Patents

Literature

78results about How to "Play the role of anti-corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental-friendly water-based fire extinguishing agent and its preparation method

InactiveCN102350032ANot easy to cause pollutionLeave quicklyFire extinguisherWater basedAntiseptic Agent

The invention relates to an environmental-friendly water-based fire extinguishing agent, which comprises: deionized water, an antiseptic agent, a metal antirust agent, a halogen-free fire retardant, a hydrocarbon surfactant, a high efficiency chelating agent, 2-5 parts of an osmotic agent and a high efficiency corrosion inhibitor. The preparation method of the water-based fire extinguishing agentconsists of the steps of: adding deionized water into a dispersing cylinder according to the weight part, then adding the antiseptic agent, the metal antirust agent, the halogen-free fire retardant and the hydrocarbon surfactant, and stirring the mixture uniformly till completely salvation of the mixture; then adding the high efficiency chelating agent, the osmotic agent and the high efficiency corrosion inhibitor, stirring them uniformly till semi-clarity, thus obtaining the finished product. Containing a halogen free fire retardant, the fire extinguishing agent of the invention can be biologically degraded 100%, thus having no pollution to surrounding equipment and space. Containing an osmotic agent, the fire extinguishing agent in the invention can penetrate articles in fire hazards ofclass A, and can penetrate into the inside of combustible articles, so that even if the fire is not completely put out due to a large fire, the part injected with the agent can effectively block a fire source and control the spreading speed of a fire. Therefore, the fire extinguishing agent provided in the invention has excellent flame resistance.

Owner:广东卫斯理化工科技有限公司

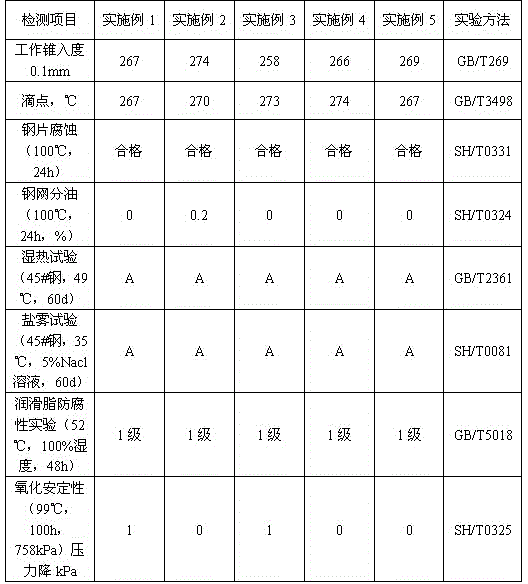

Lubricating grease for protecting aluminum-conductor steel-reinforced cables and preparation method of lubricating grease

InactiveCN104804809AMeet the needs of useGuaranteed Protection RequirementsLubricant compositionFatty amineWater resistant

The invention discloses lubricating grease for protecting aluminum-conductor steel-reinforced cables and a preparation method of the lubricating grease, and relates to the technical field of chemical engineering. The lubricating grease comprises the following components in percentage by weight: 50-90% of base oil, 1-5% of isocyanate, 1-5% of fatty amine, 1-6% of aromatic amine, 1-6% of a tackifier, 1-5% of a rust inhibitor, 0.25-0.8% of an anti-oxidant and 0.04-0.08% of a metal corrosion inhibitor, wherein the base oil is mineral oil or synthetic base oil of which the temperature is 40 DEG C and the kinematic viscosity is 120-500 mm<2> / s. The lubricating grease has the advantages that the normal operation of the aluminum-conductor steel-reinforced cables in a seriously corroded offshore industry area can be guaranteed, the service lives of the aluminum-conductor steel-reinforced cables in the seriously corroded offshore industry area can be effectively prolonged, the water-resistant, rustproof and anti-corrosive functions can be realized, and the protecting requirements for the aluminum-conductor steel-reinforced cables can be ensured.

Owner:TIANJIN JINHAILI GREASE CO LTD

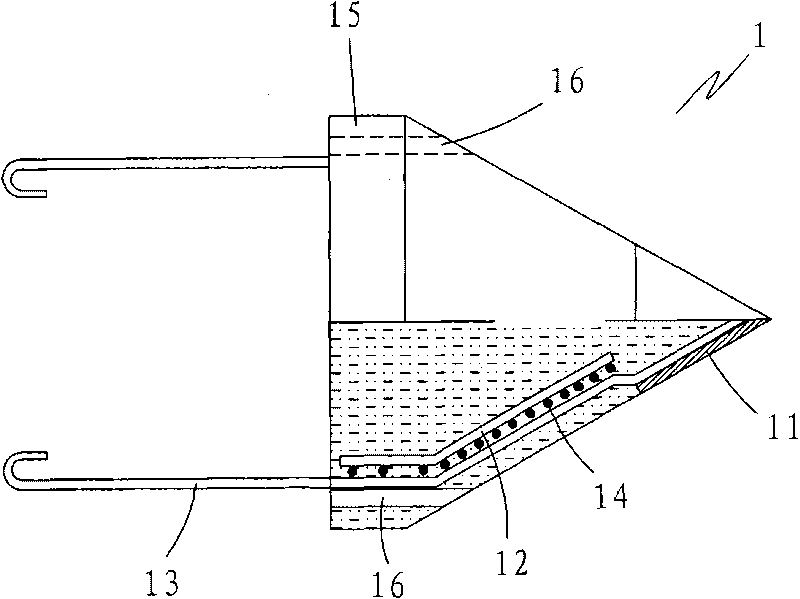

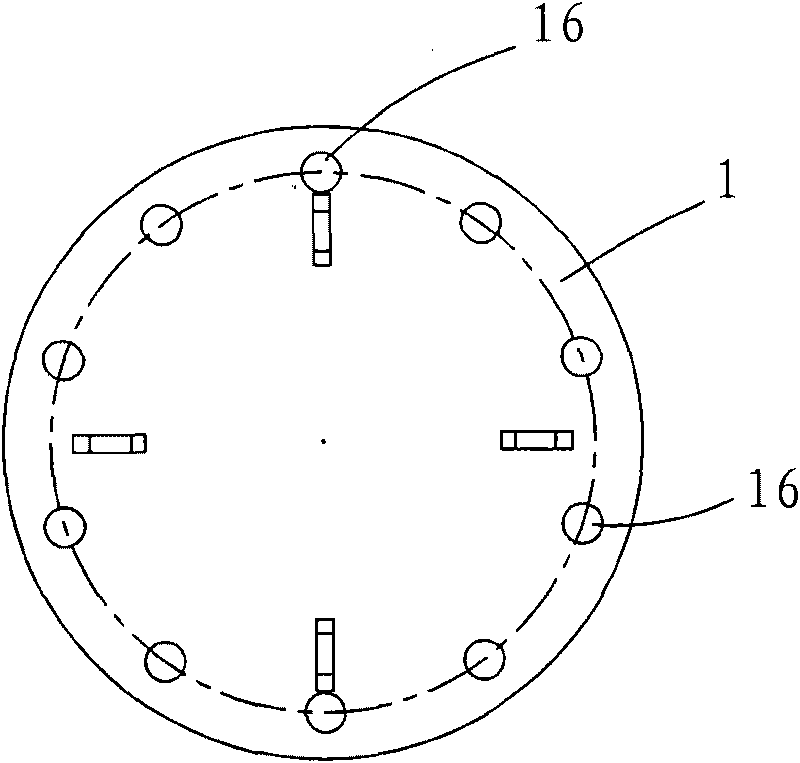

Manufacturing method of concrete head-forging pipe pile with tapered pile tip

ActiveCN101758556AAvoid connectionGuaranteed tensioning processCeramic shaping apparatusBulkheads/pilesEngineeringErosion resistance

The invention provides a manufacturing method of a concrete head-forging pipe pile with a tapered pile tip, comprising the following steps of: firstly prefabricating the tapered pile tip, then casting the tapered pile tip and a pile body into a whole, and then positioning and stretching through a stretching hole prefabricated on the tapered pile tip, and a concave hole and a butterfly-shaped hole on a purpose-made preposed stretching fixed plate in the process of casting so that the qualified concrete head-forging pipe pile with the tapered pile tip is manufactured. The manufacturing method has the advantages that the manufacturing method effectively solves the problem of integral connection of the tapered pile tip and the pipe pile and ensures the realization of a stretching technology in the production process of the pipe line. The manufactured pipe pile with the integral structure has the advantages of strong penetrating power and good integrity, can not generate the phenomenon that the tip is deviated and separated in the process of construction or pile formation, and ensures the sealing of pile ends and has the function of erosion resistance.

Owner:FUJIAN DADI CONCRETE PILE

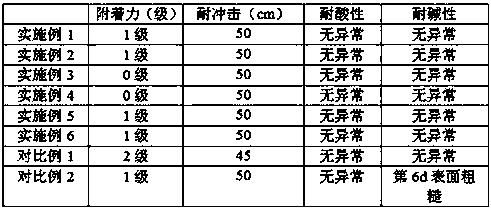

Novel waterborne epoxy resin anticorrosive coating and anticorrosive process

ActiveCN109135511AStrong oxidation abilityActivity does not affectAntifouling/underwater paintsPretreated surfacesActivated carbonEpoxy

The invention discloses novel waterborne epoxy resin anticorrosive coating. The novel waterborne epoxy resin anticorrosive coating comprises surface coating and backing coating. The surface coating comprises, by weight, 38-42 parts of waterborne epoxy resin emulsion, 15-17 parts of waterborne epoxy resin curing agents, 10-12 parts of deionized water, 8-10 parts of nanometer-sized titanium dioxide,6-8 parts of activated carbon, 2-4 parts of UV (ultraviolet) varnish, 1-2 parts of colloidal copper catalysts and 2-4 parts of No.1 antirust grease. The novel waterborne epoxy resin anticorrosive coating has the advantages that the nanometer-sized titanium dioxide is added into the surface coating, biological enzymes are added into the backing coating, accordingly, harmful substances such as formaldehyde on brushed objects can be removed, and indoor formaldehyde further can be removed; the UV varnish added in the surface coating needs to be baked by ultraviolet rays, accordingly, the nanometer-sized titanium dioxide can be conveniently photocatalyzed by the ultraviolet rays, formaldehyde removal can be accelerated, influence on the activity of the biological enzymes in the backing coatingcan be prevented, and the integral novel waterborne epoxy resin anticorrosive coating has diversified functions and is high in practicality.

Owner:ZHUHAI JELEE CHEM ENTERPRISE CO LTD

Method for producing oil paint

ActiveCN104449025AWith weak magneticImprove antistatic performanceMagnetic paintsAnti-corrosive paintsAcrylic resinAdhesive

The invention discloses a method for producing an oil paint, and relates to the field of chemical processes. The method comprises the following steps: feeding, premixing, grinding, mixing a paint, introducing oxygen, filtering and the like, namely adding materials to a twin-cylinder high-speed disperser in opening mixing during feeding; firstly adding 1 / 5 of polyurethane acrylic resin to a first cylinder to render; adding a little of conductive carbon black, chlorinated paraffin, magnetic iron powder, zeolite powder and nickel powder, adding part of polyurethane acrylic resin at an interval of 1 minute, and completely adding the residual polyurethane acrylic resin for 3-4 times; adding a mixed solution of double distilled water, butanol, an organic silicone resin fluid and an isocyanate adhesive to a second cylinder, and carrying out hydrolytic crosslinking reaction; and adding nano powder, and carrying out catalytic reaction, mixing the materials which are processed in the first cylinder and the second cylinder at the ratio, thus various defects of the oil paint can be improved; resources can be reasonably distributed; and the method is economic and applicable.

Owner:丹阳恒安化学科技研究所有限公司

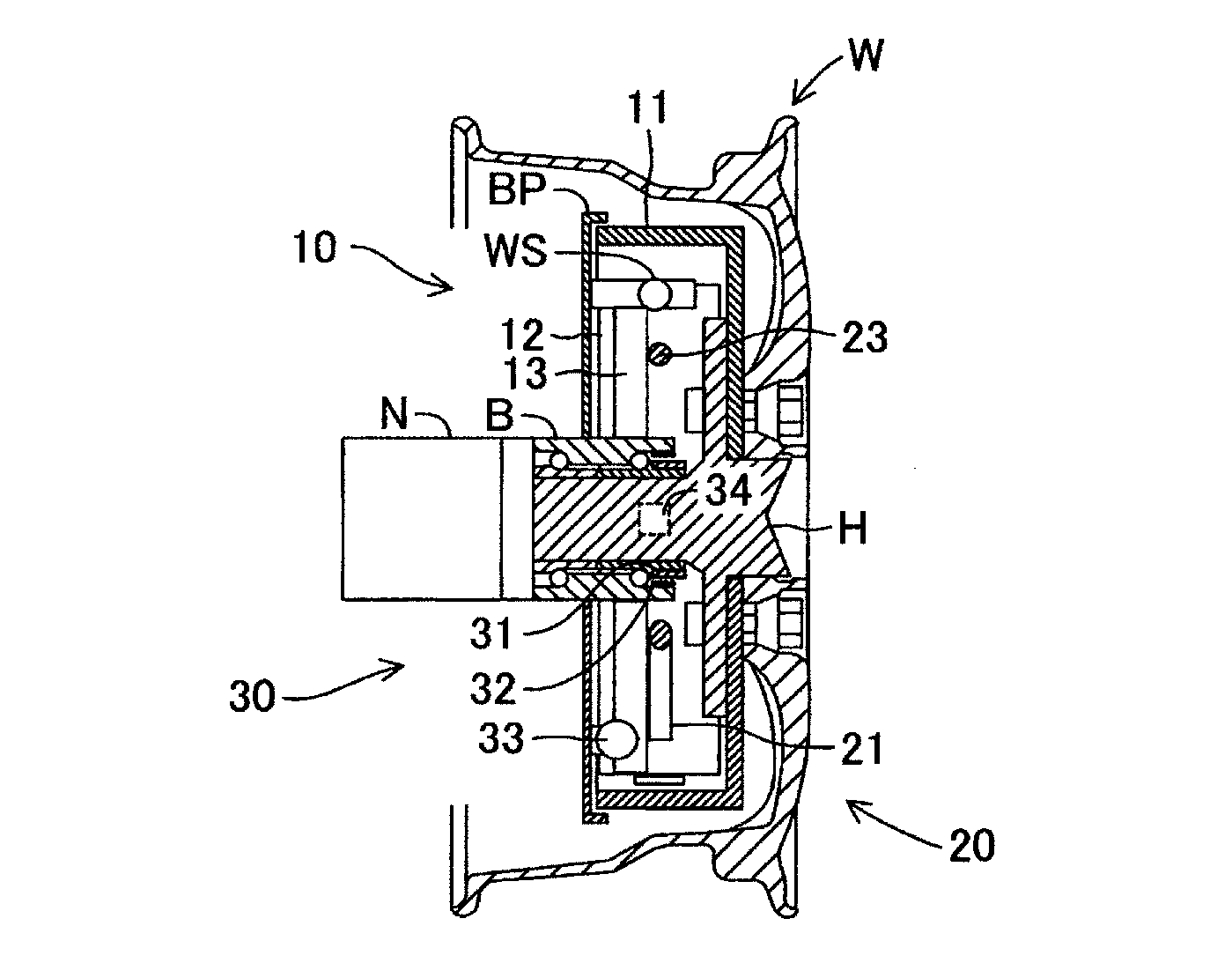

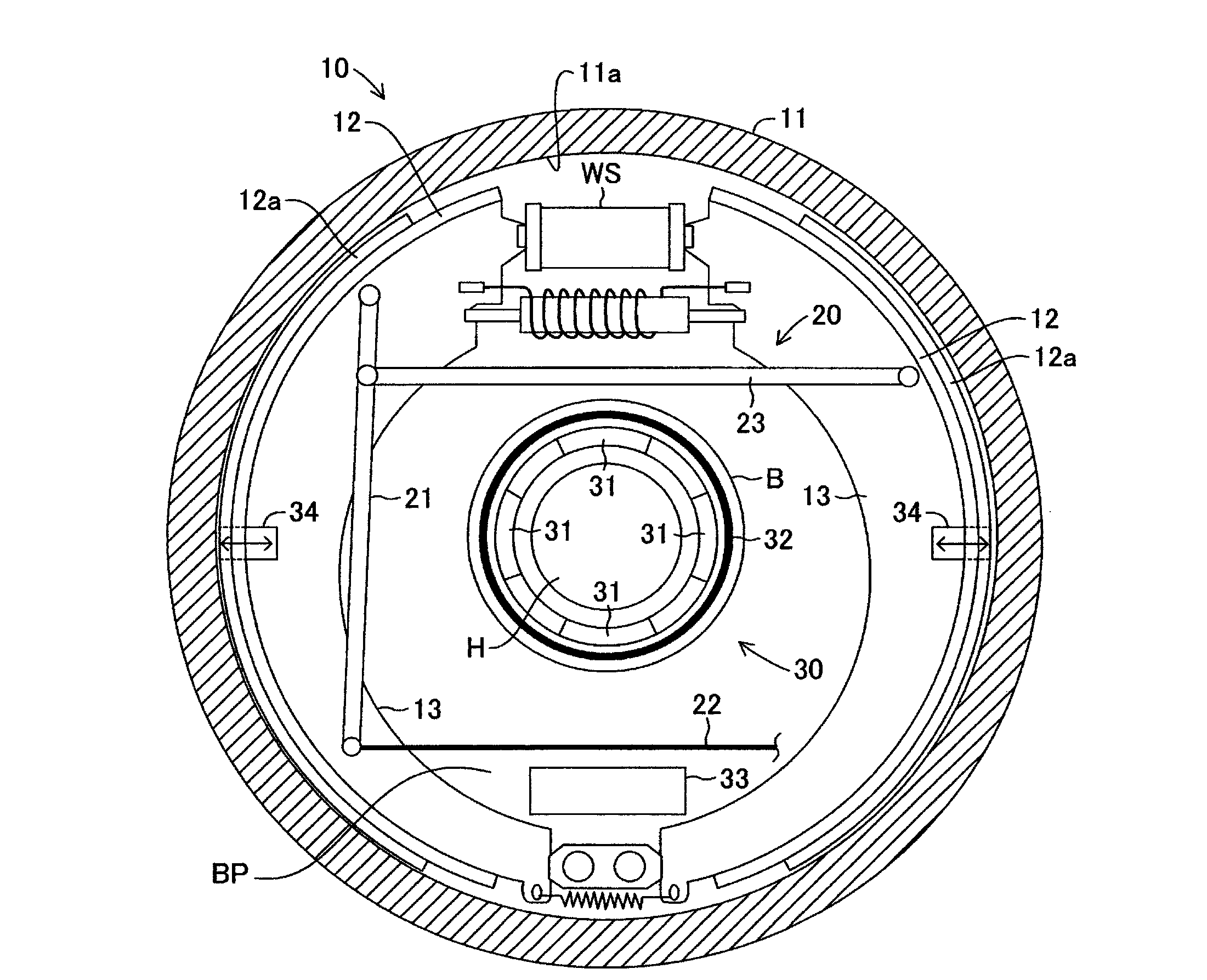

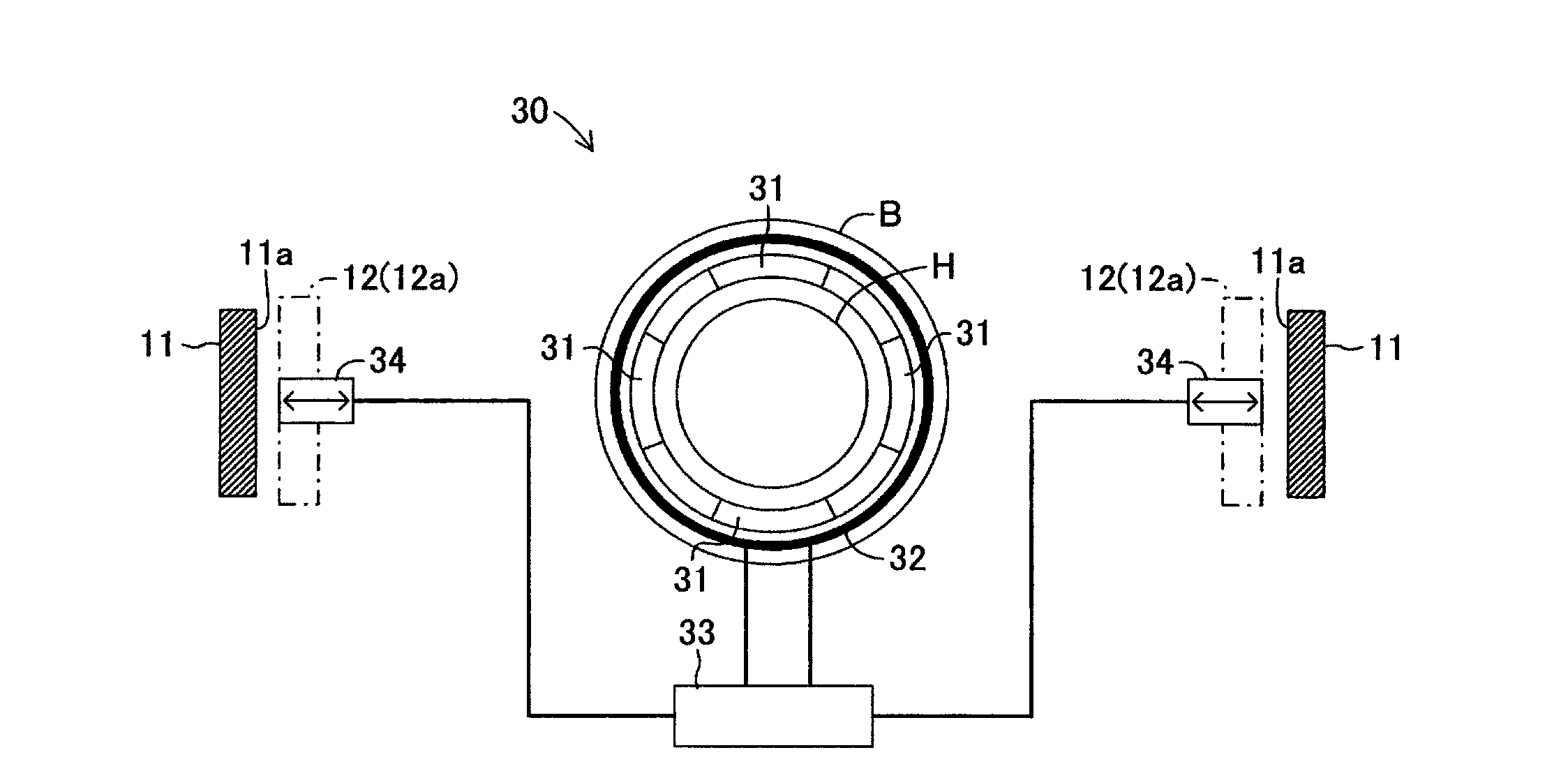

Corrosion prevention device for vehicle brake unit

InactiveCN102834637APlay the role of anti-corrosionGood electricityBraking element arrangementsAxially engaging brakesElectricityDriver/operator

Owner:TOYOTA JIDOSHA KK

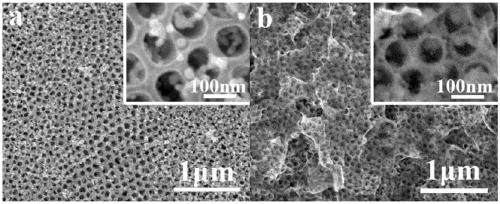

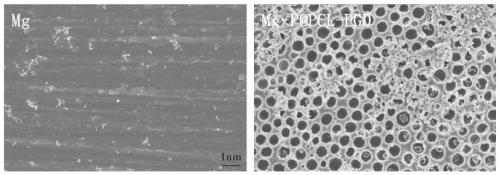

Preparation method of photocorrosion resistance titanium dioxide/cadmium selenide/graphene composite film

InactiveCN109402703AArrange neatlyAdvancedElectrolytic inorganic material coatingSurface reaction electrolytic coatingTio2 nanotubeComposite film

The invention relates to a preparation method of a photocorrosion resistance titanium dioxide / cadmium selenide / graphene composite film. The preparation method of the photocorrosion resistance titaniumdioxide / cadmium selenide / graphene composite film comprises the following steps that a TiO2 nanotube film is prepared on a titanium sheet by an anodic oxidation method according to the excellent electrical conductivity and optical performance of graphene; a titanium dioxide / cadmium selenide film is prepared by an electrochemical method; and spin-coating is carried out on the titanium dioxide / cadmium selenide film to prepare a titanium dioxide / cadmium selenide / graphene film, wherein the product is a dark red film, the film is composed of TiO2 nanotubes, the nanotubes are uniform and compact, the arrangement is neat, the pipe diameter is less than or equal to 100 nm, CdSe particles are in a nanosphere shape, and the particle diameter is less than or equal to 20 nm. The graphene film is attached to the upper part of the CdSe nanoparticles. Photocurrent of 0.2 mA / cm<2> is generated under visible light irradiation, and the attenuation speed of the electrode covered with the graphene is slow, so that the graphene plays a role in photocorrosion resistance and is used in photovoltaic products.

Owner:TAIYUAN UNIV OF TECH

Anticorrosive coating for cable bracket

InactiveCN110066572AGood film formingGood corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsSolventEmulsion

The invention discloses an anticorrosive coating for a cable bracket, and belongs to the technical field of cable brackets. The anticorrosive coating is prepared from, by weight, 40-50 parts of epoxyresin, 10-20 parts of chlorinated rubber, 0.5-2 parts of polyaniline, 1-2 parts of zinc phosphate, 1-3 parts of a styrene-acrylic emulsion, 8-12 parts of a stabilizing agent, 1-3 parts of mica powder,1-2 parts of sodium dodecyl benzene sulfonate, 0.5-1.5 parts of a silane coupling agent, 7-10 parts of a curing agent, 10-12 parts of a solvent and 3-5 parts of water. The coating has low raw material cost, excellent corrosion resistance and mechanical properties.

Owner:国网河南省电力公司邓州市供电公司

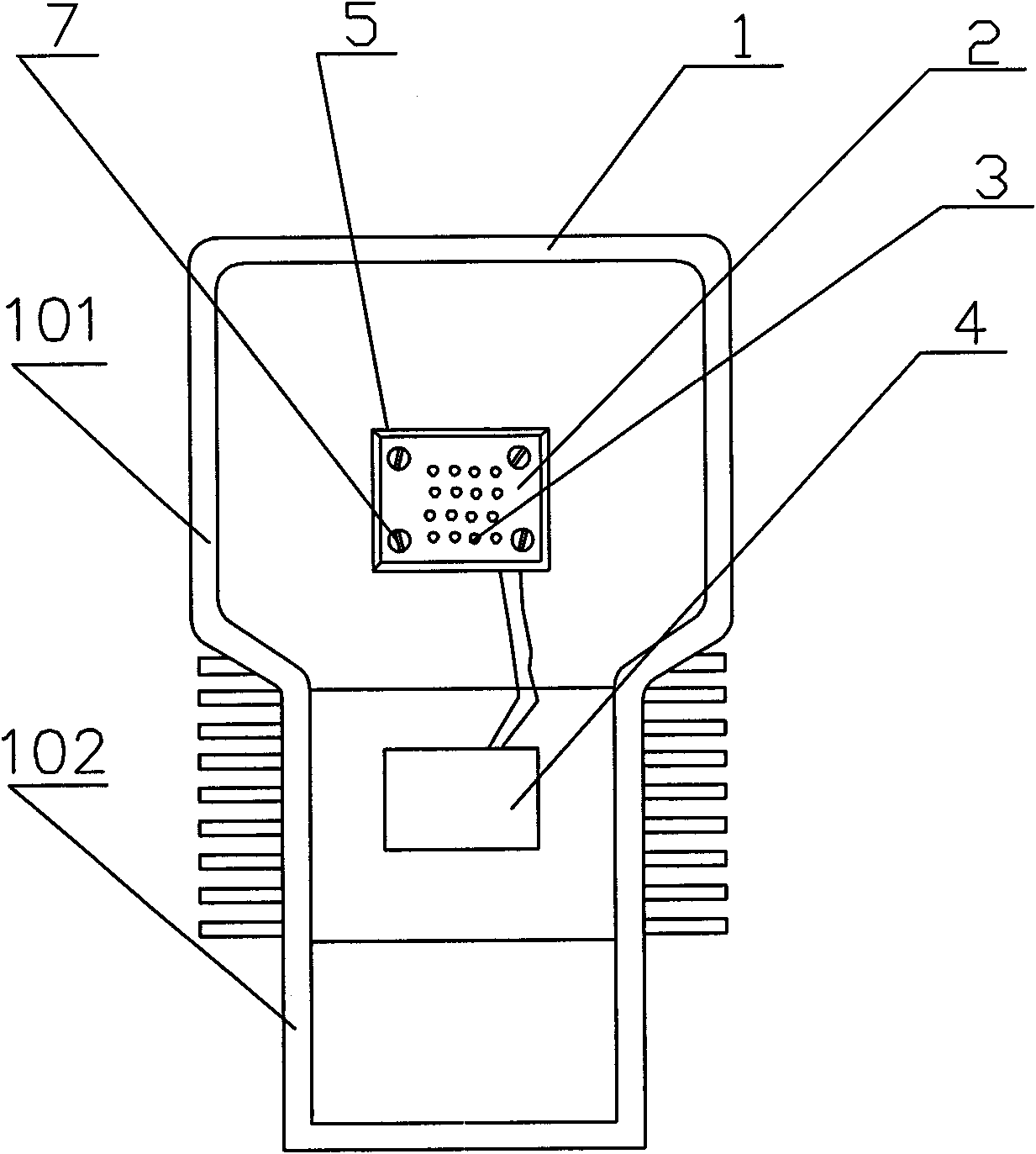

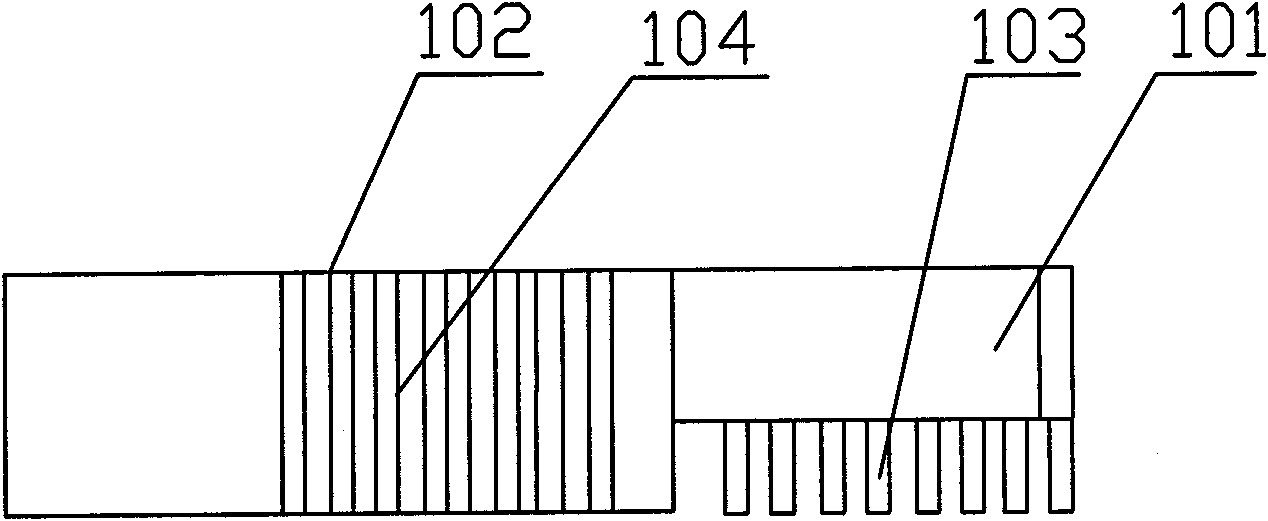

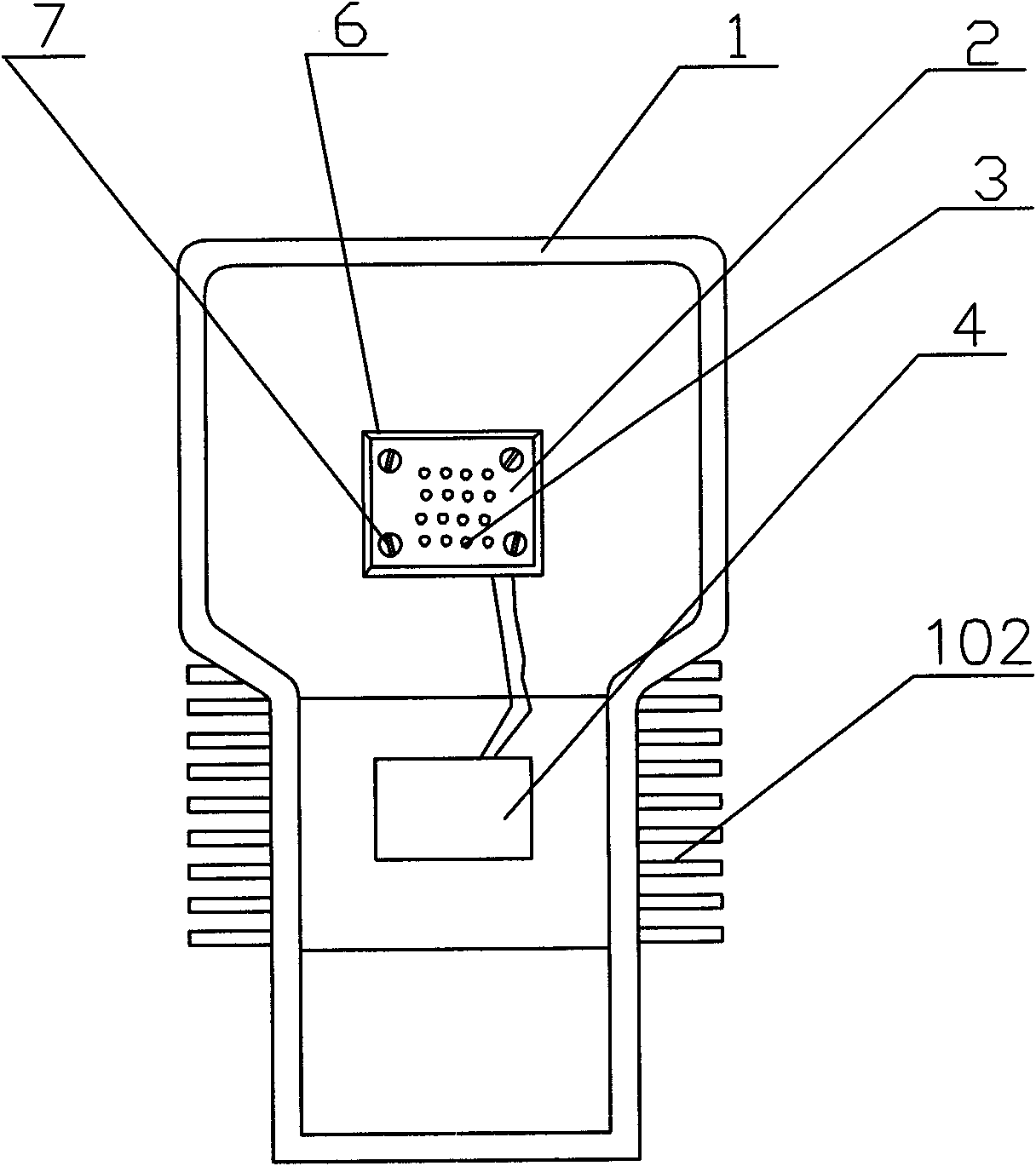

LED street lamp with high heat dissipation performance

InactiveCN101782201AGood cooling effectExtended service lifePoint-like light sourceLighting heating/cooling arrangementsHeat sinkCorrosion

The invention provides an LED street lamp with high heat dissipation performance, comprising a heat dissipation housing formed by the upper end and the lower end of an all-in-one part, LED lamps arranged in the heat dissipation housing and on a base plate and a control circuit connected with the base plate, wherein the control circuit is fixedly connected in the heat dissipation housing. The LED street lamp is characterized in that the base plate is fixedly connected with the inner wall of the heat dissipation housing; a first fin array is arranged on the rear surface of the upper end and second fin arrays are respectively arranged at the two sides of the lower end. The LED street lamp solves the problems of poor heat dissipation effect and environmental pollution of the existing LED street lamps. The fins uniformly distributed in two channels ensure the LED lamp bodies to have good heat dissipation effect and the service lives of the LED lamp bodies to be prolonged; the titanium layers coated on the fins ensure the lamp bodies to have better heat dissipation effect, have the effect of corrosion resistance and can not pollute the environment; and as the direct heat conduction structure exists between the base plate and the heat dissipation housing, the LED lamp bodies have good heat dissipation effect and the service lives of the LED lamp bodies are prolonged.

Owner:胡家培 +1

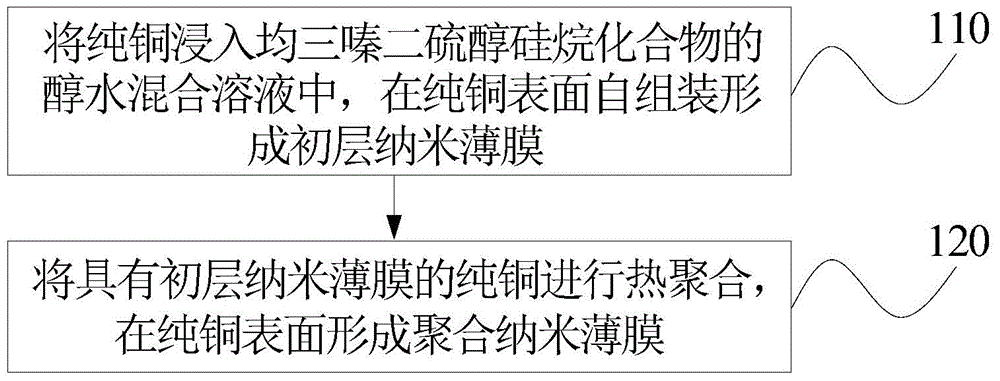

Copper metal surface anticorrosion treatment method

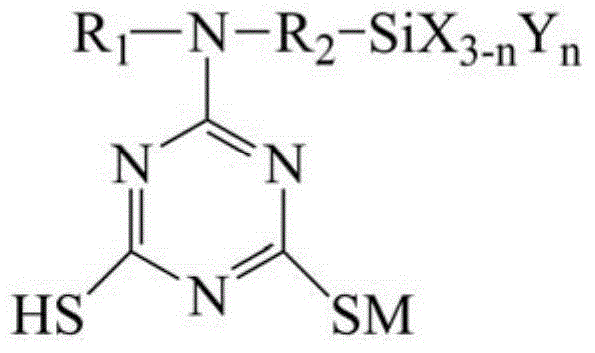

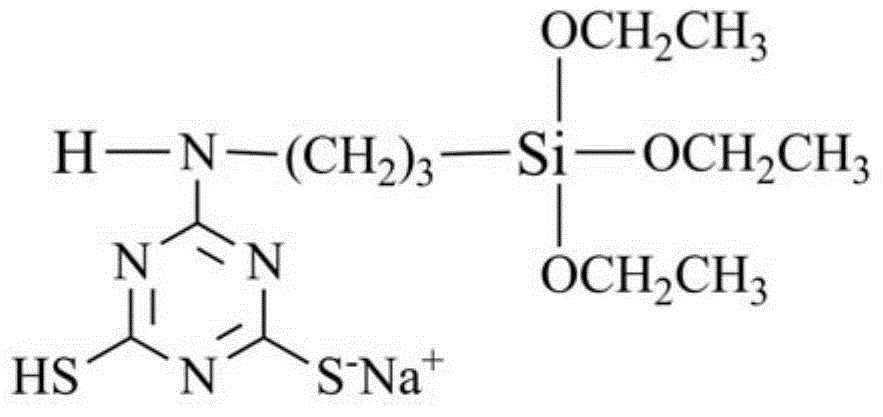

InactiveCN104630770APlay the role of anti-corrosionMetallic material coating processesCopper metalEthanedithiol

The invention discloses a copper metal surface anticorrosion treatment method. The method comprises the steps: A, immersing copper metal into an alcohol-water mixed solution of an s-triazine ethanedithiol silane compound, and forming a primary layer nano film on the surface of the copper metal in a self-assembling way; B, carrying out thermal polymerization on the copper metal with the primary layer nano film, and forming a polymerized nano film on the surface of the copper metal. The treatment method is not only suitable for the pure copper, but also is suitable for the copper alloy. The copper metal surface after being treated in the method can be prevented from being corroded and also has an active site, and the subsequent other technological treatment can be carried out. The treatment method is simple to operate; moreover, the anticorrosion effect of the copper metal surface after being treated is good.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

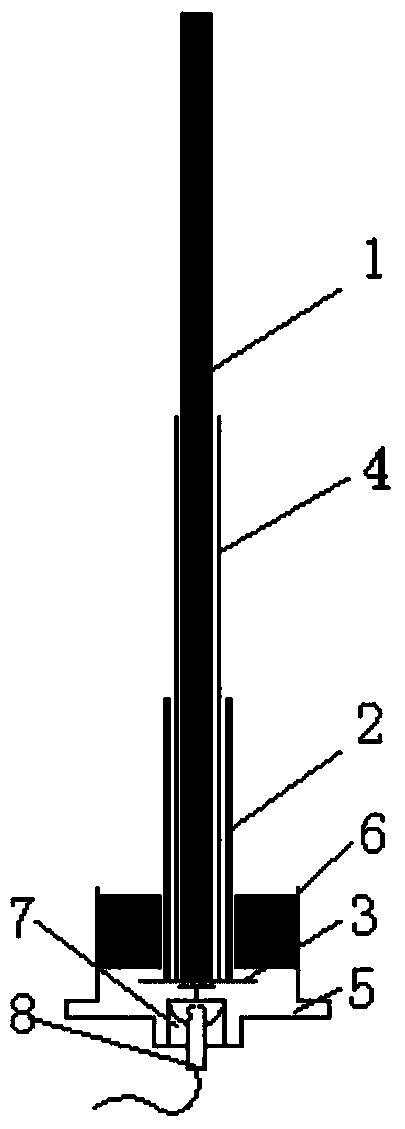

Electronic anode rod

The invention discloses an electronic anode rod. The electronic anode rod is characterized by comprising a titanium and iridium coated electronic anode, a metal pipe support body loosely sleeved with the titanium and iridium coated electronic anode, and a control circuit board positioned on the same end parts of the titanium and iridium coated electronic anode and the metal pipe support body; the metal pipe support body is connected to an electric potential control terminal of the control circuit board. Through adoption of the structure, the titanium and iridium coated electronic anode is utilized to output voltage, and a function of preventing a water heater inner container and the like from corrosion is realized through the principle of cathodic protection; cathodic protection is that a great amount of electrons are supplemented to protected metal to ensure that the whole protected metal is in a state that electrons are surplus, all points of the surface of the metal are identical in negative potential and metal atoms do not lose electrons easily to become ions to be dissolved in a solution, so that effects of preventing hydrogen from generating and corrosion resistance can be achieved.

Owner:钱伟

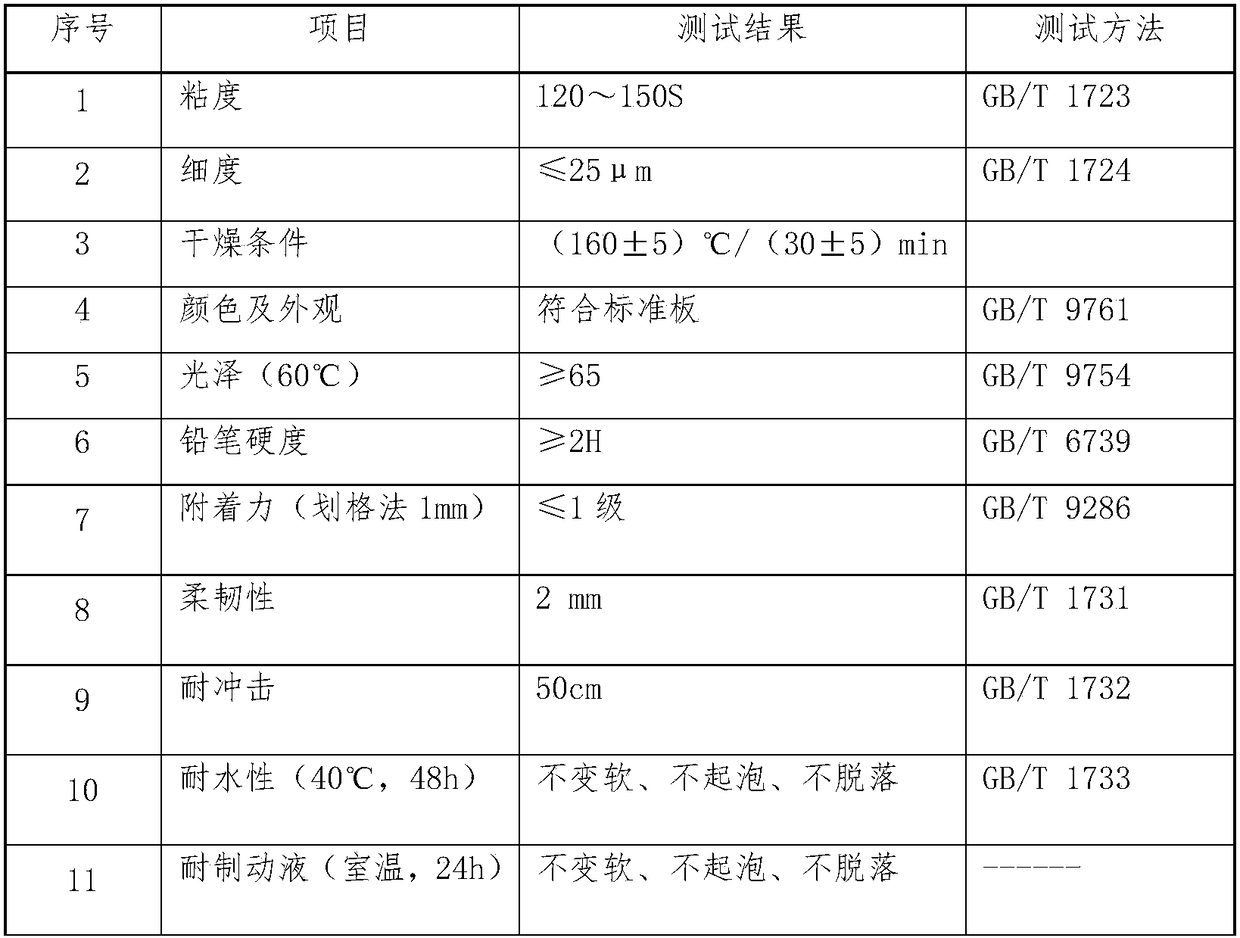

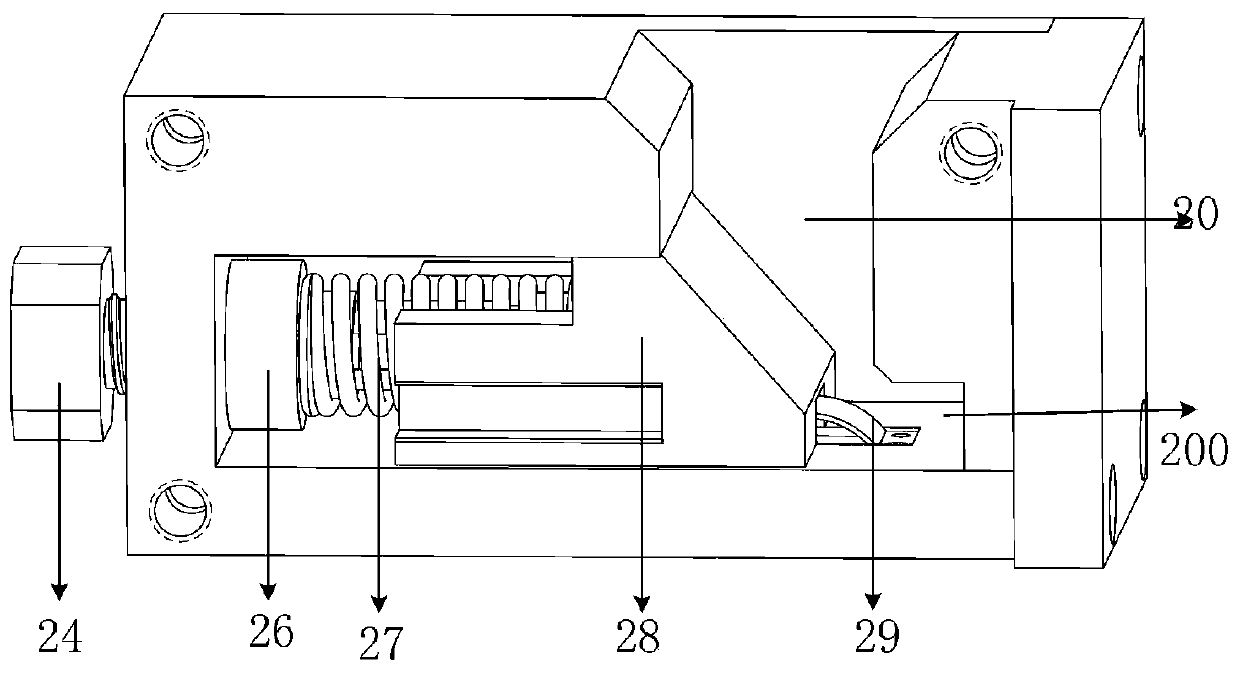

Black brake baking varnish integrating primer paint and finish paint and preparation method of black brake baking varnish

InactiveCN108250876AImprove adhesionIncrease crosslink densityAnti-corrosive paintsEpoxy resin coatingsVarnishMaterials science

The invention belongs to the technical field of surface coating of aluminum casting alloy, and relates to black brake baking varnish integrating primer paint and finish paint and a preparation methodof the black brake baking varnish. The adhesion can be improved by using preferred resin, the crosslinking density of the resin can be improved by improving the ratio, and an effect of corrosion prevention can be achieved by adding anti-corrosion filler appropriately; and it is ensured that the surface of the baking varnish is beautiful by adding a part of high-gloss resin and improving the grindfineness; the adhesion, corrosion resistance and aging resistance of the black brake baking varnish integrating the primer paint and the finish paint meet the product requirements, and the black brakebaking varnish has a beautiful appearance and a certain decorative property.

Owner:CHINA SPECIAL TYPE FLIER RES INST

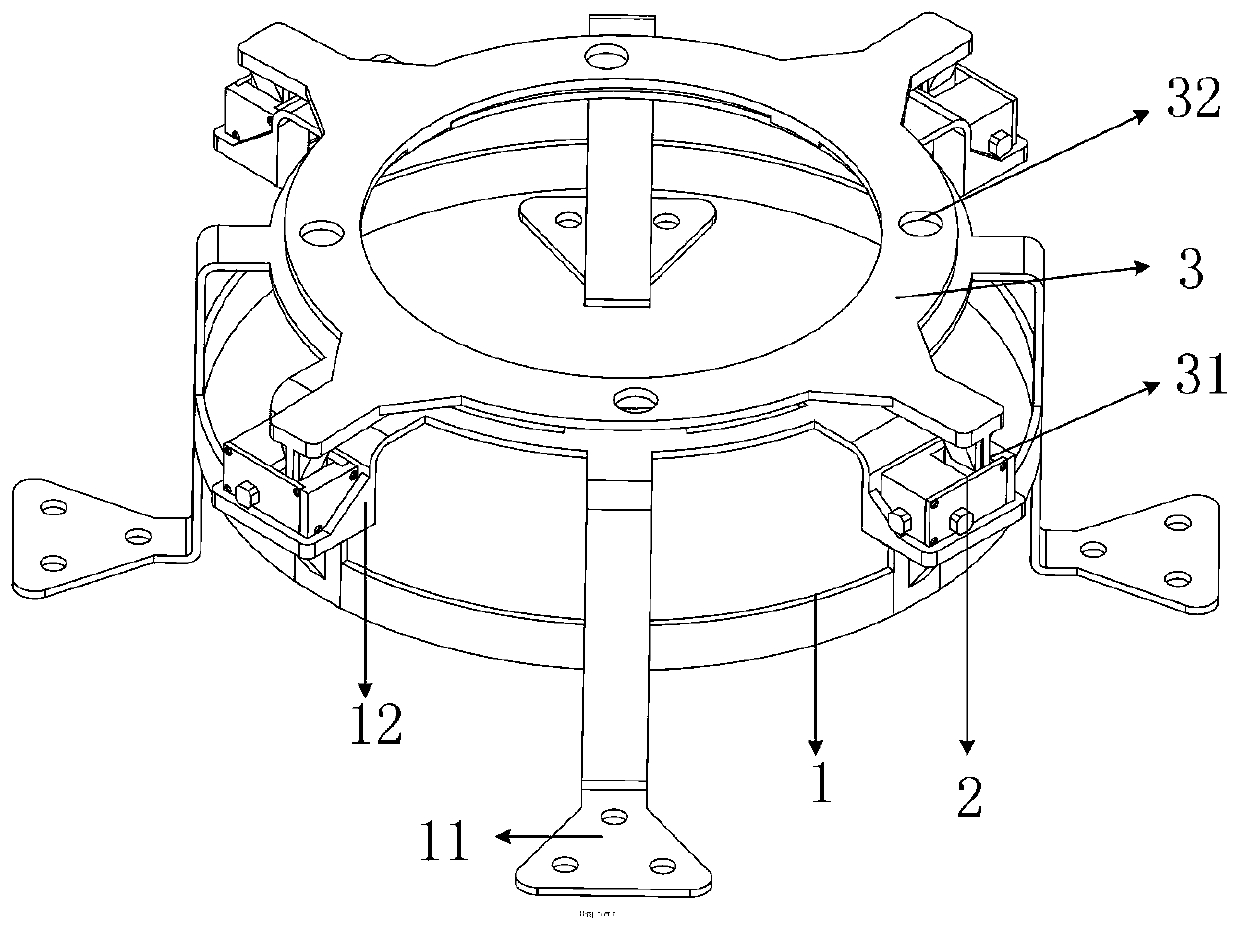

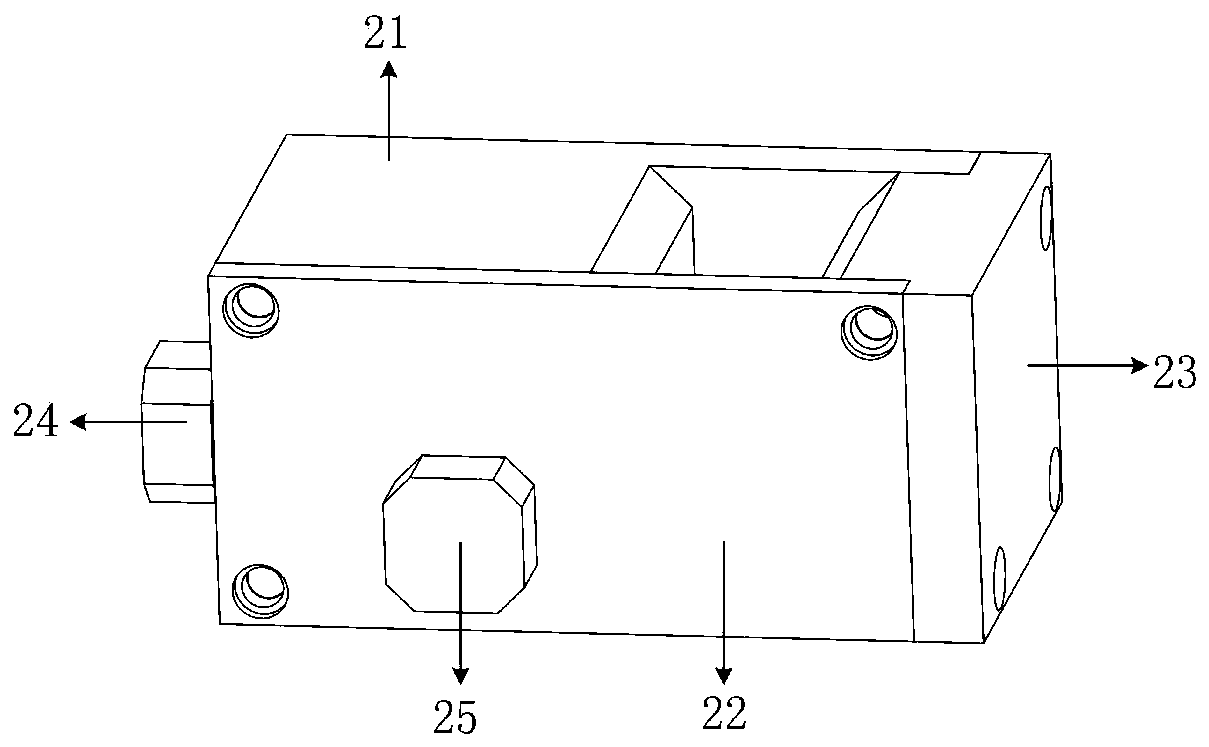

Connection device for mounting and dismounting wheel hub cover

ActiveCN110667303AReduce volumeCompact structureWheel protectionStructural engineeringMechanical engineering

Owner:YANSHAN UNIV

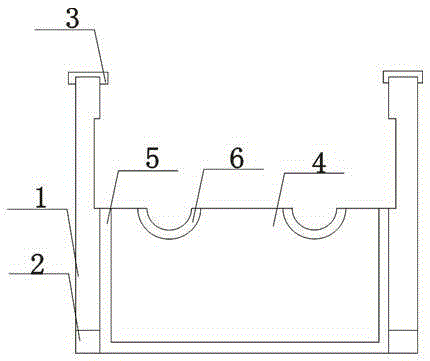

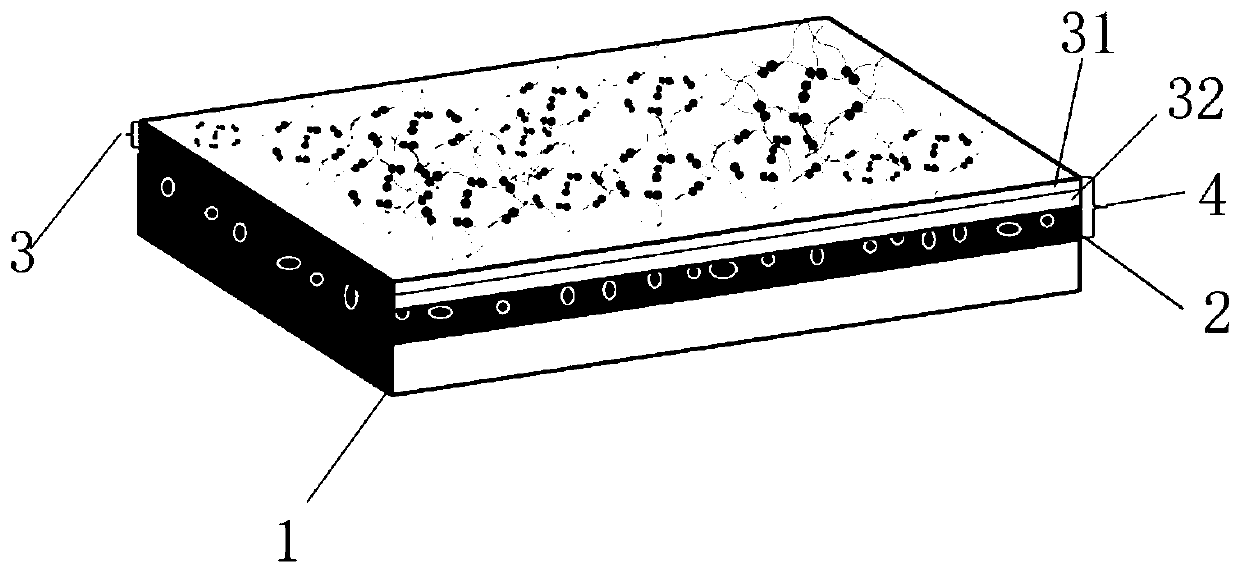

Municipal denoising isolation belt

InactiveCN106677098AOverall stabilityIncrease green areaNoise reduction constructionRoadway safety arrangementsSoil horizonTraffic noise

The invention discloses a municipal denoising isolation belt. The municipal denoising isolation belt comprises uprights, wherein the portions, close to the bottoms, of the uprights are of cavity structures; corrosion-resistant material filling layers are arranged in the cavities; illuminating apparatuses are mounted at the tops of the uprights; the illuminating apparatuses are controlled by a master control platform; the number of the uprights is two; a sound absorbing column is mounted between the two uprights; the sound absorbing column is of a concave structure; two side surfaces of the sound absorbing column are connected with the uprights in a sealed manner; the bottom of the sound absorbing column is connected with the ground surface in a seamless manner; a base is mounted in the sound absorbing column; the height of the base is consistent with that of the sound absorbing column; the interior of the base is filled with a nutritious soil layer; the height of the nutritious soil layer is consistent with that of the base; planting grooves are formed in the upper surface of the base; and the number of the planting grooves is at least two. The municipal denoising isolation belt is advantaged in that the municipal denoising isolation belt is integrally stable and can also absorb heat and adsorb smoke dusts and noises; the green area can be increased; the landscape effect is improved; traffic noises of the two sides of highways and surrounding buildings can be reduced; a corrosion-resistant effect can be achieved; and an illuminating function is also achieved.

Owner:华蓥市双河小学

High-speed train aluminum alloy supporting groove and preparation method thereof

InactiveCN113444938AIncreased strain hardening rateHigh strengthUltimate tensile strengthCorrosion resistant

The invention provides a high-speed train aluminum alloy supporting groove aluminum alloy and a preparation method thereof, and mainly relates to the field of aluminum alloys. The method comprises the following steps: providing an aluminum alloy which comprises the following components in percentage by weight: 5.0-7.5wt% of Zn, 2.0-3.5wt% of Mg, 1.0-2.5 wt% of Ag, 0.3- 0.6wt% of Sc, 0.6-0.8 wt% of Zr, less than 0.02 wt% of impurity elements and the balance of Al; The high-speed train aluminum alloy supporting groove aluminum alloy has the beneficial effects that on the premise that the mechanical strength of the aluminum alloy is guaranteed, the corrosion resistance is good, and the maintenance cost of a high-speed train is greatly reduced.

Owner:SHANDONG NANSHAN ALUMINUM

Corrosion-resistant conductive rubber key and preparation method thereof

InactiveCN111900008AGuaranteed logo stabilityHas hardnessElectric switchesKey pressingPolymer science

The invention discloses a corrosion-resistant conductive rubber key and a preparation method thereof, and relates to the technical field of rubber products. Technical key points are that: the key comprises a base and a key block, the side, away from the base, of the key block protrudes to form an identification character, at least two layers of easy-to-tear pieces are arranged on the side, away from the base, of the key block and located on the periphery of the identification character, each easy-to-tear piece comprises an aluminum layer away from the side of the base and an anti-corrosion sealing layer close to the side of the base, and the key has the advantages of abrasion resistance.

Owner:厦门胜结工贸有限公司

Self-repairing composite coating, application of self-repairing composite coating, anticorrosion material and preparation method of anticorrosion material

ActiveCN110142190AActive Repair PreparationProactive Repair UsabilityAnti-corrosive paintsSpecial surfacesBiocompatibility TestingWater layer

The invention provides a self-repairing composite coating, application of the self-repairing composite coating, an anticorrosion material and a preparation method of the anticorrosion material. The self-repairing composite coating comprises a hydrophobic layer and a hydrophilic layer, wherein the hydrophobic layer and the hydrophilic layer make contact with each other. The hydrophobic layer comprises hydrophobic matter. The hydrophilic layer comprises a self-repairing layer. The self-repairing layer comprises hydrophilic matter A. the hydrophilic matter A comprises at least one type of dynamiccovalent bonds. Compared with the prior art, the self-repairing composite coating, application of the self-repairing composite coating, the anticorrosion material and the preparation method of the anticorrosion material have the advantages that the self-repairing composite coating can be applied to the field of corrosion resistance, do not allow liquid to permeate, and can automatic repair the defects of the coating in the preparation process and the using process, and then the anticorrosion effect can be effectively achieved; and furthermore, according to the self-repairing composite coating, the situation that a substrate is corroded because liquid enters the composite coating and makes contact with the substrate is avoided, the defects of the coating can be automatically repaired in the preparation process and the using process, and the self-repairing composite coating has the excellent biocompatibility.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

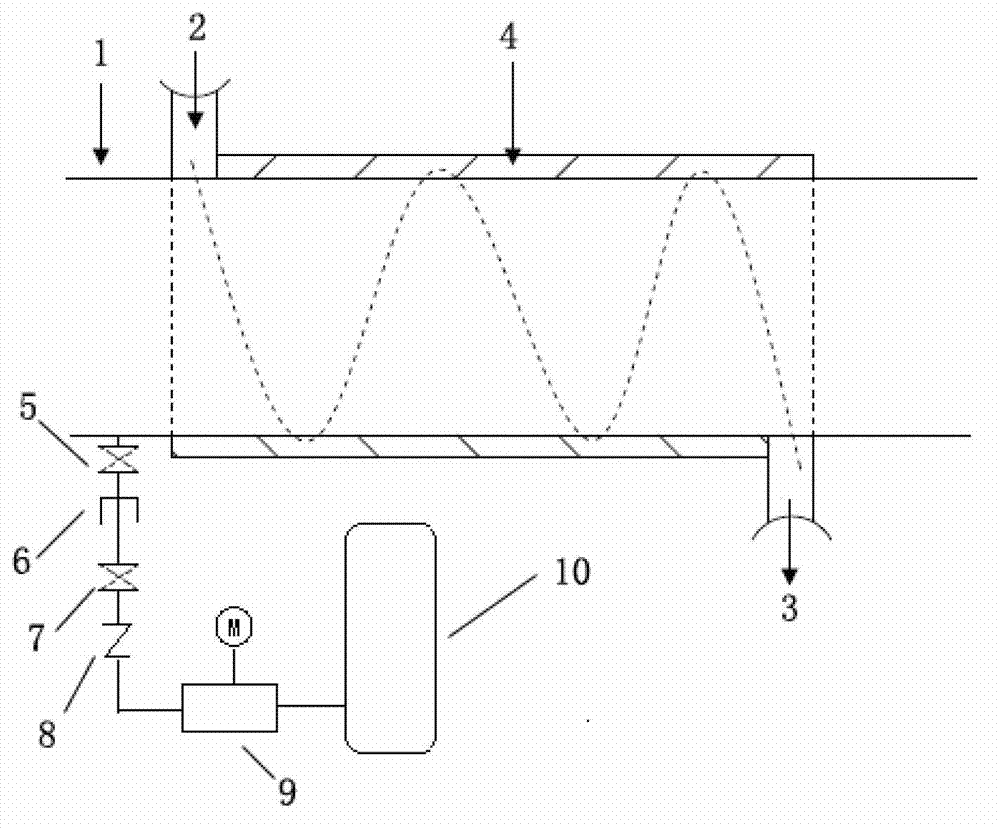

Corrosion control method and device for online film formation of pipeline of oil refining and chemical device

ActiveCN102873003AIsolated contactPlay the role of anti-corrosionPretreated surfacesCoatingsPetroleumSafe operation

The invention relates to a corrosion control method and a device for online film formation of a pipeline of an oil refining and chemical device. The method comprises the following steps of: at the pipeline upstream needing the corrosion control, injecting a film forming matter to the pipeline from a drain valve of the pipeline; and heating the pipeline needing the corrosion control to 200-500 DEG. C, and keeping the temperature for 1-240 hours; and generating a coke film on the inner surface of the pipeline needing the corrosion control. The invention also provides the corrosion control device used in the method, which comprises injecting equipment, a heating casing and heating equipment; the heating casing is provided with a heating medium inlet and a heating medium outlet, and can be spirally wound on the outer surface of a petroleum hydrocarbon device or the pipeline; and the heating device is used for heating the heating medium. The coke film generated by the method is smooth and compact in the flow boundary layer of the inner surface of the pipeline, has stable chemical property, and can isolate the contact between the matters in the pipeline and the inner surface of the pipeline to realize the corrosion control action and ensure the long-period safe operation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

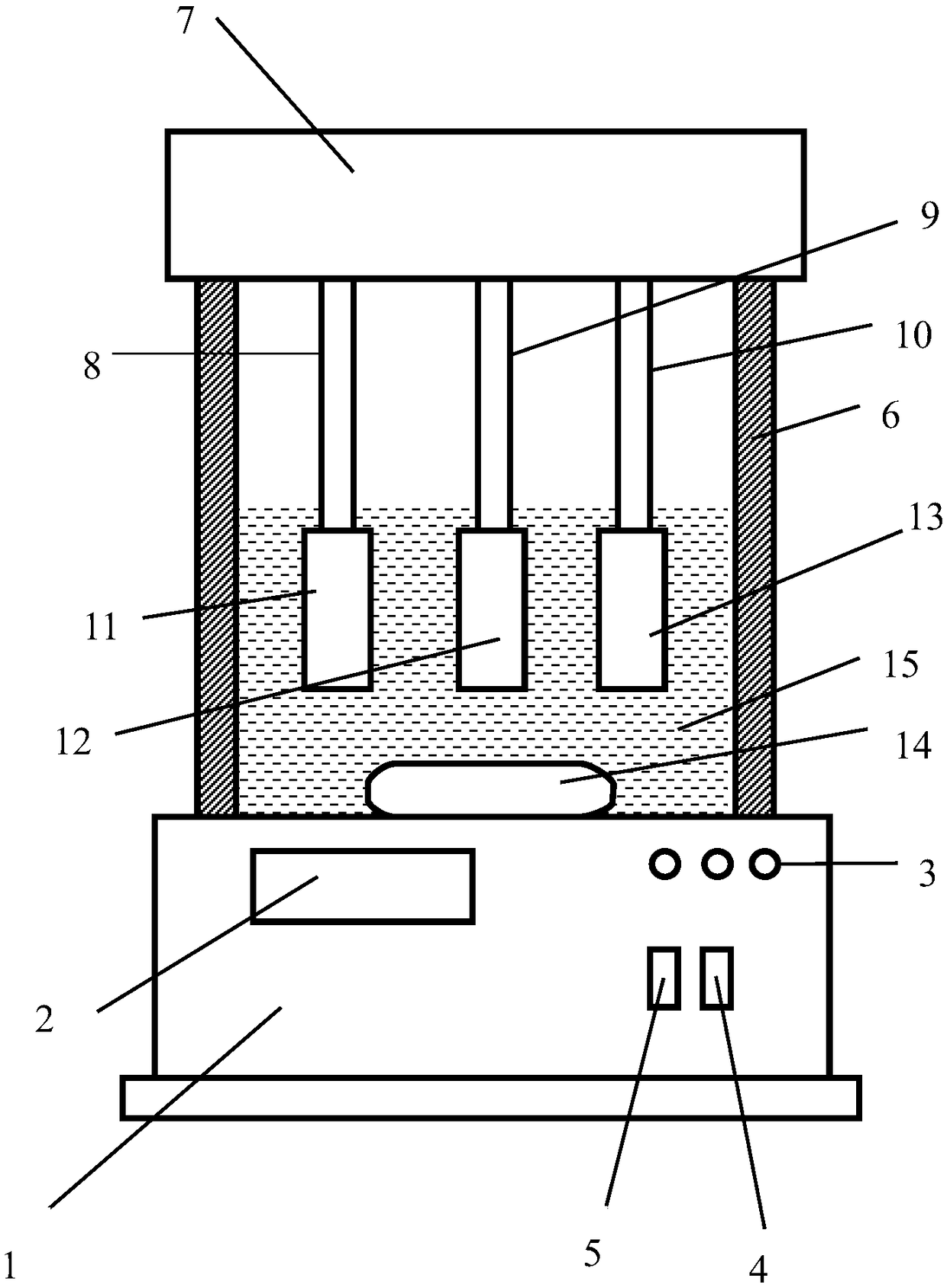

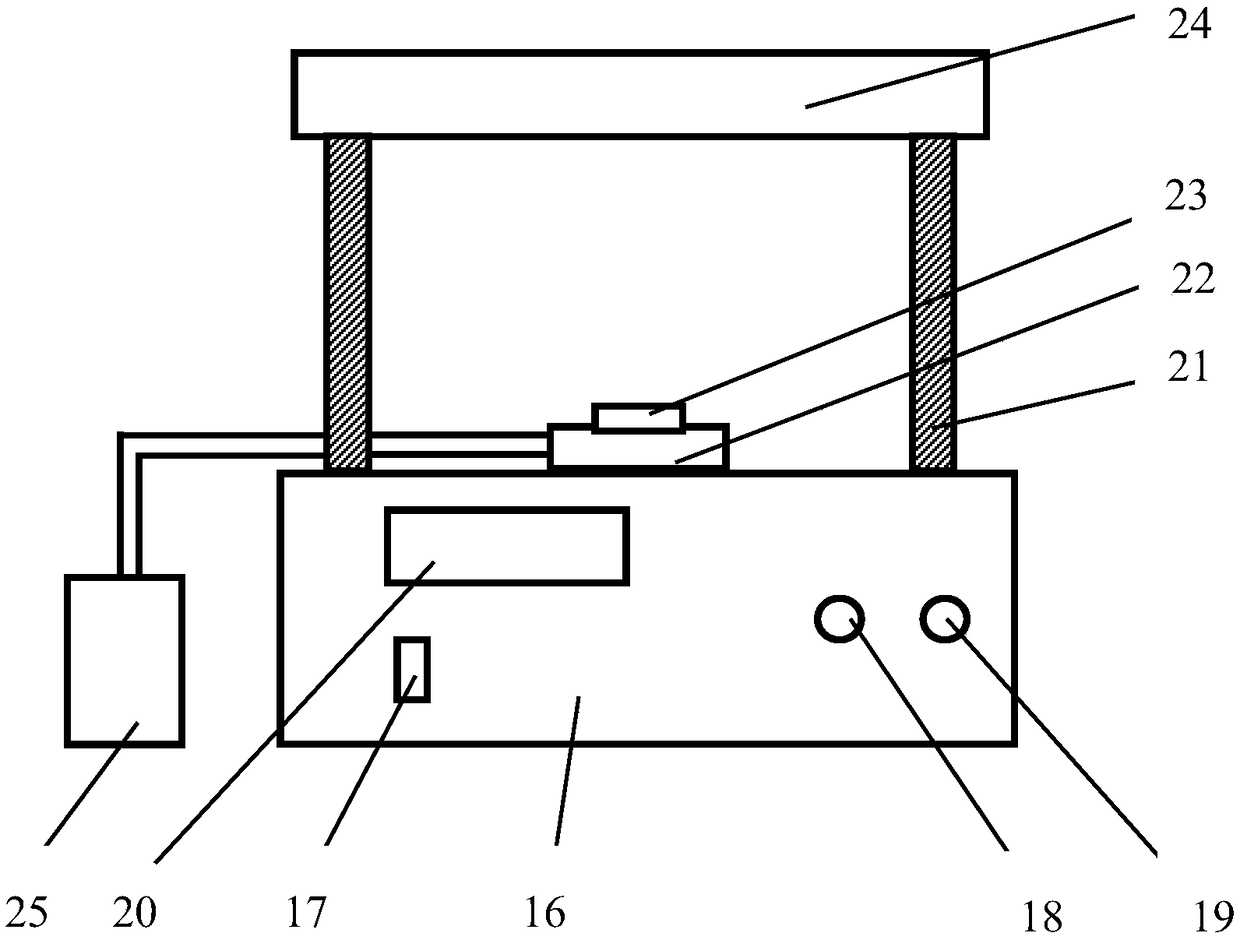

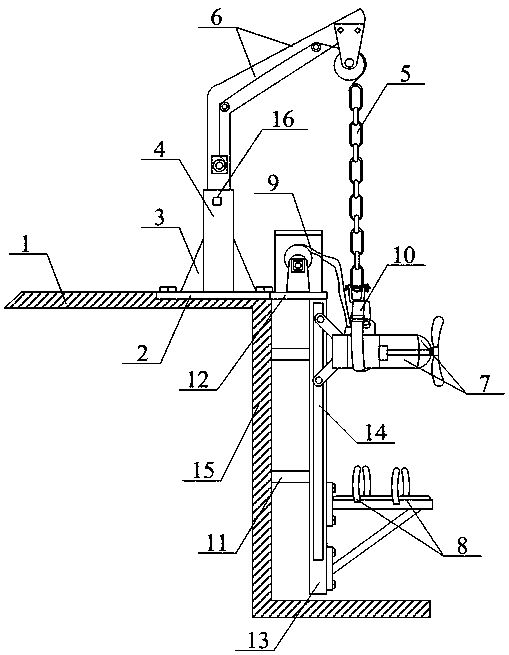

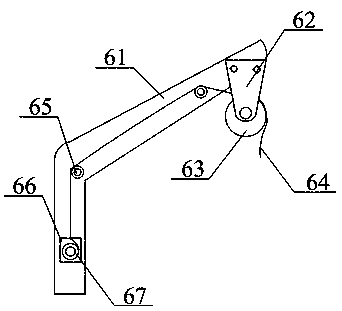

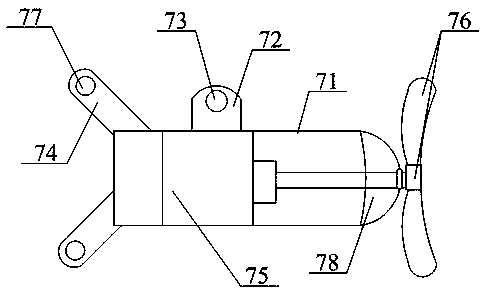

Comprehensive mixing treatment equipment for sludge settling tank

ActiveCN108751366AConducive to decentralizationMeet the mixing needsSedimentation separationWater/sewage treatment by flocculation/precipitationImpellerSludge

The invention provides comprehensive mixing treatment equipment for a sludge settling tank. The comprehensive mixing treatment equipment comprises a formation surface, an embedded steel plate, a hanger bracket, a hanger supporting pillar, a stainless steel lifting chain, an electric traction lifting bracket device, a conveniently-fixed stirrer structure, a stirring fixed limiting seat structure, acable retracting box structure, a falling prevention buckling structure, cross stay bars, a connecting plate, a supporting guide rod, a sliding chute, a sludge settling pond wall and a control switch, wherein the embedded steel plate is in bolted connection with the right-side position of the upper surface of the foundation surface. According to the comprehensive mixing treatment equipment provided by the invention, by arrangement of a hand-drive block, a pulling rope, a guide roller and a winding motor, the stirrer is beneficially released, and the stirring requirements on the sludge settling ponds with different depths can be met; by arrangement of a driving motor and a stirring impeller, sludge in the sludge settling pond is favorably stirred and a stirring effect is realized; a falling prevention strap is arranged to beneficially realize a secondary protecting effect on a submersible stirrer enclosure and the stirring impeller and enhance the fall prevention function.

Owner:徐文峰

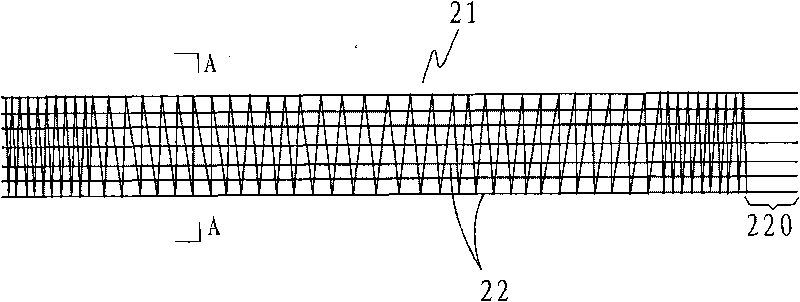

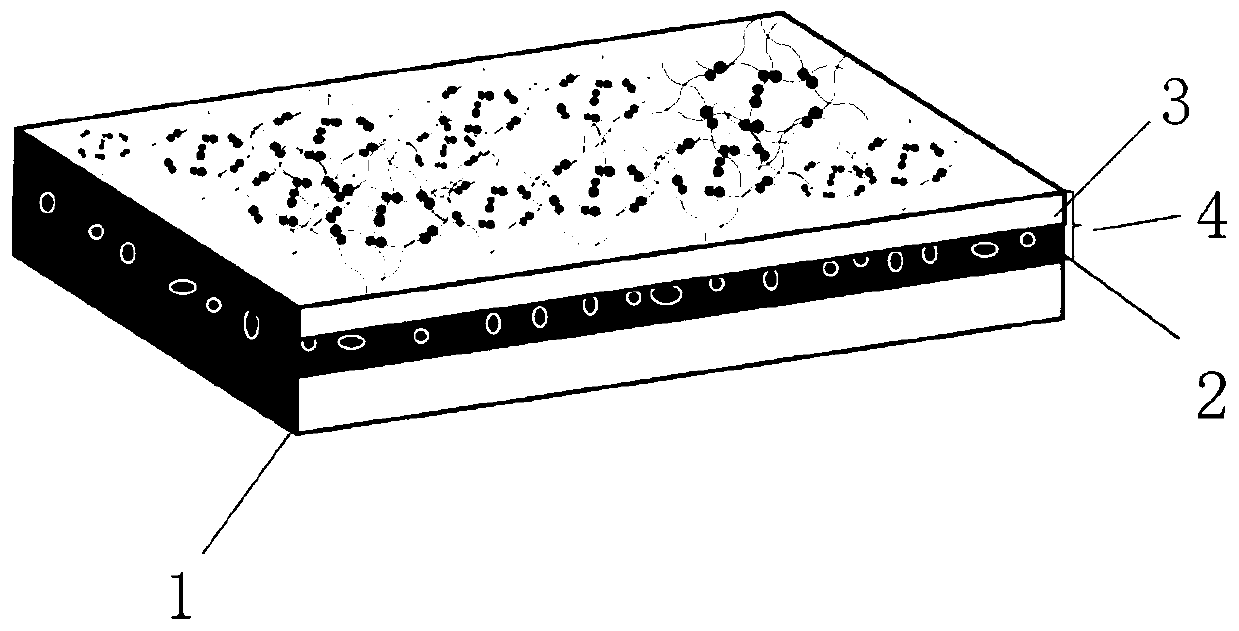

All-dielectric self-supporting optical fiber cable jacket electrical erosion resistance coating material and preparation method thereof

ActiveCN103589337AEasy to prepare componentsGuaranteed hydrolysisElectrically-conductive paintsElectrical resistance and conductanceOperability

The present invention relates to the technical field of novel coating preparation, particularly to an all-dielectric self-supporting optical fiber cable jacket electrical erosion resistance coating material and a preparation method thereof. The coating material comprises a main component organosilicon resin and an auxiliary component carbon black, wherein the amount of the carbon is 0.5-2.5% of the mass of the organosilicon resin precursor, and the carbon black is provided for adjusting coating resistance. According to the present invention, the main component of the coating material is the silicon resin, the auxiliary component is the carbon black, the silicon resin has excellent insulating property, water repellency, high temperature resistance and low temperature resistance, and the carbon black can be provided for adjusting the resistance value of the silicon resin to the required range (volume resistivity 104-107 omega / m) and avoiding dry strip arc generation on the surface of the ADSS optical fiber cable so as to provide a electrical erosion resistance effect; and the preparation method is simple, and the coating has strong operability.

Owner:STATE GRID CORP OF CHINA +1

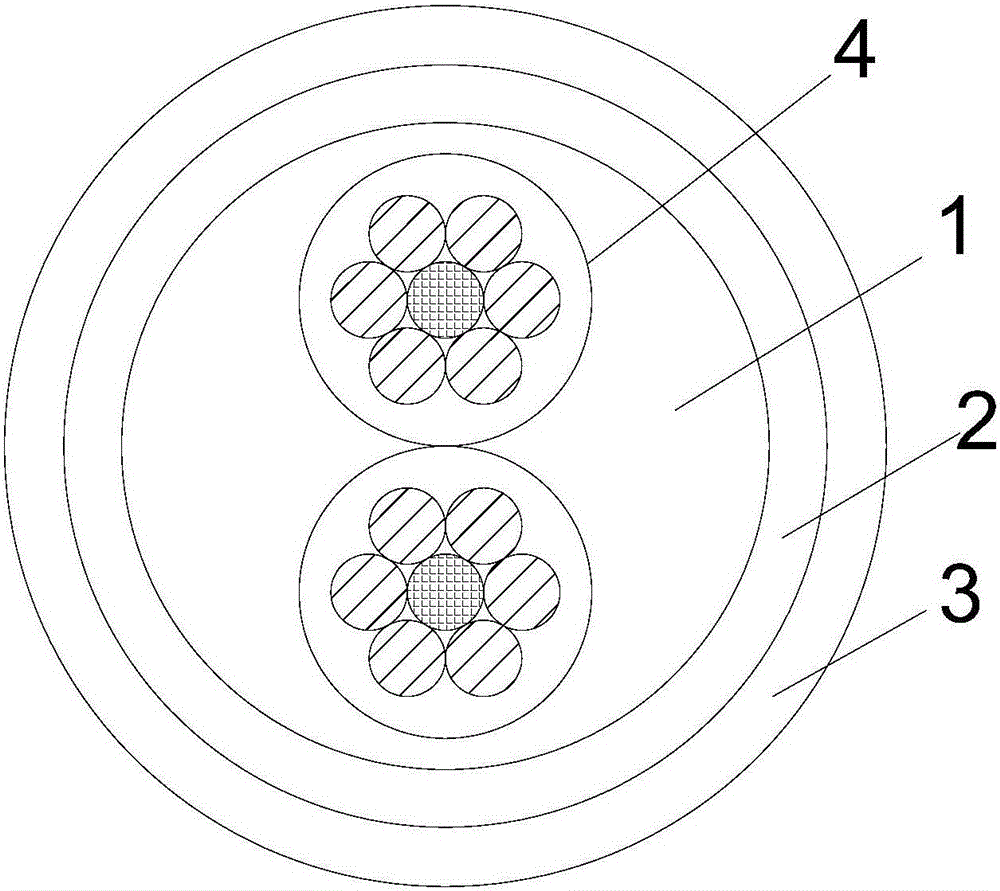

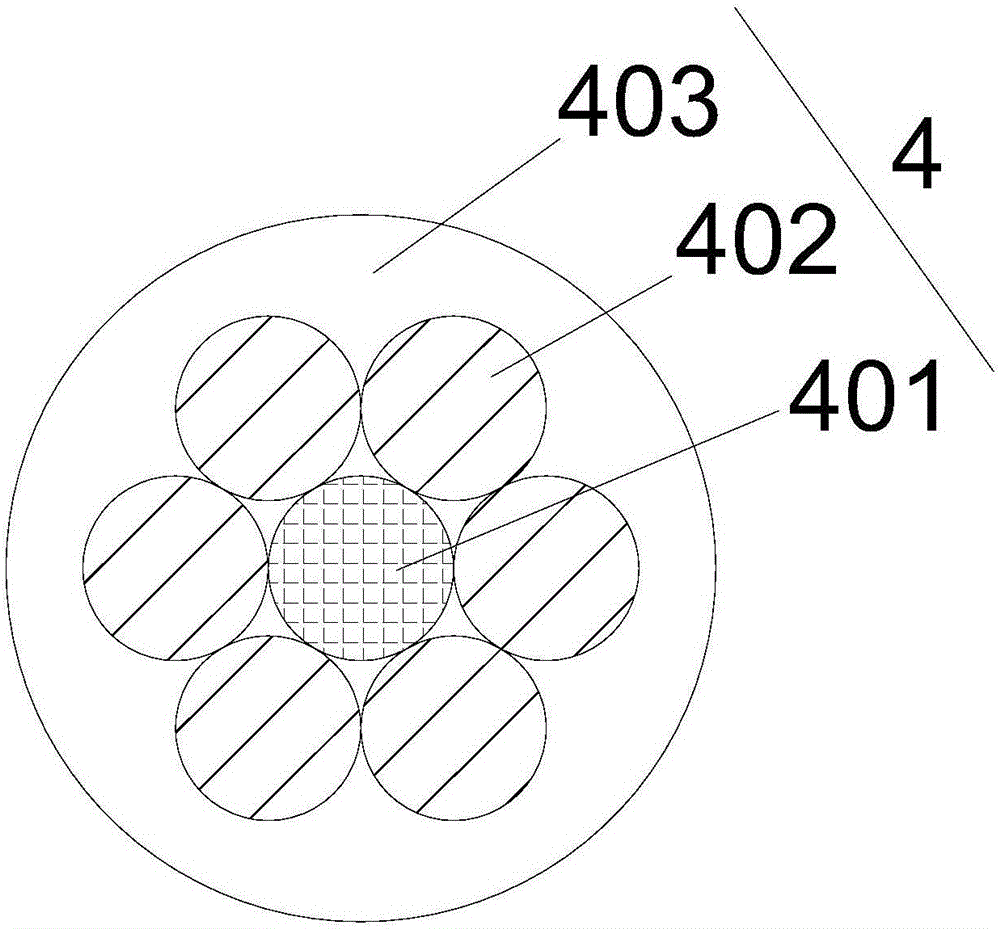

High-performance dual-core photovoltaic cable resistant to tensile and compression

PendingCN105810297AImprove tensile propertiesAvoid Galvanic CorrosionPlastic/resin/waxes insulatorsClimate change adaptationInsulation layerElectrical conductor

The invention discloses a high-performance dual-core photovoltaic cable resistant to tensile and compression. The high-performance dual-core photovoltaic cable is characterized by comprising a cable core, an armor layer and a sheath layer, wherein the cable core comprises two wire cores, a lining layer is arranged at the periphery of the cable core, the armor layer wraps the periphery of the lining layer, the sheath layer is extruded at the periphery of the armor layer, each wire core comprises a reinforcement core, a conductor layer and an insulation layer, the conductor layer wraps the periphery of the reinforcement core, and the insulation layer is extruded at the periphery of the conductor layer. The high-performance dual-core photovoltaic cable has the characteristics of good high- and low-temperature resistant performance, high insulation performance, high tensile and compression resistance and light weight.

Owner:安徽龙庵电缆集团有限公司

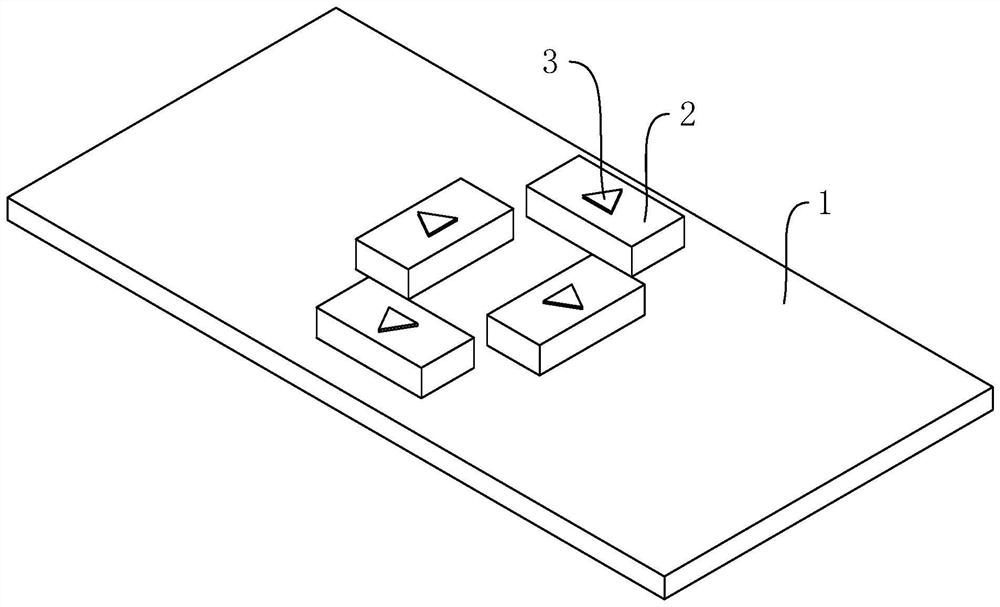

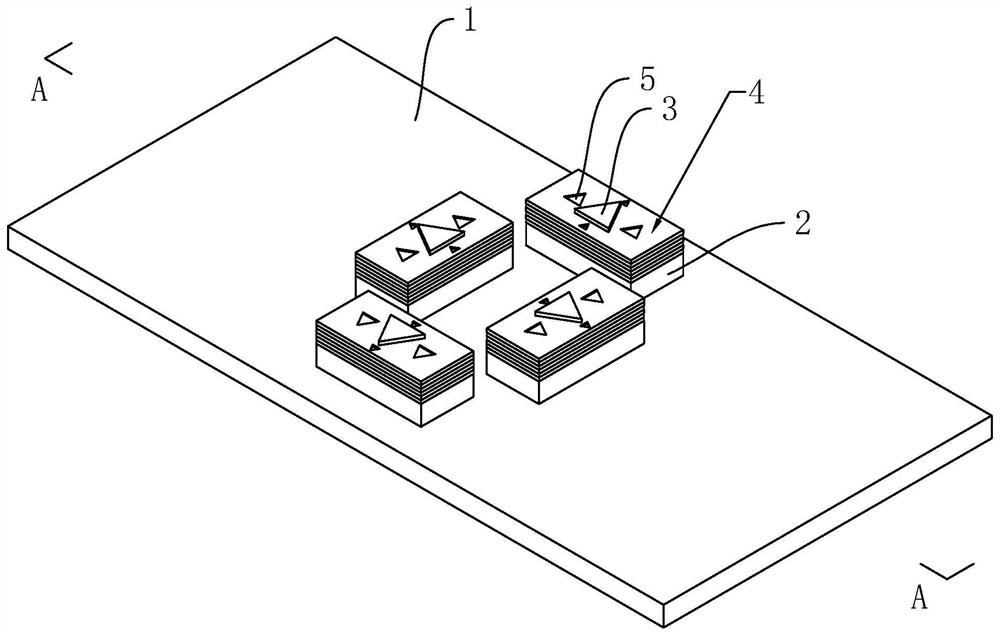

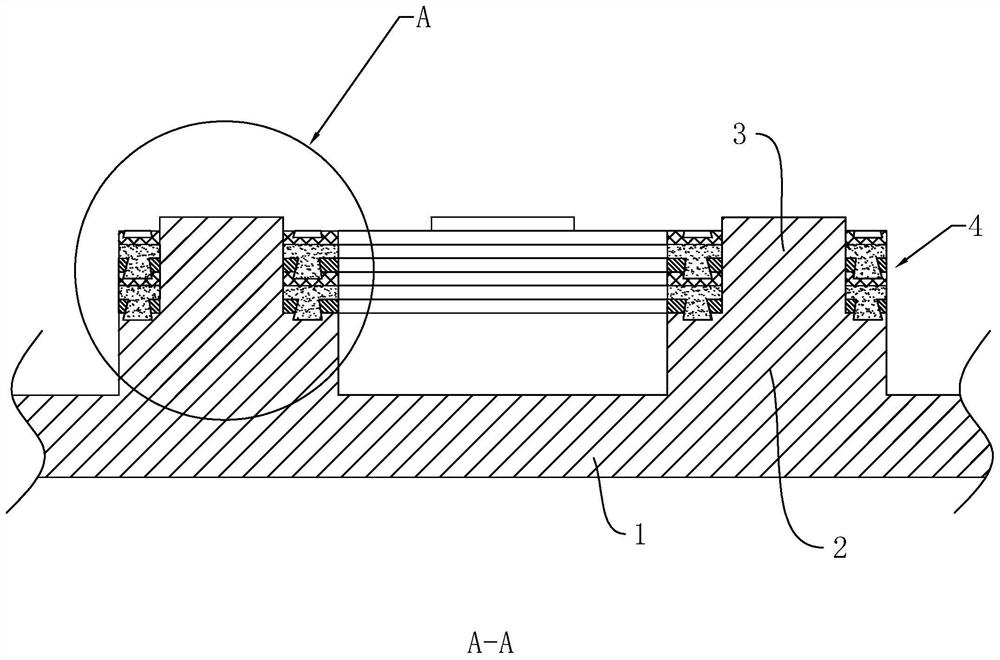

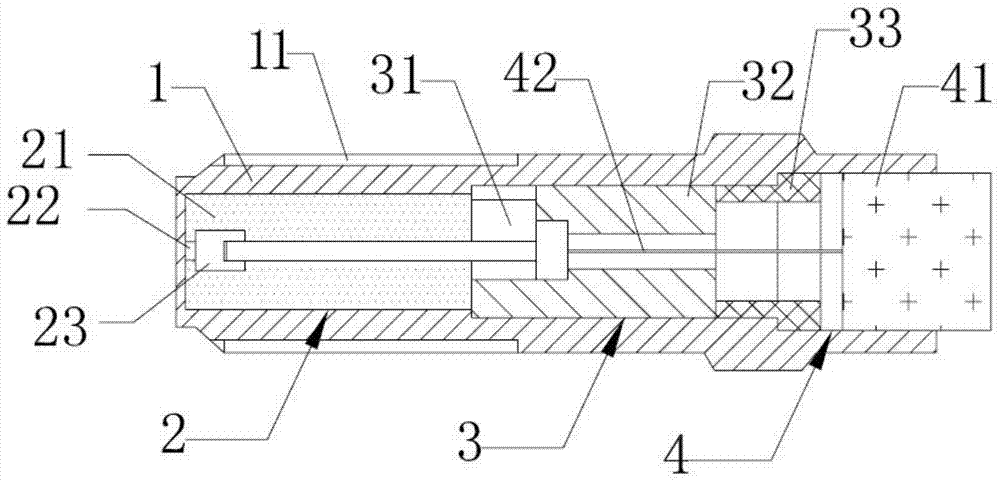

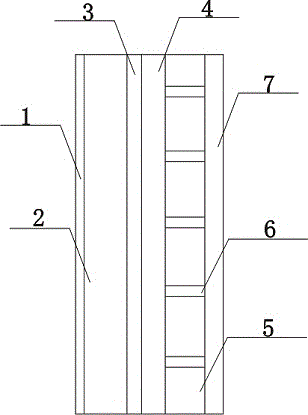

Rotating speed sensor

InactiveCN104849486ACompact and reasonable structureEasy to assemble and disassembleSpeed/acceleration/shock instrument detailsDevices using electric/magnetic meansHall elementBoron

The invention discloses a rotating speed sensor, comprising a housing (1); a segment of external threads (11) are arranged on the outside of a left end of the housing (1); a left stepped hole (2), a middle stepped hole (3) and a right stepped hole (4) are axially arranged in the housing (1); an epoxy resin sleeve (21) is embedded in the left stepped hole (2); the epoxy resin sleeve (21) is internally provided with a Hall element (22) and a neodymium boron iron magnetic steel (23); the middle stepped hole (3) is internally provided with a printed circuit board combination (31), a sleeve (32) and a mounting sleeve (33); the right stepped hole (4) is also internally provided with an aviation plug (41). The rotating speed sensor is provided with the external threads, and the housing is internally provided with the epoxy resin sleeve, allowing a relevant circuit board to be arranged in a relatively sealed space; the housing is prepared by stainless steel materials, and possesses the functions of dust prevention and corrosion protection; the rotating speed sensor has a reasonable and compact structure, is convenient to assemble and disassemble, and can prolong the service life of a product.

Owner:重庆斯凯力科技有限公司

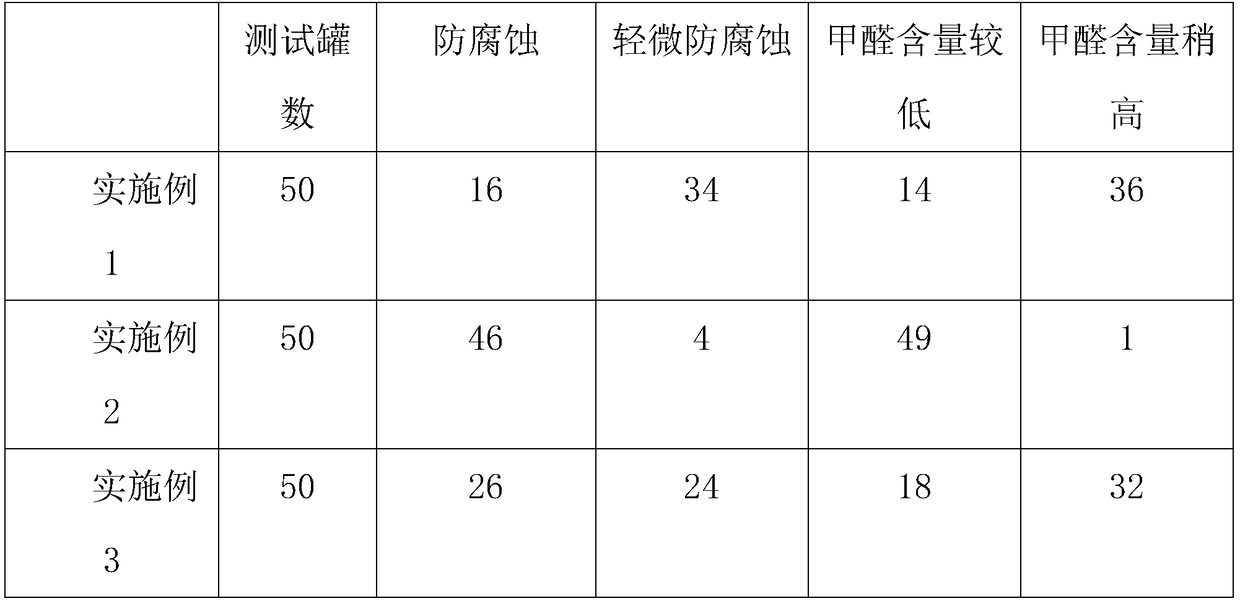

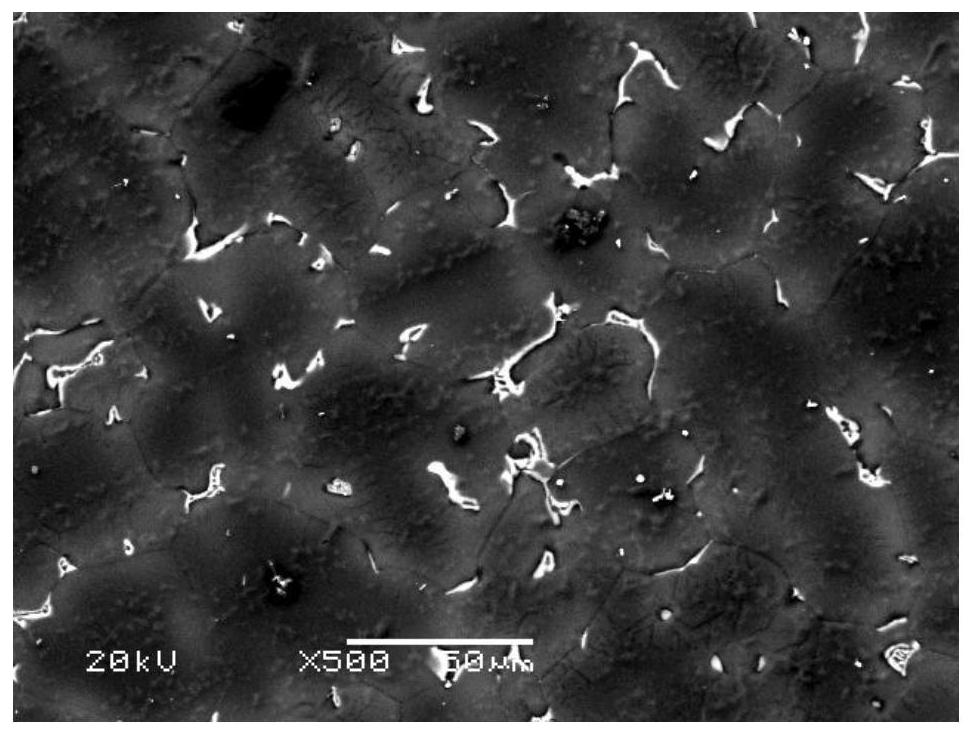

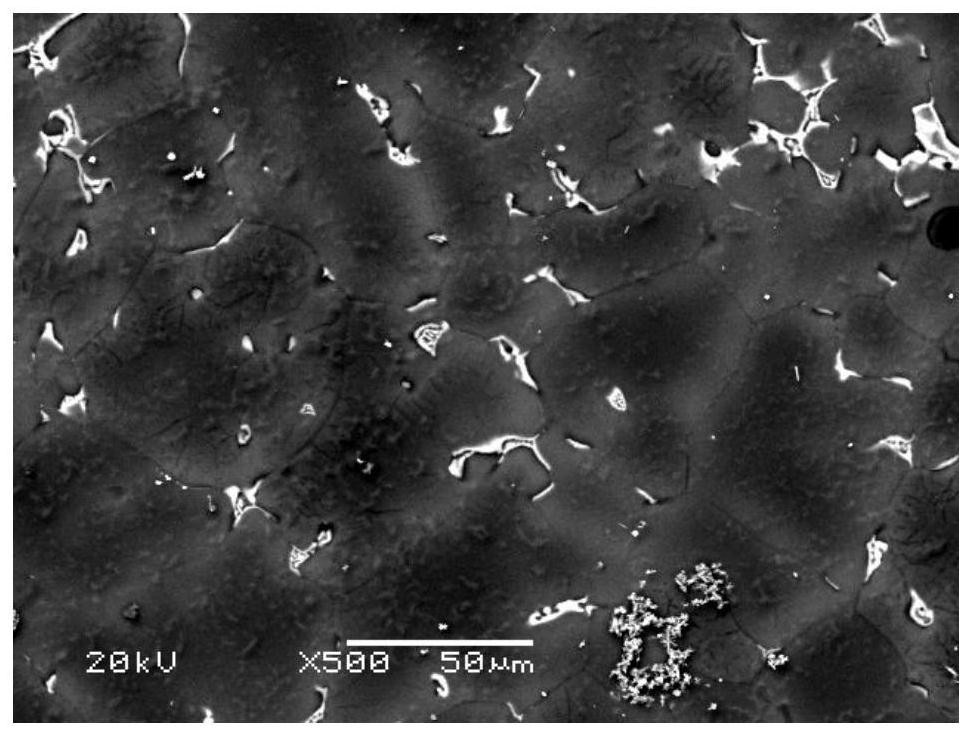

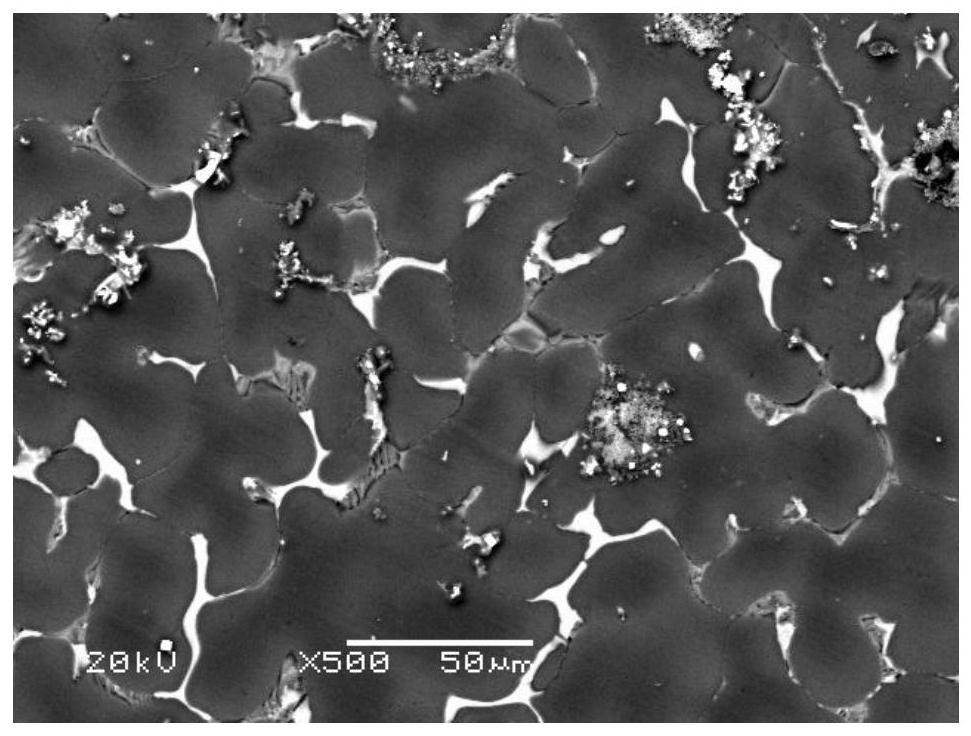

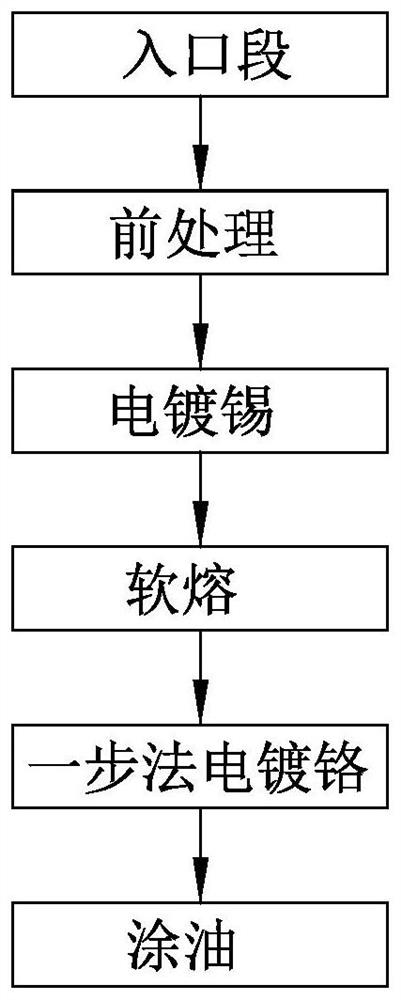

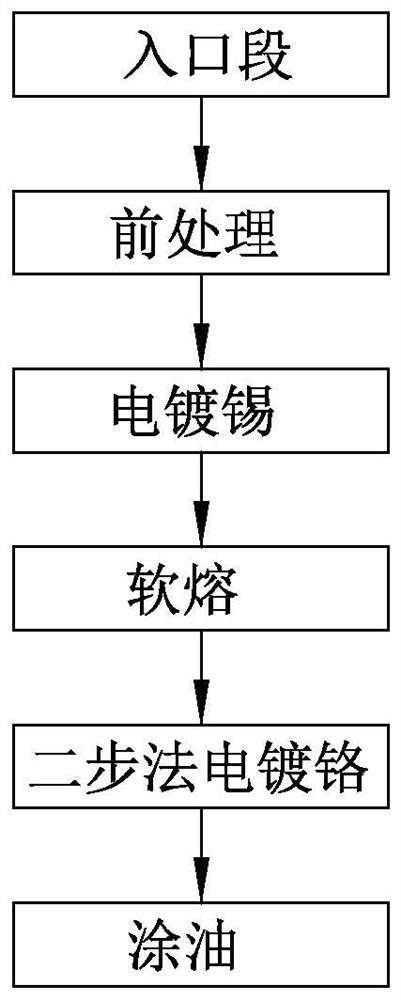

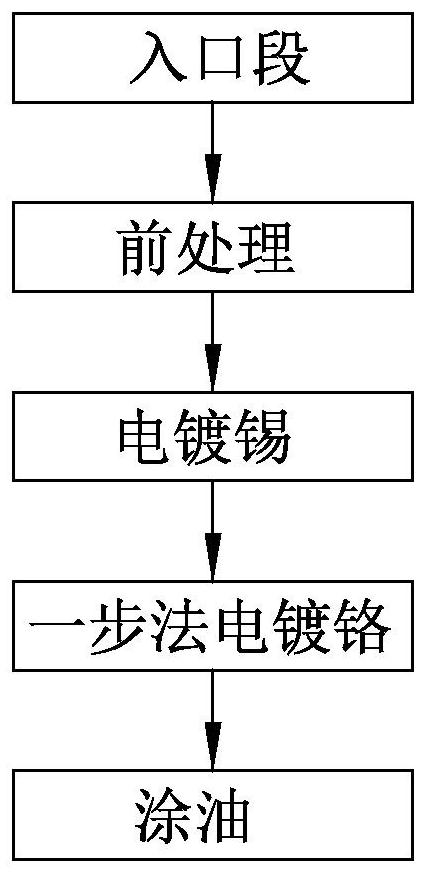

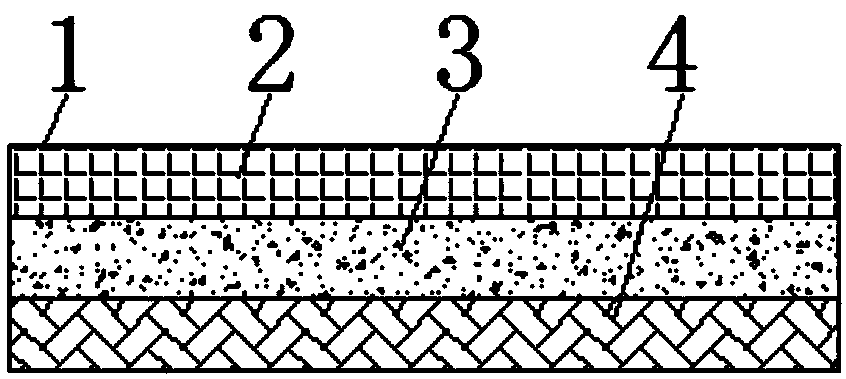

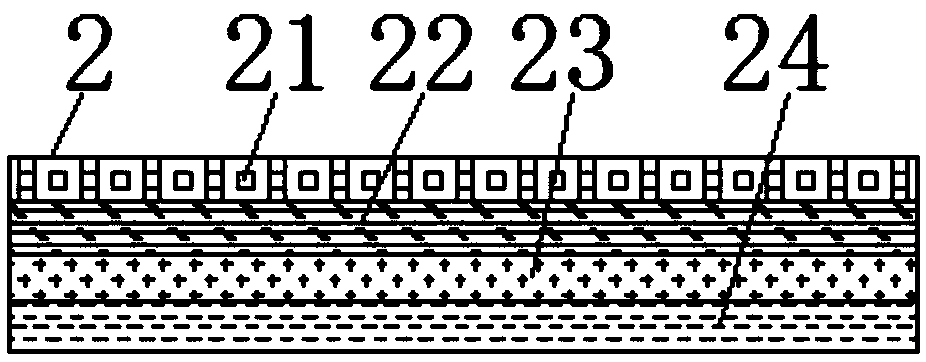

Tinplate production process for composite coating and tinplate

The invention relates to a tinplate production process for a composite coating and a tinplate. The tinplate production process comprises the following steps of step S10, pretreatment: degreasing and pickling a steel substrate; step S20, electroplating tin: electroplating tin on the steel substrate, and then rinsing to form a pure tin layer on the surface of the steel substrate; step S30, electroplating chromium: electroplating chromium on the surface of the steel substrate where step S20 has been completed, and rinsing to form a chromium metal layer and a chromium hydrated oxide layer on the surface of the pure tin layer; and step S40, oiling: oiling on the surface of the steel substrate where step S30 has been completed to form an oil film layer. According to the tinplate production process provided by the invention, the tinplate formed by using the process has the tin-plated and chromium-plated composite coating, based on the excellent corrosion resistance of metal chromium, the chromium-plated layer on the outer surface mainly plays a role of anti-corrosion, the tin in the inner layer has good welding performance, and acts as a soldering flux when welding is needed to ensure thewelding quality when making cans, so that chrome-plated iron can also be used to make three-piece cans, and the cost is reduced.

Owner:ZHONGSHAN ZHONGYUE TINPLATE IND CO LTD

Steel formwork structure

InactiveCN104878920ATight seamsImprove structural performanceForming/stuttering elementsArchitectural engineeringCorrosion

The present invention discloses a steel formwork structure. The steel formwork structure comprises an outer protection plate; an inner side surface of the outer protection plate is provided with a ribbed plate; detachable screws are connected between the ribbed plate and the outer protection plate; an inner side surface of the ribbed plate is connected with a reinforcing rib; the reinforcing rib is connected with the ribbed plate via reinforcing screws; an inner side surface of the reinforcing rib is connected with a vertical rib outer rim; the vertical rib outer rim is bonded with the reinforcing rib; an inner side surface of the vertical rib outer rim is provided with a flow deflector; a sealing gasket is connected between the flow deflector and the vertical rib outer rim; the vertical rib outer rim is clamped to the flow deflector; the flow deflector is provided with more than three deflector holes; a side surface of the flow deflector is connected with a securing plate; the securing plate is of a hard steel structure; and the securing plate is fixedly connected with the flow deflector. The steel formwork structure is higher in integrated structural property and bearing capacity, and is resistant to corrosion, has tight seams between formworks and smooth moulding surfaces, and has a certain deflector effect, construction quality is effectively guaranteed, and construction efficiency is improved.

Owner:HEBEI ROAD & BRIDGE GROUP

Anti-corrosion treatment method for surface of metal part

InactiveCN108914123AEffective protectionExtended service lifeMetallic material coating processesCopper platingSilver plate

The invention discloses an anti-corrosion treatment method for the surface of a metal part. The anti-corrosion treatment method is characterized in that coating is carried out on the surface of the metal part, wherein coating layers comprise a tin-plated layer, a zinc-plated layer, a nickel-plated layer, a copper-plated layer and a silver-plated alloy coating layer, the chromate treatment is firstly carried out in the process of manufacturing the zinc-plated layer, so that a chromate conversion coating is formed, the silver-plated alloy coating layer is a silver-plated copper alloy layer and contains copper with the 1.3% mole fraction, the nickel-plated layer adopts copper alloy as a bottom coating, the zinc-plated layer is an anode coating, and the nickel-plated layer and a chromium-plated layer are arranged outside the copper-plated layer for protection. According to the anti-corrosion treatment method for the surface of the metal part, the extremely high corrosion resistance is achieved, the service life of the metal part can be effectively prolonged, and a good market prospect is achieved.

Owner:苏州瑞沁精密机械有限公司

Corrosion preventing method for tinplate

InactiveCN104415897AExtended service lifeConveniencePretreated surfacesSpecial surfacesSand blastingFluorocarbon

The invention provides a corrosion preventing method for a tinplate. The tinplate is coated with a corrosion preventing composite layer, wherein a corrosion preventing composite layer coating process comprises the following steps: firstly, cleaning a tinplate substrate; secondly, performing sand-blasting treatment; thirdly, spraying anti-corrosive paint; in the first step, pollutants on the surface of the tinplate is cleaned by using ethanol; in the second step, chilled cast iron sand with the particle size of 0.2 to 0.5 mm is adopted for the sand-blasting treatment; in the third step, the sprayed anti-corrosive paint is organic fluorocarbon paint. According to the corrosion preventing method for the tinplate, the effect of preventing corrosion can be achieved effectively; the service life of the tinplate is prolonged; the corrosion preventing method has the advantages of convenience, practicability and low cost.

Owner:天津尚永科技有限公司

Hot melt adhesive pipe, production technology thereof and technology for adhering refrigerating pipe to heat-conductive plate

InactiveCN105172086AQuality improvementPlay the role of anti-corrosionPipe connection arrangementsTubular articlesComposite materialEvaporator

The invention relates to a hot melt adhesive pipe, a production technology thereof and a technology for adhering a refrigerating pipe to a heat-conductive plate. Ethylene ethylacrylate copolymer materials are adopted, the temperature of an extruding machine is set, a hot melt adhesive pipe is extruded and formed, and after being cooled, the hot melt adhesive pipe is manufactured. The refrigerating pipe is sleeved with the hot melt adhesive pipe, heating is carried out so that the hot melt adhesive pipe can be hot-melted, and the refrigerating pipe is connected with the heat-conductive plate. Hot melt adhesive has an anti-corrosion effect on the surface of the refrigerating pipe. The refrigerating pipe does not need to be oxidized, the production technology is simplified, and energy consumption is reduced. Besides, the adhesion area of the hot melt adhesive and the refrigerating pipe and the adhesive area of the hot melt adhesive and the heat-conductive plate are large, and adhesion is firmer. Adhesion portions are not prone to disengaging in the subsequent foaming treatment process of an evaporator, and the quality of the refrigerator evaporator is improved.

Owner:孙建平

Alloy nut connecting piece low in weight and high in strength and preparation method thereof

The invention discloses an alloy nut connecting piece low in weight and high in strength. The alloy steel nut connecting piece is characterized by being prepared from, by weight percent, 0.26%-0.34% of carbon, 0.17%-0.25% of manganese, 0.05%-0.14% of niobium, 2.15%-3.25% of aluminum, 0.03%-0.05% of molybdenum, 2.4%-2.7% of magnesium, 0.073%-0.14% of nickel, 0.032%-0.045% of tungsten, 0.07%-0.08% of tin, 20%-25% of a refining slag regulating agent, a proper amount of nitrogen and the balance Fe and inevitable impurities; and the refining slag regulating agent is prepared from, by weight, 20-45 parts of bauxite, 15-25 parts of marble, 19-44 parts of silica sand, 5-10 parts of barium, 10-11 parts of active lime, 9-10 parts of fluorgypsum, 4-8 parts of silica powder, 6-7 parts of electric smelting magnesium powder, 5-10 parts of albite and 2-5 parts of an aluminum shot. The alloy nut connecting piece is low in weight and high in strength, and dephosphorization is thorough; and a pattern is sprayed to the surface of a nut, and therefore the attractiveness of the nut is improved while rust prevention is achieved.

Owner:MAANSHAN WANXIN CASTING

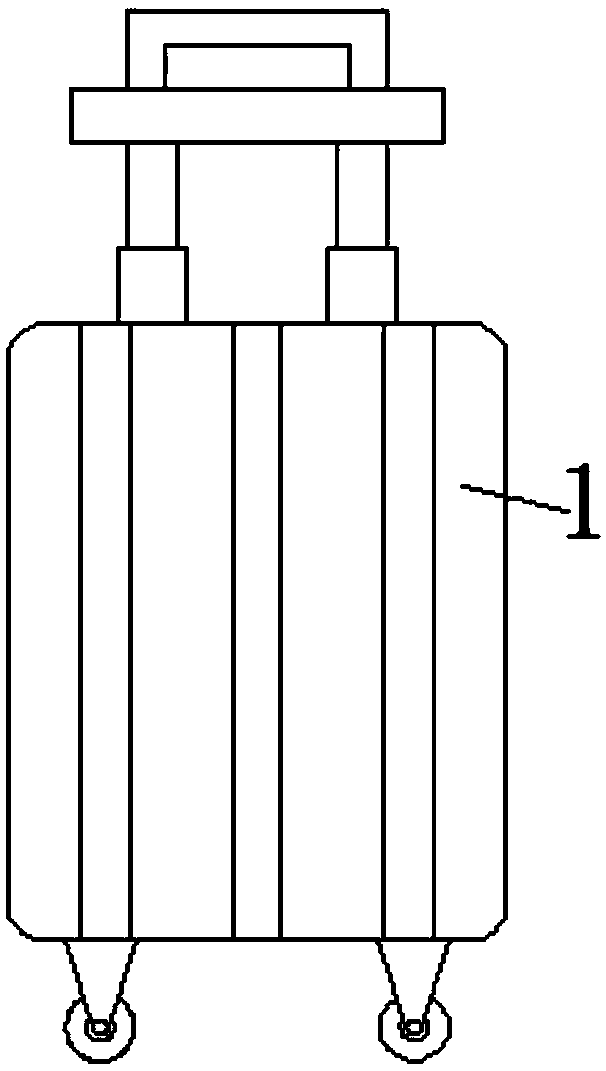

High-strength travel luggage

InactiveCN109156949AWear resistancePlay the left role of waterproofingSynthetic resin layered productsBagsSulfurWear resistant

The invention discloses a high-strength travel luggage which comprises a luggage body, wherein an inner cavity of the luggage body comprises a wear resistant layer, a water-proof layer and an anti-corrosion layer; the wear resistant layer is located at the top of the water-proof layer; the water-proof layer is located at the top of the anti-corrosion layer; an inner cavity of the anti-corrosion layer comprises a benzene-potassium-sulfur layer, an antimony trioxide layer, a magnesium hydroxide layer and PTFE (polytetrafluoroethylene)-polyethylene; the benzene-potassium-sulfur layer is located at the top of the antimony trioxide layer; the antimony trioxide layer is located at the top of the magnesium hydroxide layer; the magnesium hydroxide layer is located at the top of the PTFE-polyethylene. The wear resistant layer, the benzene-potassium-sulfur layer, the antimony trioxide layer, the magnesium hydroxide layer and the PTFE-polyethylene are matched with one another, so that when the luggage is used, a wear resisting effect on the luggage can be achieved, the conditions that the existing luggage is damaged after long-time use and cannot be used normally as the existing luggage doesnot have the wear resisting effect are avoided, therefore, the high-strength travel luggage is suitable for promotion and use.

Owner:南京景熙箱包有限公司

A kind of paint production method

ActiveCN104449025BWith weak magneticImprove antistatic performanceMagnetic paintsAnti-corrosive paintsAdhesiveAcrylic resin

The invention discloses a method for producing an oil paint, and relates to the field of chemical processes. The method comprises the following steps: feeding, premixing, grinding, mixing a paint, introducing oxygen, filtering and the like, namely adding materials to a twin-cylinder high-speed disperser in opening mixing during feeding; firstly adding 1 / 5 of polyurethane acrylic resin to a first cylinder to render; adding a little of conductive carbon black, chlorinated paraffin, magnetic iron powder, zeolite powder and nickel powder, adding part of polyurethane acrylic resin at an interval of 1 minute, and completely adding the residual polyurethane acrylic resin for 3-4 times; adding a mixed solution of double distilled water, butanol, an organic silicone resin fluid and an isocyanate adhesive to a second cylinder, and carrying out hydrolytic crosslinking reaction; and adding nano powder, and carrying out catalytic reaction, mixing the materials which are processed in the first cylinder and the second cylinder at the ratio, thus various defects of the oil paint can be improved; resources can be reasonably distributed; and the method is economic and applicable.

Owner:丹阳恒安化学科技研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com