Rotating speed sensor

A speed sensor and housing technology, applied in the direction of instruments, speed/acceleration/shock measurement, speed/acceleration/electric shock meter details, etc., can solve the problems of damaged product service life, driving safety disadvantages, machine parts damage, etc., to achieve Prolonged service life, compact and reasonable structure, good dust and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

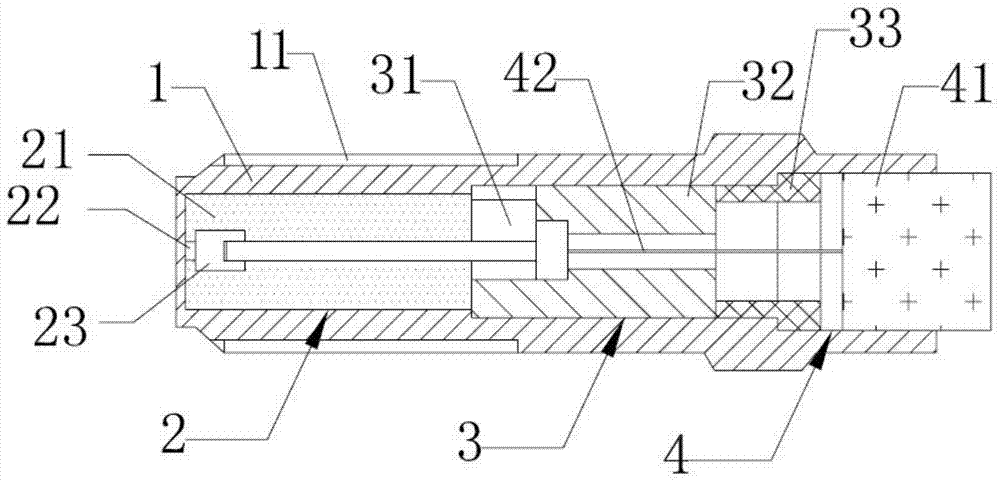

[0013] Such as figure 1 As shown, the present invention is composed of a housing 1 made of stainless steel, etc., the wall thickness of the left end of the housing 1 is 1 mm, and a section of external thread 11 is provided on the outside of the left end of the housing 1. 1 is provided with a stepped through hole along the axial direction, and the stepped through hole is composed of a left stepped hole 2, a middle stepped hole 3 and a right stepped hole 4, and an epoxy resin sleeve is embedded in the left stepped hole 2 21. Hall elements 22 and NdFeB magnets 23 are arranged in sequence from left to right at the left end of the epoxy resin sleeve 21; a printed circuit board assembly 31 and a sleeve are arranged in the middle step hole 3 32 and an installation sleeve 33, the printed circuit board assembly 31 is inserted into the epoxy resin sleeve 21 to the left and connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com