Corrosion control method and device for online film formation of pipeline of oil refining and chemical device

A pipeline and film-forming technology, used in devices for coating liquids on surfaces, pre-treatment surfaces, coatings, etc., can solve the problems of complex components, high anti-corrosion costs, uneven formation, etc. The effect of stable characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

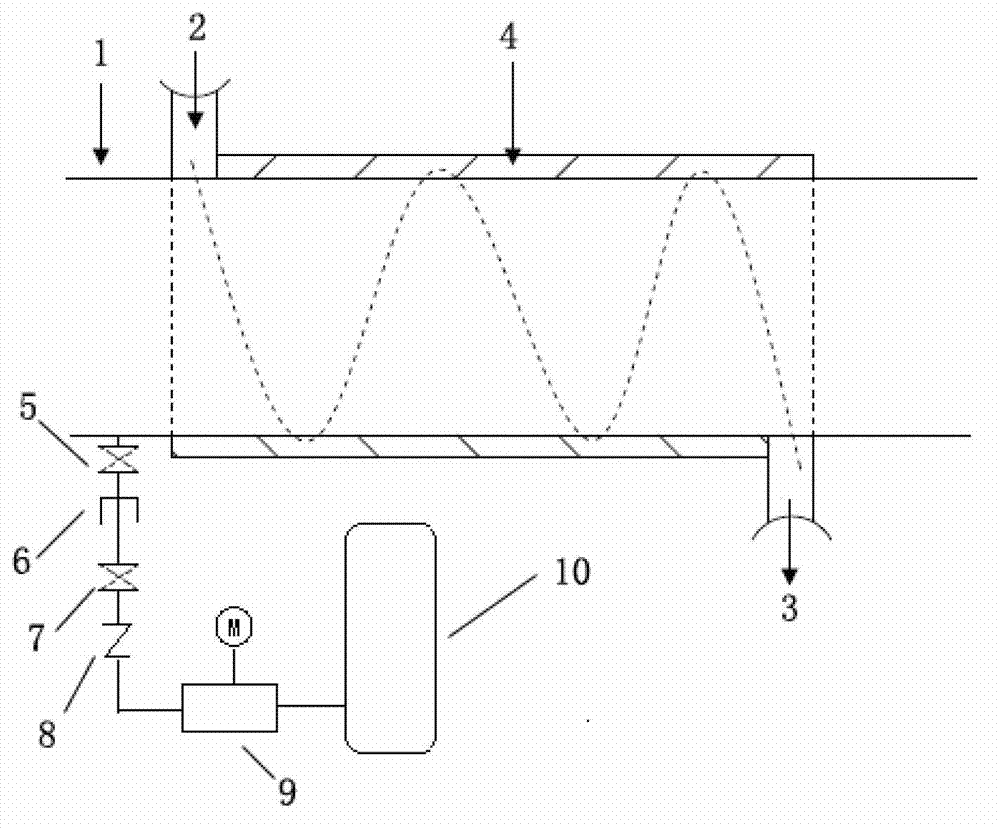

[0041] This embodiment provides an anti-corrosion device for online film formation of pipelines in oil refining and chemical plants, which includes: injection equipment, heating sleeve 4 and heating equipment (not shown in the figure), wherein the injection equipment includes temporary joints connected in sequence 6. Stop valve 7, one-way valve 8, metering pump 9 and film-forming material storage tank 10, temporary joint 6 is used to connect with the original drain valve 5 (located at the bottom of the pipeline) of pipeline 1 for injection For the film-forming substance, the shut-off valve 7 is used to control the injection, the one-way valve 8 is used to prevent backflow, the metering pump 9 is used to measure the injection speed of the film-forming substance injected, and the film-forming substance storage tank 10 is used to store the film-forming substance The heating sleeve 4 is provided with a heating medium inlet 2 and a heating medium outlet 3, which are respectively use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com