Anticorrosive coating for cable bracket

A technology for anti-corrosion coatings and cable brackets, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of high cost, achieve good film-forming properties, increase service life, and prevent sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

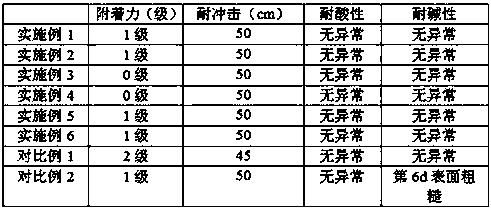

Examples

Embodiment 1

[0022] An anti-corrosion coating for a cable support, comprising the following raw materials in parts by weight: 40 parts of epoxy resin, 20 parts of chlorinated rubber, 0.5 parts of polyaniline, 1 part of zinc phosphate, 3 parts of styrene-acrylic emulsion, 8 parts of stabilizing agent, mica 1 part of powder, 2 parts of sodium dodecylbenzenesulfonate, 0.5 parts of silane coupling agent, 7 parts of curing agent, 10 parts of solvent and 5 parts of water.

[0023] The solvent is xylene, acetone, and n-butanol mixed in a weight ratio of 1:1:1; the curing agent is curing agent T31; the silane coupling agent is trifluoropropyltrimethoxysilane; the stabilizing agent is organic bentonite , diatomaceous earth and sodium hydroxymethyl cellulose are mixed in a weight ratio of 4:1:0.5.

[0024] Anti-corrosion coating for cable support, prepared by the following method:

[0025] Mix epoxy resin, chlorinated rubber, solvent and water evenly, then add polyaniline, zinc phosphate, styrene-a...

Embodiment 2

[0027] An anticorrosion coating for a cable support, comprising the following raw materials in parts by weight: 42 parts of epoxy resin, 18 parts of chlorinated rubber, 0.8 parts of polyaniline, 1.2 parts of zinc phosphate, 2.5 parts of styrene-acrylic emulsion, 9 parts of stabilizing aids, mica 1.5 parts of powder, 1.8 parts of sodium dodecylbenzenesulfonate, 0.58 parts of silane coupling agent, 7 parts of curing agent, 10 parts of solvent and 5 parts of water.

[0028] Among them, the solvent is xylene, acetone, and n-butanol mixed in a weight ratio of 1:1:1; the curing agent is curing agent NX-2003; the silane coupling agent is isobutyltriethoxysilane; the stabilizing agent is Organic bentonite, diatomaceous earth and sodium hydroxymethyl cellulose are mixed at a weight ratio of 5:1:0.5.

Embodiment 3

[0030] An anticorrosion coating for a cable support, comprising the following raw materials in parts by weight: 44 parts of epoxy resin, 16 parts of chlorinated rubber, 1 part of polyaniline, 1.4 parts of zinc phosphate, 2 parts of styrene-acrylic emulsion, 10 parts of stabilizing aid, mica 2 parts of powder, 1.6 parts of sodium dodecylbenzenesulfonate, 1.0 parts of silane coupling agent, 8 parts of curing agent, 11 parts of solvent and 4 parts of water.

[0031] The solvent is xylene, acetone, and n-butanol mixed in a weight ratio of 1:1:2; the curing agent is curing agent T31; the silane coupling agent is isobutyltriethoxysilane; the stabilizing agent is organic bentonite , diatomaceous earth and sodium hydroxymethyl cellulose are mixed at a weight ratio of 6:1:0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com