Corrosion-resistant conductive rubber key and preparation method thereof

A conductive rubber, corrosion-resistant technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve problems such as wear, corrosion, and keys are not easy to identify, achieve good wear resistance, ensure relatively fixed, and avoid the effect of being worn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

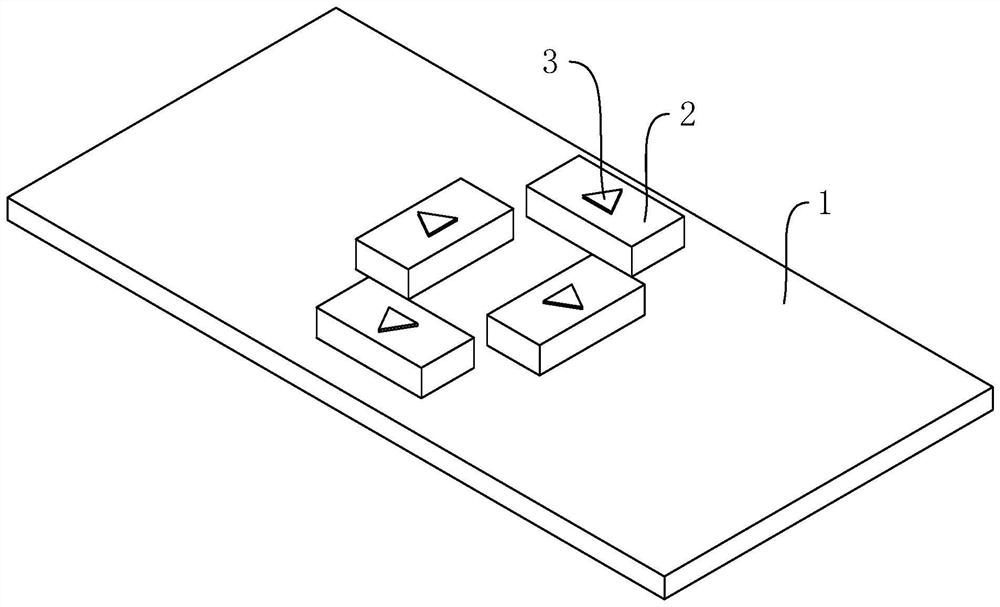

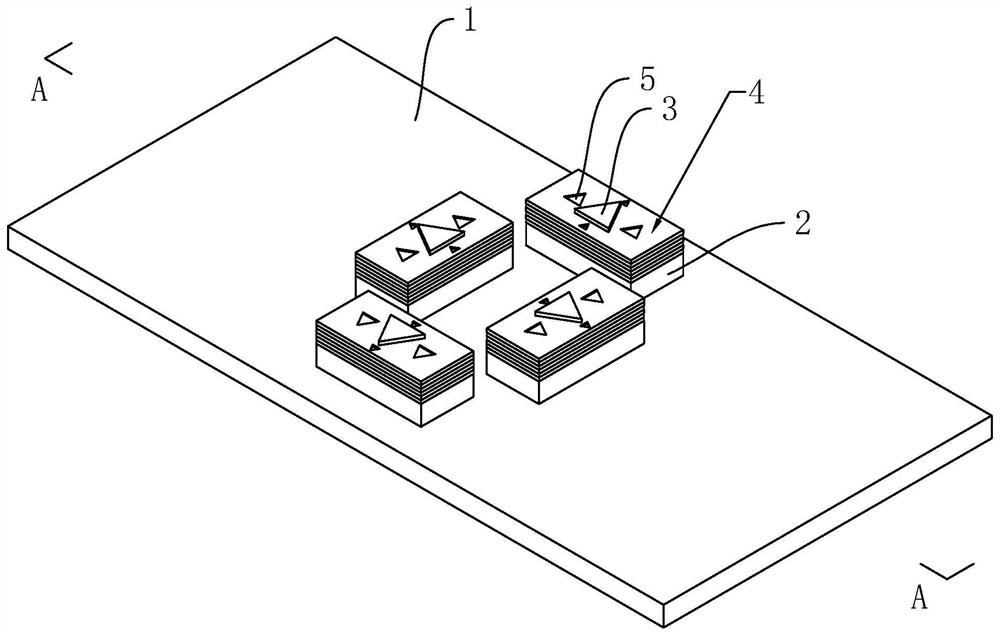

[0046] Embodiment 1: A kind of corrosion-resistant conductive rubber button, refer to figure 2 , including a base 1 and several key blocks 2 integrally formed on the base 1 , the side of the key block 2 away from the base 1 protrudes with identification characters 3 , and the side of the key blocks 2 away from the base 1 is located on the peripheral side of the identification characters 3 At least two layers of easy-to-tear sheets 4 are provided. In this embodiment, the number of layers of easy-to-tear sheets 4 is two layers, and the identification characters 3 protrude from the end wall of the outermost easy-to-tear sheet 4 .

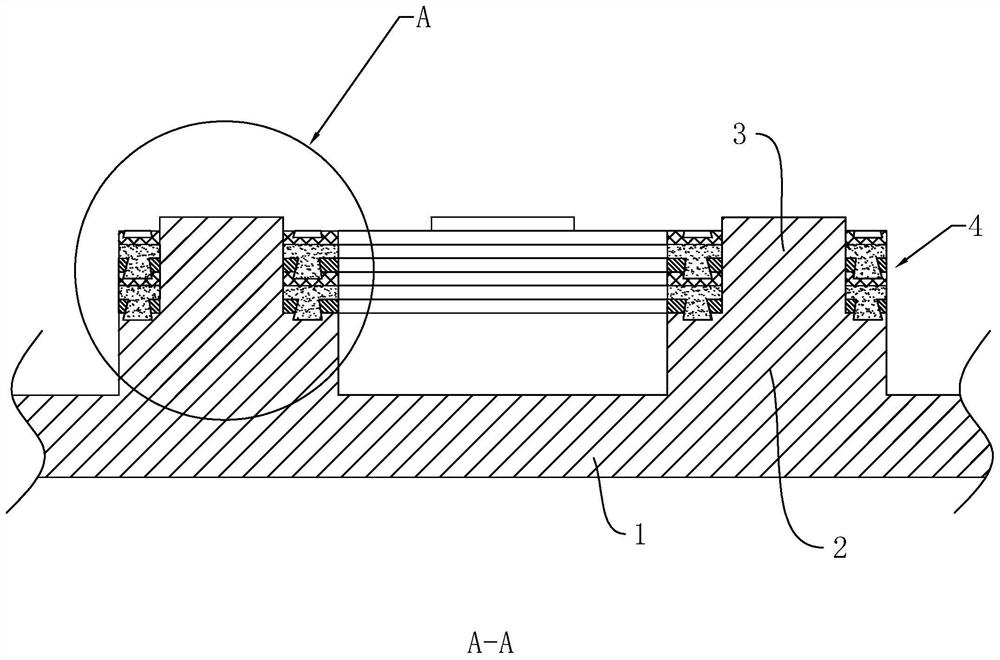

[0047] refer to image 3 and Figure 4 The easy-to-tear sheet 4 includes an aluminum layer 401 on a side away from the base 1 and an anti-corrosion sealing layer 402 on a side close to the base 1, and the anti-corrosion sealing layer 402 includes an outer layer 4021 on a side close to the aluminum layer 401 and an outer layer 402 The inner layer 402...

Embodiment 2-4

[0056] Embodiment 2-4: A corrosion-resistant conductive rubber button. The difference from Embodiment 1 is that the components of the inner layer 4022 and the outer layer 4021 and their corresponding parts by weight are shown in Table 1.

[0057] Each component and parts by weight thereof in table 1 embodiment 1-4

[0058]

[0059]

Embodiment 5

[0060] Embodiment 5: A corrosion-resistant conductive rubber button. The difference from Embodiment 1 is that the melting point of paraffin wax in the raw material of the inner layer 4022 in this embodiment is 58°C.

[0061] The beneficial effects of the present invention are as follows: firstly, the identification characters 3 are protruding and can be directly injection-molded, which saves the spraying process and optimizes the production process of the rubber key; secondly, the easy-to-tear sheet 4 can be corroded or Torn off after wear and tear, so that the identification characters 3 are exposed again, ensuring the stability of the identification characters 3; moreover, the aluminum layer 401 is made of aluminum, has a certain hardness, and has good wear resistance; and the surface of the aluminum will A dense oxide film is formed, and the oxide film can play an anti-corrosion role; finally, the anti-corrosion sealing layer 402 can not only play a role in anti-corrosion, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com