Copper metal surface anticorrosion treatment method

A processing method and technology of copper metal, applied in the direction of metal material coating process, coating, etc., can solve the problems of loss of active sites, chemical sites that cannot provide activity, complicated and complicated processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

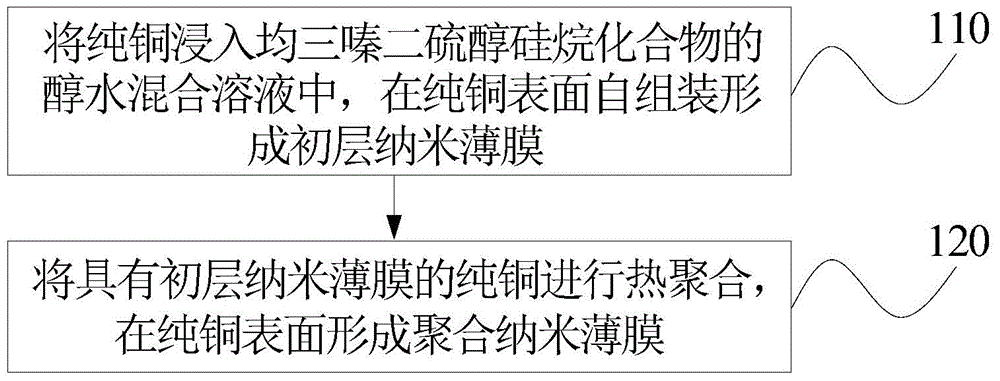

[0024] figure 1 It is a flow chart of the steps of the copper metal surface anticorrosion treatment method according to the embodiment of the present invention.

[0025] refer to figure 1 , the copper surface anti-corrosion treatment method according to the embodiment of the present invention comprises the following steps:

[0026] In step 110, the pure copper is immersed in the alcohol-water mixed solution of the s-triazinedithiol silane compound, and self-assembles on the surface of the pure copper to form a primary nano-film.

[0027] Specifically, in this embodiment, the sheet of pure copper whose size is 50mm×30mm×0.2mm is first cleaned on its surface before being immersed in the alcohol-water mixed solution of s-triazinedithiol silane compound. .

[0028] The cleaning method is as follows: ultrasonically wash the pure copper substrate with acetone for 10 minutes, and after drying at room temperature, degrease and decontaminate the pure copper surface with 1% nitric ac...

Embodiment 2

[0036] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between embodiment 2 and embodiment 1 is that in step 110, the base is a cupronickel (copper alloy with nickel as the main additive element) sheet with a size of 50mm * 50mm * 0.2mm, and the cupronickel sheet is treated with ethanol Ultrasonic cleaning for 15min, after drying at room temperature, cleaning and drying with 5% sulfuric acid solution; place the cleaned white copper sheet in an alcohol-water mixed solution containing 5mmol / L s-triazinedithiol compound (the volume of ethanol and water ratio of 1:19), self-assembly was carried out at room temperature; after 30 minutes of self-assembly, the white copper sheet with the first layer of nano-film was obtained by washing and drying.

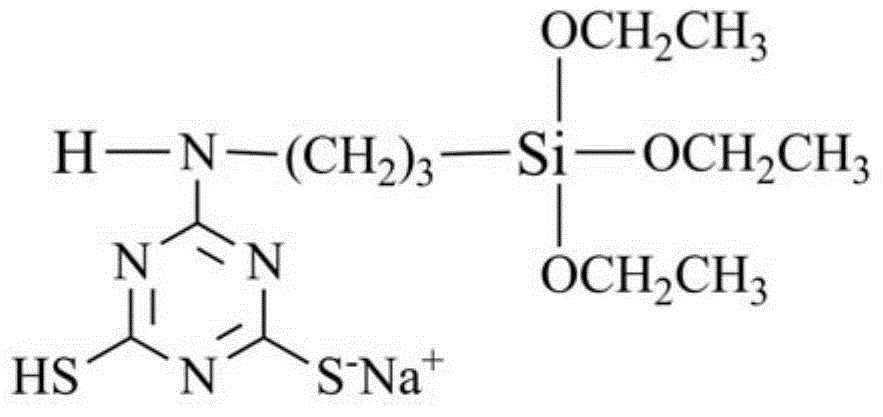

[0037] In this embodiment, the s-triazine dithiol compound is:

[0038]

[0039] In step 120, the temperatu...

Embodiment 3

[0042] In the description of Embodiment 3, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between embodiment 3 and embodiment 1 is that in step 110, the substrate is a brass (copper-zinc alloy) sheet with a size of 50mm×20mm×0.4mm, and the brass sheet is ultrasonically cleaned with acetone for 20 minutes, After drying at room temperature, clean and dry with 2% nitric acid solution; place the cleaned brass sheet in an alcohol-water mixed solution containing 4mmol / L s-triazinedithiol compound (the volume ratio of methanol and water is 1 : 19), self-assembly is carried out at room temperature; after self-assembly 30min, the brass sheet with the first layer nano film is obtained through cleaning and drying.

[0043] In this embodiment, the s-triazine dithiol compound is:

[0044]

[0045] In step 120, the temperature of thermal polymerization is 150°C and the time is 30 minutes to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current | aaaaa | aaaaa |

| Corrosion current | aaaaa | aaaaa |

| Corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com