Black brake baking varnish integrating primer paint and finish paint and preparation method of black brake baking varnish

A brake, black technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of substrate adhesion, poor appearance of environmental aging resistance, etc., achieve beautiful appearance, improve grinding fineness, and improve resin The effect of crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

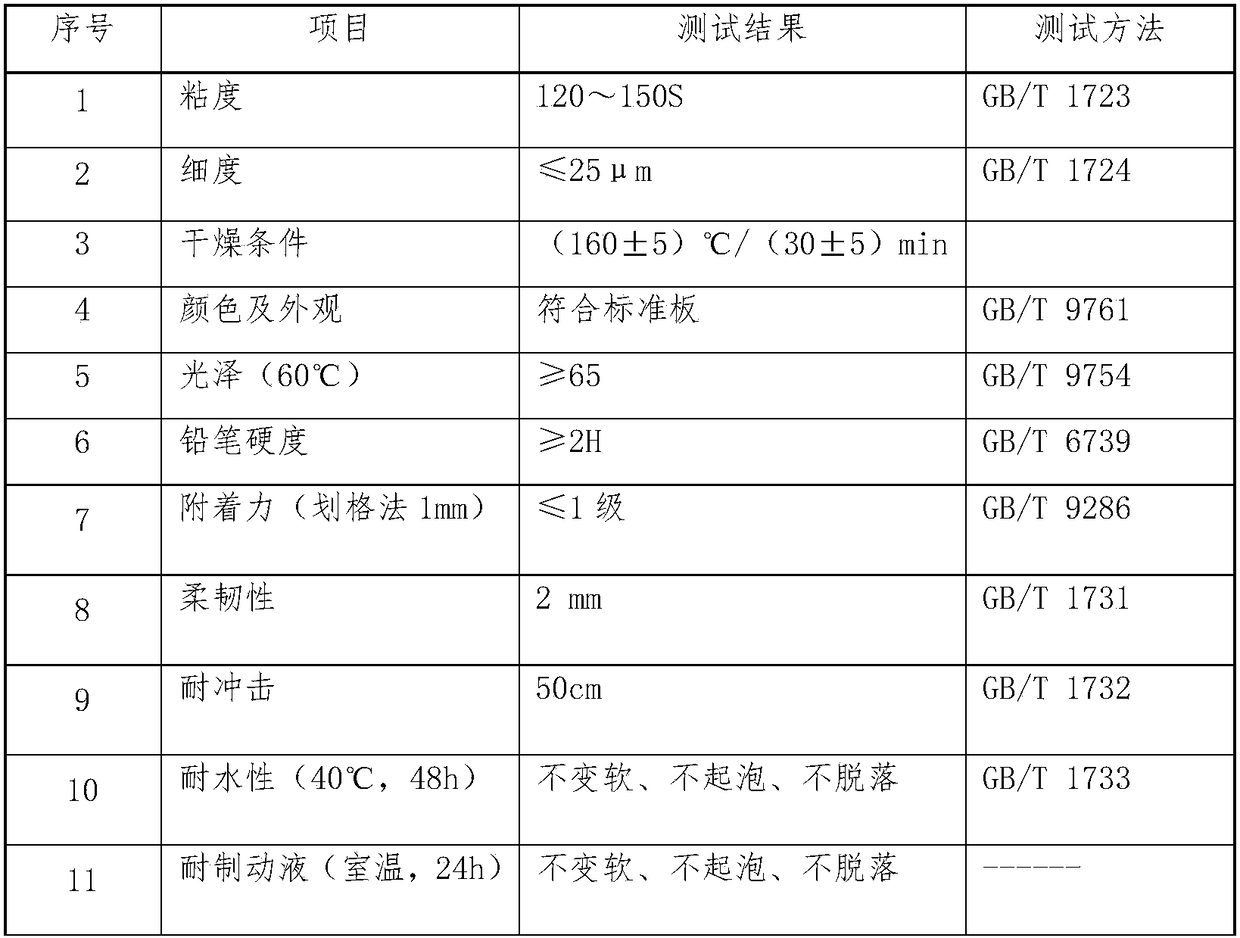

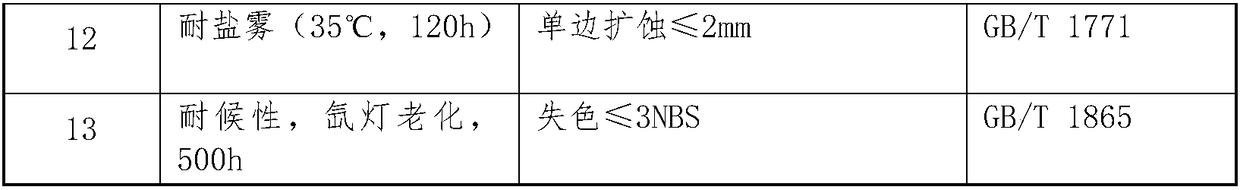

Examples

Embodiment 1

[0045] In this case, the ingredients are calculated according to the following components and weight percentages:

[0046] Step 1: Prepare the raw materials according to the following proportions:

[0047] YP5625 amino resin 11%;

[0048] DF1890 acrylic resin 42%;

[0049] Bayer 670 polyester resin 4.5%;

[0050] E-44 epoxy resin 3%;

[0051] Dandong carbon black 8%;

[0052] OK500 matting powder 0.5%;

[0055] Zinc phosphochromate 3%;

[0056] N45 dispersant 0.5%;

[0057] N159 leveling agent 0.5%;

[0058] R972 adhesion promoter 0.5%;

[0059] Isopropanol 3.5%;

[0060] Propylene Glycol Methyl Ether 3%;

[0061] PMA 11%.

[0062] Step 2: Put Dandong carbon black 8% + isopropanol 3.5% into the tank and stir and disperse fully to fully dissolve the carbon black;

[0063] Step 3: Add 4% of barium sulfate, 5% of mica powder, 3% of zinc phosphochromate, 0.5% of N45 dispersant and 11% of YP5625 amino resin to the a...

Embodiment 2

[0068] In this case, the ingredients are calculated according to the following components and weight percentages:

[0069] Step 1: Prepare the raw materials according to the following proportions:

[0070] YP5625 amino resin 15%;

[0071] DF1890 acrylic resin 45%;

[0072] Bayer 670 polyester resin 2.5%;

[0073] E-44 epoxy resin 1%;

[0074] Dandong carbon black 5%;

[0075] OK500 matting powder 0.5%;

[0077] Mica powder 5%;

[0078] Zinc phosphochromate 3%;

[0079] N45 dispersant 0.5%;

[0080] N159 leveling agent 0.5%;

[0081] R972 adhesion promoter 0.5%;

[0082] Isopropanol 3.5%;

[0083] Propylene Glycol Methyl Ether 3%;

[0084] PMA 11%.

[0085] Step 2: Put Dandong carbon black 5% + isopropanol 3.5% into the tank and stir and disperse fully to fully dissolve the carbon black;

[0086] Step 3: Add 4% of barium sulfate, 5% of mica powder, 3% of zinc phosphochromate, 0.5% of N45 dispersant and 15% of YP5625 amino resin to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com