre-concentration-stage grinding-fine screen tower rolling magnetic separation process. The process comprises coarse breaking and mildbreaking, and is characterized by further comprising the following steps that ores with the grade being 30%-32% and the granularity being -25mm are subjected to closed circuit high compression rolling; rolling products are subjected to beforehand magnetic separation; premagnetization concentrates are subjected to first-stage closed-circuit grinding; primary overflow is subjected to first-stage magnetic separation; first-stage magnetic separation concentrates are subjected to second-stage closed-circuit grinding; secondary overflow is subjected to second-stage magnetic separation and fine screening; screen residues are subjected to third-stage closed-circuit tower milling and grinding; third-time graded overflow products are graded by a third-stage magnetic separator; concentrates of the third-stage magnetic separator and screen underflow products are subjected to fine magnetic separation to obtain 67%-67.5% final concentrates; and tailings of all stages of magnetic separation work arecombined to be combined tailings. The magnetite high compression rolling wet pre-concentration-stage grinding-fine screen tower rolling magnetic separation process has the advantages that (1) high compression rolling pre-concentration is conducted, so that the particle size of grinding feed is reduced, and the grade of crude ores and grinding fineness are improved; (2) a cyclone and a tower millare combined, so that one stage of fine screening and multiple stages of magnetic separation operation are omitted; (3) the flow is simplified, and the ore mineral separation cost is lowered.

Owner:ANSTEEL GRP MINING CO LTD

Liquid high-efficiency cement grinding aid reinforcing agent and producing method thereof

InactiveCN101209908AReduce coagulationEliminate hazardsSolid waste managementCement productionAluminium sulfatePolyol

The invention relates to a liquid cement grinding-assisting reinforcing agent and a production method thereof, particularly to a high-efficient liquid compound non-chlorinated and low alkali cement grinding-assisting reinforcing agent of a defoaming mechanism and cement stability performance and a production method thereof. Pulp waste liquid is used as main material which is in complexation with triethanolamine and polyol and added with small amount of stabilizers of phosphogypsum and aluminum sulfate, etc., to eliminate the harm of free state CaO, and ethal etc. is added to play a role of defoaming, thereby the stability and density of the cement is enhanced and the intensity of the cement is further enhanced. The production method is to separate grinding-assisting reinforcing ingredient and additive ingredient respectively and averagely which are then stirred and mixed. In addition to simple technique and low price, the product is easy for storage and transportation, which occupies little cement mixed weight, obviously enhances the early and later period intensity of the cement and is extremely applicable to wide application in cement industry.

Owner:DALIAN UNIV OF TECH

Chlorine-free highly effective composite enhanced solid cement grinding aids and production method

The invention provides a chlorine-free high-efficiency composite reinforcing type solid cement grinding aid and production method, the grinding aid is composed of inorganic substrate material, organic material and water, strong antifreeze and antirust; the inorganic substrate material is composed of powder coal ash, sodium carbonate and sodium silicate, the mixing solution of any three or four among triethanolamine, glycol, propanediol, glycerolor paper pulp waste liquid is selected as the organic material, the inorganic strong antifreeze is composed of aluminum sulfate, calces or sodium hydrogen, sodium acetate or carbamide, and the antirust is sodium dihydrogen phosphate. The production method is the following: first the inorganic strong antifreeze is utilized to perform the complexation and modification of the organic material solution, and then the obtained mixing solution and the inorganic substrate material are furthermore compounded, reacted, blended and crushed. The invention has simple process, low cost, wide application range, good anti-freezing anti-rusting functions, and can improve later strength of cement obviously without disadvantage influence, and also obviously reduce the using amount of cement clinker by 20 percent, thereby having outstanding economical benefit.

Owner:DALIAN UNIV OF TECH

Sun-proof printing ink as well as preparation method and application thereof in sun-proof transfer film

The invention relates to the technical fields of a transfer film and a printing ink formulation, and particularly relates to sun-proof printing ink as well as a preparation method and an application thereof in a sun-proof transfer film. The sun-proof printing ink is prepared from the following components in parts by mass: 18-20 parts of inorganic paint, 1-1.5 parts of a wetting agent, 45-50 parts of acrylic resin liquid, 12-18 parts of cellulose acetate resin liquid, 1-1.5 parts of a dispersing agent, 1-1.5 parts of fumed silica, 5-6 parts of isopropanol and 12-15 parts of n-propyl acetate. The inorganic paint and the wetting agent are mixed and ground, so as to obtain paint powder with high fineness; the printing ink is uniformly mixed. The sun-proof printing ink is applied to the sun-proof transfer film, has a sun-proof level up to an 8 level, and is particularly suitable for printing outdoor products.

Owner:DONGGUAN ZHUOYI PRINTING PROD

Preparation method of silver solder paste and silver solder paste product

ActiveCN101837526AWell mixedIncrease the baking temperatureWelding/cutting media/materialsSoldering mediaRetention timePotassium fluoride

The invention provides a preparation method of silver solder paste, which comprises the following steps: 1, preparing raw materials and pretreating the raw material; 2, stirring the raw materials; 3, roasting the raw materials; and 4 grinding the raw materials. The invention also provides silver solder paste prepared by the method. The silver solder paste is prepared from the following raw materials in percentage by weight: boric acid 33-38, potassium fluoborate 28-32, potassium fluoride 20-25, monomer boron 2.0-2.5 and distilled water 10-20. Compared with the prior art, the method has the advantages of stable product quality and high material utilization rate. The product has the characteristics of long soldering high-temperature life, long activity retention time, high solder wettability and high soldered joint quality.

Owner:HUIZHOU WUFU IND TECH

Ball-milling process for superfine ceramic powder

The invention discloses a ball-milling process for superfine ceramic powder. The ball-milling process comprises the following steps of proportionally feeding ceramic powder, water and primary grinding ball stones into a first section of ball-milling tank, mixing the added ceramic powder, water and primary grinding ball stones with stirring by virtue of the first section of ball-milling tank, and performing primary medium-fineness crushing on the ceramic powder in a stirring mixing process by virtue of the primary grinding ball stones; pumping slurry out after the feed liquid is stirred for a long time by the ball-milling tank and the ceramic powder in the slurry is ground to medium fineness, simultaneously filtering the primary grinding ball stones in the slurry, and feeding the filtered slurry into a second section of ball-milling tank; adding secondary grinding ball stones into a second section of ball-milling tank according to a certain proportion, stirring the slurry within a preset time, and secondarily and finely grinding the ceramic powder in the slurry by virtue of the secondary grinding ball stones in the second section of ball-milling tank until final fineness is achieved.

Owner:佛山市阳光陶瓷有限公司

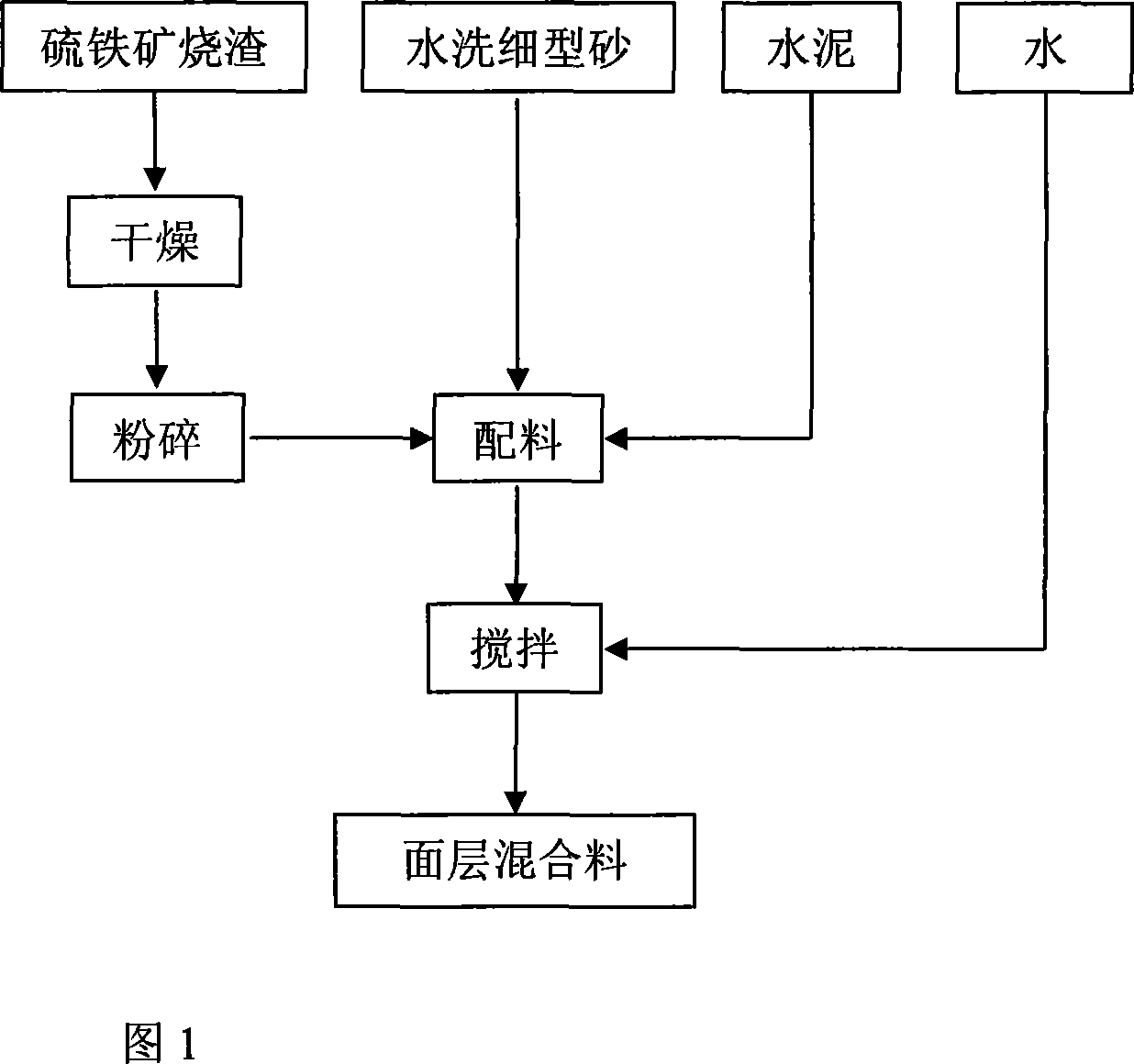

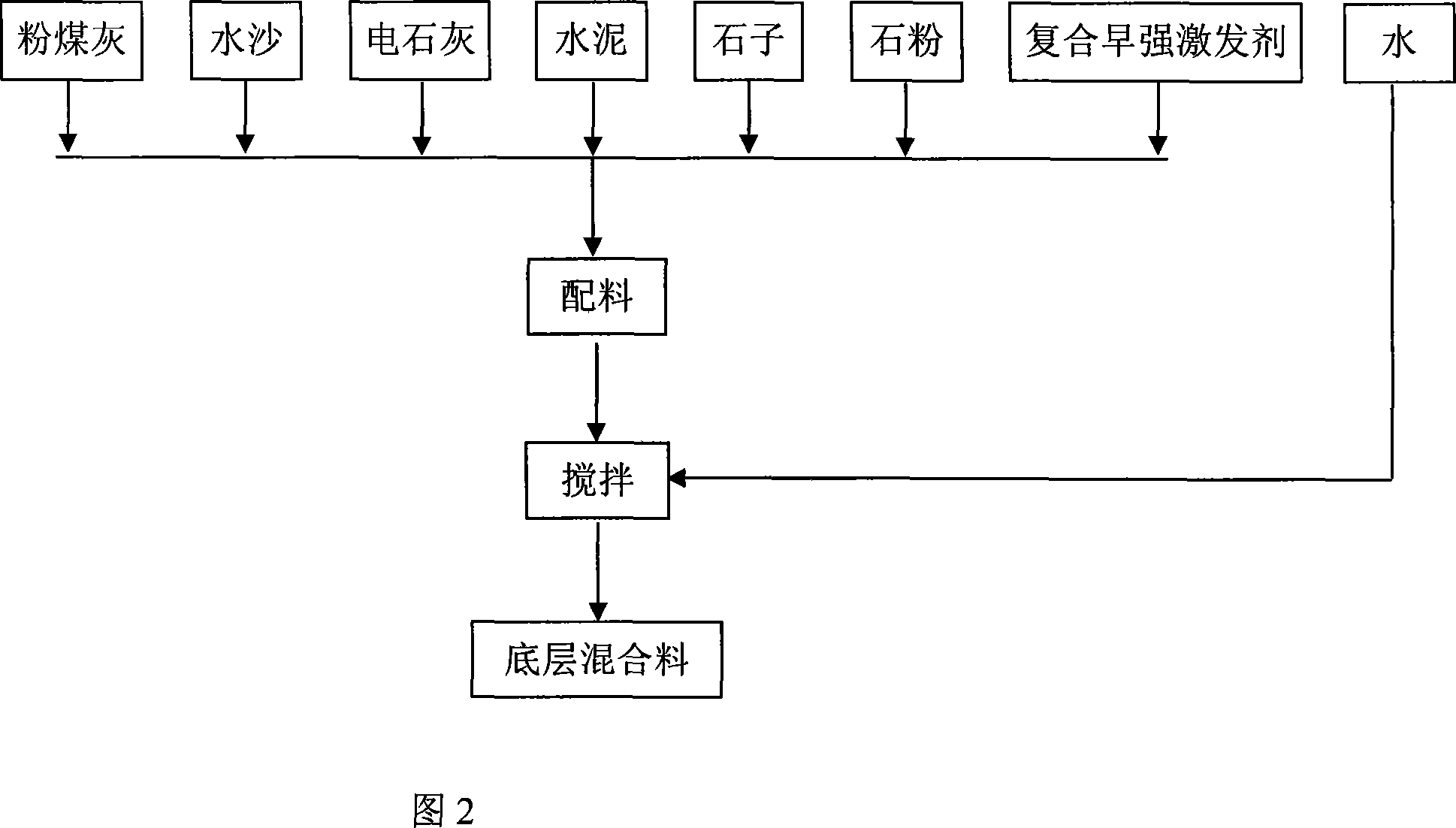

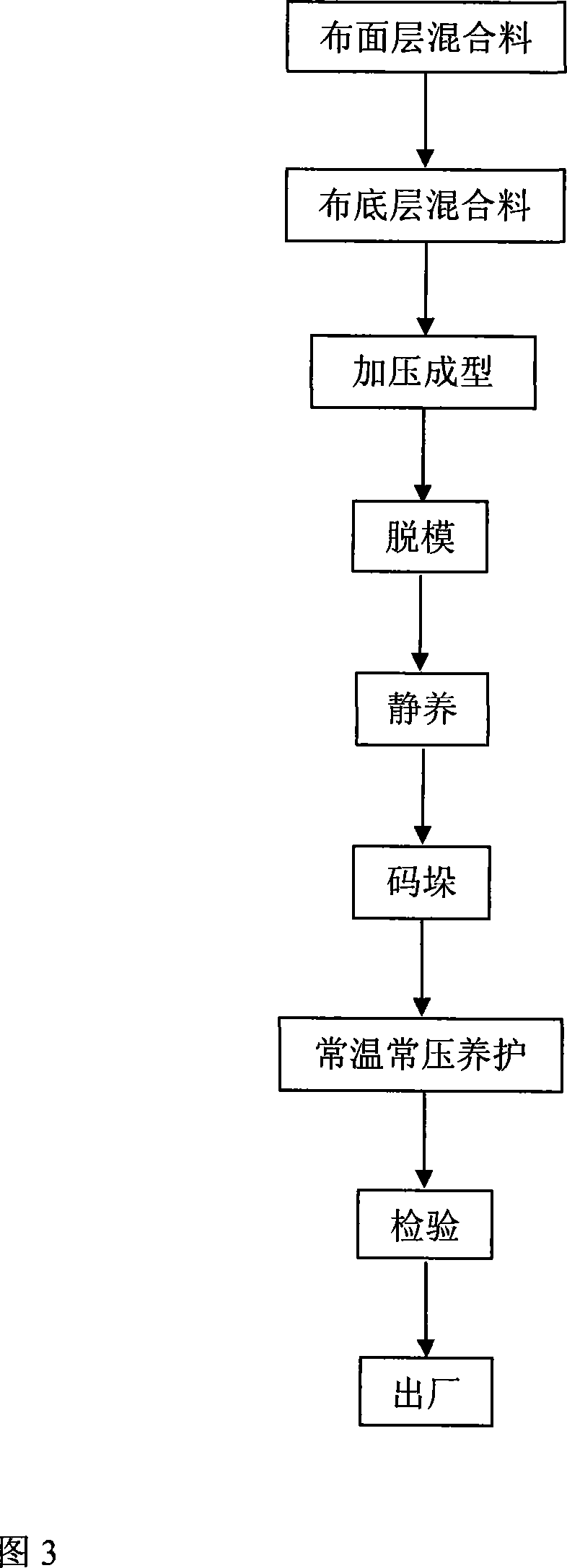

Anti-skid penetrating color brick of lump pyrite fired slag and its production

InactiveCN101074577AImprove early strengthImprove grinding finenessConstruction materialSolid waste managementBrickSlag

The invention relates to the seepage and antiskid colorful tiles made of pyrite cinder and their preparation method. The materials include pyrite cinder, fly ash, water and sediment, electric lime, water fine sand, pebble, stone powder, ordinary portland cement, white cement, complex early strength activator and water. Dry the pyrite cinder and crush it into 100-200 orders powder. Malaxate 10-60% pyrite cinder, 0-60% water fine sand, 20-40% white cement and 4-8% water to get the pavement surface mixtures. Malaxate 25-30% fly ash, 10-30% water and sediment, 5-15% electric lime, 15-30% pebble, 10-15% stone powder, 5-10% ordinary portland cement, 1.5-2.0% complex early strength activator and 8-12% water to get bottom mixtures. Spread the pavement surface and bottom mixtures into the die, pressure molding, demould, stay, palletize and maintain to get the seepage and antiskid colorful tiles made of pyrite cinder. The invention takes full advantages of the color property of the pyrite cinder and the gelling property of the fly ash, water and sediment and electric lime, which changes waste into valuables. Its products have competitive price, light mass, seepage, antiskid, high strength, energy saving and environmental protection.

Owner:HENAN POLYTECHNIC UNIV

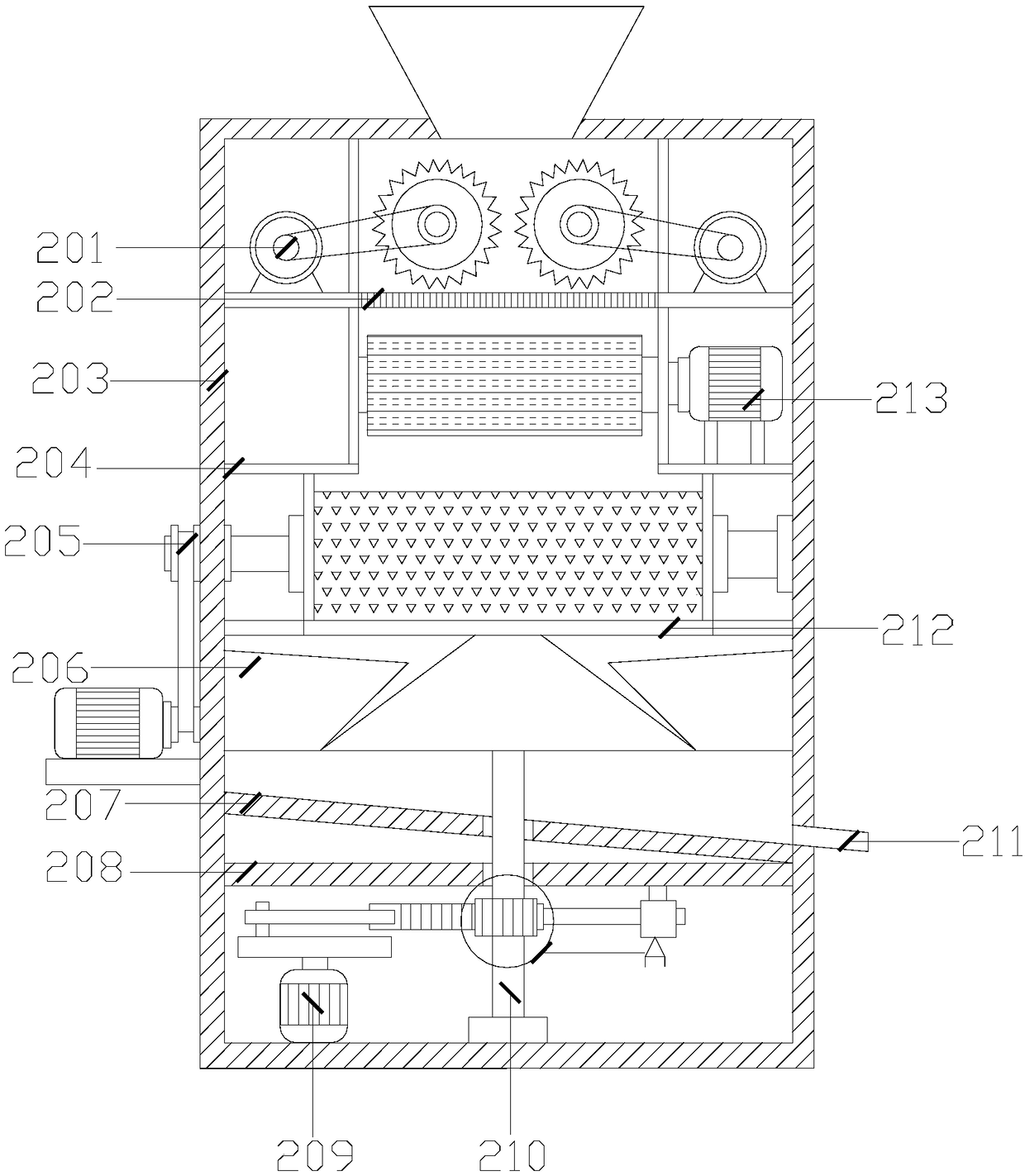

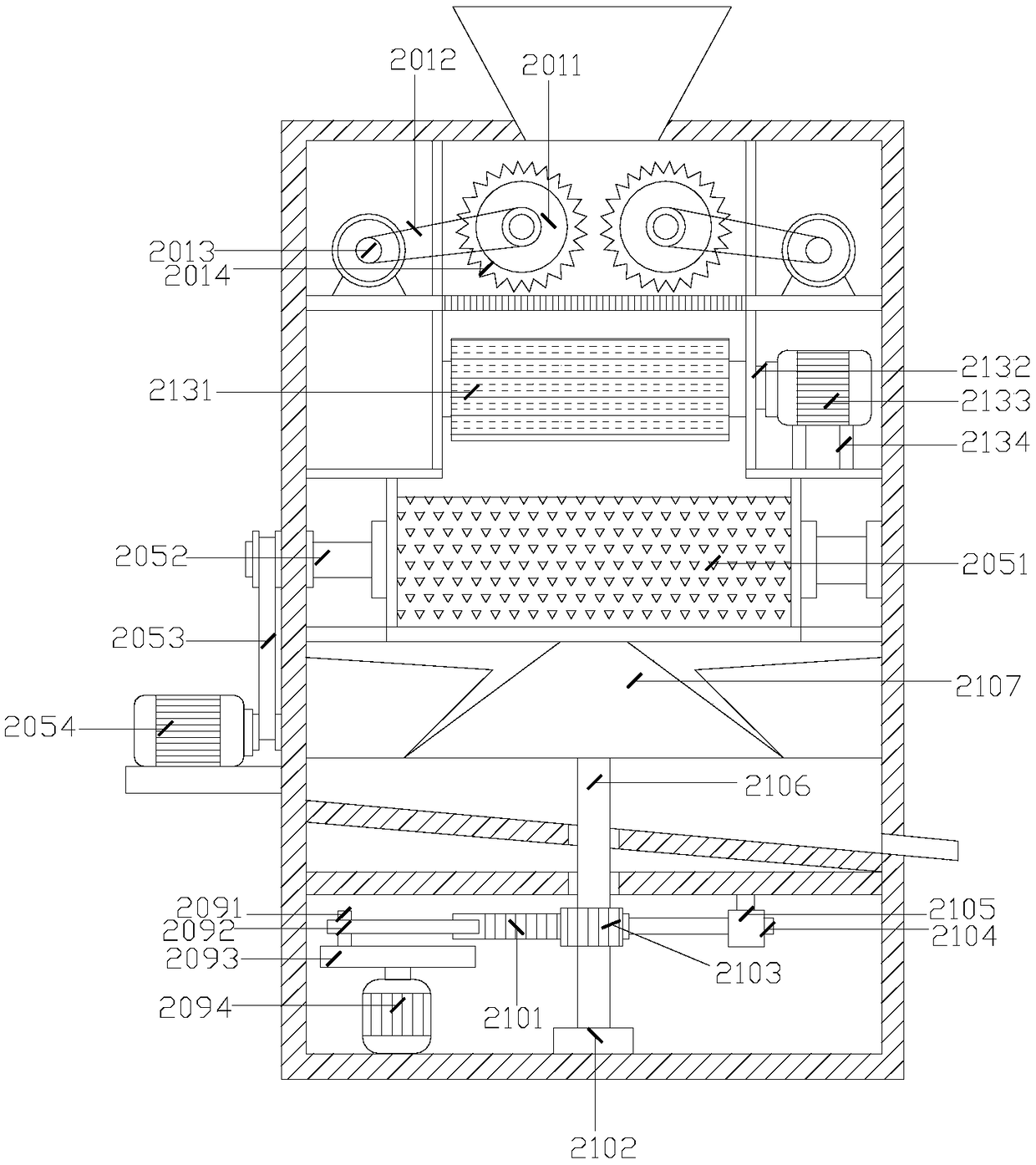

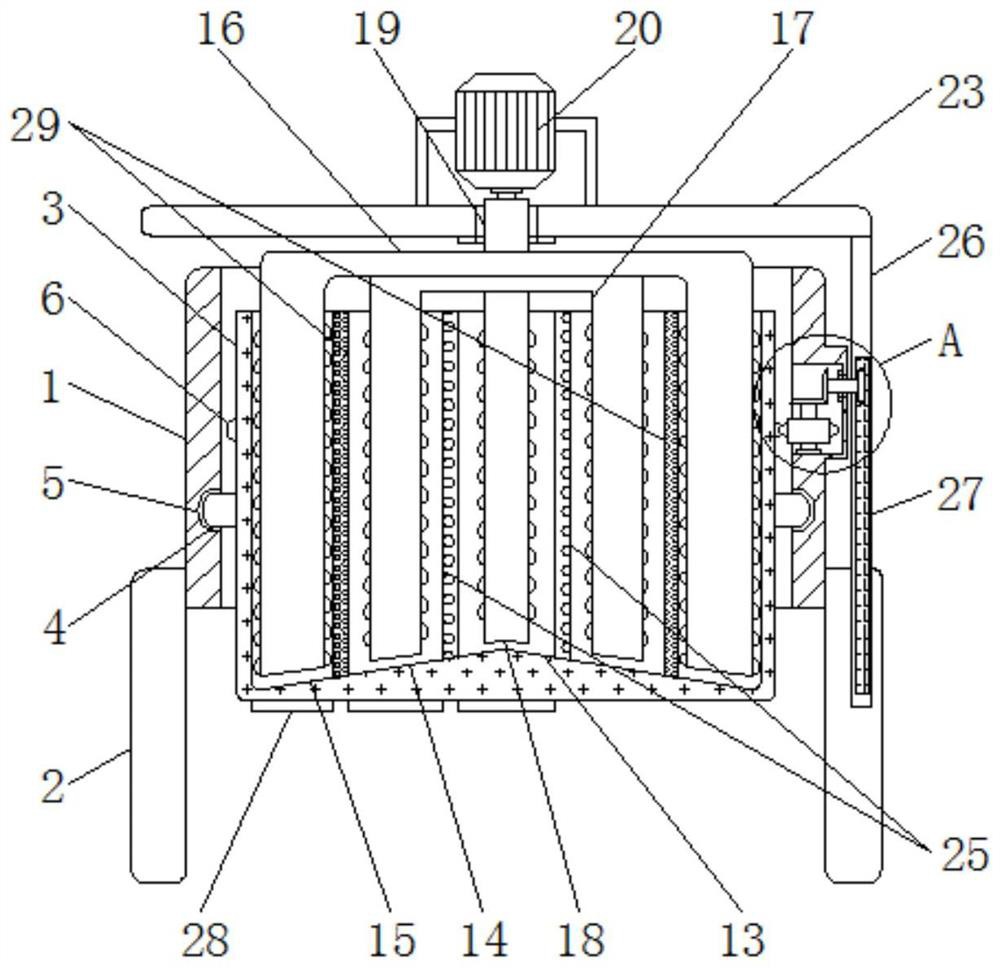

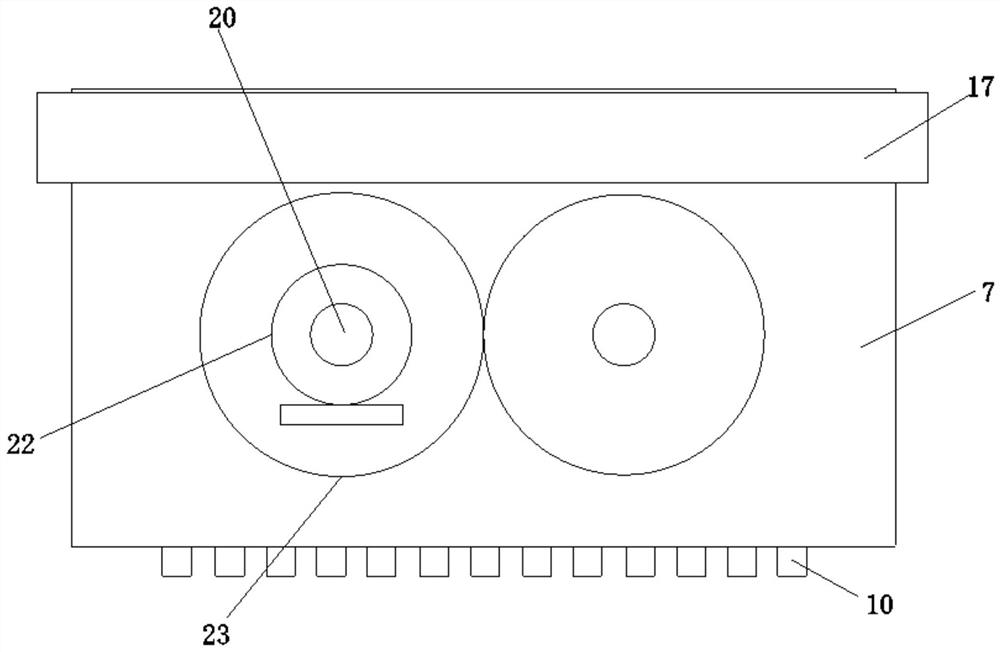

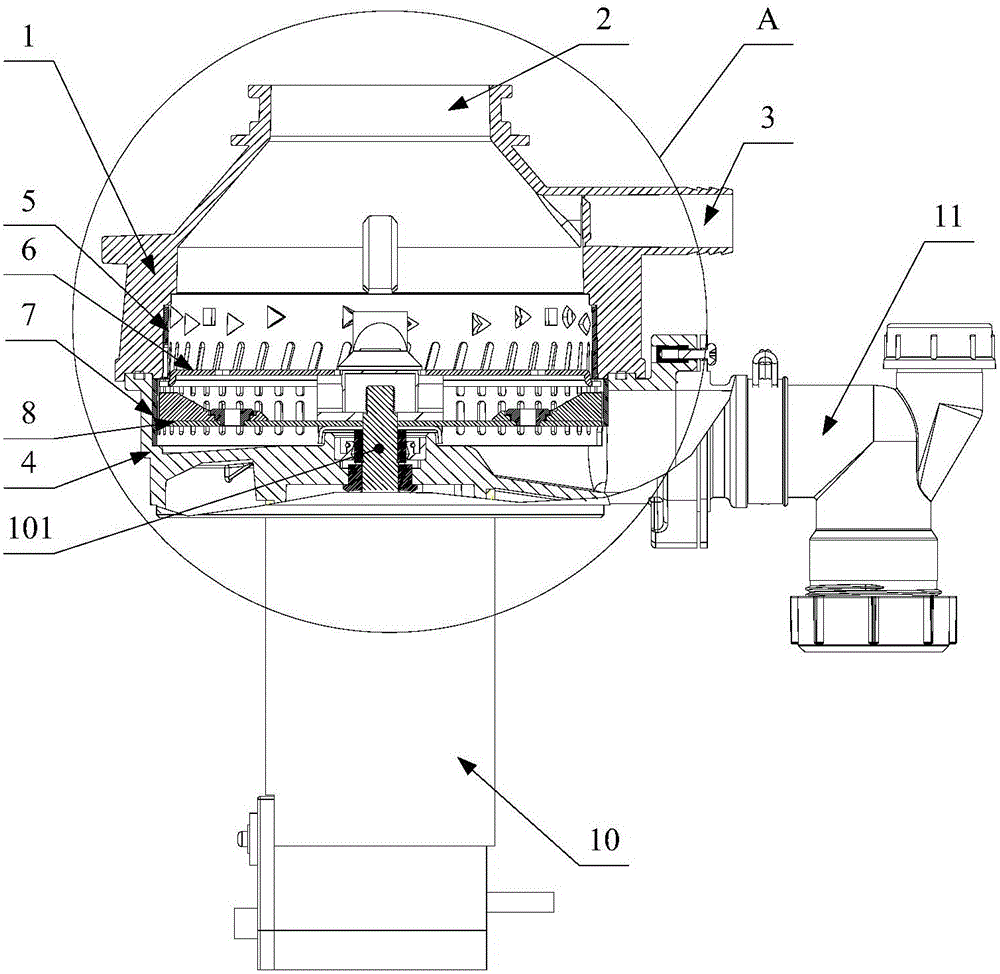

Stokehole coal pulverization device

InactiveCN108772176AGrind fullyGuaranteed grinding qualityGrain treatmentsMotor driveElectric machinery

The invention discloses a stokehole coal pulverization device. The device structurally comprises a powder outlet, a grinding pulverization mechanism, a control main engine, a regulator, a hopper and an iron material gate. According to the improved pulverization device, coal particles are grinded through a grinding roll, the gap between the grinding roll and a grinding seat is gradually decreased,and the grinding fineness is gradually improved, so that the coal grinding quality is ensured; the grinded coal falls on a filter screen, and a first motor drives the filter screen to vibrate, so as to vibrate and screen the coal particles; when coal particles which are small enough slide between the grinding seat and a second grinding roll, a third motor is started, the third motor rotates to ensure that a rack moves leftwards and rightwards and the second grinding roll rotates forwards and backwards so as to grind the coal particles; and the grinded coal slides rightwards from a material sliding plate and then slides out through a discharging groove, so that the coal is sufficiently grinded and the grinding efficiency and effect are improved.

Owner:湖州振锋贸易有限公司

Seawater resistant cement

ActiveCN101659525AImprove corrosion resistanceImprove grinding finenessSolid waste managementSlagSulfate

The invention relates to seawater resistant cement, in particular to seawater resistant cement with excellent seawater corrosion resistance, which comprises the following components in percentage by weight: 40 to 55 percent of cement clinker, 3 to 5 percent of gypsum, 12 to 15 percent of manganese slag, 12 to 15 percent of fly ash, 12 to 15 percent of slag, 2 to 5 percent of active silica, 2 to 5percent of resistant components and 2 to 5 percent of micro-expansion components. The manufacturing process of the seawater resistant cement comprises the following steps of: pre-extruding to crush the cement clinker, the gypsum, the resistant components, the active silica and the manganese slag in a roll squeezer, mixing the powder with the fly ash, the slag and the micro-expansion components ina miller to grind, putting the ground mixture in a homogenizing silo to mix with the air while stirring, pouring the mixture out of the silo to package in bulk and then conveying the packages out of the factory. The seawater resistant cement has the excellent properties such as high strength, compactness, seepage resistance, seawater corrosion resistance, seawater scouring resistance and the like, and is particularly applied to underground, harbors, docks and other projects eroded by erosion media such as a sulfate and the like.

Owner:ZHEJIANG MINGFENG CEMENT

Composite straw sheet and preparation method thereof

ActiveCN104098309APromote excitationMeet the hydration rateSolid waste managementAluminiumAlkaline water

The invention discloses a preparation method of a composite straw sheet. The method includes: increasing the content of sulphate aluminium cement clinker into common sulphate aluminium cement, adding hydraulic calcium oxide as an exciting agent, and conducting blending to form compound sulphoaluminate cement, and bonding the cement with crop straw to obtain the sheet. And the side effects of straw on cement setting and hardening can be overcome. In the method, the straw is not soaked by alkaline water, a chlorine-containing material is unnecessary for modification treatment on straw, wastewater discharge does not exist, heating is not needed, smoke dust and exhaust emission are absent. The advantages of light weight and abundant fiber of crop straw are utilized for low energy consumption and pollution-free preparation of the composite straw sheet.

Owner:四川什邡国正环保科技有限公司

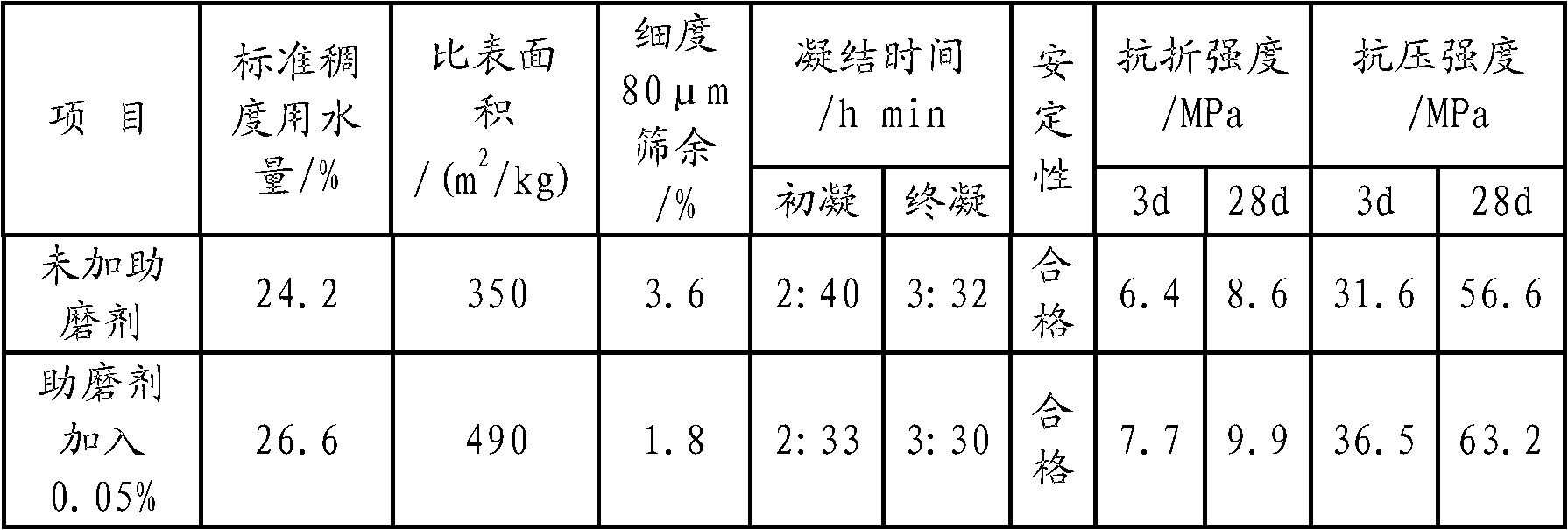

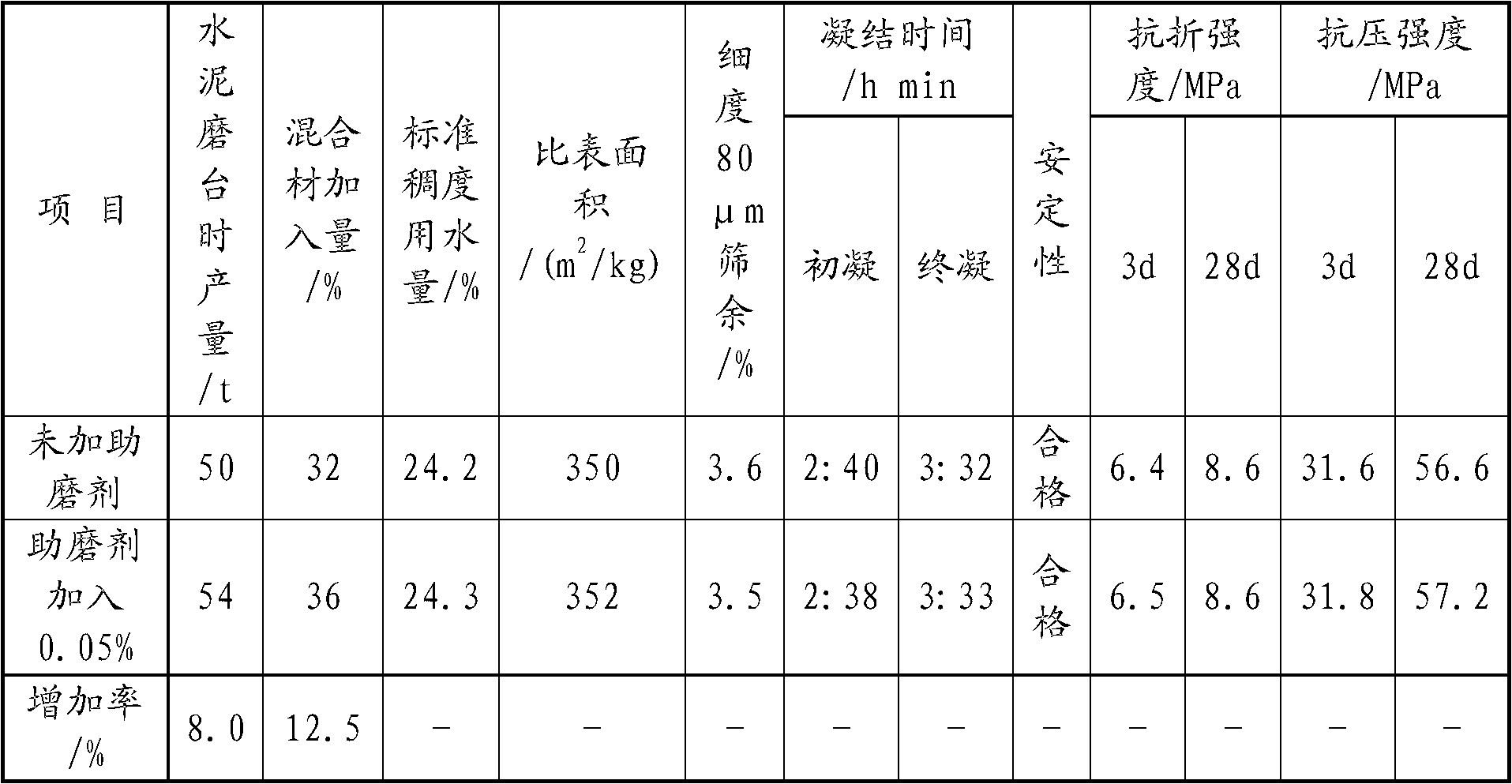

Preparation process of polyglycerol cement grinding aid

InactiveCN103011653AImprove performanceGood effectEther preparation by compound dehydrationElectrostatic adsorptionCement particle

The invention relates to the technical field of cement production, and particularly relates to a preparation process of a polyglycerol cement grinding aid. The polyglycerol cement grinding aid is prepared by mixing 90-95% of polyglycerol and 5-10% of inorganic reinforcer. The polymerization process of the polyglycerol comprises the following steps: adding 15-30% of recovered glycerol, 1-3% of NaOH and 69-84% of kerosene into a reactor, heating to 120-180 DEG C under the condition of introducing N2 for protection, and reacting for 4-8 hours while keeping the temperature, wherein the average polymerization degree n is calculated by determining the refractive index of the reactant, and the average polymerization degree n of the polyglycerol is controlled to be 3-5. According to the invention, the prepared cement grinding aid can change the dispersity of a material in a mill, effectively eliminate electrostatic adsorption and mill bonding phenomena of fine cement particles and optimize the gradation of the cement particles under the condition of not changing the status of the cement grinding mill. The original yield of the grinding mill is kept unchanged, the cement grinding rate and specific area are increased, the 3d strength of the cement is increased by 15%, and the 28d strength is increased by more than 8%. Alternatively, the existing cement grinding rate and specific area are kept, and the yield of the cement grinding mill can be increased by more than 10%.

Owner:安徽珍珠水泥集团股份有限公司 +1

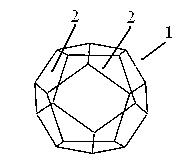

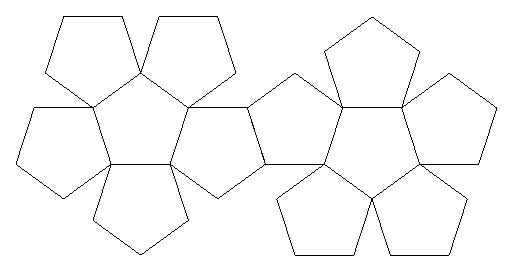

Regular dodecahedron-shaped grinding body of ball grinder

InactiveCN103071569AIncrease productionImprove grinding finenessGrain treatmentsMineral SourcesDodecahedron

The invention discloses a regular dodecahedron-shaped grinding body of a ball grinder. The outer surface of the grinding body is a sealed regular dodecahedron including 12 regular pentagons; and the seamed edges of each regular pentagon are superposed with seamed edges of five regular pentagons adjacent to the regular pentagon, and are 10 mm. The grinding body related to the invention is a regular dodecahedron-shaped spherical grinding body. When two grinding bodies conduct grinding, comprehensive contact friction between points, lines and surfaces can be generated, so as to improve the yield and the grinding fineness of the ball grinder, and further improve the grinding efficiency. Moreover, the area-weight ratio of the grinding body is high, so as to improve economic benefits, and reduce mineral resource consumption.

Owner:NINGGUO ZHONGYI WEAR RESISTANT MATERIALS

Polisher capable of adjusting polishing height of lipping of rail head

PendingCN107165008ALarge swing angleImprove swing flexibilityRailway track constructionPhysicsElectric machinery

The invention discloses a polisher capable of adjusting the polishing height of lipping of rail head, and belongs to the technical field of railway maintenance equipment. The polisher comprises a rack. The polisher is characterized by further comprising a vertically moving device and a travelling device; the vertically moving device comprises a hanging bracket, ball bearing bases, ball screws and ball nuts, stepper motors and vertically sliding blocks are arranged on the rack, and the hanging bracket is connected with the rack in a sliding mode through the vertically sliding blocks; the travelling device comprises a driving gear, a driven gear, a travelling wheel, a rolling wheel and a motor, wherein the driving gear is connected with the motor shaft of the motor, the driven gear is driven by the driving gear through gear meshing, and the travelling wheel is connected with the driven gear. According to the polisher capable of adjusting the polishing height of the lipping of the rail head, when polishing is conducted on the lipping of the rail head, the polisher can uniformly move at a low speed, and a grinding wheel is driven to automatically feed in the vertical direction, so that polishing in the vertical direction is conducted on the lipping of the rail head, and the polishing speed is uniform; moreover, the grinding wheel can vertically move, and polishing is conducted on any position of the height of the lipping of the rail head, so that the overall effect of polishing of the lipping of the rail head is improved.

Owner:西藏天仁科技发展有限公司

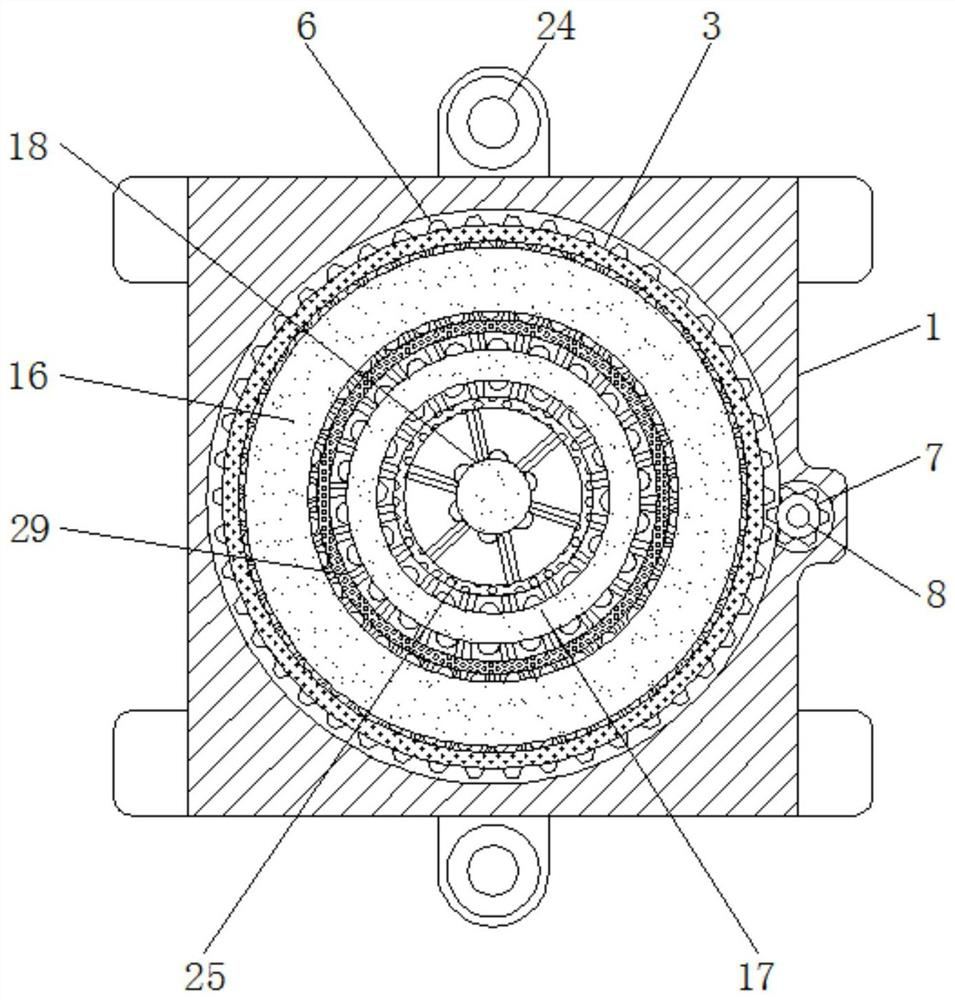

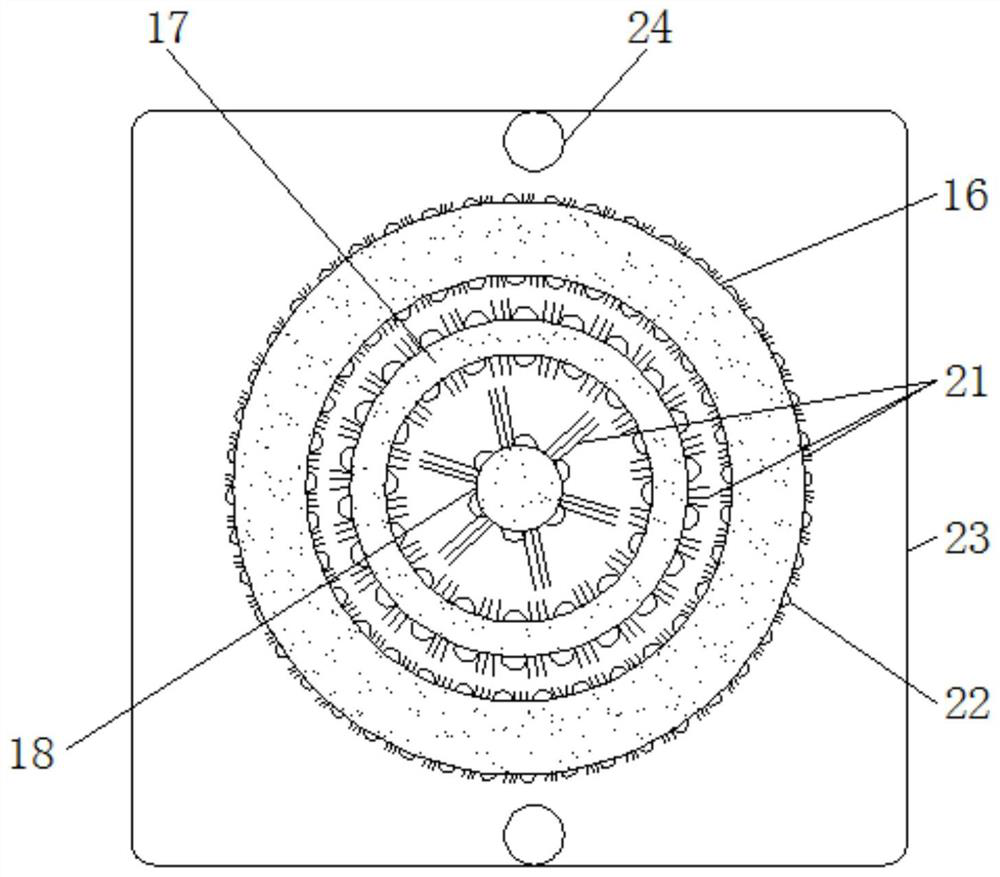

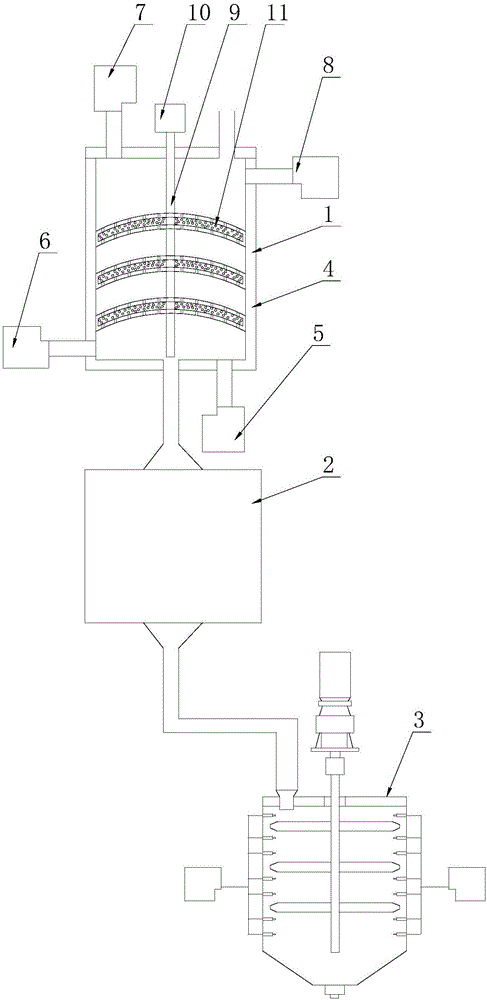

Biopharmaceutical grinding device with multi-layer separation and purification functions

ActiveCN111822091AWith multi-layer separation and purification functionReduce wall thicknessSievingScreeningGrindingElectric machinery

The invention discloses a biopharmaceutical grinding device with multi-layer separation and purification functions. The biopharmaceutical grinding device comprises an outer shell, a limiting ring anda motor, a supporting base is connected to the outer side of the lower end of the outer shell in a welded mode, an inner shell is arranged on the inner side of the outer shell, the limiting ring is fixedly installed on the outer side of the lower portion of the inner shell and is located on the inner side of a limiting groove, and the limiting groove is formed in the inner side of the outer shell.According to the biopharmaceutical grinding device with the multi-layer separation and purification functions, an outer grinding roller, an inner grinding roller and a middle grinding roller correspond to a third grinding groove, a second grinding groove and a first grinding groove in position one to one, and the wall thicknesses of the outer grinding roller, the inner grinding roller and the middle grinding roller are sequentially reduced; medicine is sequentially filtered into the second grinding groove and the third grinding groove from the first grinding groove through centrifugal force,the medicine can be subjected to multi-stage grinding through cooperation of the outer grinding roller and the inner grinding roller, and the grinding fineness of the medicine is improved.

Owner:陈守中

Ceramic production waste recovery device

ActiveCN113019557AEasy for secondary crushingEasy to realize crushing operationGrain treatmentsCeramic materials productionGear wheelElectric machinery

The invention relates to the technical field of ceramic production, and discloses a ceramic production waste recovery device. The device solves the problems of incomplete crushing of ceramic waste and larger labor input, and comprises a recovery box body and a recovery box cover, the recovery box cover is mounted at the top end of the recovery box body, and a feed inlet is formed in the middle of the top end of the recovery box cover. A discharging box is arranged in the recovery box body, supporting columns located at the bottom end in the recovery box body are arranged at the periphery of the bottom end of the discharging box, and a discharging pipe penetrating through the side wall of the recovery box body and extending to the outside of the recovery box body is arranged at one side of the discharging box; and by arranging a smashing box, a rotating shaft, a smashing roller, a second motor and a second gear, smashing operation on ceramic waste chips is conveniently achieved, meanwhile, through the action of a grinding plate, a grinding base, a first motor, a first belt wheel, a conveyor and a first gear, secondary smashing on the waste chips is facilitated, manual smashing can be avoided, and then the smashing efficiency is effectively improved.

Owner:XUCHANG UNIV

Ceramic grinding device for manufacturing Lei Cha (specialty food)

ActiveCN108212428AUniform amount of materialGuaranteed efficiencyGrain treatmentsSpecialty foodsMetallurgy

The invention relates to a ceramic grinding device for manufacturing Lei Cha (specialty food). The ceramic grinding device comprises a grinding bar which comprises a handheld part and a grinding partwhich are connected, a grinding face is arranged at the front end of the grinding part and comprises a grinding side face and a grinding bottom face which are connected, a plurality of grinding grooves are formed in the grinding face, grinding balls are arranged in the grinding grooves, the grinding balls cannot penetrate out of groove openings of the grinding grooves, and each grinding groove comprises a grinding section arranged at the top of the grinding groove, a feeding section and a discharging section, wherein the feeding section and the discharging section are arranged on the two sidesof the corresponding groove opening. The grinding device has the beneficial effects of being simple in structure and convenient to use; in addition, the grinding grooves are additionally arranged, the requirements are improved, and therefore the grinding efficiency, the grinding fineness and the grinding uniformity can be obviously improved; and the grinding bar made of a ceramic material is small in abrasion, and the grinding capacity is higher.

Owner:BAOJING COUNTY JINFENG CERAMIC

Seawater resistant cement

ActiveCN101659525BImprove corrosion resistanceImprove grinding finenessSolid waste managementSlagSulfate

The invention relates to seawater resistant cement, in particular to seawater resistant cement with excellent seawater corrosion resistance, which comprises the following components in percentage by weight: 40 to 55 percent of cement clinker, 3 to 5 percent of gypsum, 12 to 15 percent of manganese slag, 12 to 15 percent of fly ash, 12 to 15 percent of slag, 2 to 5 percent of active silica, 2 to 5percent of resistant components and 2 to 5 percent of micro-expansion components. The manufacturing process of the seawater resistant cement comprises the following steps of: pre-extruding to crush the cement clinker, the gypsum, the resistant components, the active silica and the manganese slag in a roll squeezer, mixing the powder with the fly ash, the slag and the micro-expansion components ina miller to grind, putting the ground mixture in a homogenizing silo to mix with the air while stirring, pouring the mixture out of the silo to package in bulk and then conveying the packages out of the factory. The seawater resistant cement has the excellent properties such as high strength, compactness, seepage resistance, seawater corrosion resistance, seawater scouring resistance and the like, and is particularly applied to underground, harbors, docks and other projects eroded by erosion media such as a sulfate and the like.

Owner:ZHEJIANG MINGFENG CEMENT

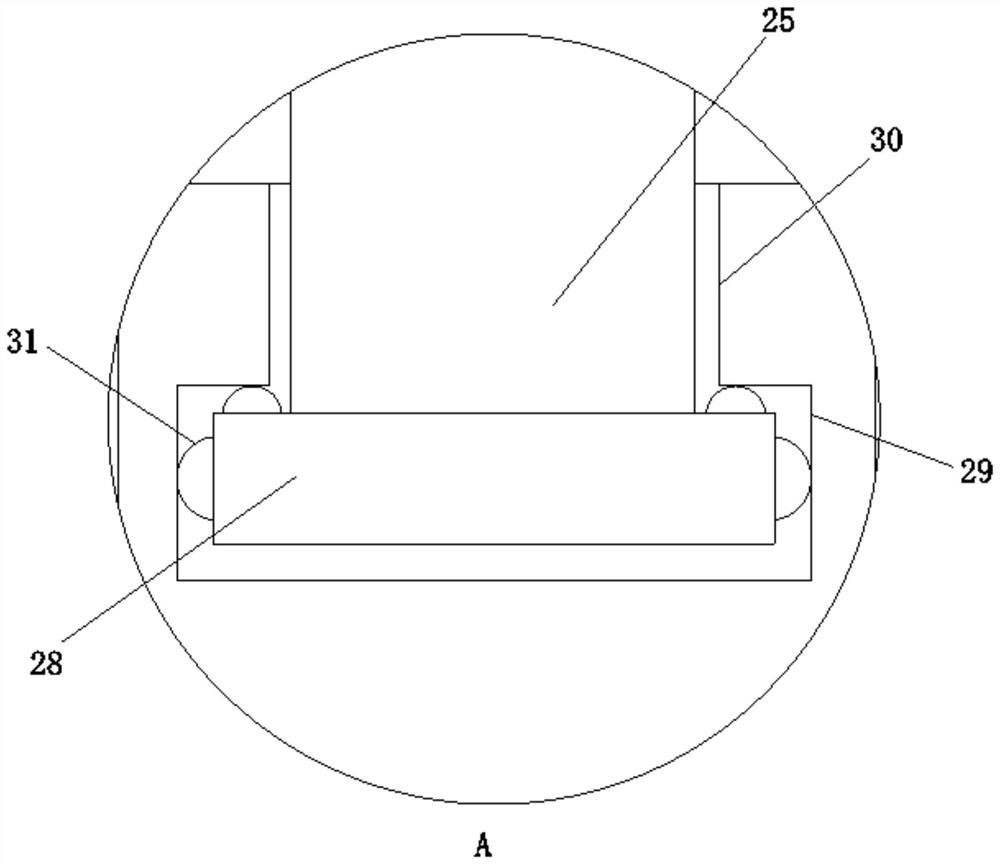

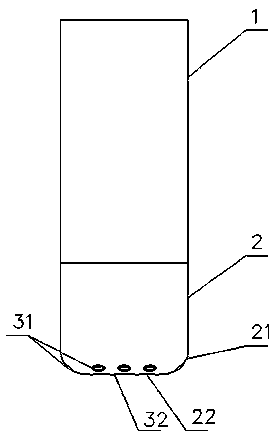

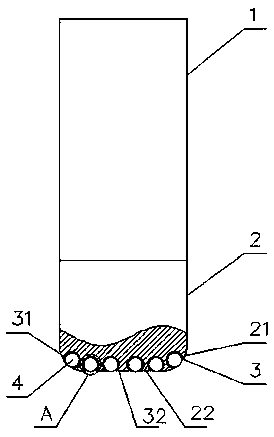

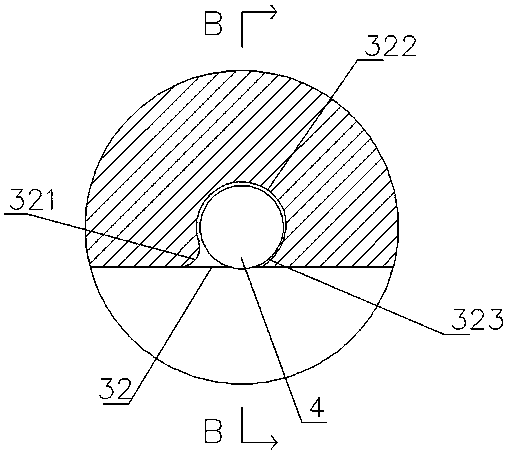

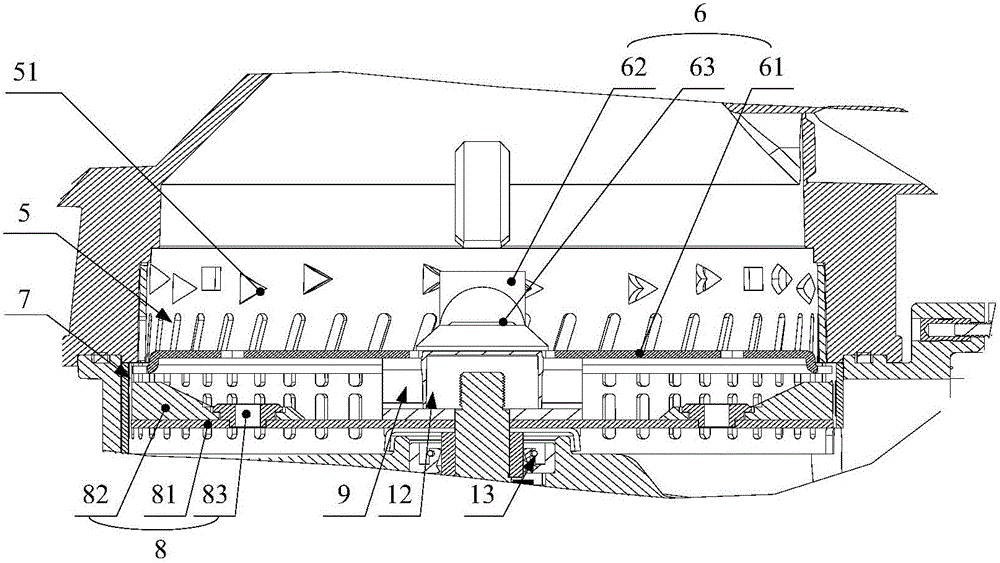

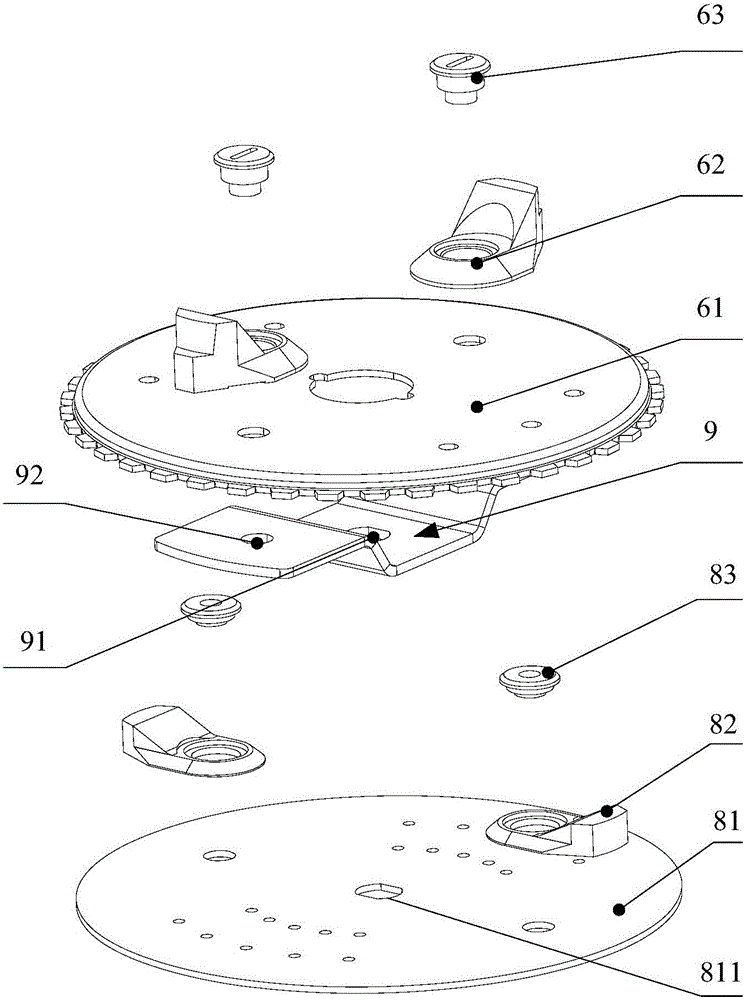

Food waste disposer and grinding mechanism thereof

ActiveCN105689065AImprove grinding finenessFully cutDomestic plumbingGrain treatmentsSewerageMotor shaft

Owner:GREE ELECTRIC APPLIANCES INC

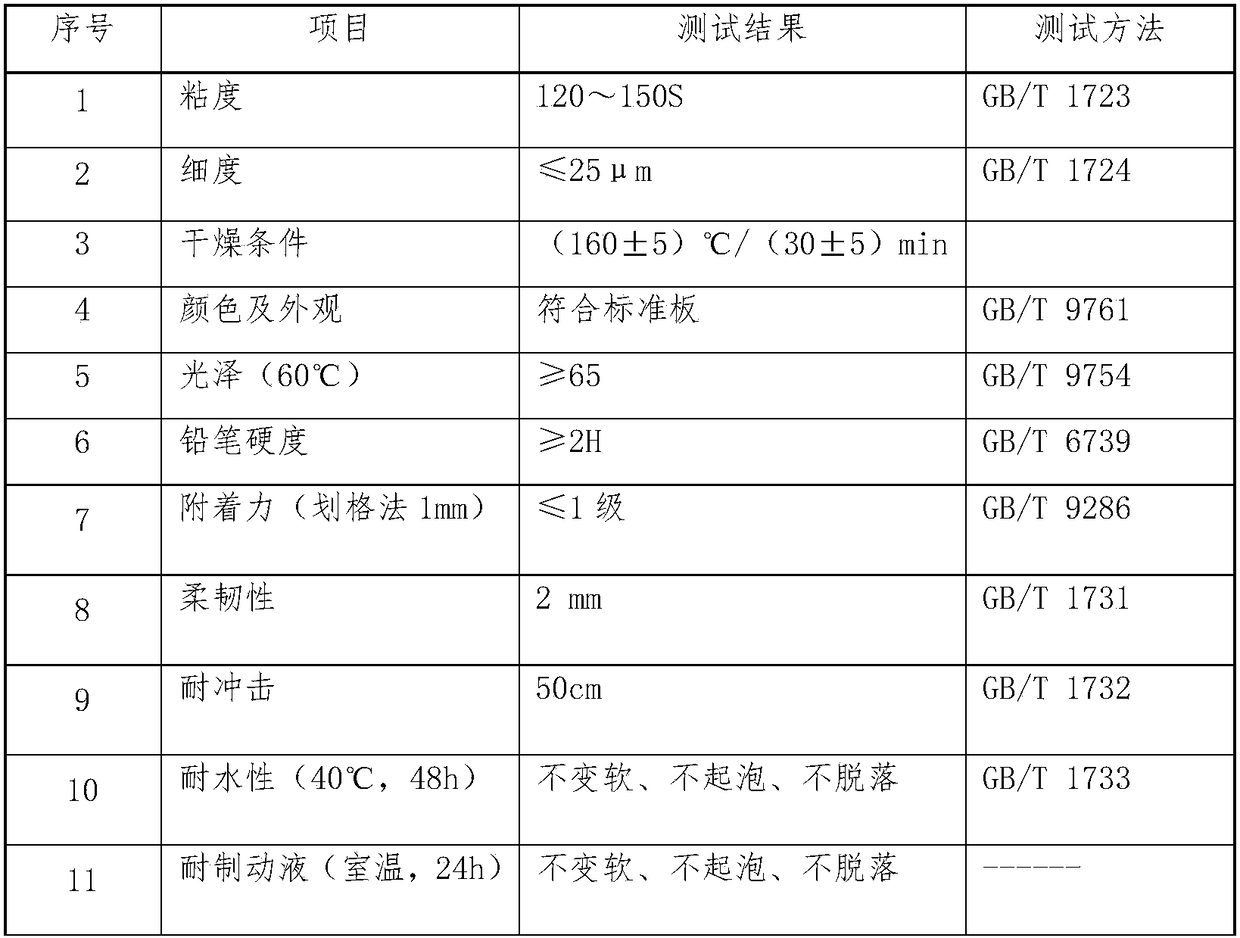

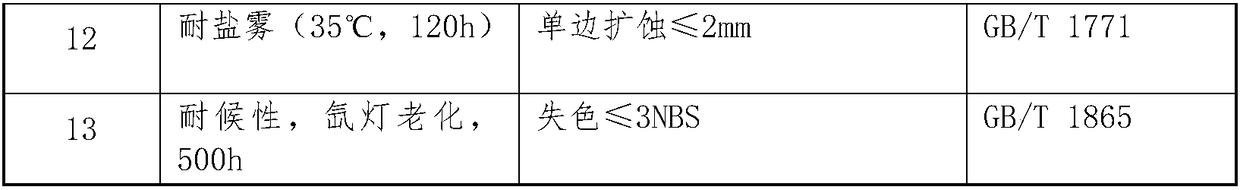

Black brake baking varnish integrating primer paint and finish paint and preparation method of black brake baking varnish

InactiveCN108250876AImprove adhesionIncrease crosslink densityAnti-corrosive paintsEpoxy resin coatingsVarnishMaterials science

The invention belongs to the technical field of surface coating of aluminum casting alloy, and relates to black brake baking varnish integrating primer paint and finish paint and a preparation methodof the black brake baking varnish. The adhesion can be improved by using preferred resin, the crosslinking density of the resin can be improved by improving the ratio, and an effect of corrosion prevention can be achieved by adding anti-corrosion filler appropriately; and it is ensured that the surface of the baking varnish is beautiful by adding a part of high-gloss resin and improving the grindfineness; the adhesion, corrosion resistance and aging resistance of the black brake baking varnish integrating the primer paint and the finish paint meet the product requirements, and the black brakebaking varnish has a beautiful appearance and a certain decorative property.

Owner:CHINA SPECIAL TYPE FLIER RES INST

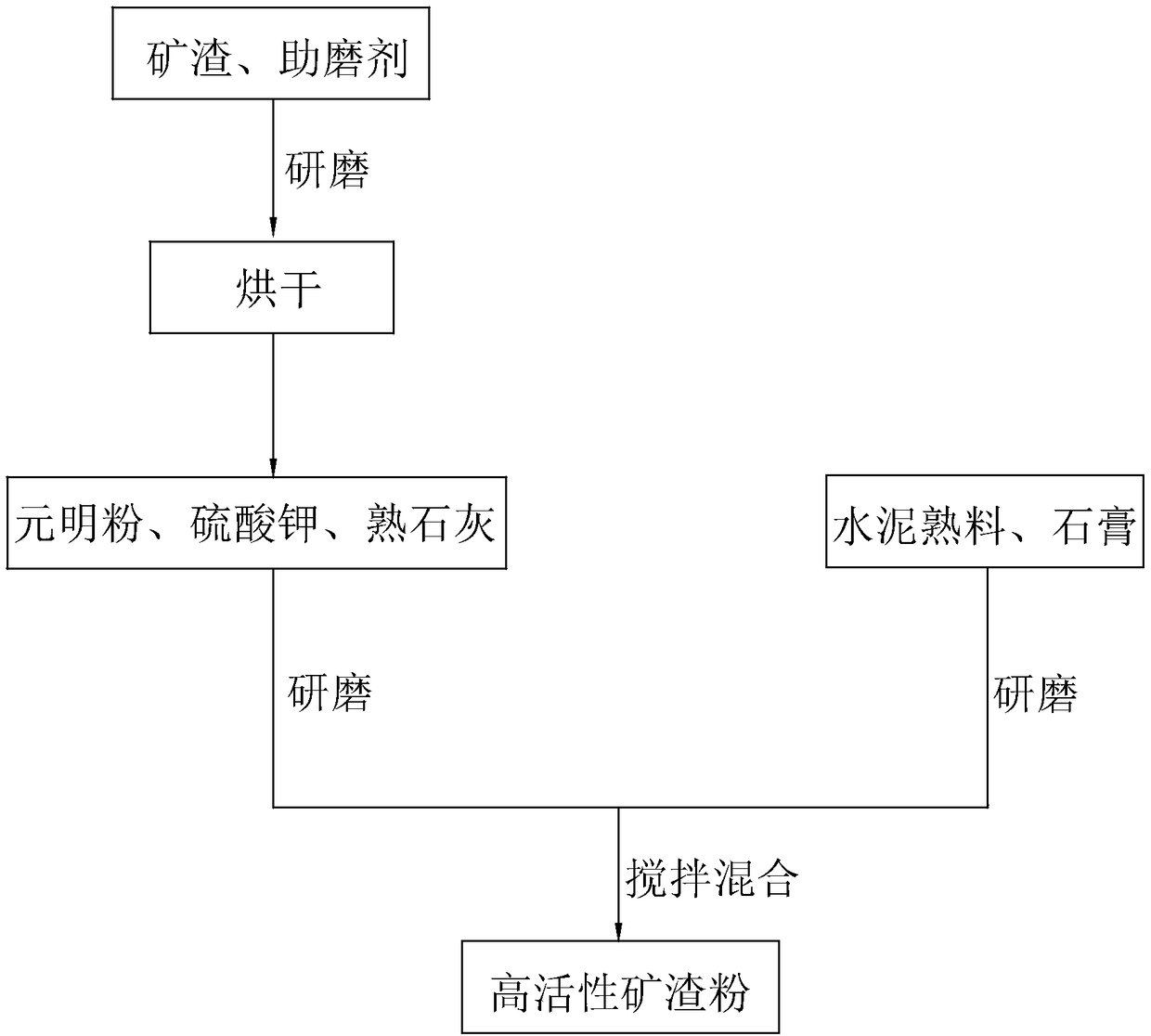

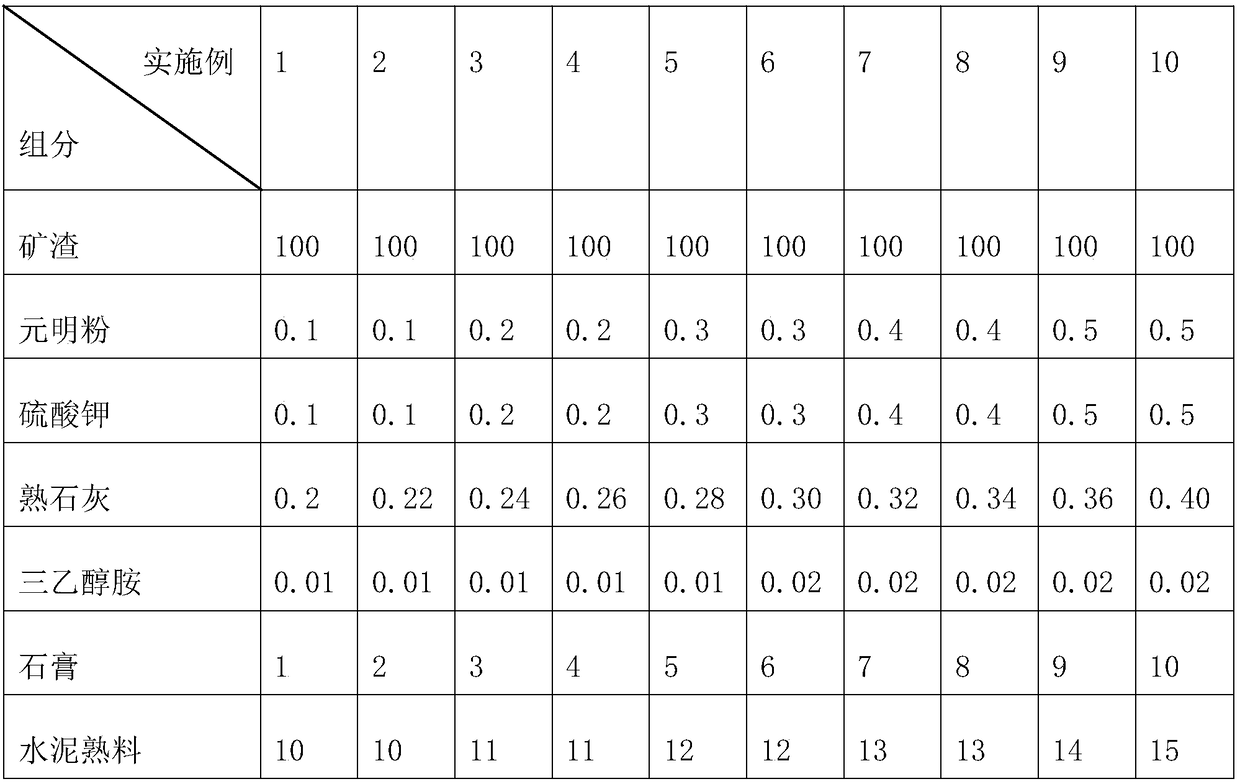

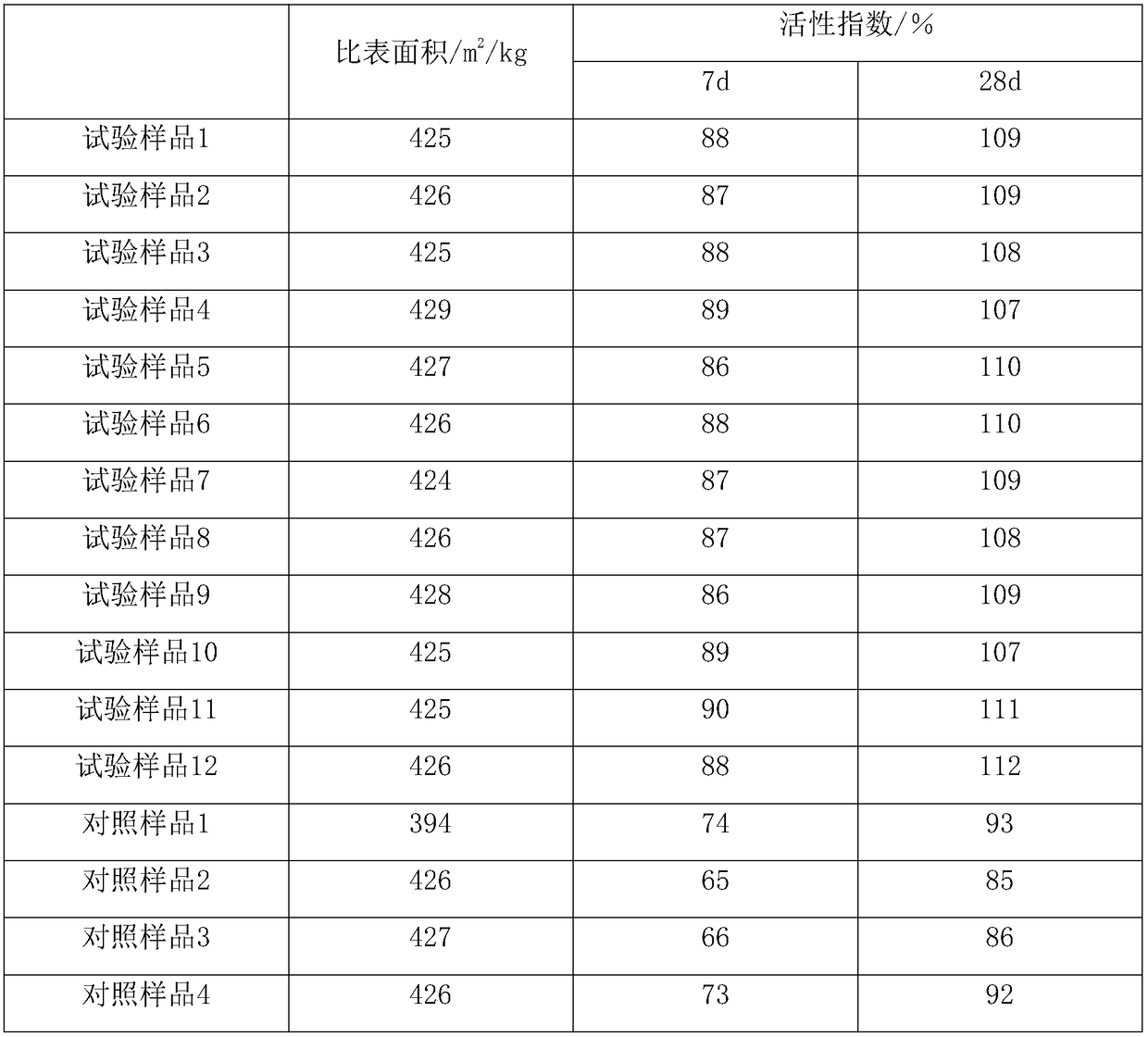

High-activity ore slag powder and preparation technology thereof

InactiveCN109265041AImprove grinding finenessLarge specific surface areaSolid waste managementLow activitySlag

The invention discloses a high-activity ore slag powder and a preparation technology thereof, and relates to the technical field of concrete, which can solve the technical problem of lower activity index of ore slag powder. The high-activity ore slag powder is technically characterized by being prepared from the following components in parts by weight: 100 parts of ore slag, 0.1 to 0.5 part of anhydrous sodium sulphate, 0.1 to 0.5 part of potassium sulfate, 0.2 to 0.4 part of slaked lime, and 0.015 to 0.02 part of a grinding additive. The high-activity ore slag powder has the advantages that the activity index is high, and the specific surface area is large.

Owner:上海明氏建材有限公司

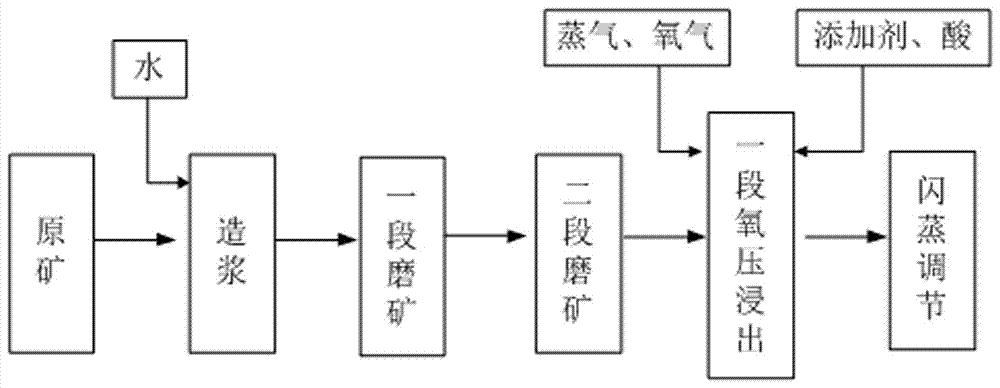

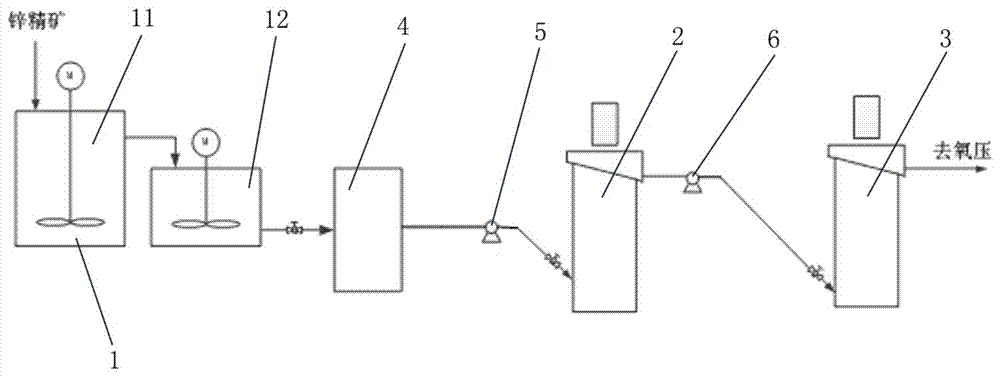

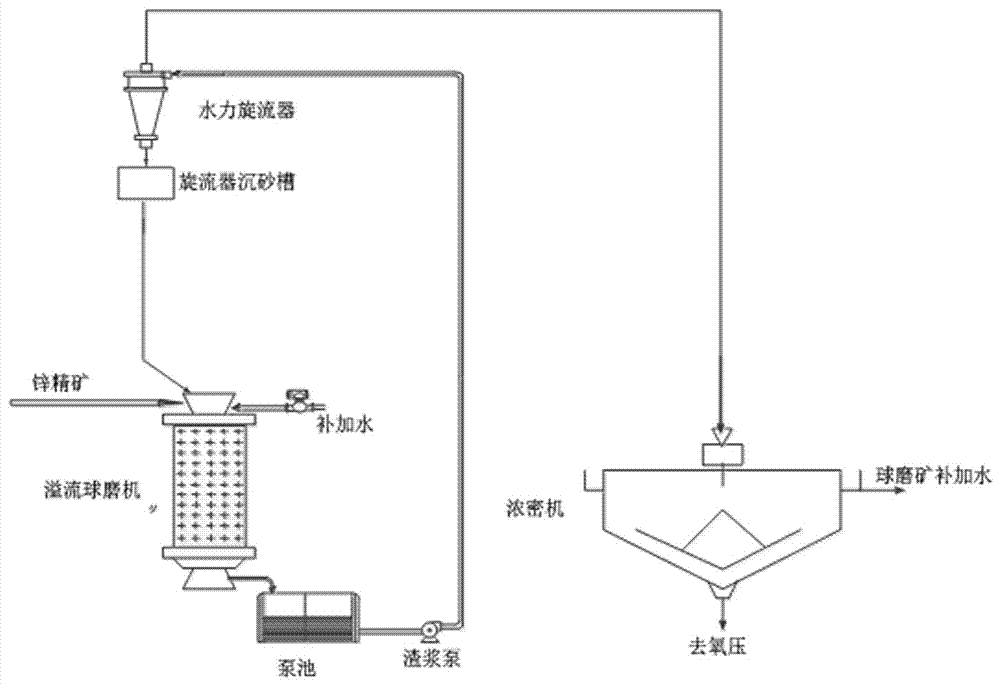

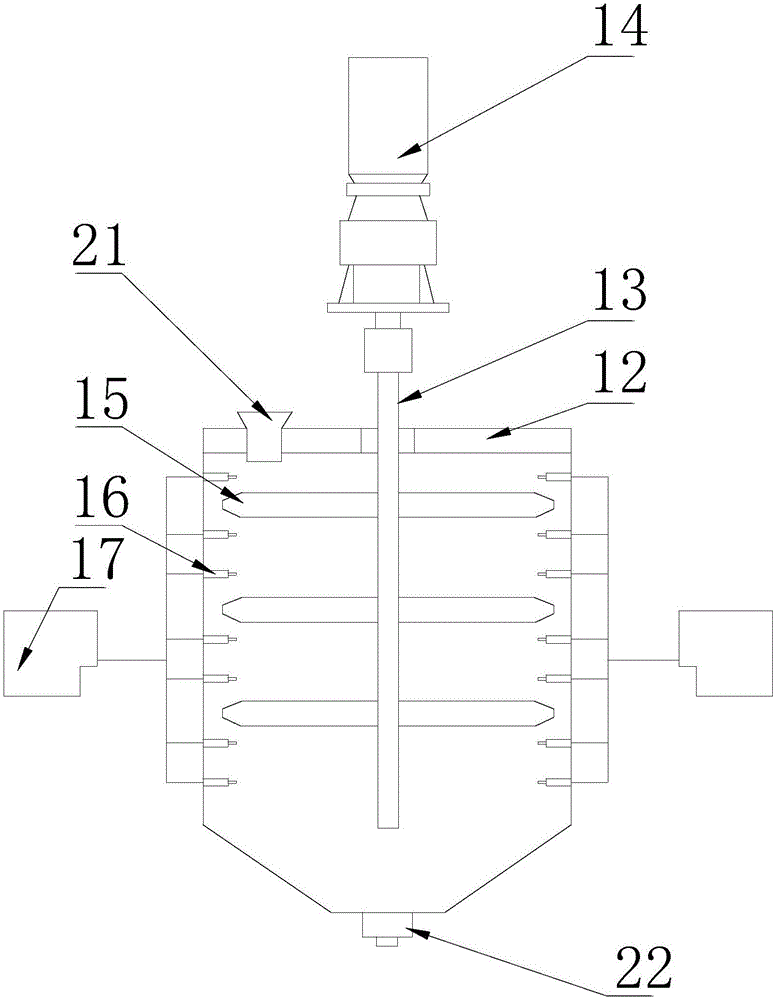

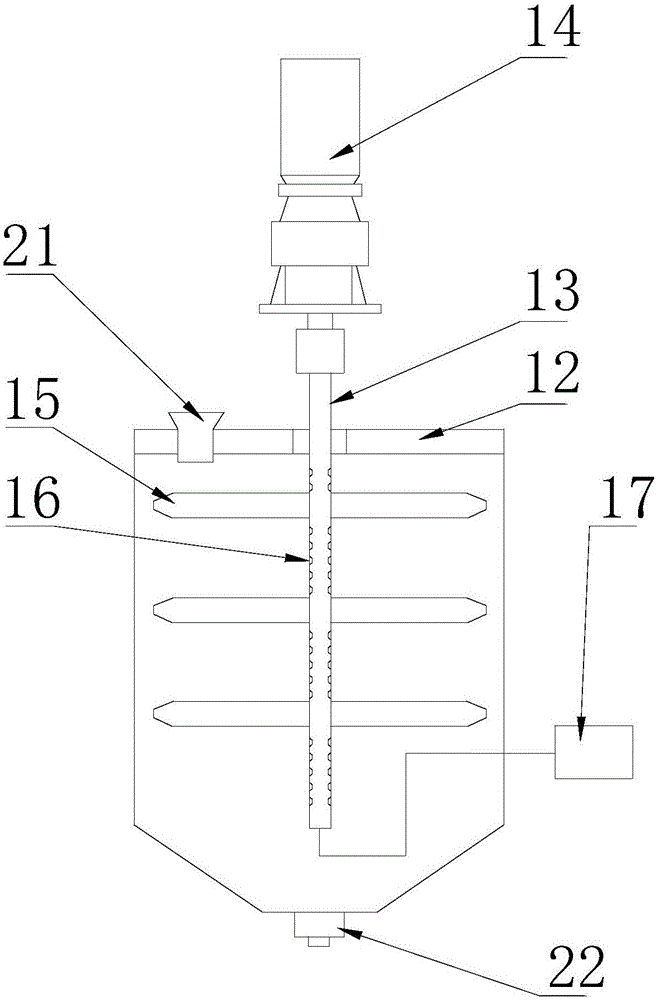

Preparation method of zinc oxidizing pressure leaching raw material and two-section vertical stirring grinder series-connection open-circuit ore grinding system

The invention discloses a preparation method of a zinc oxidizing pressure leaching raw material and a two-section vertical stirring grinder series-connection open-circuit ore grinding system. The method comprises the steps that a to-be-ground zinc concentrate material is firstly pulpified to obtain ore pulp with a certain concentration; the ore pulp obtained after pulpifying enters a primary-section vertical stirring grinder to be roughly ground; a material with the high ore grinding fineness and with the ore pulp concentration keeping unchanged is obtained after rough grinding; the material obtained after rough grinding enters a secondary-section vertical stirring grinder again to be finely ground; and a material with the higher ore grinding fineness and with the ore pulp concentration keeping unchanged is obtained after fine grinding, that is, the stable zinc oxidizing pressure leaching raw material is obtained. The system comprises a pulpifying device, the primary-section vertical stirring grinder and the secondary-section vertical stirring grinder. An output opening of the pulpifying device is connected with a feeding opening of the primary-section vertical stirring grinder, and a discharging opening of the primary-section vertical stirring grinder is connected with a feeding opening of the secondary-section vertical stirring grinder. The method and the system have the beneficial effects of being low in investment, low in cost, short in process, low in operating cost, stable and reliable in work and good in fine grinding effect.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

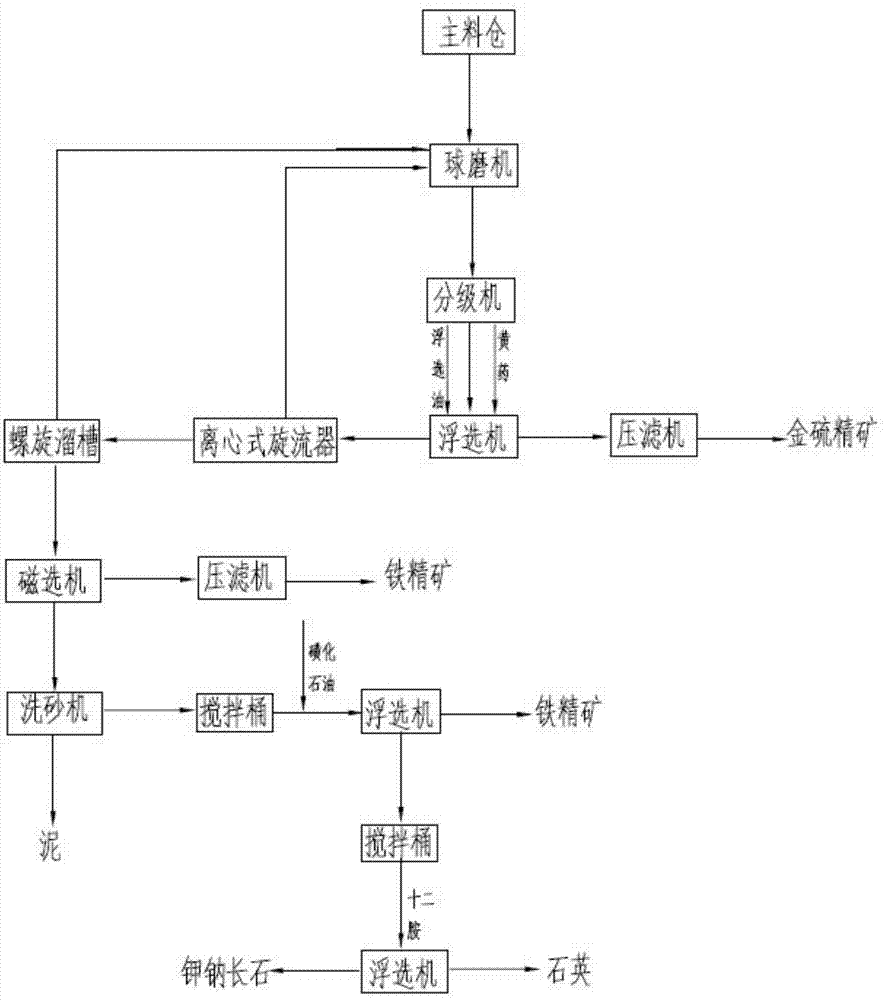

A method for recovering multiple elements from gold tailings waste slag

ActiveCN106000624BImprove grinding finenessDowngradeSolid separationElectronic waste recyclingCycloneSlag

The invention relates to a multi-element recovery method of gold tailings waste residue. The gold tailings waste residue is extracted by a vibrating screen to extract stones, garbage, etc., and then enters the main silo, and then enters a ball mill by a belt conveyor for grinding, and then goes through a mixing tank for each Add 24-26 grams of xanthate to tailings waste residue per ton, and 19-20 grams of flotation oil. After fully stirring, enter the flotation machine for flotation. The selected product is sulfur concentrate, and the tailings are discharged by sweeping. The ore pump enters the cyclone, and the bottom flow returns to the ball mill for regrinding. After the overflow enters the spiral chute, the enriched tailings enter the ball mill and flotation machine for regrinding and re-selection, so that the gold content in the tailings is significantly reduced, and then the spiral chute The iron ore concentrate is extracted from the tailings by three-stage magnetic separation. The beneficial effect of the invention is that: the tailings grinding fineness is improved by adopting the technology provided by the invention, the recovery rate is increased from the original 58% to 84%, and the grade of gold in the tailings is significantly reduced after treatment.

Owner:SHANDONG JIUQU SHENGJI NEW BUILDING MATERIALS

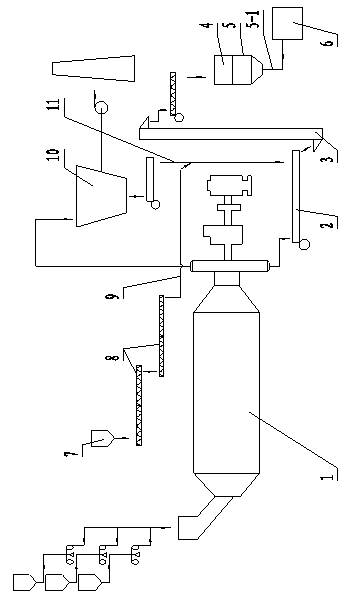

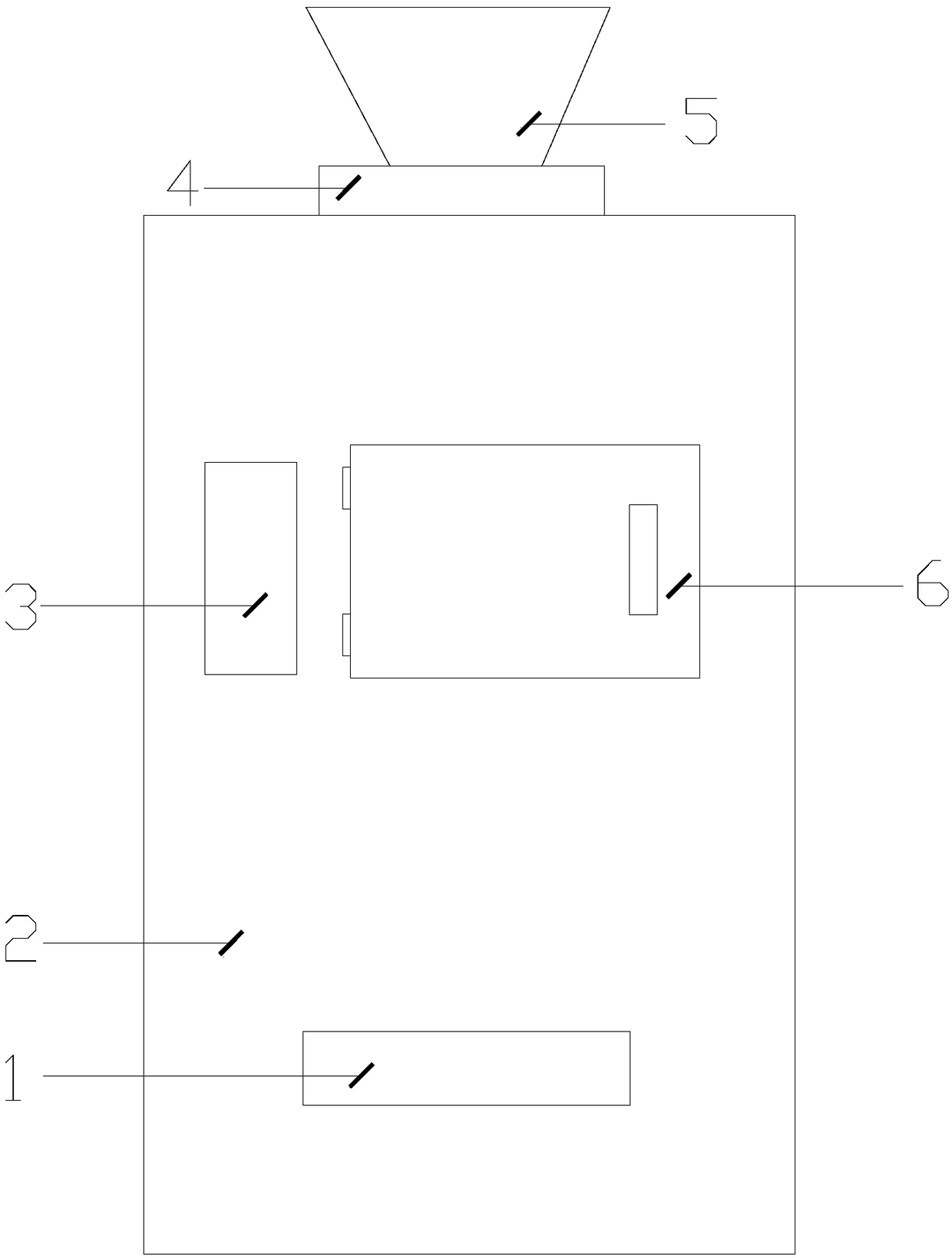

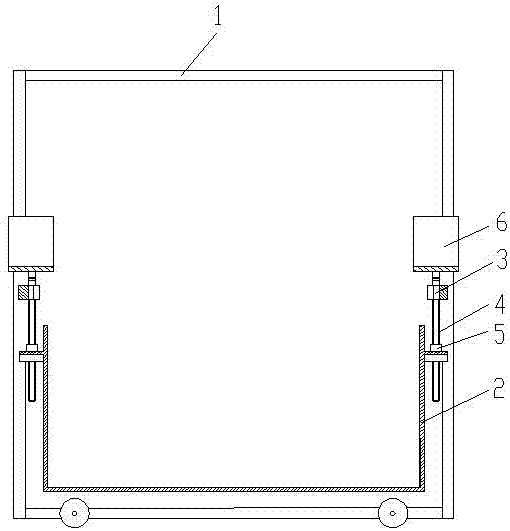

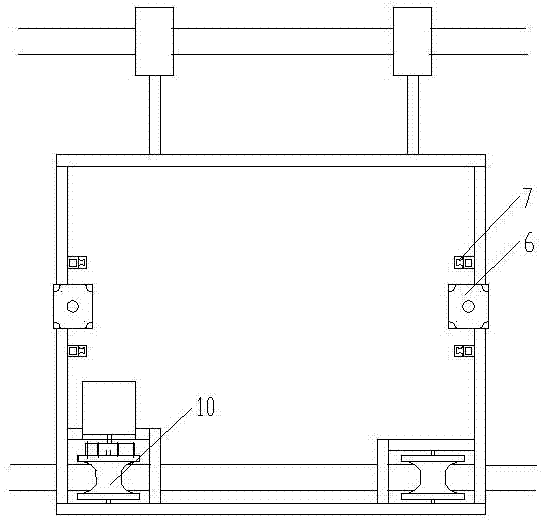

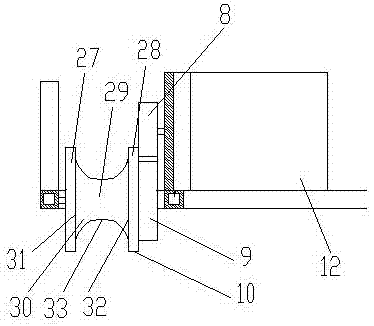

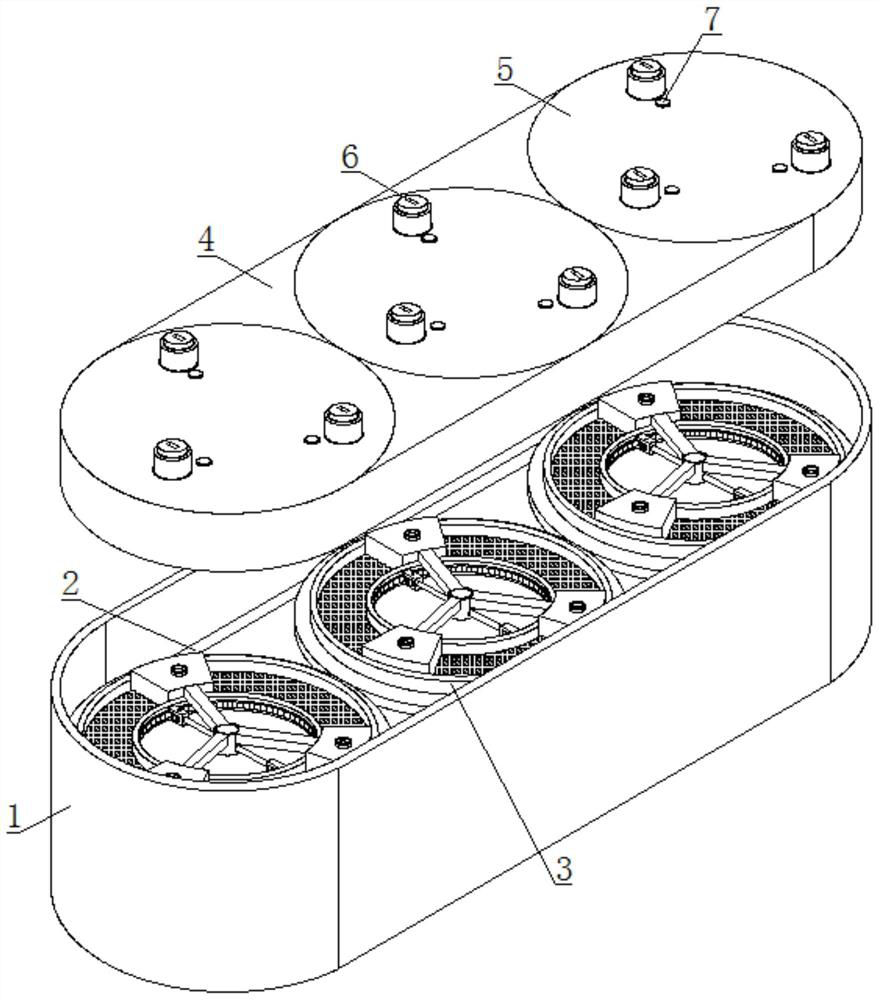

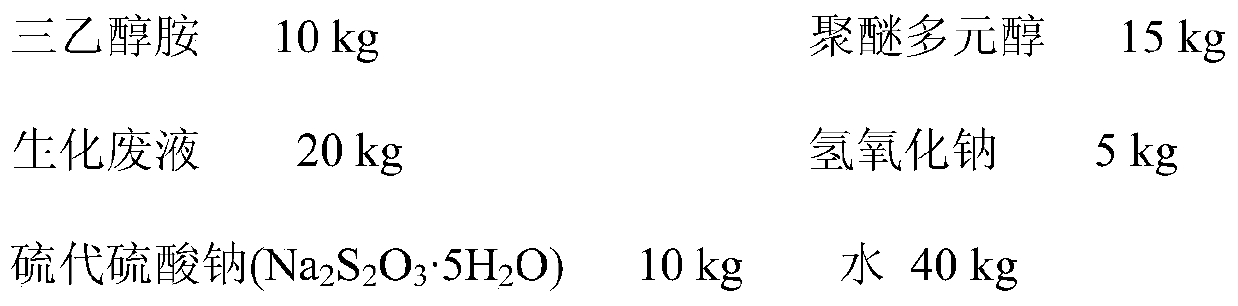

Making production equipment for high-quality wood paint

PendingCN106823954AImprove grinding finenessImprove uniformityTransportation and packagingMixersLacquerFineness

The invention discloses making production equipment for high-quality wood paint. The making production equipment of the high-quality wood paint comprises a circulation grinding mechanism, a material storage mechanism and a stirring and filling mechanism; a discharging port of the circulation grinding mechanism is connected with a feeding port of the material storage mechanism; a discharging port of the material storage mechanism is connected with a feeding port of the stirring and filling mechanism; the stirring and filling mechanism comprises a stirring tank; a stirring shaft is arranged in the center of the stirring tank; the top of the stirring shaft is connected with an output shaft of a stirring motor; a plurality of stirring blades are arranged on the stirring shaft; multiple groups of spraying and blowing heads are arranged on the inner wall of the stirring tank; each group of spraying and blowing heads comprises a plurality of spraying and blowing heads which are arranged uniformly in an annular array form; and the spraying and blowing heads are connected with an air pump outside the stirring tank. The making production equipment for the high-quality wood paint can greatly increase the grinding fineness of powder by utilizing an airflow disturbance principle and cooperating with a grinding disk with a special structure; and the multiple groups of spraying and blowing heads on the inner wall of the stirring tank can greatly increase the uniform degree of mixing by utilizing the airflow disturbance principle, so the product quality is improved and the making production equipment for the high-quality wood paint is worthy of being promoted vigorously.

Owner:GUIZHOU UNIV

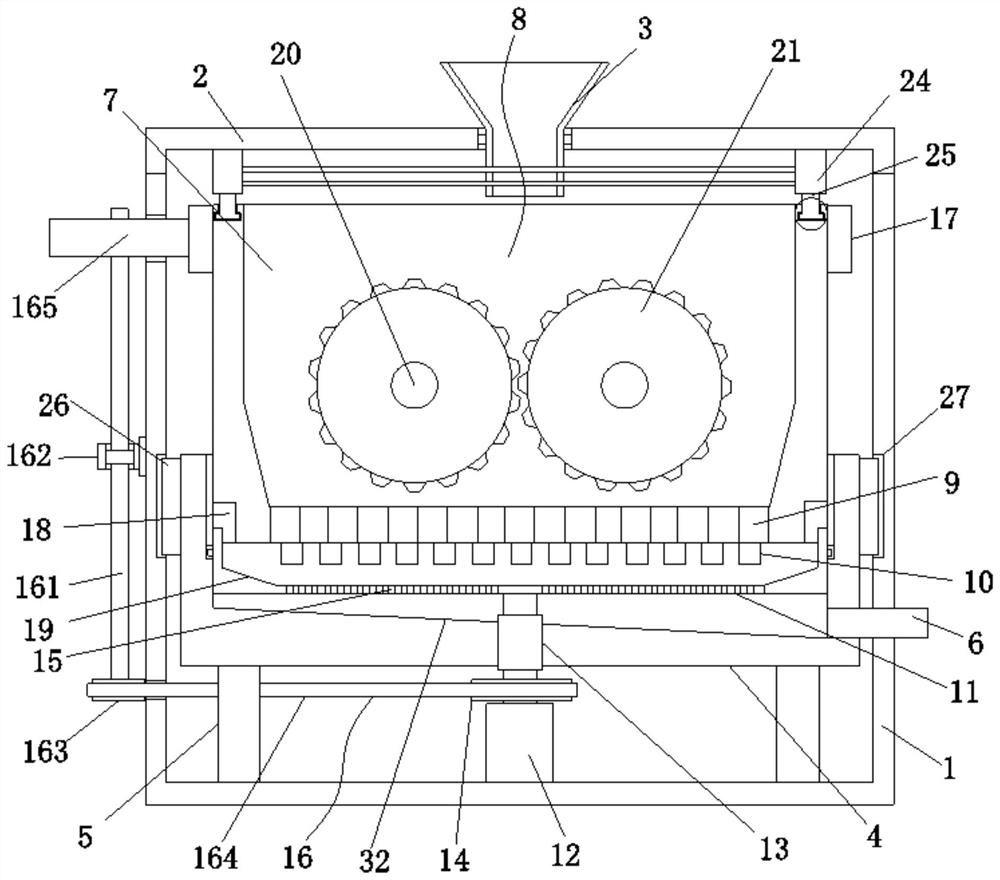

Water-based ink grinding and mixing device with proportion regulation and control function and implementation mode of water-based ink grinding and mixing device

ActiveCN114289152APrevent overflowThe amount added is good for regulationGrain treatmentsEngineeringMechanical engineering

The invention discloses a water-based ink grinding and mixing device with a proportion regulation and control function and an implementation mode thereof, belongs to the technical field of water-based ink, and aims to solve the problems that the control strength of the ink material proportion depends on the accuracy of material metering, an existing grinding machine is poor in applicability to blending a small amount of water-based ink, ground materials are difficult to quickly and uniformly distribute, and the working efficiency is low. And the utilization rate of the grinding machine is not high when a small amount of ink is ground. When the extrusion block is close to the center of the turntable, the diameter of the circular motion route of the extrusion block is reduced, and the pressing height of the piston disc is reduced; when the extrusion block is far away from the center of the turntable, the diameter of the circular motion route of the extrusion block is increased, and the pressing height of the piston disc is increased; three groups of materials are ground and mixed through grinding connection of the grinding tooth surface and the grinding concave-convex surface, the grinding tooth surface is attached to the grinding concave-convex surface, the materials slowly enter the grinding cavity along the lower opening of the discharging through pipe, and the materials are tightly attached to the grinding mechanism, so that various materials can be quickly and uniformly distributed.

Owner:江苏云合新材料科技有限公司

a cement grinding aid

The invention provides a cement grinding aid. The cement grinding aid comprises raw materials as follows: triethanolamine, polyether polyol, sodium hydroxide, sodium thiosulfate and a biochemical waste liquid, wherein the biochemical waste liquid is one of or a mixture of a waste liquid produced during production of industrial sodium gluconate and a waste liquid produced during production of an industrial itaconic acid product. The cement grinding aid can optimize the cement grain composition, activate the early strength of cement, improve the powder grinding efficiency of the cement and reduce energy consumption.

Owner:ZHANGQIU HUAMING CEMENT

Cement grinding aid and preparation method thereof

InactiveCN110713356AImproved particle size distributionImprove liquidityHydration reactionSilicic acid

The invention discloses a cement grinding aid, which is prepared from triethanolamine, polyol, modified cyanamide, paper pulp, molasses, biochemical waste liquid, a surfactant, magnesium silicate andwater as raw materials, and is prepared by the following steps: adding water, triethanolamine and modified cyanamide into a reaction kettle, carrying out stirring reaction, adding polyol, and continuing stirring the components to obtain a mixture; and adding paper pulp, molasses and magnesium silicate into the mixture, controlling the temperature of the reaction kettle to be 75-80 DEG C and the speed to be 600-900 r / min, stirring the mixture, performing standing treatment with heat preservation, adding biochemical waste liquid and a surfactant, and carrying out stirring reaction for 10-15 minto obtain the cement grinding aid. The cement grinding aid is low in manufacturing cost, the grinding efficiency of a mill system can be obviously improved, hydration reaction of cement is induced, and the strength of the cement at all ages is improved.

Owner:衡阳县海华水泥有限责任公司

Production equipment of turbulent flow type paint preparation production tank

PendingCN106807293AImprove grinding finenessImprove uniformityTransportation and packagingMixersAir pumpPulp and paper industry

The invention discloses production equipment of a turbulent flow type paint preparation production tank. The production equipment comprises a circulation grinding mechanism, a storage mechanism and a stirring and filling mechanism, wherein the material outlet of the circulation grinding mechanism is connected with the material inlet of the storage mechanism; the material outlet of the storage mechanism is connected with the material inlet of the stirring and filling mechanism; the stirring and filling mechanism comprises a stirring tank; a stirring shaft is arranged in the center of the stirring tank; the top of the stirring shaft is connected with the output shaft of a stirring motor; a plurality of stirring blades are arranged on the stirring shaft; the lower section of the stirring shaft adopts a hollow structure; a plurality of air holes are formed in the outer part of the stirring shaft; the bottom of the stirring shaft is connected with an air pump through an air pipe. The production equipment can greatly improve the grinding fineness of powder through a principle of air disturbance and a grinding disc with a special structure, the stirring shaft, with the air pipe being connected with the lower section part and the air holes being formed in the outer part, can greatly improve the mixing uniformity degree through the principle of air disturbance, the product quality is improved, and the equipment is worth of energetic popularization.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com