Tinplate production process for composite coating and tinplate

A technology of composite coating and production process, applied in the field of tinplate, can solve problems such as difficult welding and affecting use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

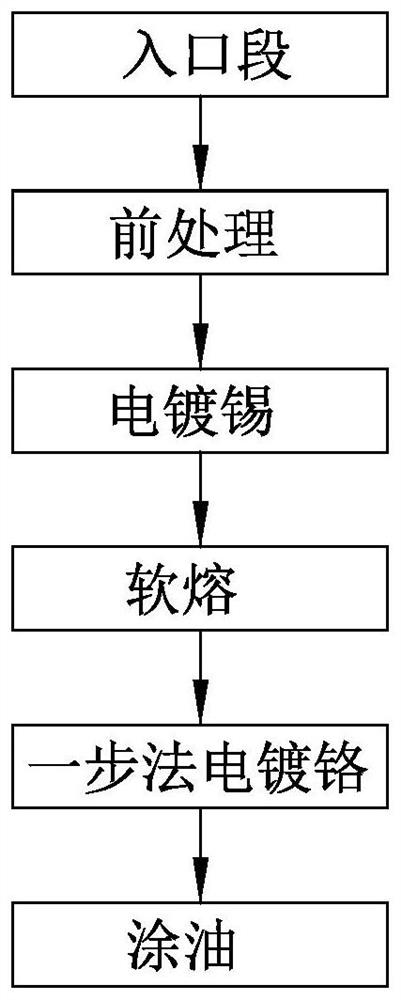

[0030] Such as figure 1 As shown, the embodiment of the present application proposes the tinplate production process of composite coating, and it comprises:

[0031] S09, entrance section: open the steel coil and process it to form strip steel, and use the strip steel as the steel matrix 1;

[0032] S10, pre-treatment: degreasing and pickling the steel substrate 1 to remove stains such as oil and rust on the surface of the steel substrate 1 .

[0033] S20, electroplating tin: electroplating tin on the steel substrate 1, and then rinsing to form a pure tin layer 3 on the surface of the steel substrate 1, wherein the amount of tin plating on one side of the electroplating tin is 0.15-1.0g / m 2 , much less than the general tin-plated steel sheet. Generally, for the specifications of electro-tinned thin steel sheets, the best amount of tin plating is the specification of E2.8, that is, the amount of tin plating on one side is set to 2.8g / m 2 ;Set at 1.0g / m for some special purpo...

Embodiment 2

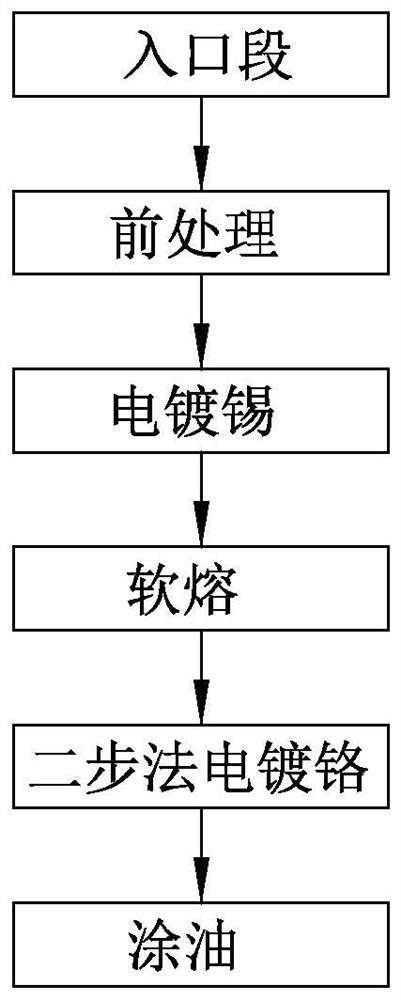

[0040] Such as figure 2 As shown, the embodiment of the present application proposes the tinplate production process of composite coating, and it comprises:

[0041] S09, entrance section: open the steel coil and process it to form strip steel, and use the strip steel as the steel matrix 1;

[0042] S10, pretreatment: degreasing and pickling the steel substrate 1 .

[0043] S20, tinning electroplating: electroplating tin on the steel substrate 1, and then rinsing to form a pure tin layer 3 on the surface of the steel substrate 1, wherein the amount of tin plating on one side of the electroplating tin is 0.15-1.0g g / m 2 .

[0044] S21, remelting: heating the tin-plated steel substrate 1 to above 232°C to melt the tin coating layer on the surface of the steel substrate 1, so that the melted tin coating layer is leveled to produce a bright surface, and the steel substrate 1 and the pure tin layer 3 form a tin-iron alloy layer 2.

[0045]S30, two-step chromium electroplating:...

Embodiment 3

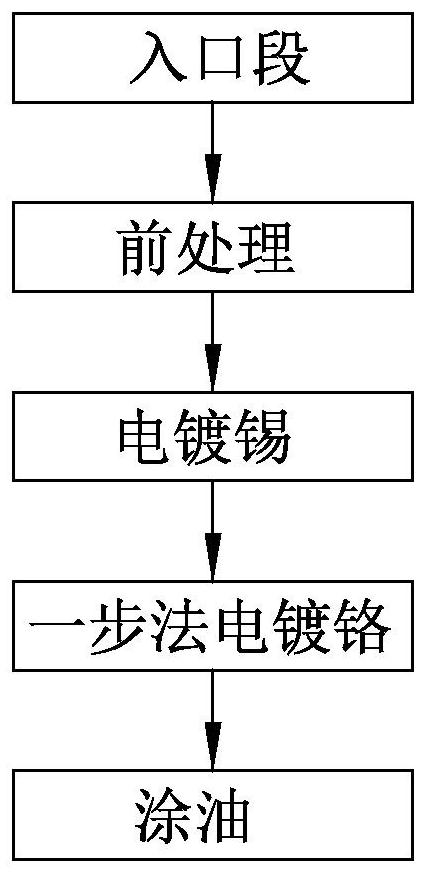

[0049] Such as image 3 As shown, the embodiment of the present application proposes the tinplate production process of composite coating, and it comprises:

[0050] S09, entrance section: open the steel coil and process it to form strip steel, and use the strip steel as the steel matrix 1;

[0051] S10, pretreatment: degreasing and pickling the steel substrate 1 .

[0052] S20, tinning electroplating: electroplating tin on the steel substrate 1, and then rinsing to form a pure tin layer 3 on the surface of the steel substrate 1, wherein the amount of tin plating on one side of the electroplating tin is 0.15-1.0g g / m 2 .

[0053] S30, one-step electroplating of chromium: electroplating chromium on the surface of the steel substrate 1 that has completed step S20 and rinsing to form a chromium metal layer 4 and a chromium hydrated oxide layer 5 on the surface of the pure tin layer 3, wherein the chromium electroplating step The concentration of the electroplating solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com