High-speed train aluminum alloy supporting groove and preparation method thereof

A technology for high-speed trains and aluminum alloys, applied in the field of aluminum alloys, can solve the problems of unclear evolution law of corrosion damage, increased maintenance costs of high-speed trains, and inability to evaluate the remaining life of components, so as to ensure mechanical strength and ductility, improve Dispersion and precipitation effect, the effect of improving solid solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

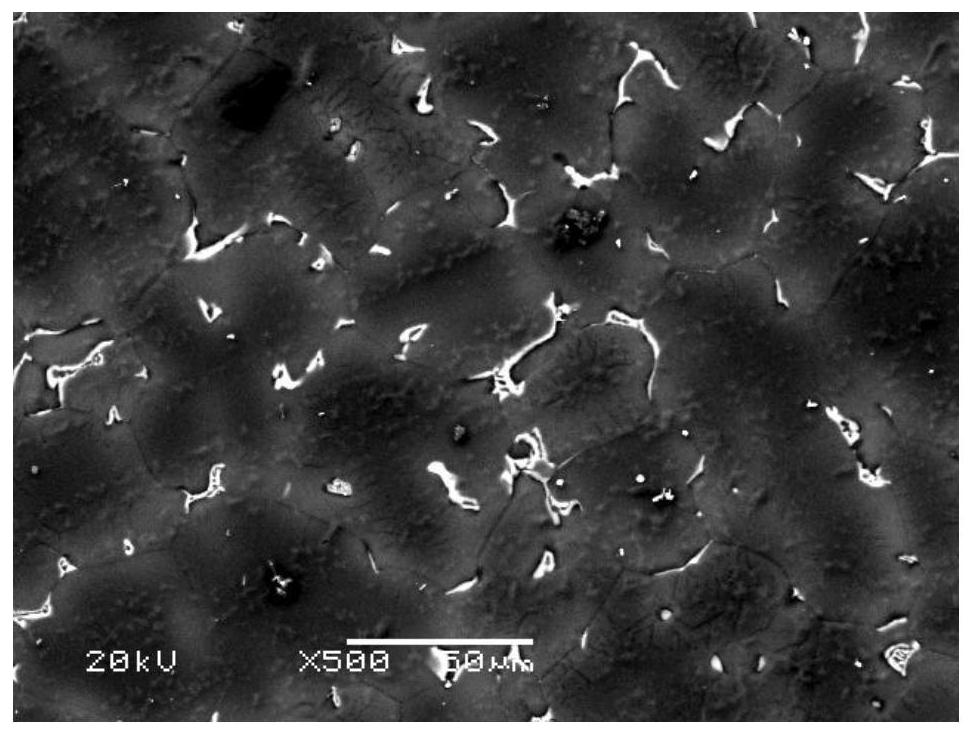

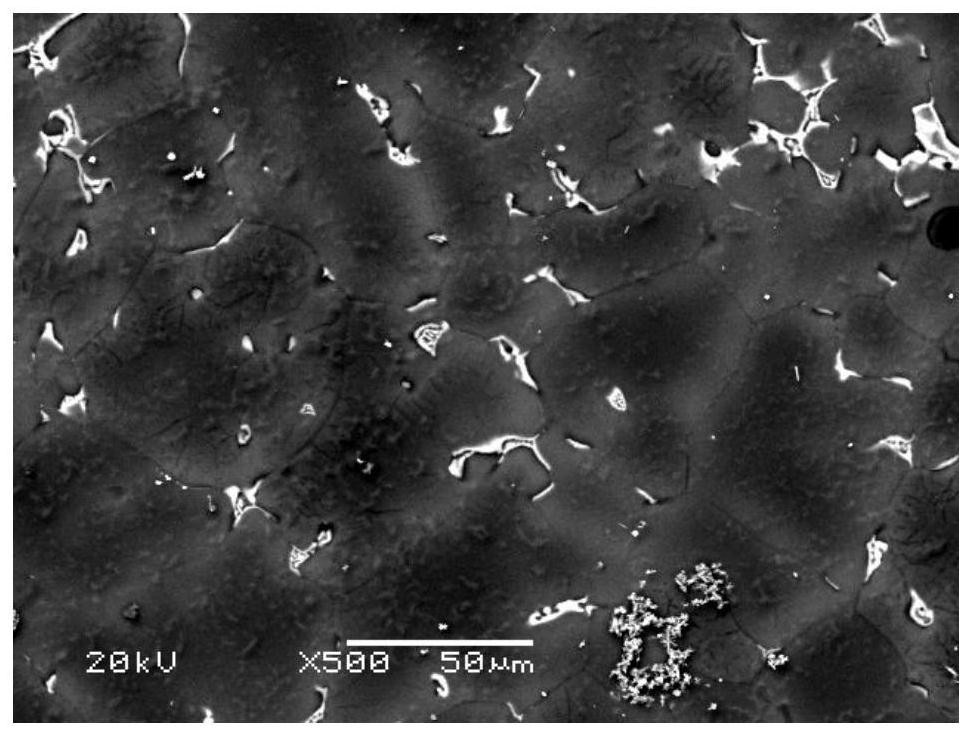

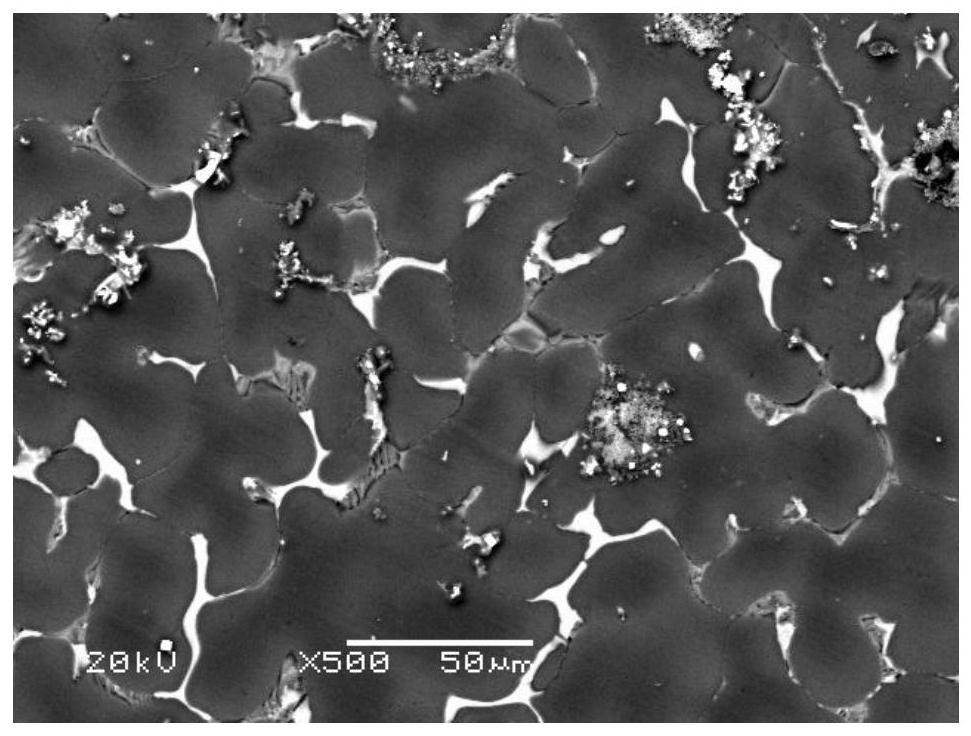

Image

Examples

Embodiment 1

[0024] The high-speed train aluminum alloy support channel aluminum alloy in this embodiment includes the following components in mass percentage: Zn: 5.0wt.%, Mg: 2.0wt.%, Ag: 1.0wt.%, Sc: 0.3wt.%. , Zr: 0.6wt.%, the balance is Al and unavoidable impurities;

[0025] Its preparation method is as follows:

[0026] First, add pure Al, pure Zn, and pure Mg into the melting furnace and heat to 700°C to melt, then add Al-20Ag master alloy and Al-25Sc master alloy after heating up to 720°C; then pass high-purity argon gas, at 730°C Keep it warm for 20 minutes, then add Al-25Zr master alloy and keep it warm for 1 hour, finally cool down to 680°C, let it stand for 15 minutes, and cast it at 660-690°C to make an aluminum alloy ingot. Then the aluminum alloy is homogenized, and the homogenization treatment is to keep warm at 430° C. for 20 hours. Then the obtained aluminum alloy ingot is subjected to low-temperature pre-extrusion, the extrusion temperature is 100 degrees, and the ext...

Embodiment 2

[0028] The high-speed train aluminum alloy support channel aluminum alloy in this embodiment includes the following components in mass percentage: Zn: 6.5wt.%, Mg: 3.0wt.%, Ag: 2.0wt.%, Sc: 0.5wt.%. , Zr: 0.7wt.%, the balance is Al and unavoidable impurities;

[0029] Its preparation method is as follows:

[0030] First, add pure Al, pure Zn, and pure Mg into the melting furnace and heat to 700°C to melt, then add Al-20Ag master alloy and Al-25Sc master alloy after heating up to 720°C; then pass high-purity argon gas, at 730°C Keep it warm for 20 minutes, then add Al-25Zr master alloy and keep it warm for 2 hours, finally cool down to 680°C, let it stand for 15 minutes, and cast it at 660-690°C to make an aluminum alloy ingot. Then the aluminum alloy is homogenized, and the homogenization treatment is to keep warm at 430° C. for 20 hours. Then the obtained aluminum alloy ingot is subjected to low-temperature pre-extrusion, the extrusion temperature is 100 degrees, and the ex...

Embodiment 3

[0032] The high-speed train aluminum alloy support channel aluminum alloy in this embodiment includes the following components in mass percentage: Zn: 7.5wt.%, Mg: 3.5wt.%, Ag: 2.5wt.%, Sc: 0.6wt.%. , Zr: 0.8wt.%, the balance is Al and unavoidable impurities;

[0033] Its preparation method is as follows:

[0034] First, add pure Al, pure Zn, and pure Mg into the melting furnace and heat to 700°C to melt, then add Al-20Ag master alloy and Al-25Sc master alloy after heating up to 720°C; then pass high-purity argon gas, at 730°C Keep it warm for 20 minutes, then add Al-25Zr master alloy and keep it warm for 2 hours, finally cool down to 680°C, let it stand for 15 minutes, and cast it at 660-690°C to make an aluminum alloy ingot. Then the aluminum alloy is homogenized, and the homogenization treatment is to keep warm at 430° C. for 20 hours. Then the obtained aluminum alloy ingot is subjected to low-temperature pre-extrusion, the extrusion temperature is 100 degrees, and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com