Corrosion prevention device for vehicle brake unit

A braking unit, vehicle technology, applied in the direction of brake components, brakes, vehicle components, etc., can solve the problems of easy deterioration of vehicle appearance, deterioration of appearance, destruction of braking force braking feeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

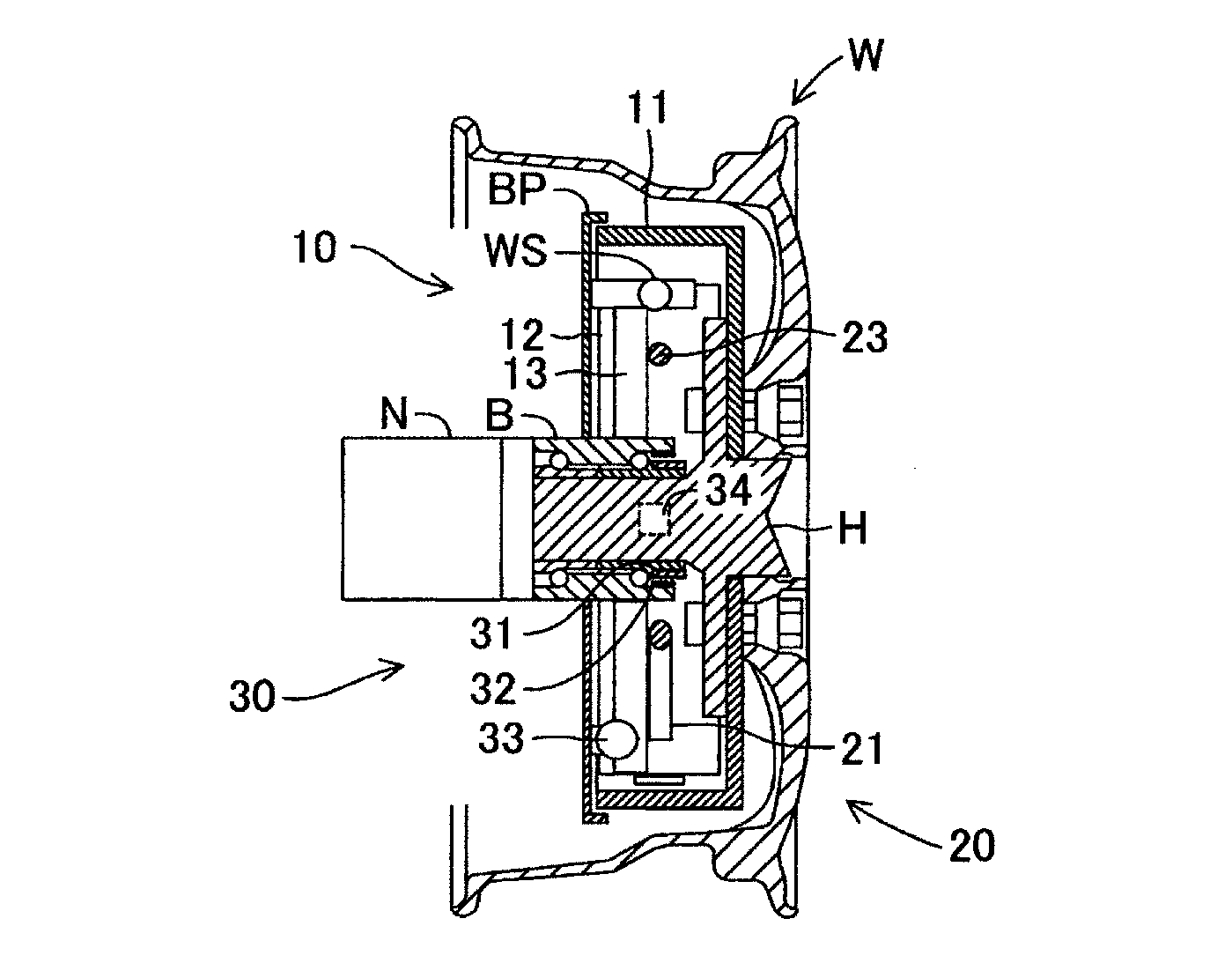

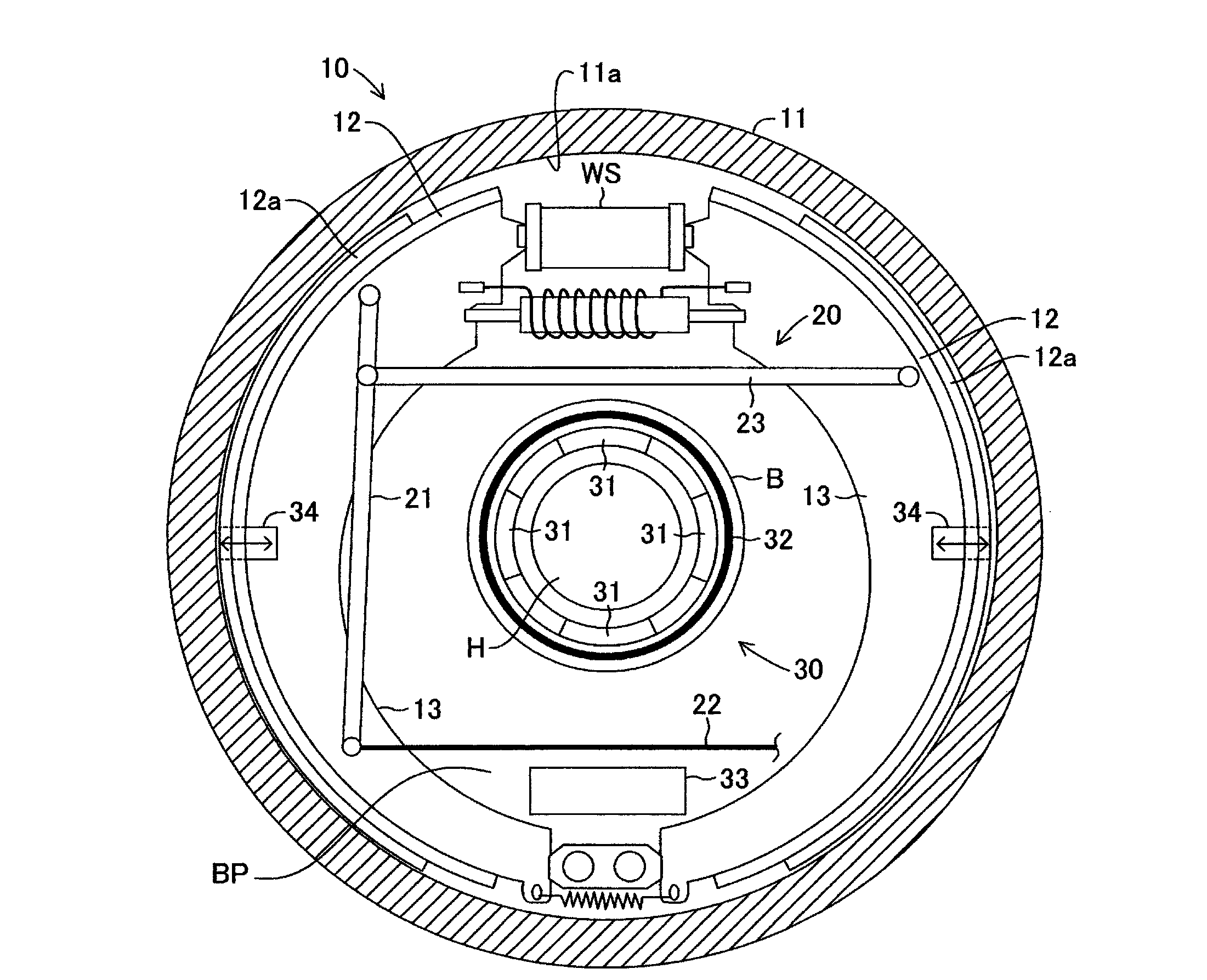

[0037] figure 1 According to the first embodiment of the present invention, a system configuration of a vehicle brake unit 10 to which a corrosion protection device for a vehicle brake unit is applied is schematically shown. The vehicle brake unit 10 (hereinafter also simply referred to as “brake unit 10 ”) in the first embodiment is a so-called drum brake unit. Therefore, the brake unit 10 includes a brake drum 11 as a metal rotating member included in the metal member constituting the brake unit 10 , and a brake shoe as a frictional engagement unit that frictionally engages with the brake drum 11 . 12. In addition, the detailed structure and operation of the drum brake unit as the brake unit 10 are the same as those of known drum brake units and are not directly related to the present invention, so they will be briefly described below.

[0038] The brake drum 11 is attached to a knuckle N constituting a suspension device of a vehicle (not shown) and is mounted on the side ...

no. 2 approach

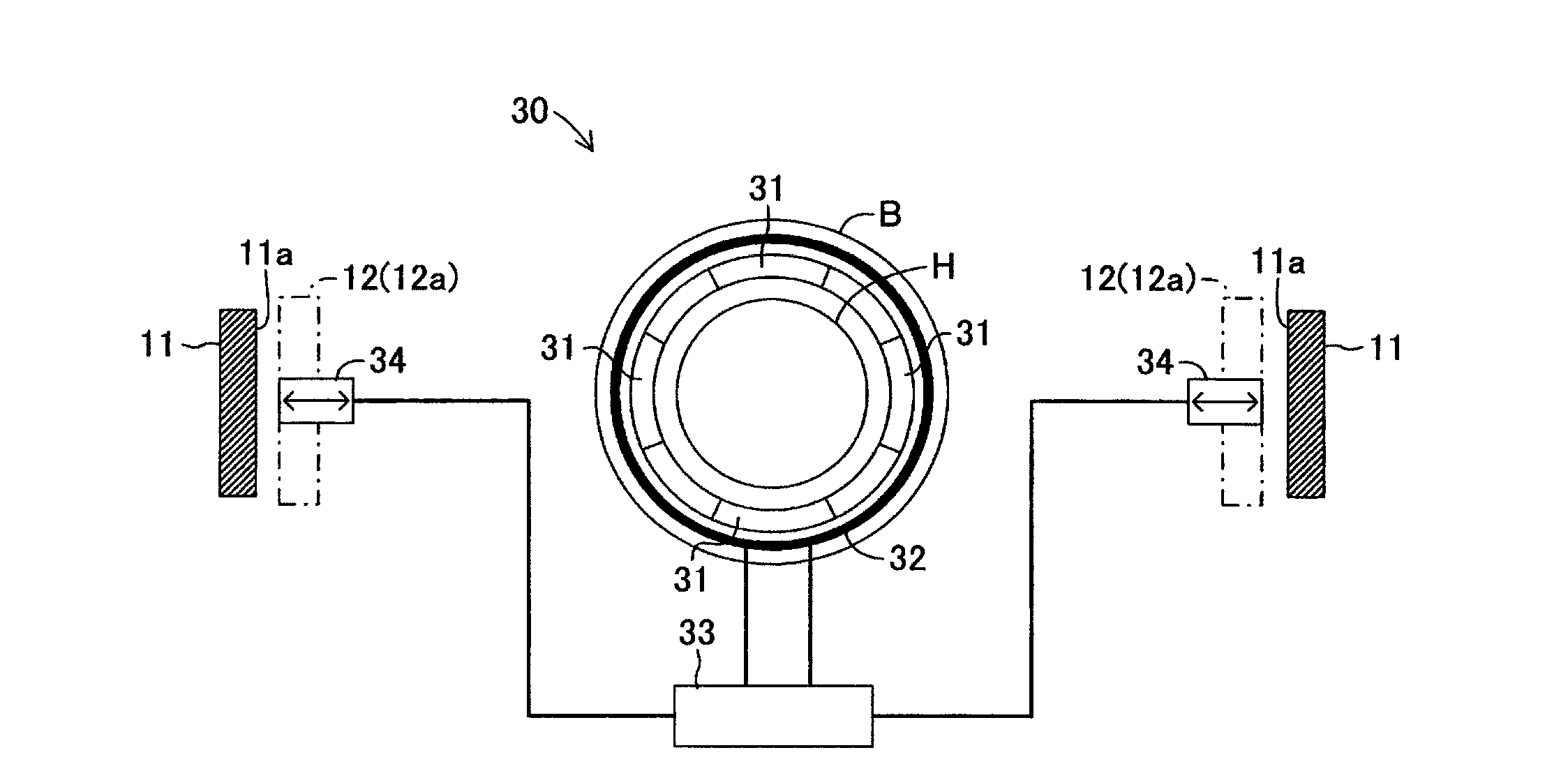

[0056] In the second embodiment described above, a drum brake unit that can be structurally provided with a parking brake mechanism 20 is employed as the vehicle brake unit 10 . In addition, in the first embodiment described above, the brake unit 10 can be configured in conjunction with the parking brake operation by the driver during parking (stopping), that is, with the operation of the parking brake mechanism 20 . The brake drum 11, the hub bearing B, and the hub H, which are the metal parts, are energized with a predetermined current, so as to reliably exert the electrical anti-corrosion function and effectively prevent corrosion (rust) from occurring. The anticorrosion device for a vehicle brake unit according to the present invention can also be applied to a so-called disc brake unit as the vehicle brake unit 10 . Hereinafter, this second embodiment will be described in detail, and the same parts as those in the above-mentioned first embodiment will be denoted by the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com