Patents

Literature

37results about How to "Uniform and dense grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-frequency low-loss MnZn ferrite material and manufacturing method thereof

The invention provides a high-frequency low-loss MnZn ferrite material, which comprises main components and auxiliary components, wherein the main components are 53-56 mol percent of ferric oxide, 34-41 mol percent of manganese oxide and 6-10 mol percent of zinc oxide, the content of manganese oxide is measured by Mn; the auxiliary components are at least three selected from CaCO3, SiO2, Nb2O5, CoO, V2O5, SnO2 and TiO2, and based on the total weight of the main components, the auxiliary components comprise: 0.02-0.08 weight percent of CaCO3, 0.002-0.01 weight percent of SiO2, 0.02-0.06 weight percent of Nb2O5, 0.03-0.20 weight percent of CoO, 0.01-0.05 weight percent of V2O5, 0-0.20 weight percent of SnO2 and 0-0.10 weight percent of TiO2. The invention also provides a manufacturing method of the high-frequency low-loss MnZn ferrite material.

Owner:江门江益磁材有限公司

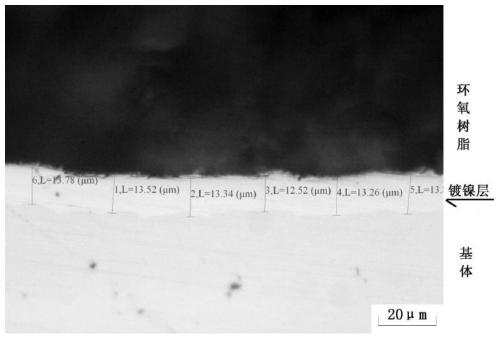

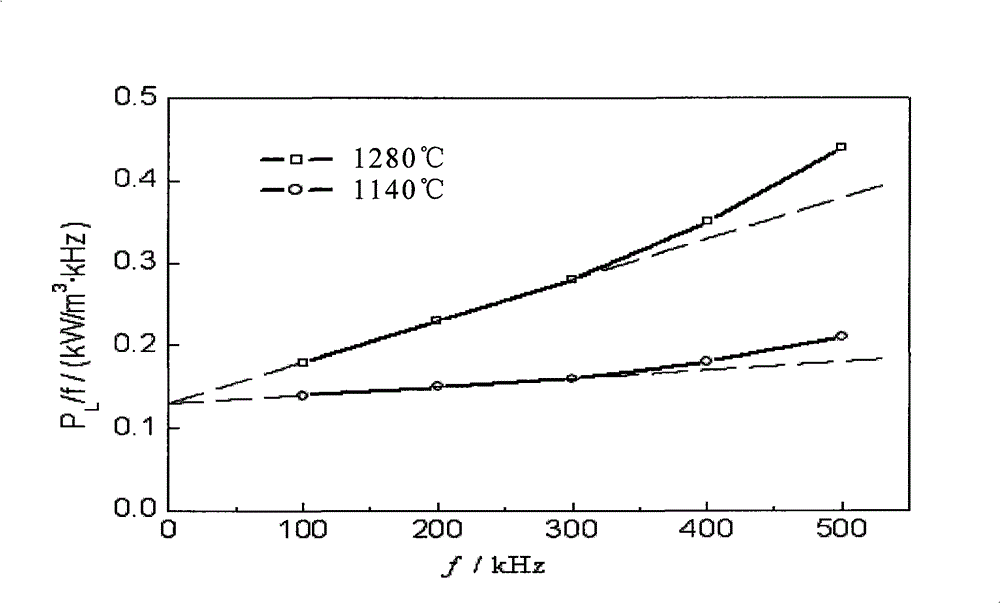

Wide temperature ultra-low loss MnZn soft magnetic ferrite material and preparing method thereof

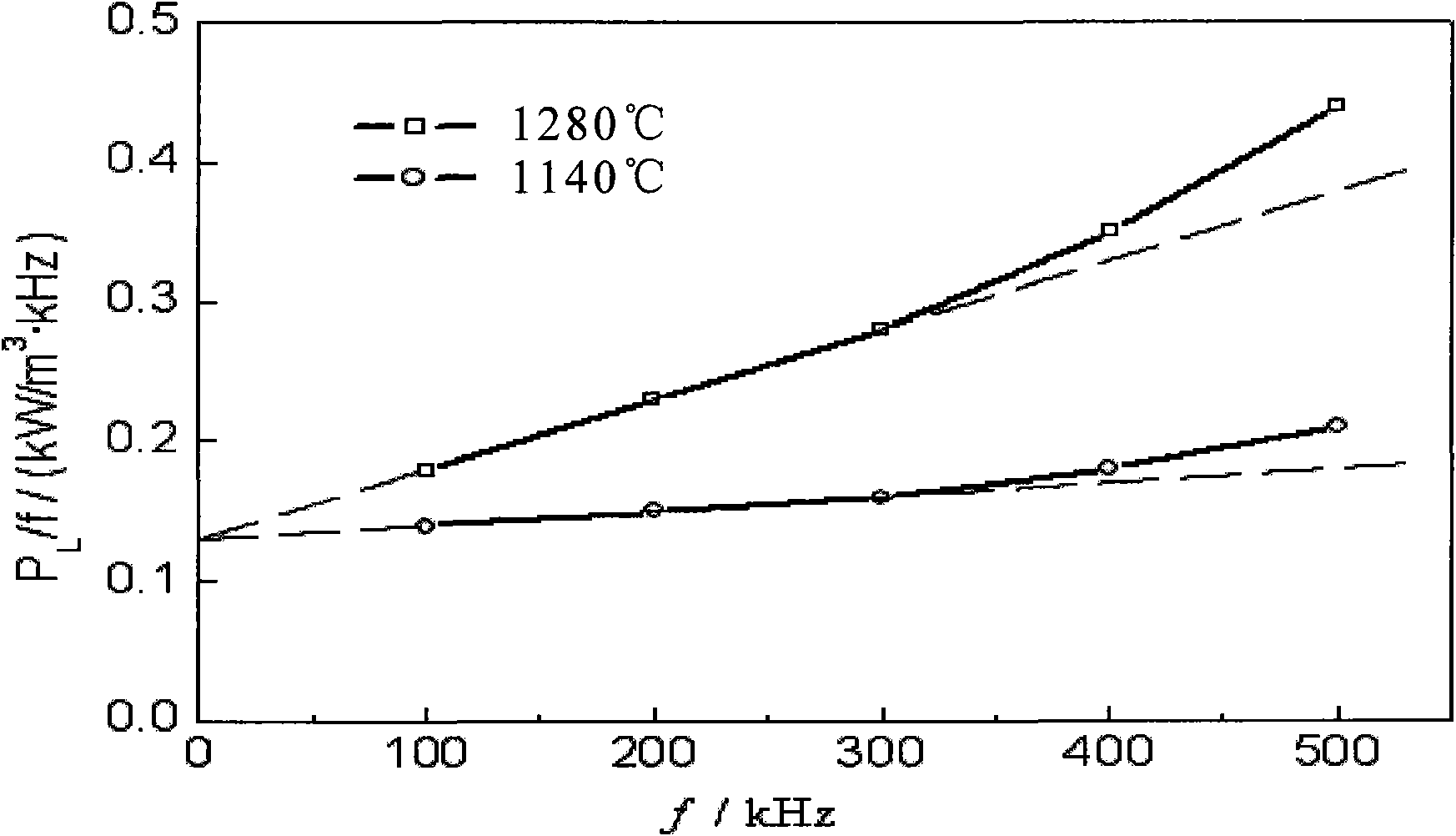

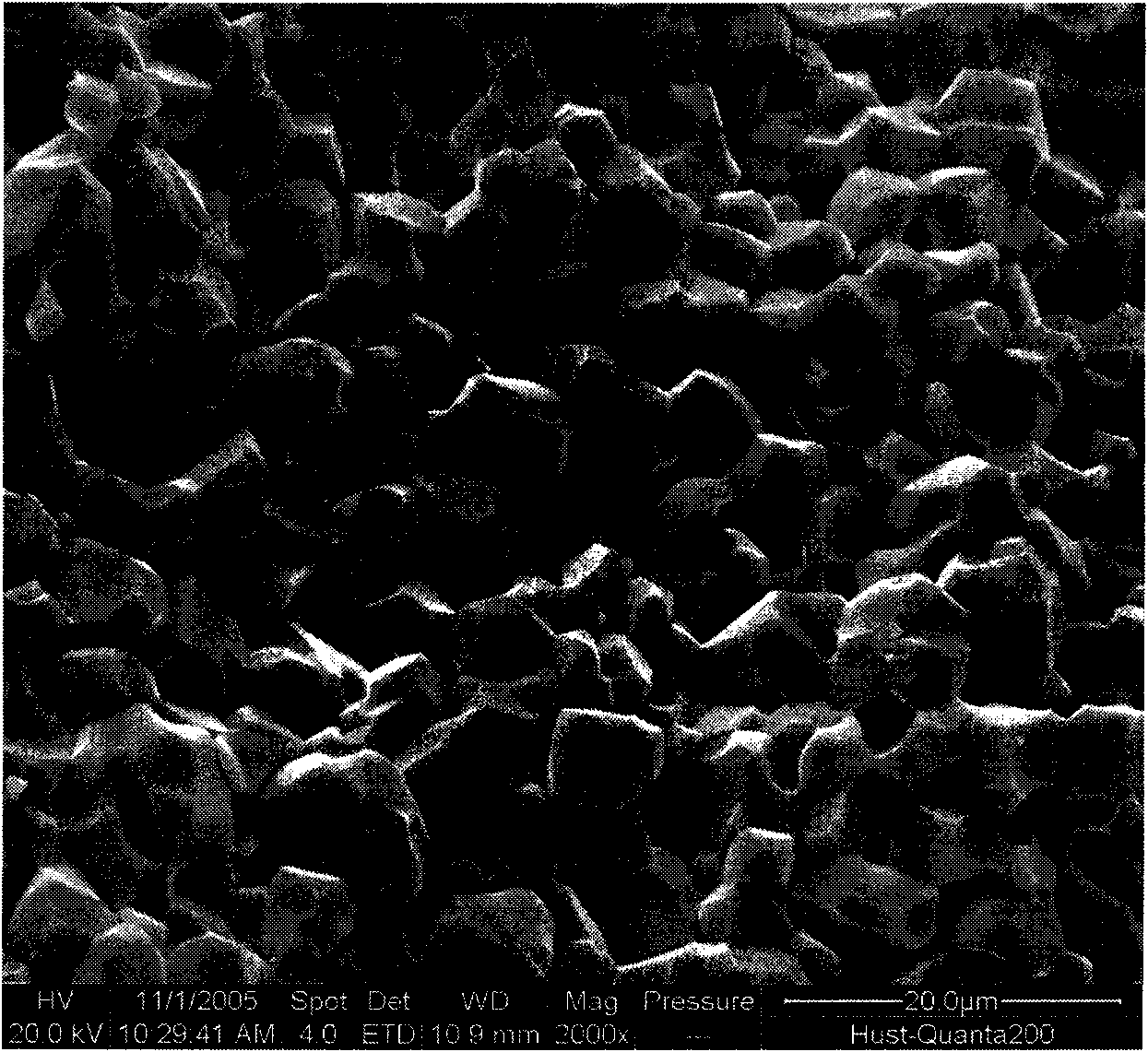

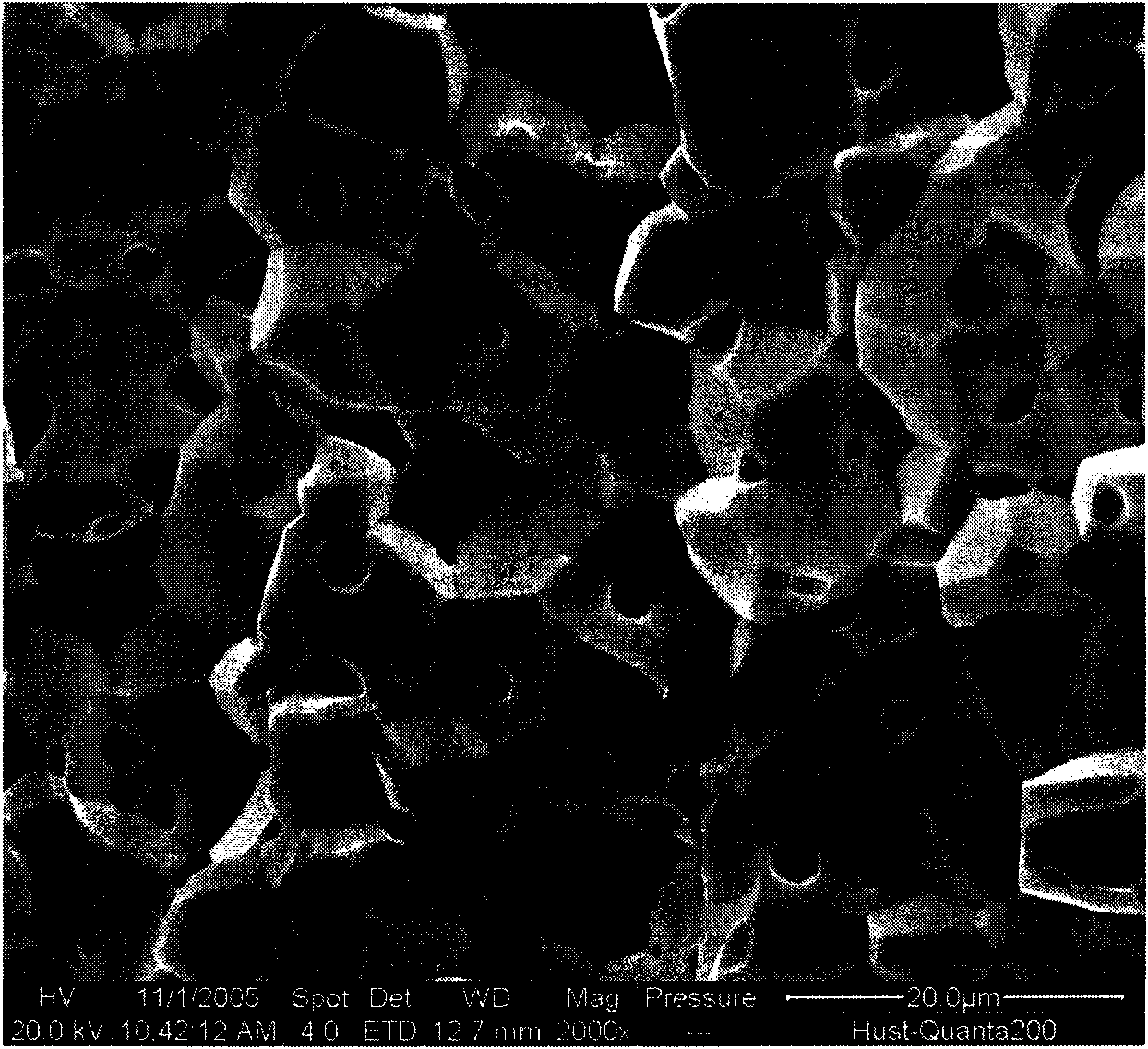

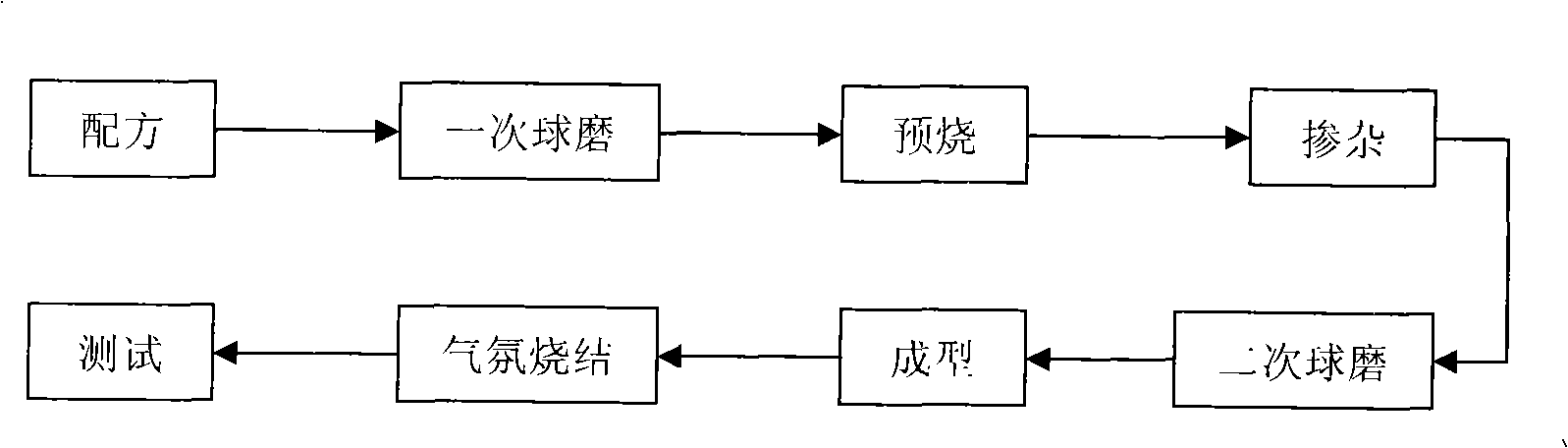

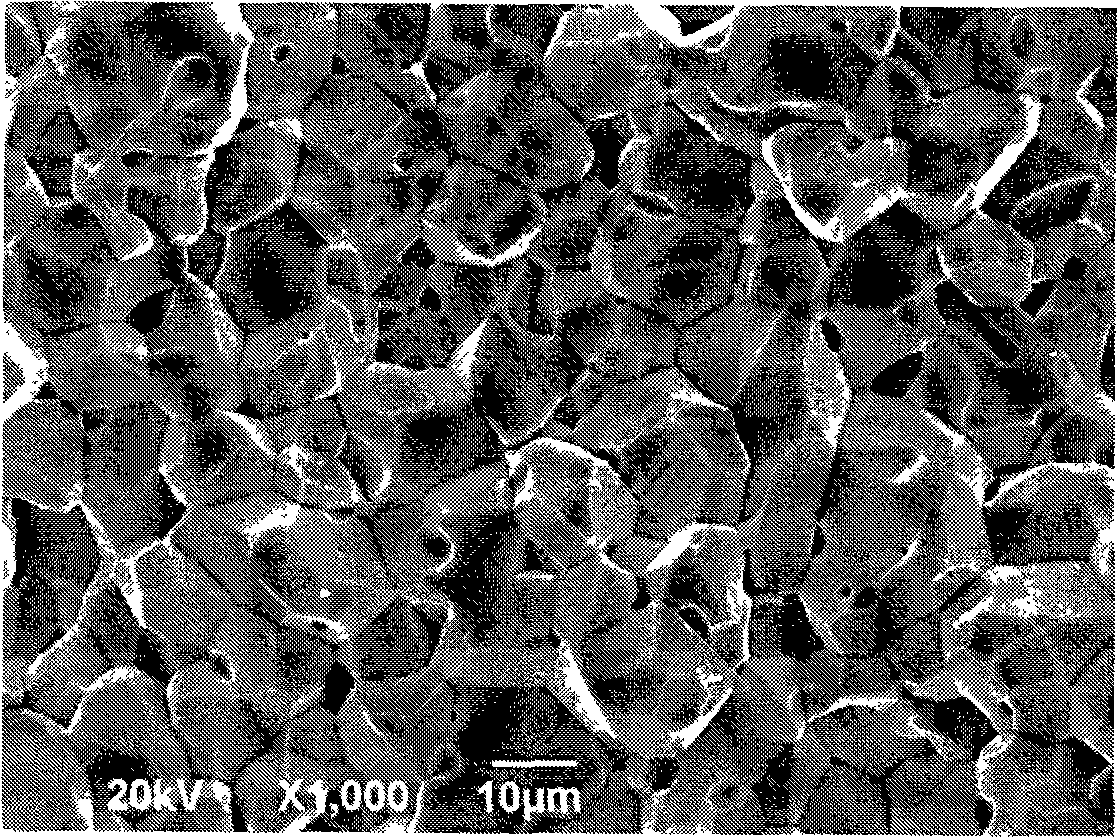

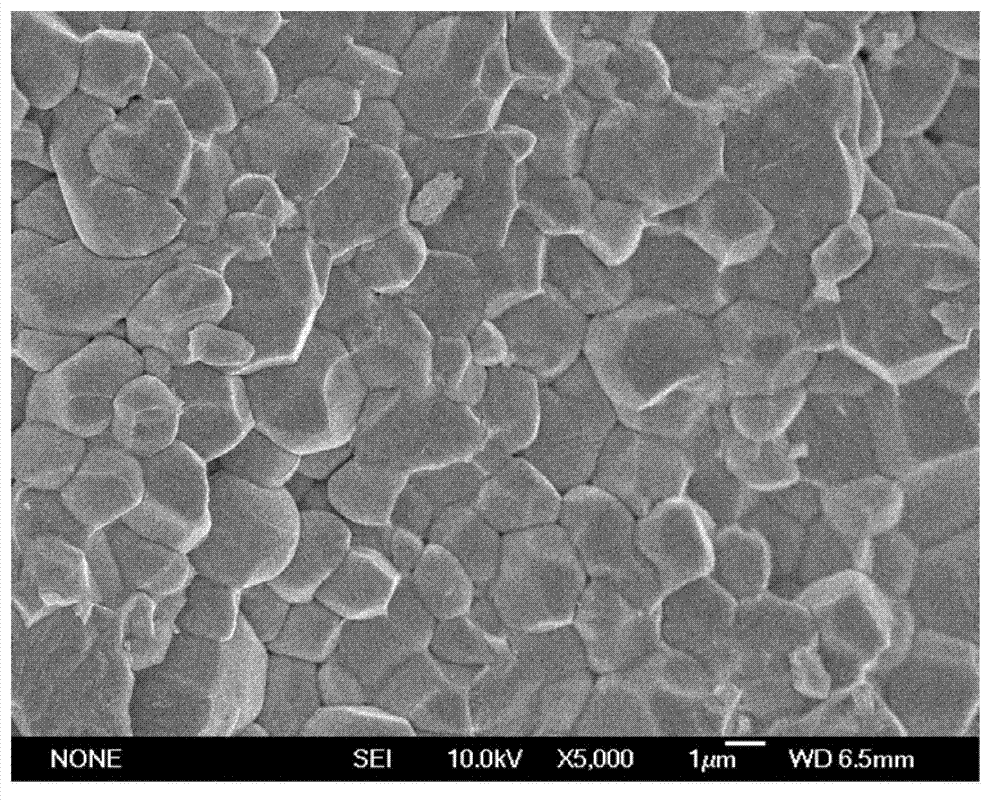

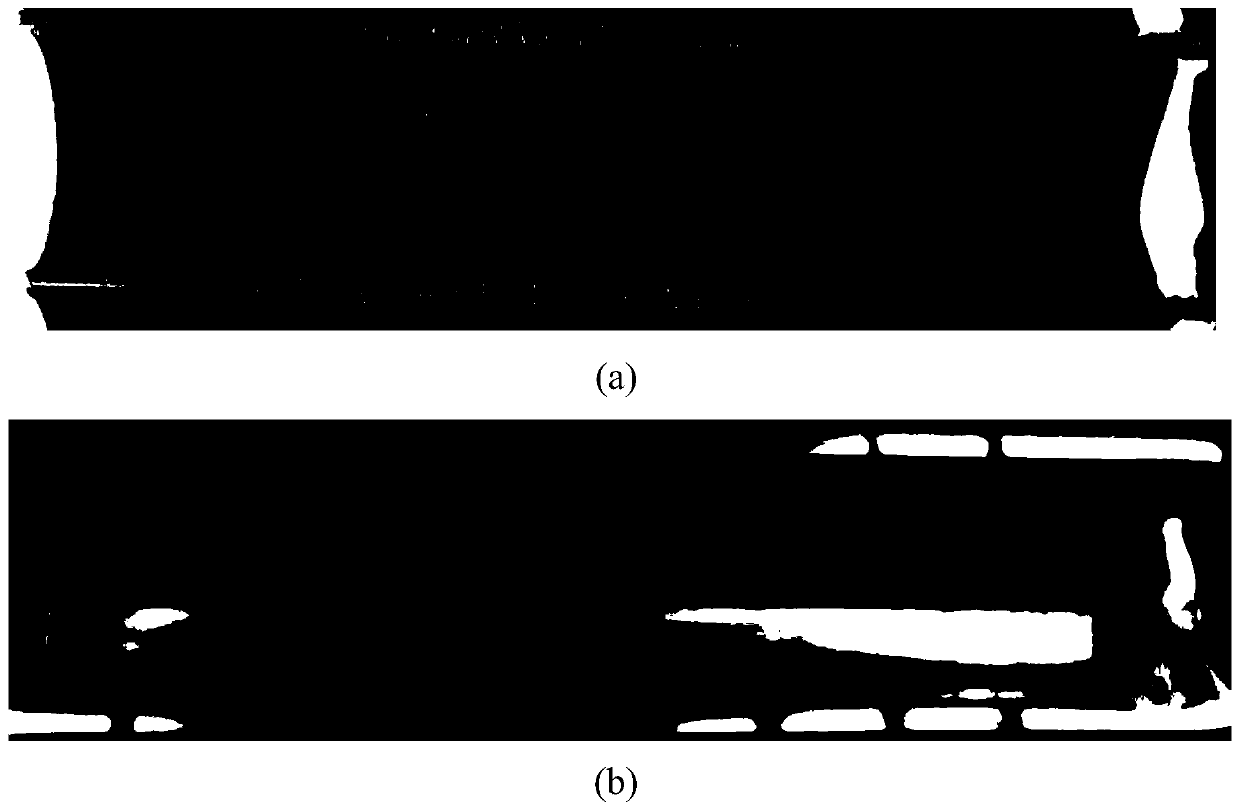

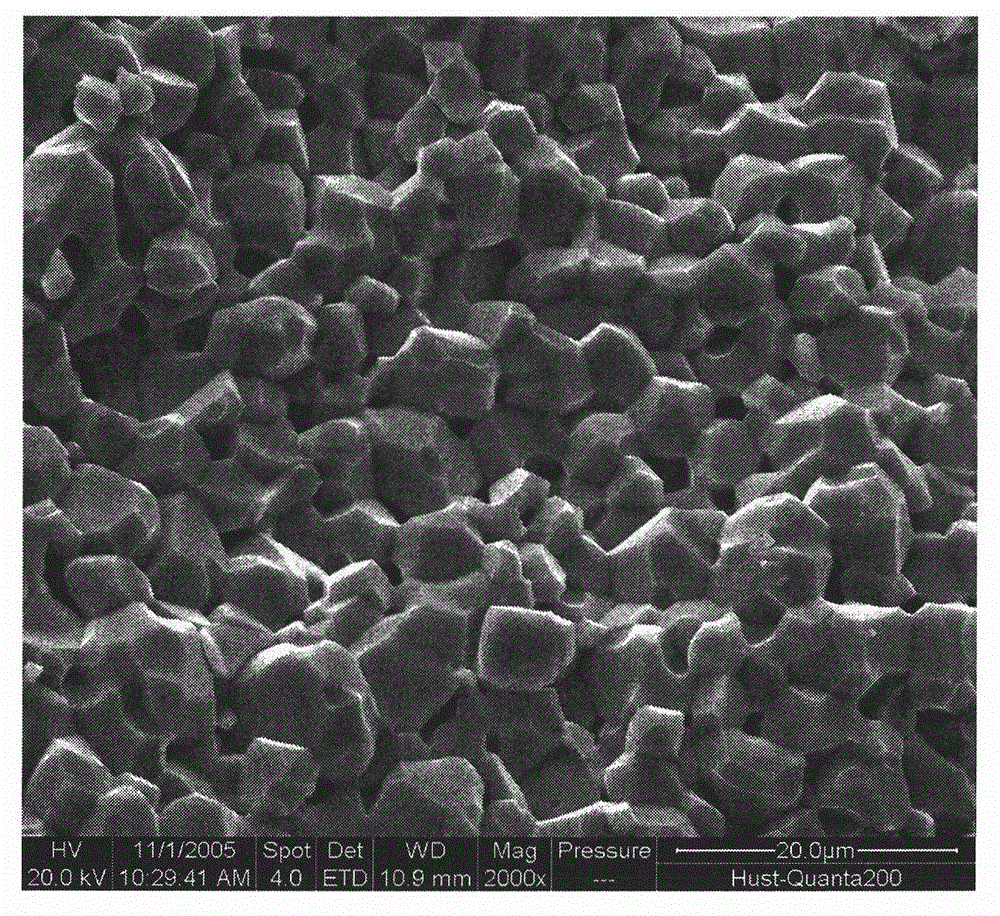

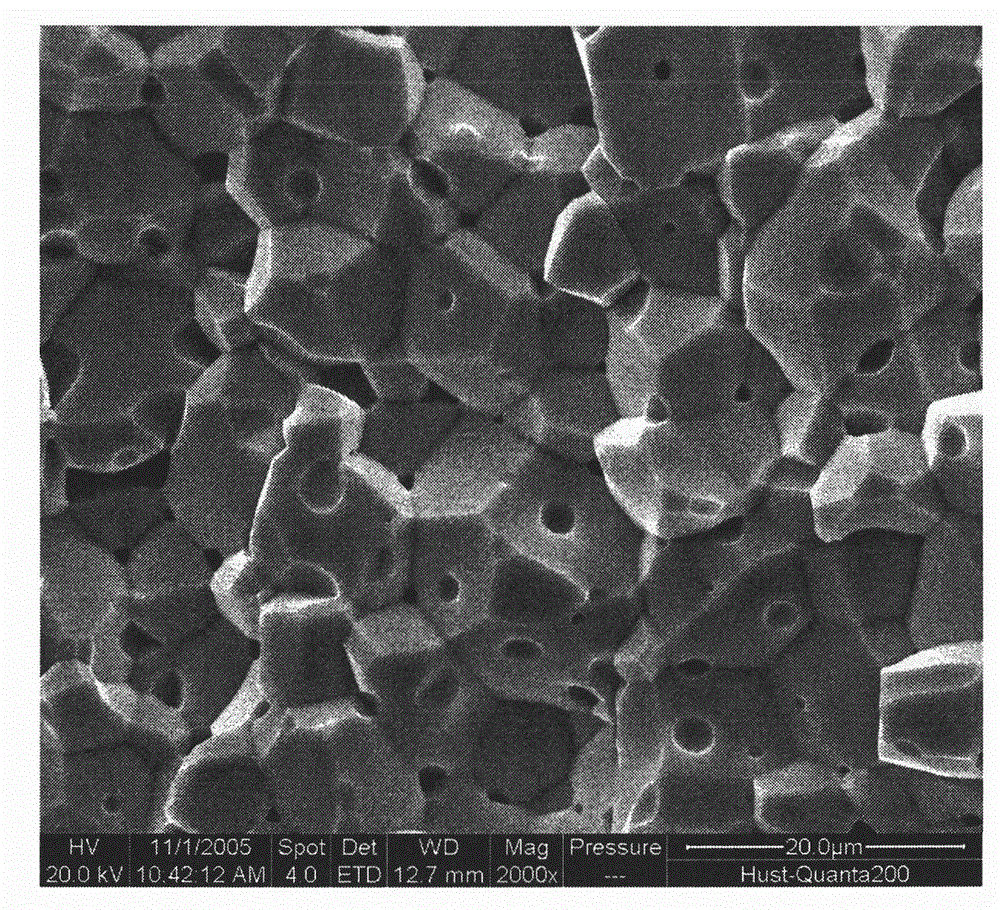

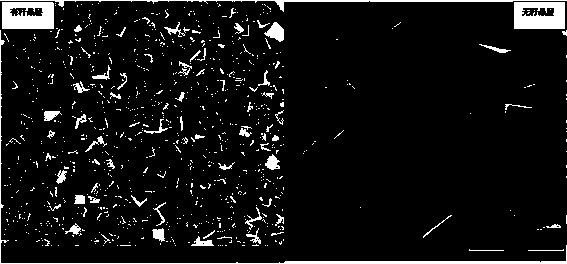

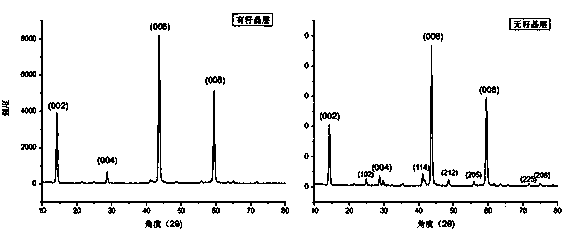

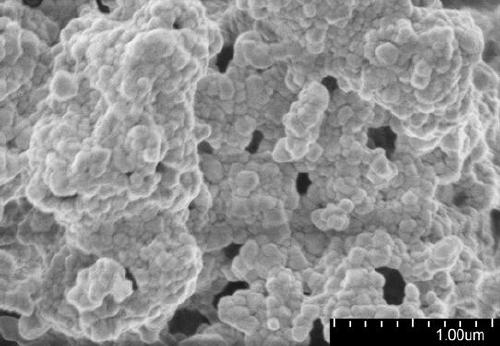

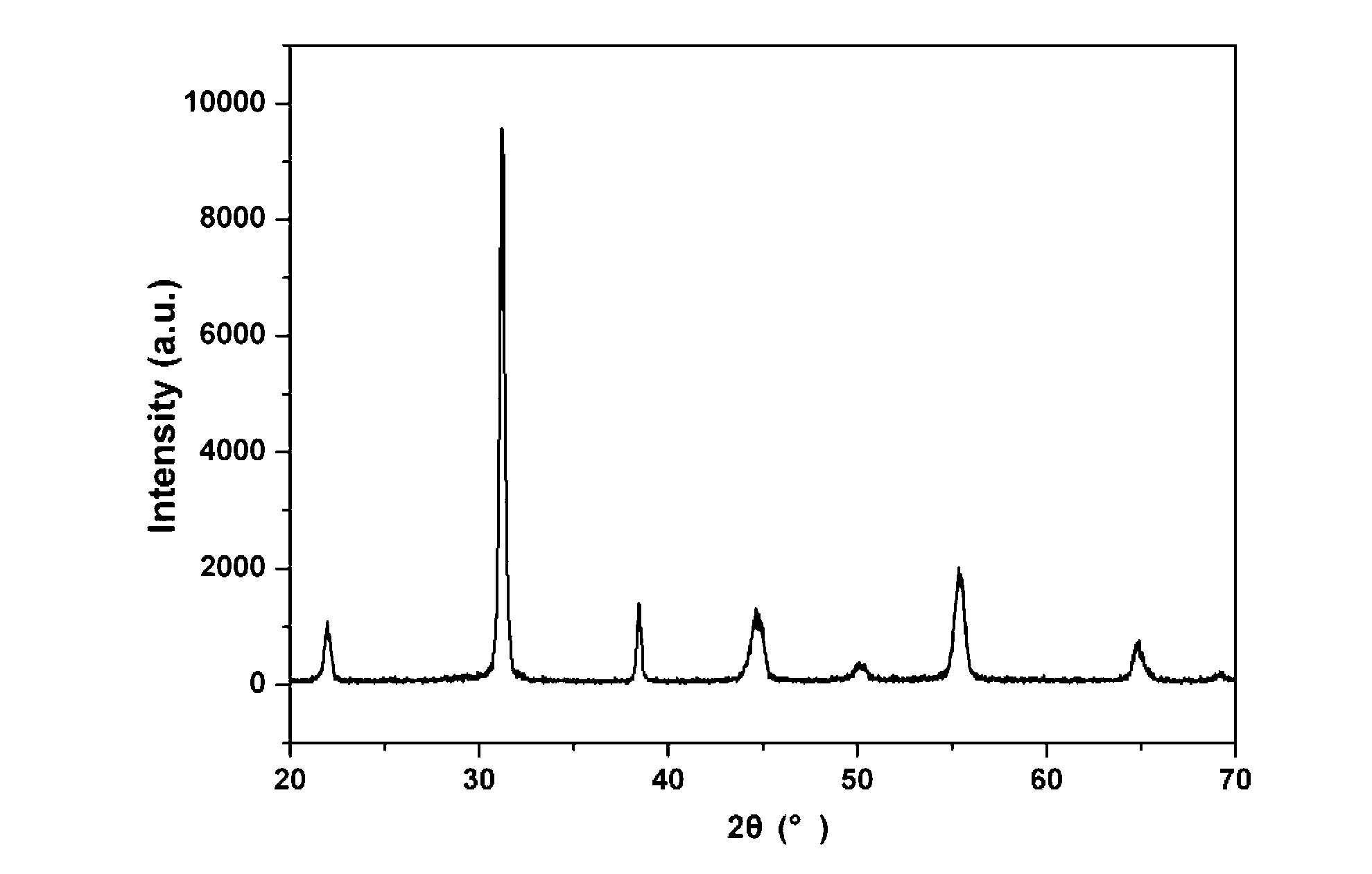

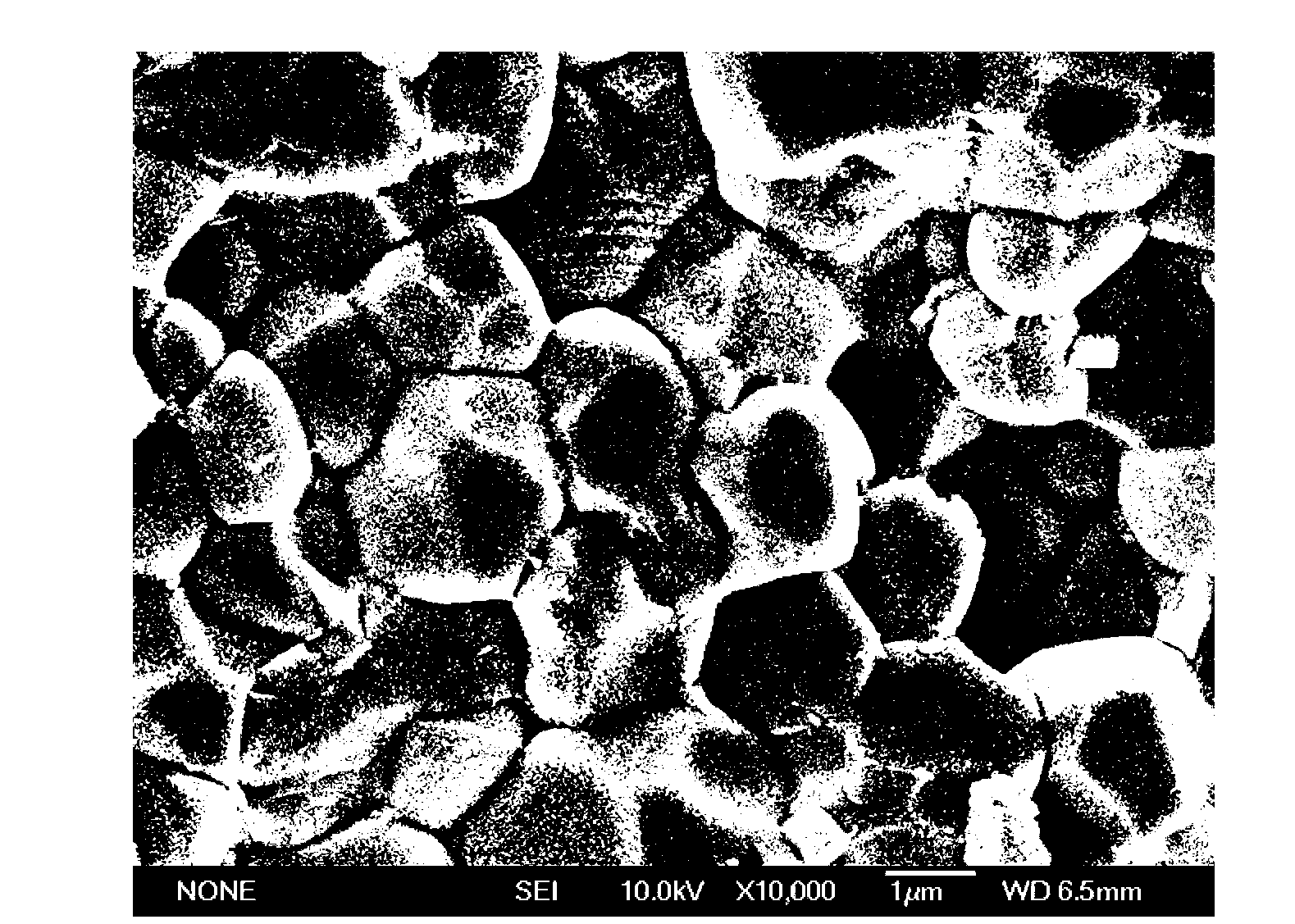

InactiveCN101256866AUniform and dense grainInorganic material magnetismCrystalliteElectronic materials

The present invention relates to wide-temperature ultra-low-loss MnZn soft magnetic ferrite material and method for manufacturing, and belongs to electronic material technology field. The main constituent is calculated by oxide with molar percentage: 65-75mol%Fe2O3, 13-20mol%ZnO, 0.0001-0.5mol%TiO2, allowance being Mn3O4; weight percentage of doping agent: 0.01-0.1wt%CaO, 0.01-0.09wt%Nb2O5, 0.01-0.1wt%V2O5, 0.001-0.1wt%ZrO2, and 0.05-1wt%Co2O3. Grain of wide-temperature ultra-low-loss MnZn soft magnetic ferrite material of the invention is uniform and dense, and average grain dimension is about 12-18Mum.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

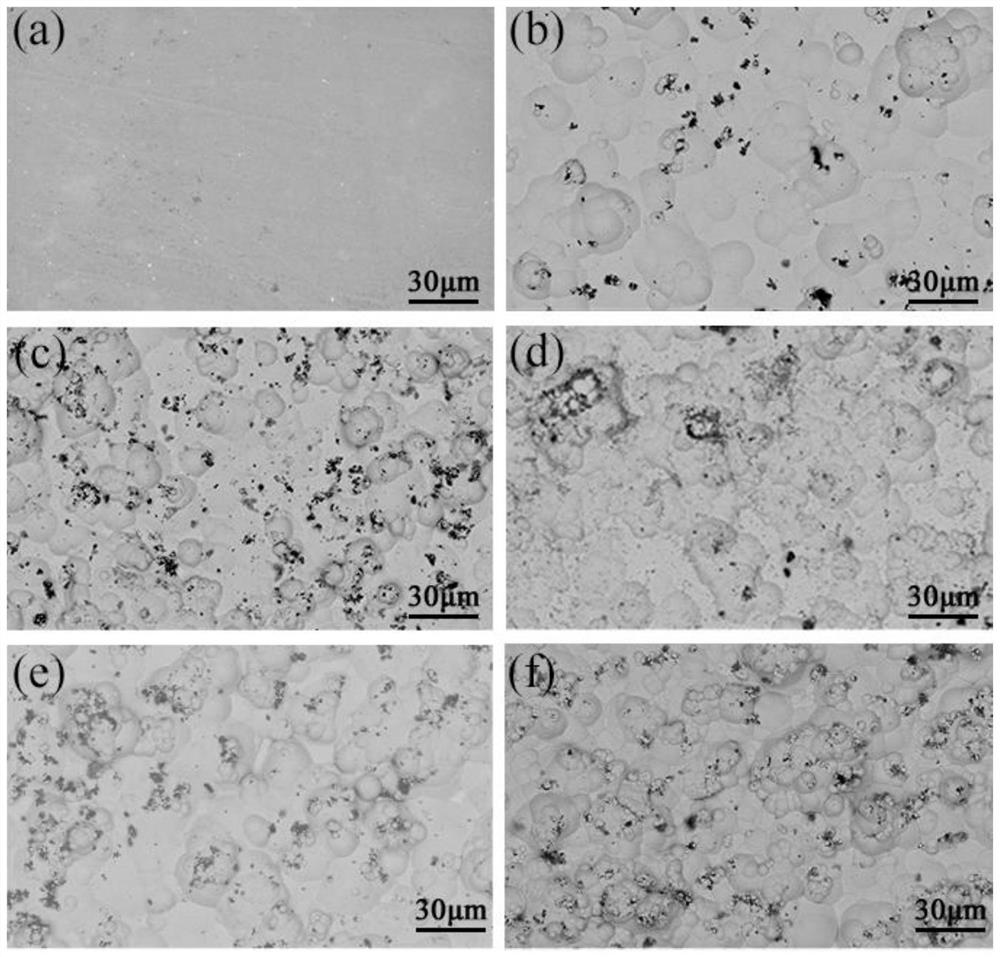

Crystallized honey and making method thereof

ActiveCN105010928AThe taste is dense and waxyUniform and dense grainFood preparationAdditive ingredientSeed crystal

The invention provides a making method of crystallized honey. According to the method, seed crystal is prepared by a twice crystallization process of firstly carrying out quantitative inoculation and secondly carrying out natural crystallization; and then, the crystallized honey product is prepared by a crystallization process of repeated alternate steps of air agitation and standing. The prepared crystallized honey has uniform and dense crystalline grains and has good ductility. The crystallized honey will not be obviously molten or layered when being stored at 30 DEG C or below, not influencing choices of consumers due to appearance of the crystallized honey. The crystallized honey is convenient to take and tastes dense and fine. In addition, other ingredients are not added, and honey is completely used as the raw material to prepare the crystallized honey. Thus, consumers' fear for the harm of other added additives is eliminated. Besides, the making method of the crystallized honey has high crystallization efficiency, and a creamy crystallization state with particle size according with requirements can be obtained within 24-48 hours.

Owner:COFCO GROUP +2

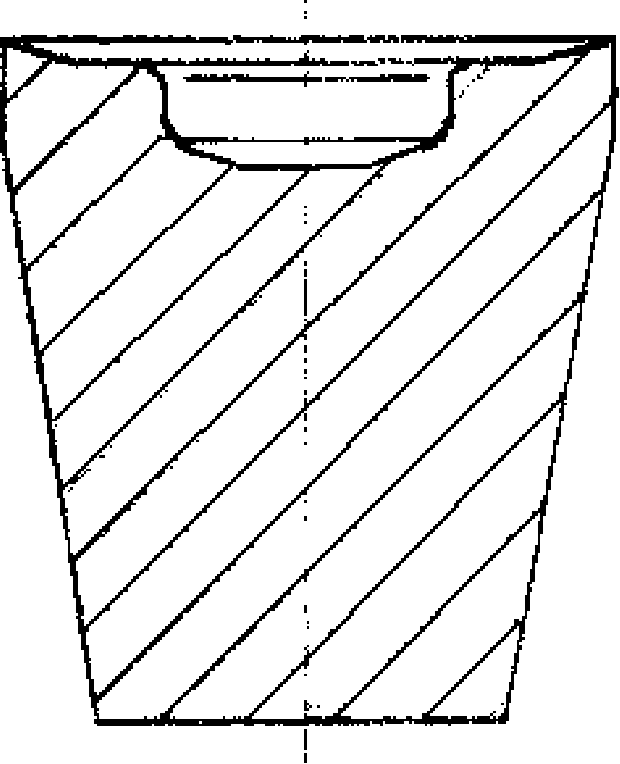

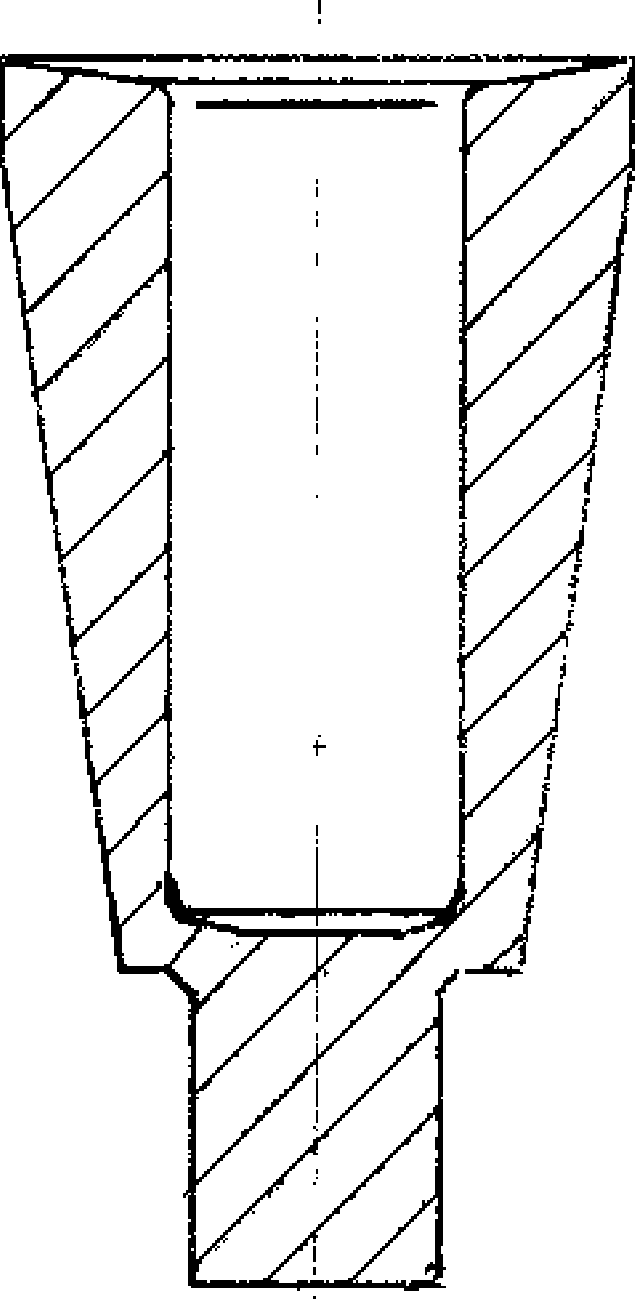

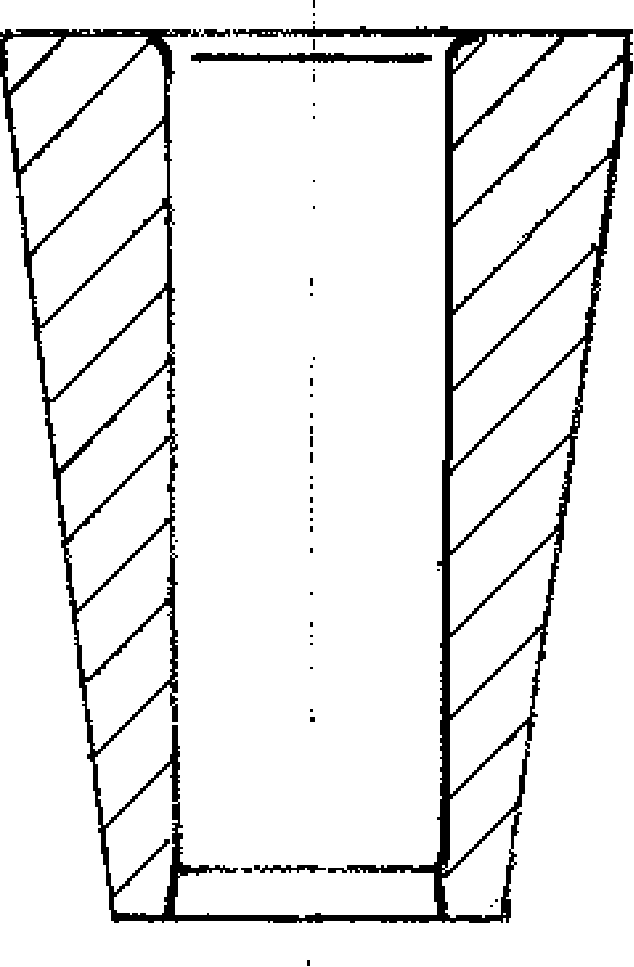

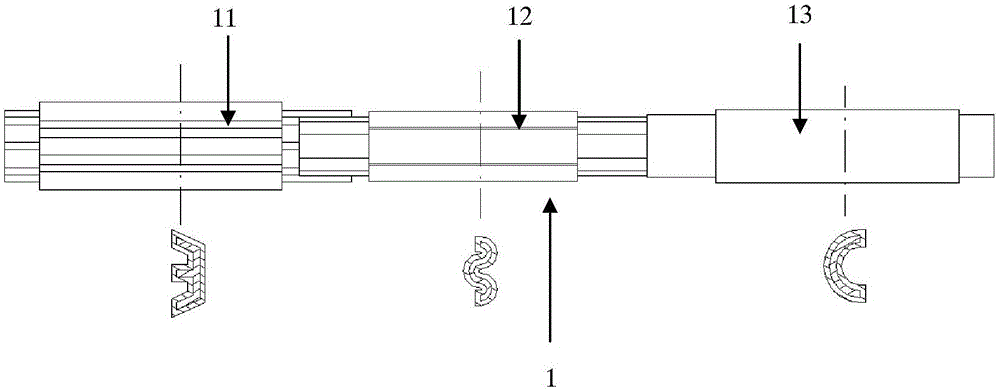

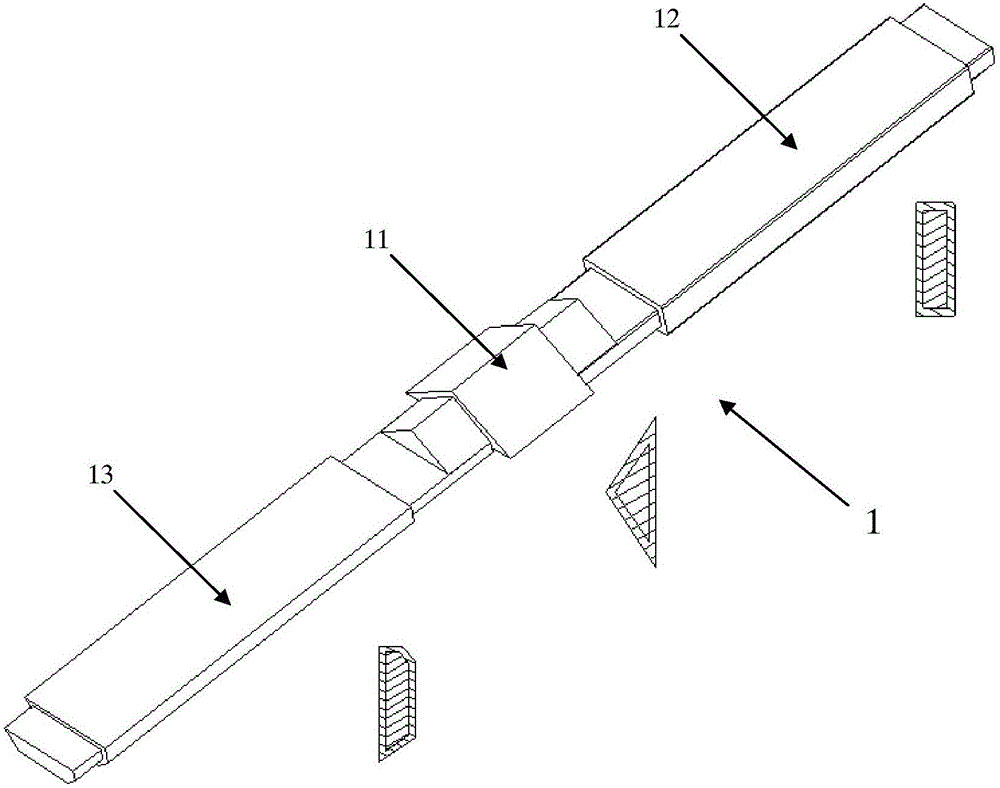

Anchor clipper through hole type workblank cold pressing technique

The invention relates to an anchorage device clamping piece through-hole type blank cold flow pressing process used in a pre-stressed anchorage device system, which is characterized in that after a round bar and a stock are chosen, the following steps are performed in sequence: discharging, shot blasting treatment, phosphorizing and saponifying treatment, performing, normalizing treatment, shot blasting treatment, phosphorizing and saponifying treatment, extrusion forming, punching forming, shot blasting treatment, phosphorizing and saponifying treatment and extrusion forming, the anchorage device clamping piece through-hole type blank similar to the finished product clamping piece can be prepared out by adopting the steps. The invention has the advantages that the availability and the saving rate of material are high; the machine processing amount is greatly reduced; the compactness of the clamping piece is increased.

Owner:阚柳凤

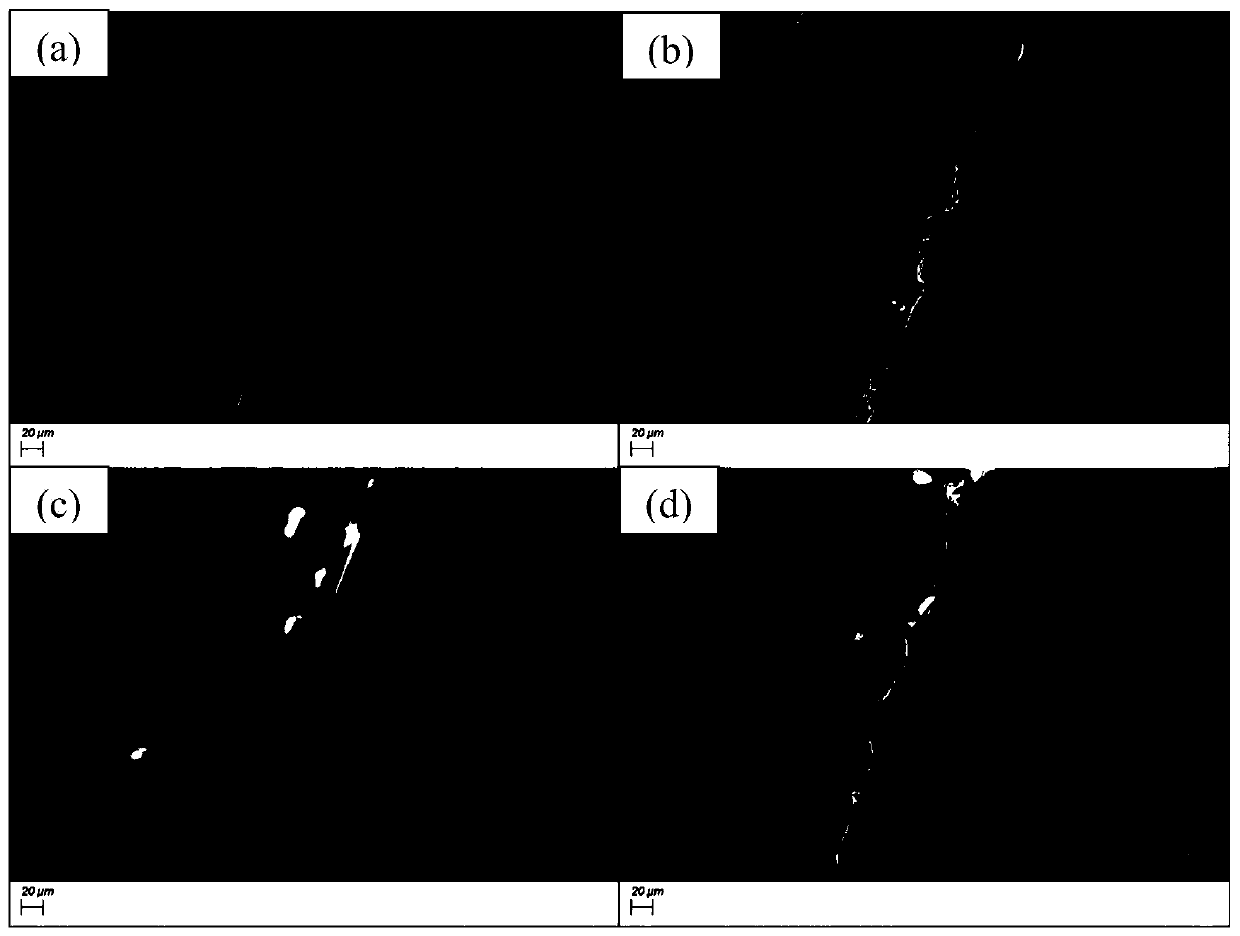

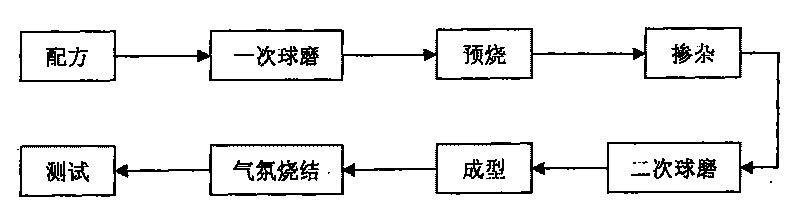

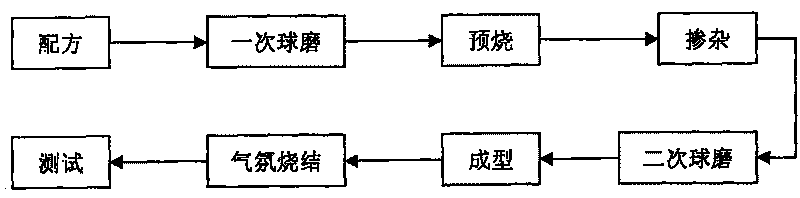

Method for preparing rare-earth-doped manganese-zinc ferrite material

InactiveCN109553408AChanging grain boundary compositionChange ionic valencePolyvinyl alcoholRare earth

The invention relates to the technical field of magnetic materials, and discloses a method for preparing a rare-earth-doped manganese-zinc ferrite material, comprising the steps of adding manganese oxide, zinc oxide and iron oxide as main components to a ball mill and conducting ball milling to obtain a mixture A; pre-firing the mixture A, and then conducting cooling to room temperature to obtaina pre-fired material; adding the pre-sintered material, vanadium oxide, niobium oxide, bismuth trioxide, molybdenum oxide, phosphorus pentoxide, copper oxide and a composite rare earth additive into aball mill, and conducting secondary ball milling and drying to obtain a mixture B, wherein the composite rare earth additive is composed of cerium oxide, yttrium oxide and lanthanum oxide; adding a polyvinyl alcohol solution to the mixture B, conducting mixing and granulation, and then conducting sieving by a sieve of 40-80 mesh, so as to obtain pellets; adding the pellets into a molding machinefor pressing, so as to obtain a blank; and sintering the blank and conducting cooling. The rare-earth-doped manganese-zinc ferrite material prepared by the method of the invention has high initial magnetic conductivity and saturation magnetic flux density.

Owner:ZHONGDE ELECTRONICS

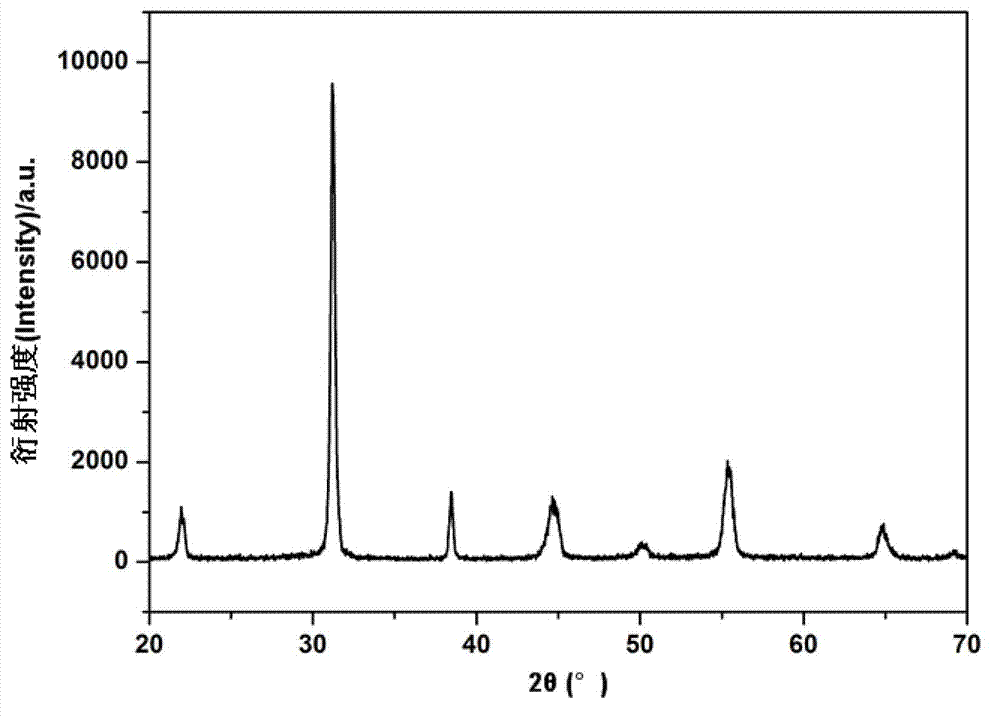

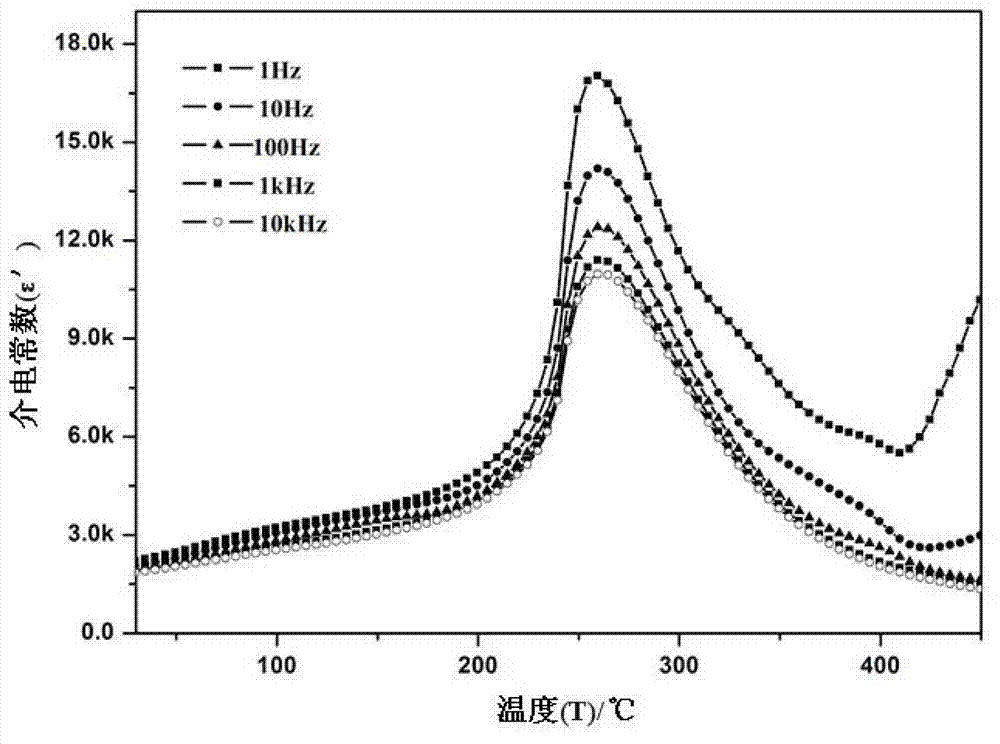

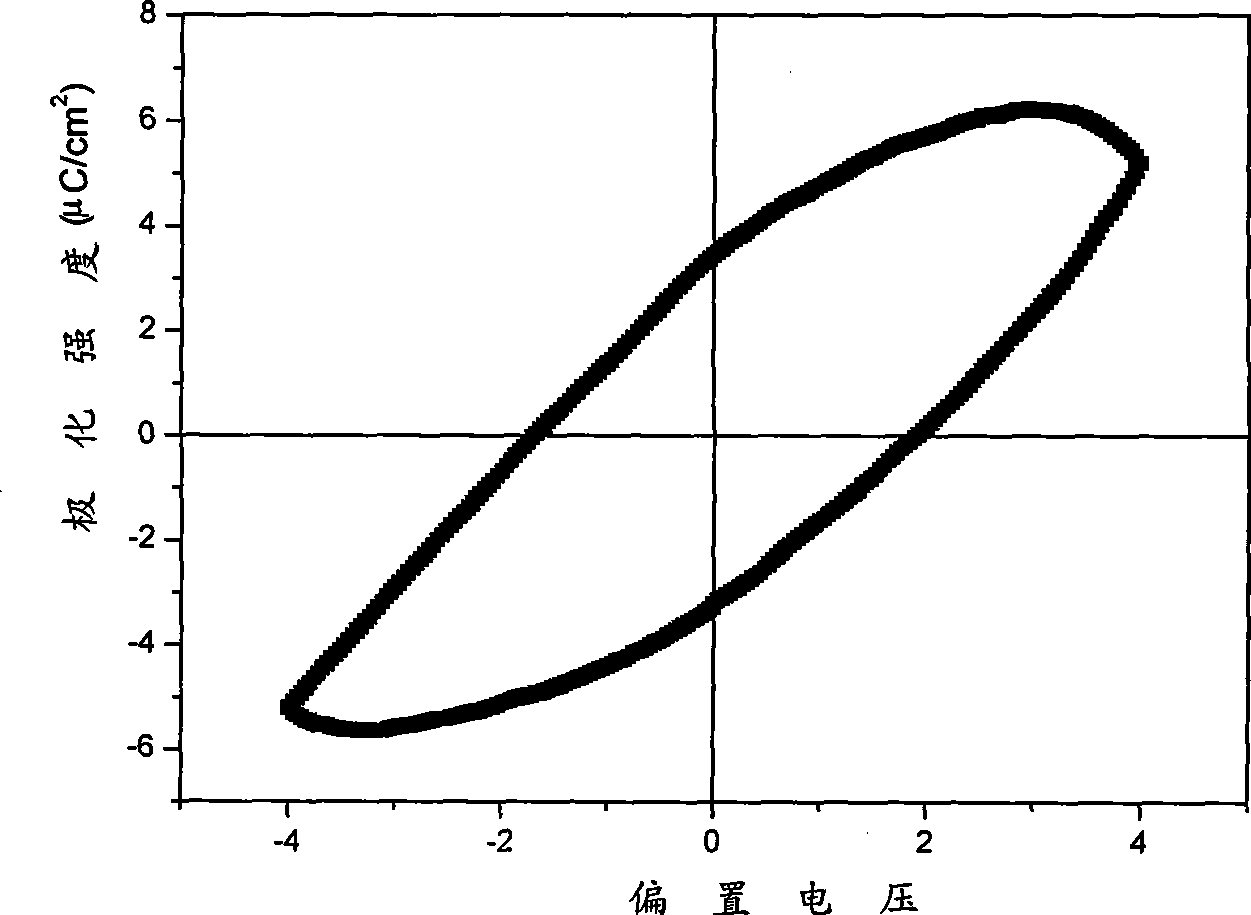

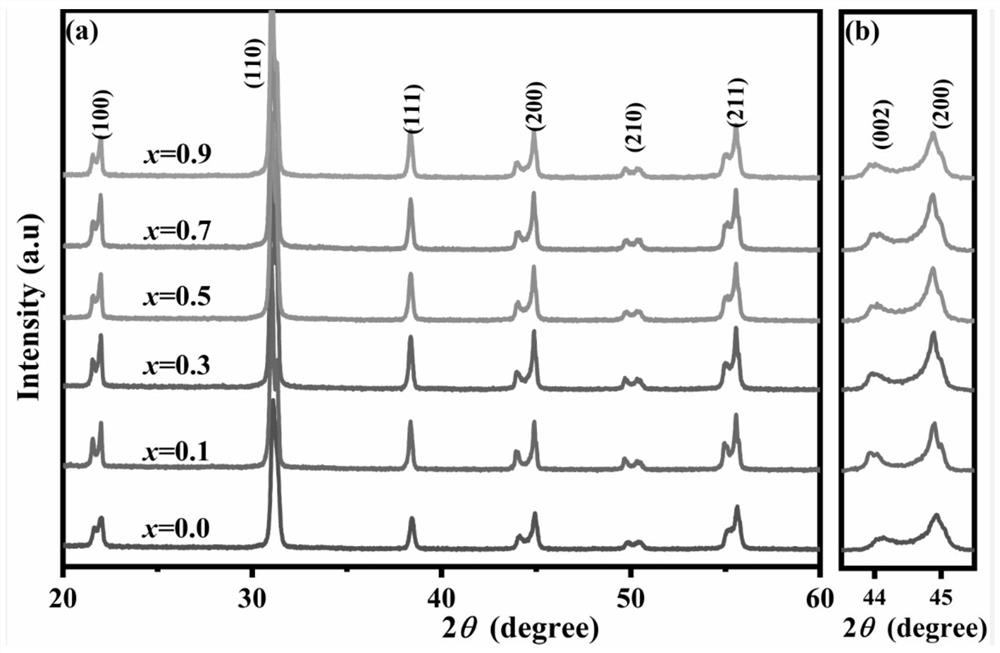

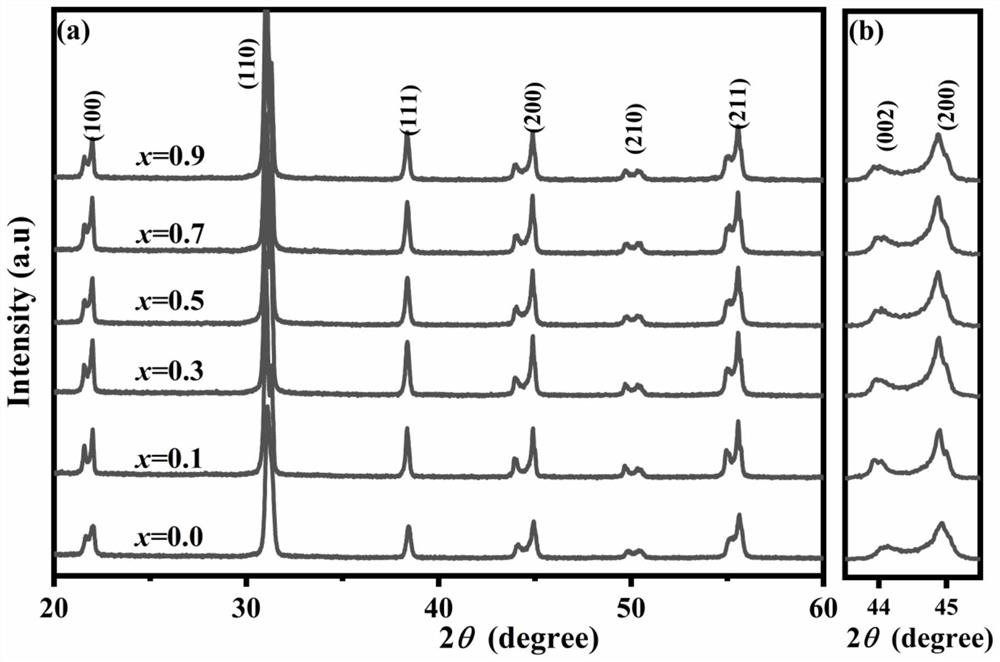

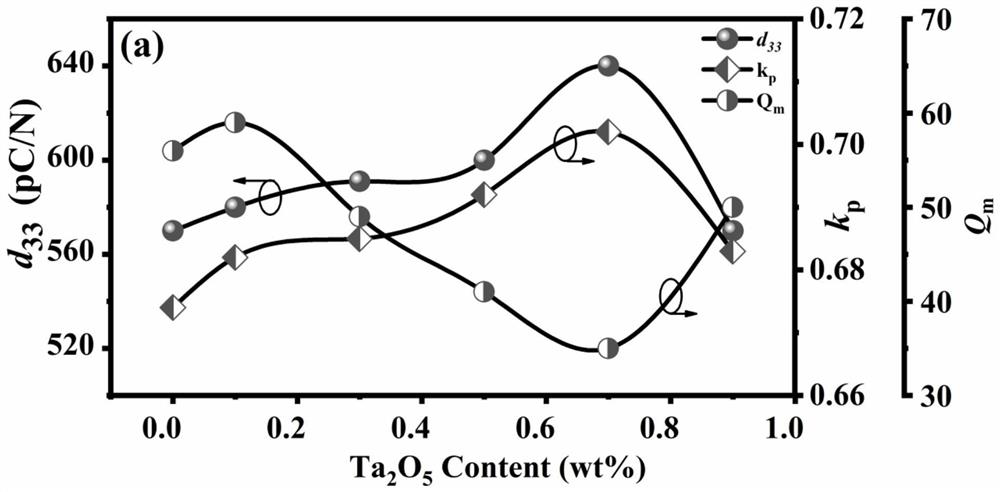

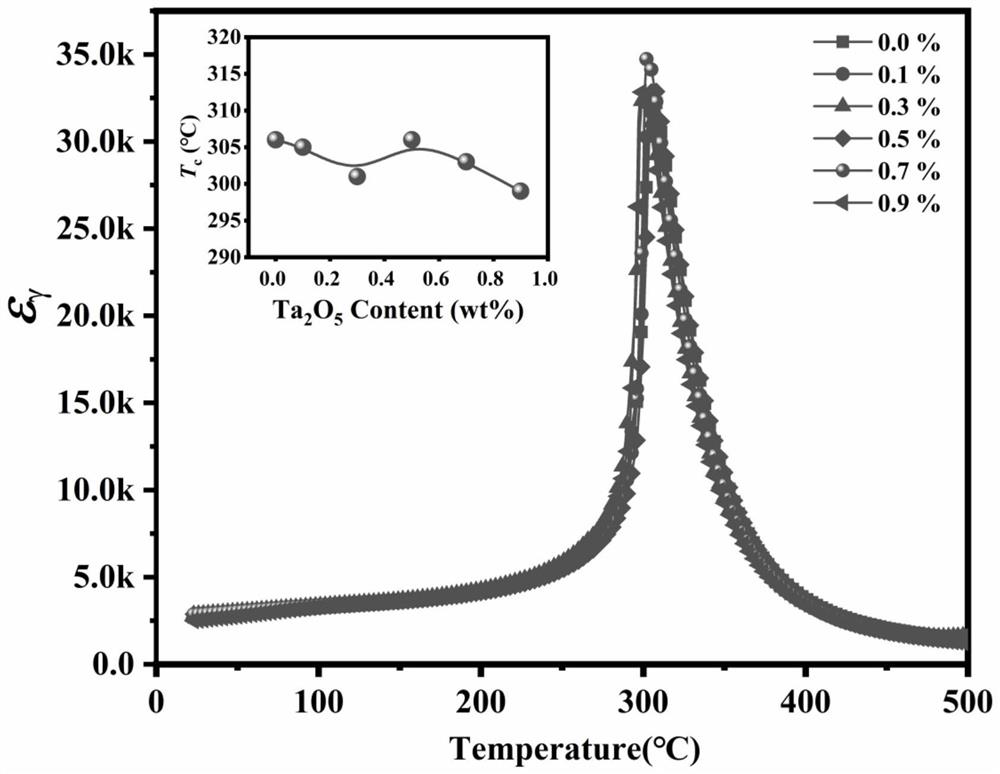

Ternary ferroelectric solid solution lead niobate ytterbate-lead zinc niobate-lead titanate

The invention relates to a ternary ferroelectric solid solution lead niobate ytterbate-lead zinc niobate-lead titanate. The chemical formula of the solid solution is xPb(Yb1 / 2Nb1 / 2)O3-yPb(Zn1 / 3Nb2 / 3)O3-(1-x-y)PbTiO3, wherein x is more than 0 and less than 1, and y is more than 0 and less than 1, and the solid solution belongs to a typical composite perovskite structure. The system is good in piezoelectric and electromechanical performance, high in Curie temperature and good in thermal stability, and has a wide application prospect.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

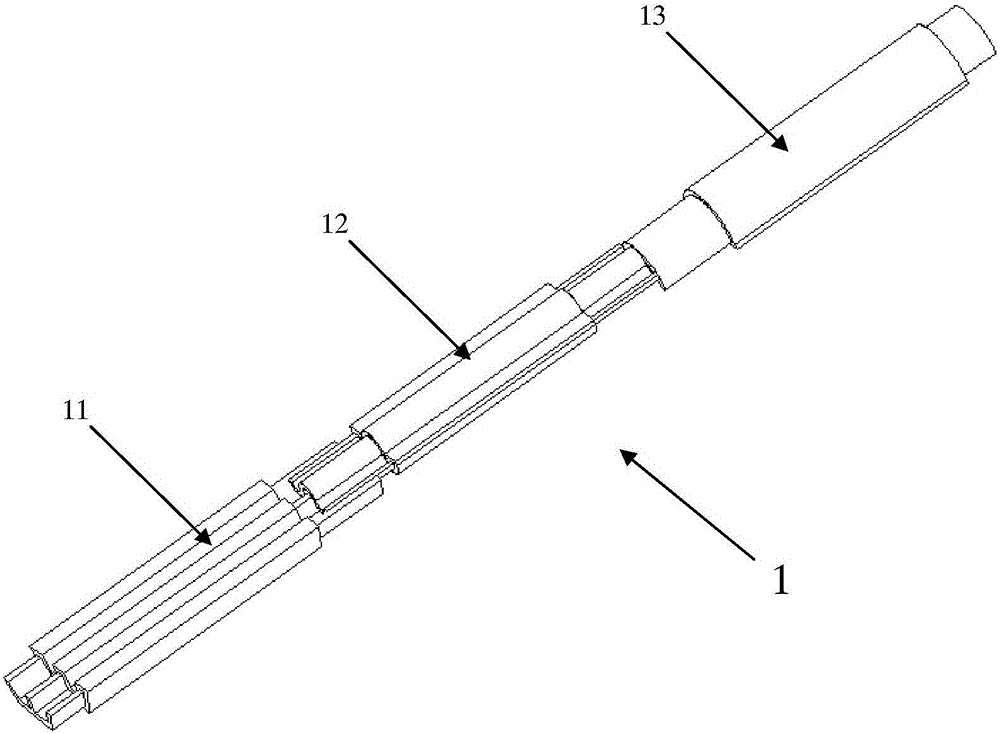

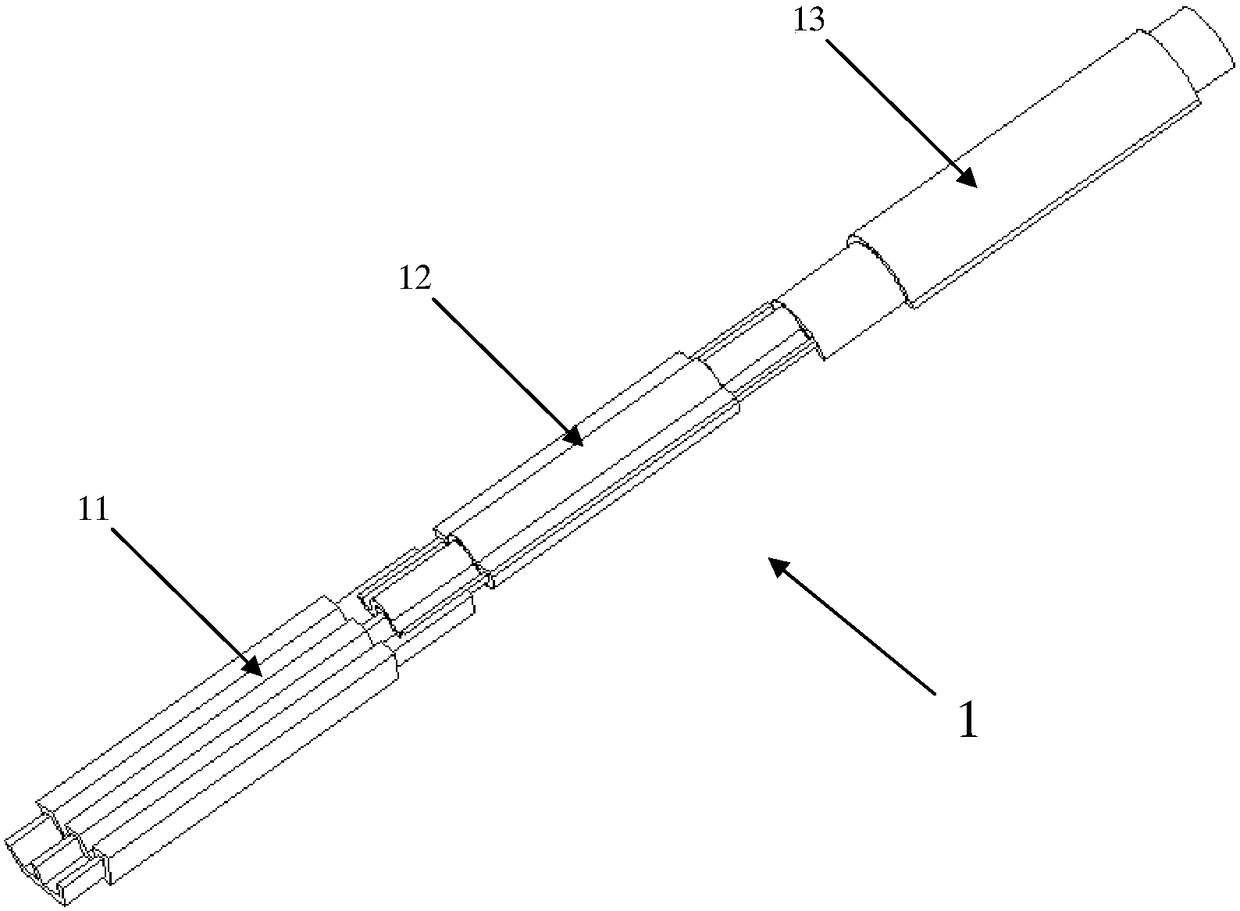

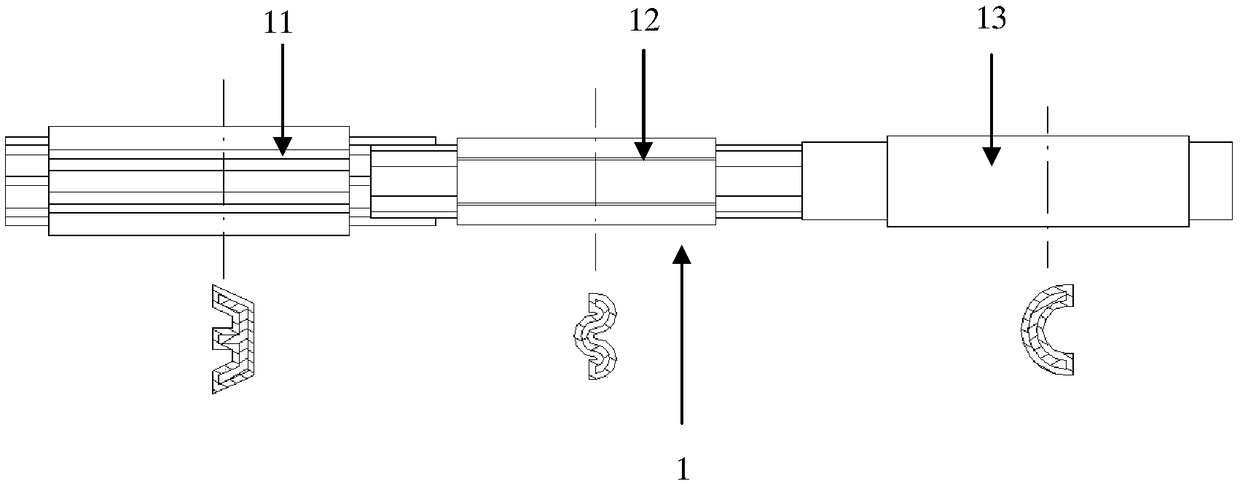

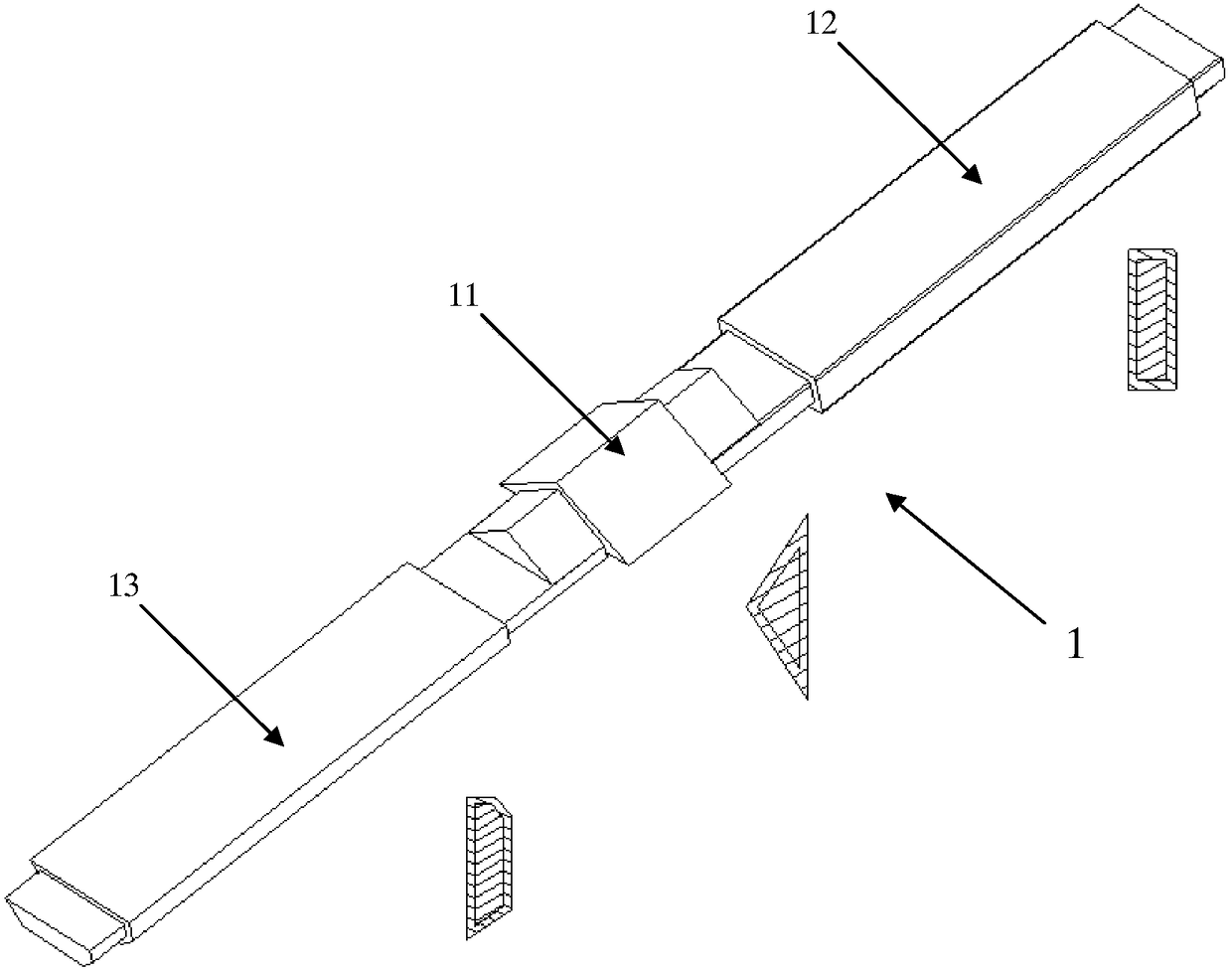

Special-shaped cable and preparation method thereof

ActiveCN106653163ADoes not affect operationReduced eddy current effectDetails of conductive coresManufacturing wire harnessesAbnormal shapedConsumables

The invention discloses a special-shaped cable and a preparation method thereof. The conductive core of the special-shaped cable is composed of at least two conductive core segments in an end-to-end way, wherein the cross sections of the conductive core segments are different in shape. The conductive core segments are externally wrapped by an insulating layer. The contour of the insulating layer is fit with the conductive core segments. The cable has great bending performance and can also be greatly fit with a vehicle body so that consumables can be saved and the safety performance can be greatly enhanced. The cable is made of the aluminum or aluminum alloy conductive cores so that the vehicle body is enabled to be light-weighted, and the production cost of the motor vehicle can be reduced. The preparation method of the special-shaped cable comprises the steps of manufacturing the conductive core segments, connection of the conductive core segments and manufacturing of the insulating layer so that the production efficiency and the productivity can be effectively enhanced according to different production requirements and the production cost can be reduced.

Owner:长春捷翼汽车科技股份有限公司

Low temperature method for preparing Nano crystal thin film of semiconductor in Znl-xMgxO structure of wurtzite

InactiveCN1727516ANo side effectsEasy to getVacuum evaporation coatingSputtering coatingHigh energyNanocrystal

A low-temp process for preparing the nanocrystal film of the semiconductor Zn1-xMgxO (x=0-0.36) with wurtzite structure includes emitting high-energy electron beams by electronic gun, focusing, bombarding the target made up of MgO and ZnO through high-temp sintering, evaporating ZnO and MgO moleculae, depositing on the surface of heated substrate, diffusing to form crystal nuclei, continuous growing to form nanocrystal film, and high-temp (300-600 deg.C) annealing in O2.

Owner:ZHEJIANG UNIV

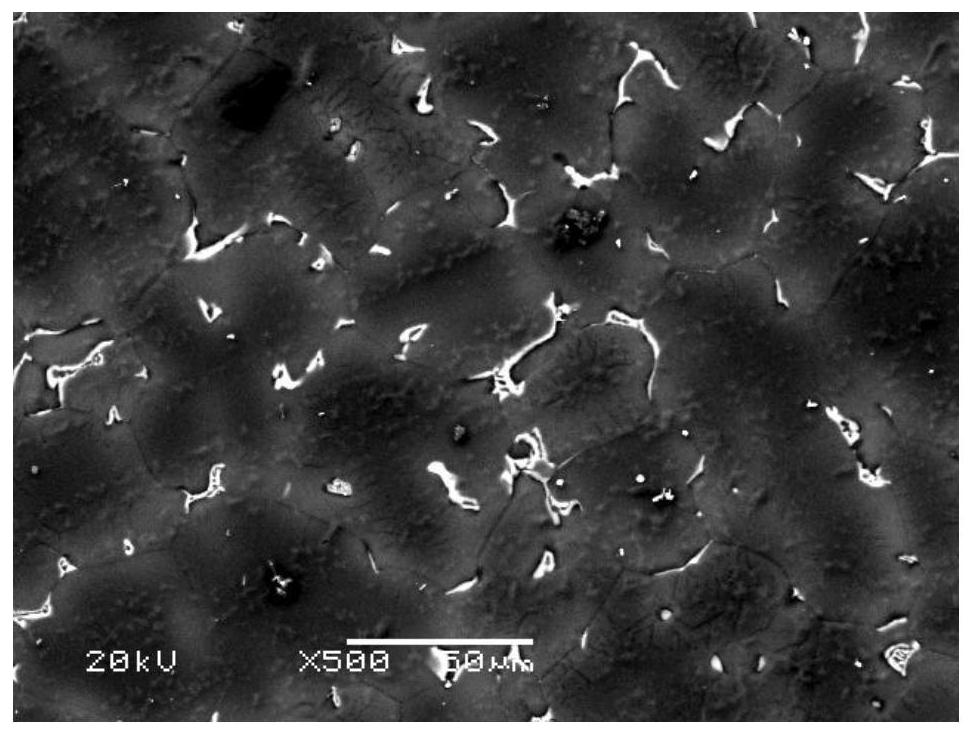

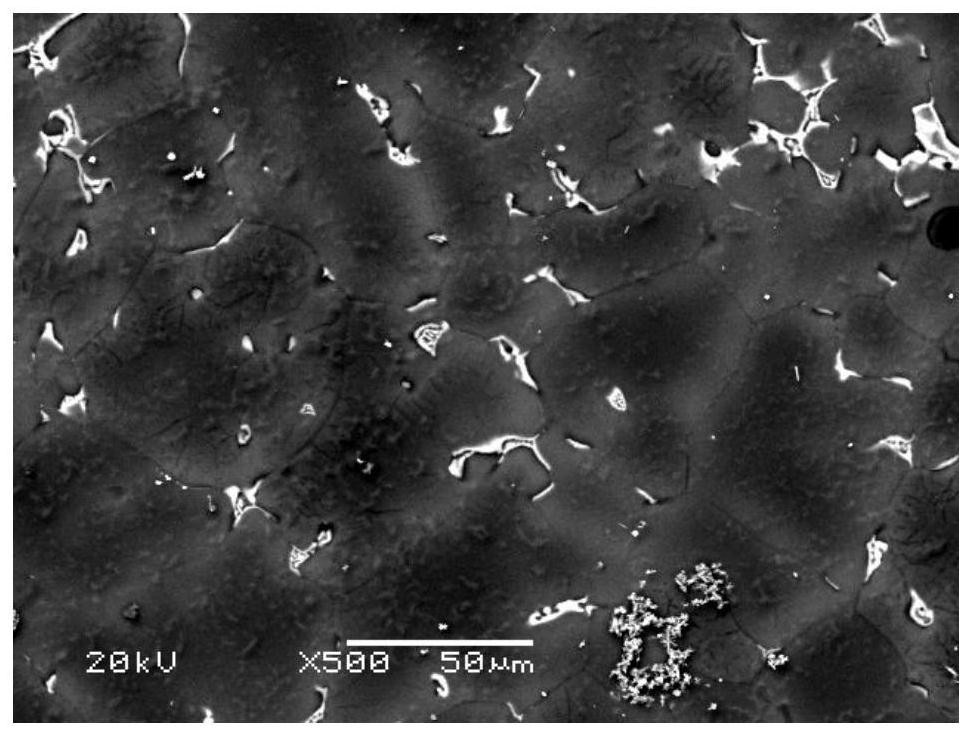

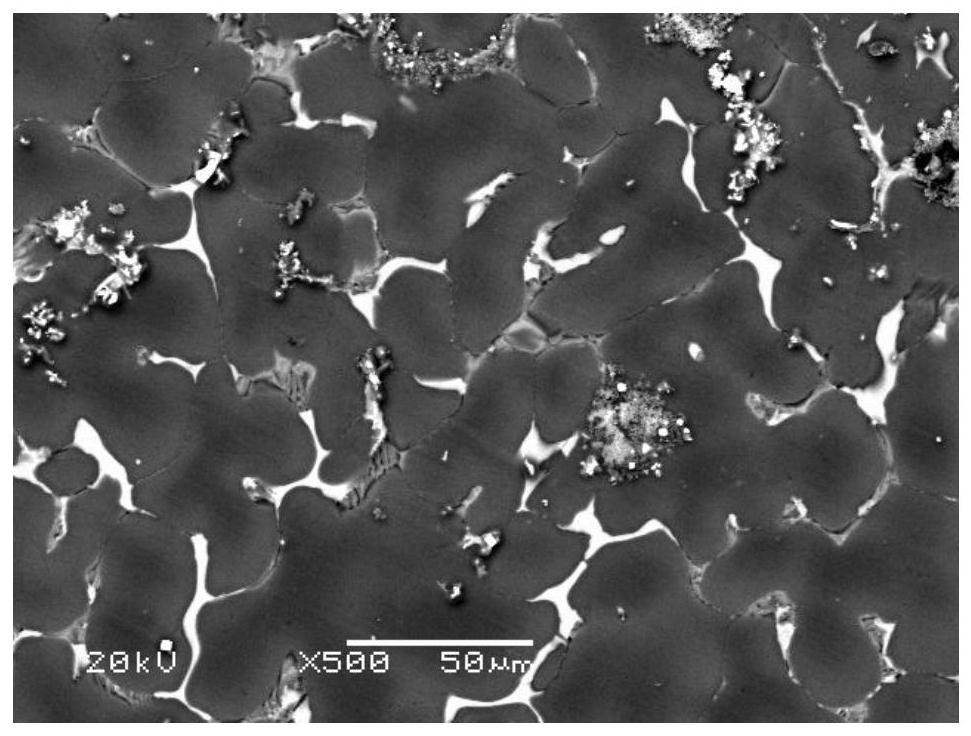

High-volume diamond reinforced metal-based composite material and preparation method and application thereof

ActiveCN111471978AImprove wettabilityMaintain high thermal conductivityChemical vapor deposition coatingMetal matrix compositeThermal conductivity

The invention discloses a high-volume diamond reinforced metal-based composite material and a preparation method and application thereof. The high-volume diamond reinforced metal-based composite material comprises a gradient boron-doped diamond reinforced metal-based composite material and a diamond layer strengthening phase, wherein the diamond layer strengthening phase coats the surface of the gradient boron-doped diamond reinforced metal-based composite material; the gradient boron-doped diamond reinforced metal-based composite material comprises a gradient boron-doped diamond reinforcementbody and a metal matrix; and the gradient boron-doped diamond reinforcement body comprises an undoped diamond reinforcement body and a gradient boron-doped diamond modified layer arranged on the surface of the diamond reinforcement body. According to the material, the preparation method and application thereof, the thermal conductivity is greatly improved by increasing the volume of diamond in the composite material, and meanwhile, due to the fact that a pure diamond layer is uniform in hardness, the pure diamond layer is easier to machine, and is more conveniently applied to various fields.

Owner:CENT SOUTH UNIV

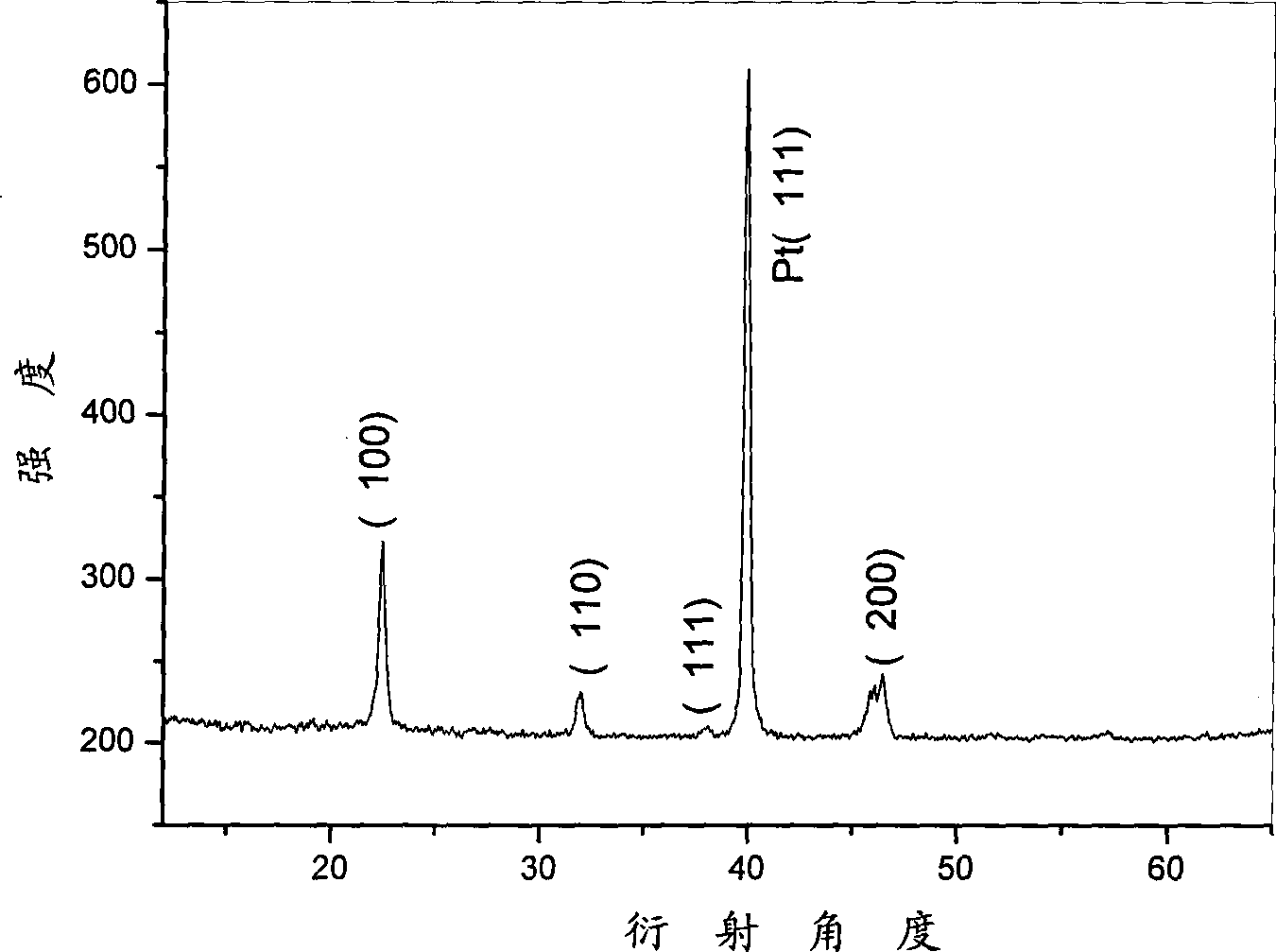

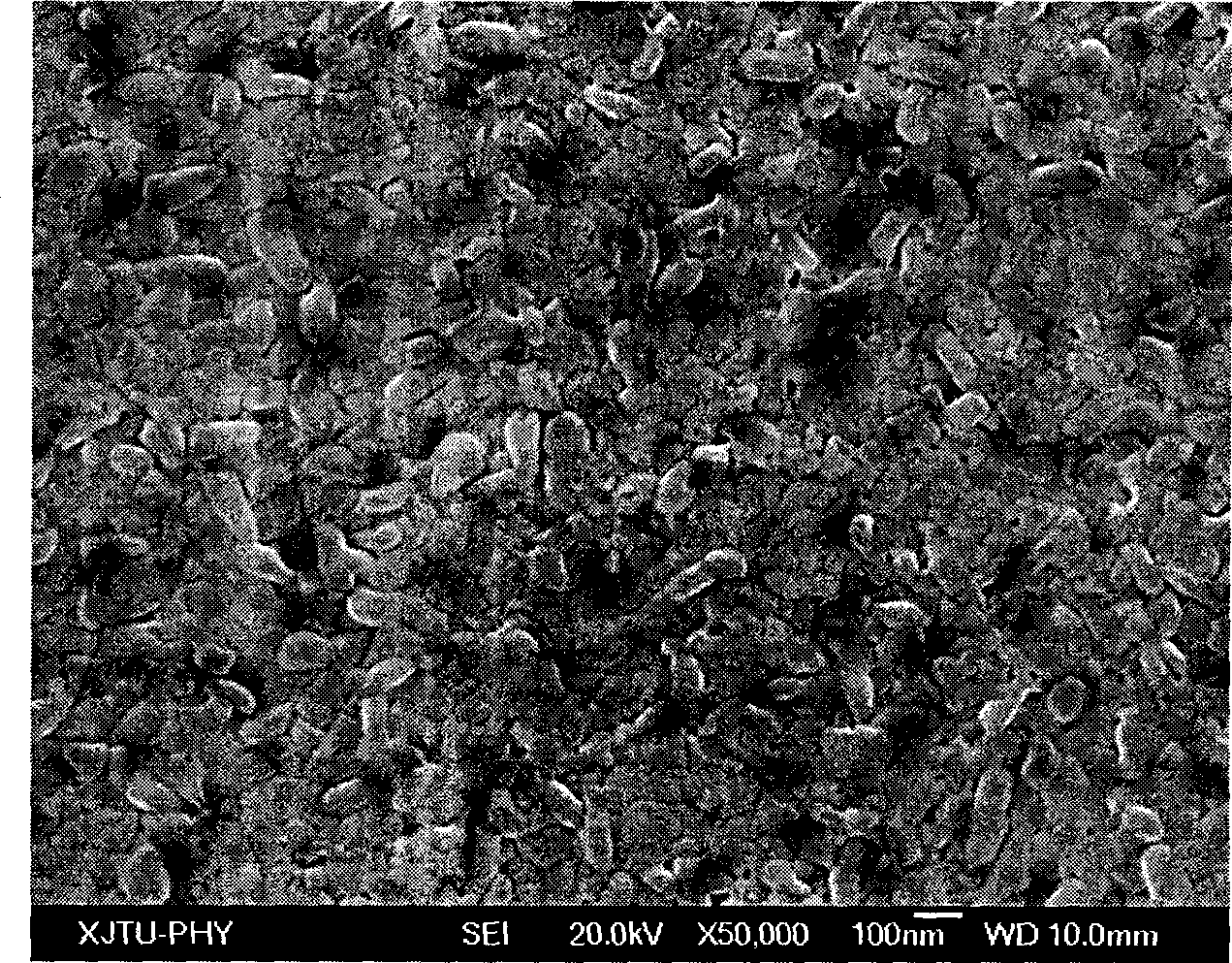

Method for preparing leadless piezoelectric potassium sodium niobate film

The invention relates to the field of lead-free functional piezoelectric materials, in particular to a preparation method of a lead-free piezoelectric potassium-sodium niobate film. The method includes the following steps: absolute columbium pentachloride NbCl5 and absolute ethyl alcohol are weighed and anhydrous benzene is used as a reaction solvent. Ammonia gas is added, and then sucking filtration, washing and distillation are carried out to obtain a columbium ethoxide solution; anhydrous sodium acetate and anhydrous potassium acetate are weighted and dissolved in a hexanoic acid solution to obtain a mixed solution containing potassium and sodium; secondly, the columbium ethoxide solution is weighed and dissolved in an ethylene glycol monomethyl ether solution to obtain a solution containing columbium; the mixed solution containing potassium and sodium and the solution containing columbium, obtained previously, are mixed, heated and stirred to obtain the solution of potassium-sodium niobate collosol which is used as a precursor solution for preparing the film by the use of a rotary film making method.

Owner:XI AN JIAOTONG UNIV

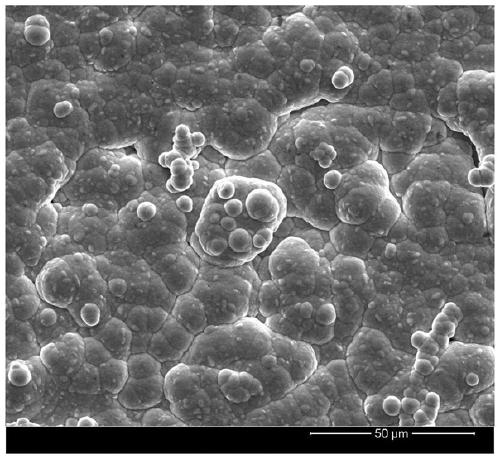

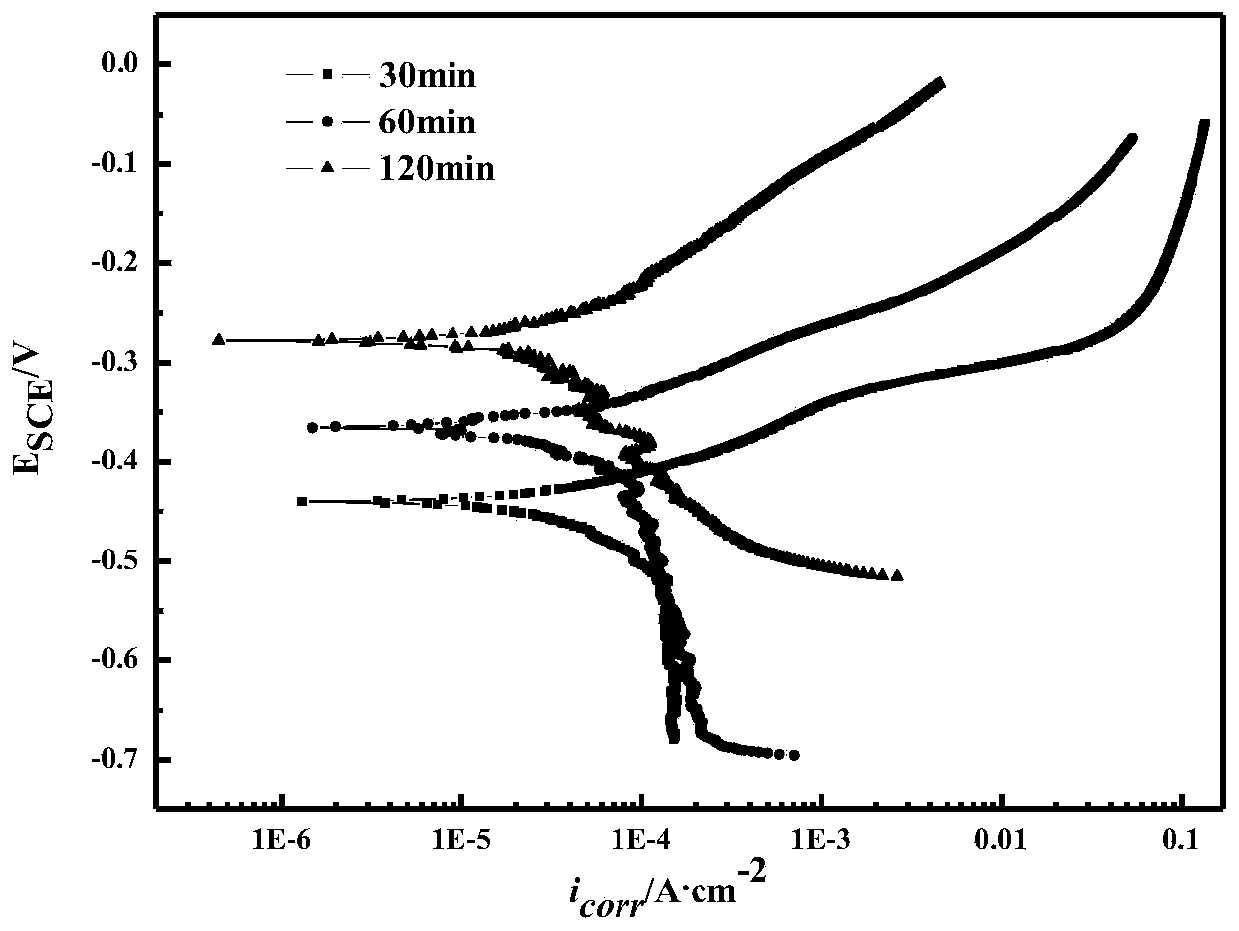

Deep hole nickel electroplating plating solution and preparation method thereof

The invention discloses a deep hole nickel electroplating plating solution, a preparation method and an electroplating method, and belongs to the technical field of nickel electroplating. The problemsthat in the prior art, nickel sulfate and nickel sulfamate based plating solution can not be used for deep hole plating are solved. The deep hole nickel electroplating plating solution comprises thenickel sulfate, nickel chloride, a boric acid, a dodecylbenzene sulfonic acid, sodium citrate, an ammonium sulfate, a hydroxypropyl pavement agent and a PS reagent; and the nickel electroplating plating solution comprises 200 - 300 g / L of the nickel sulfate, 30 - 50 g / L of the nickel chloride, 30 - 50 g / L of the boric acid, 0.006 - 0.10 g / L of the dodecylbenzene sulfonic acid, 50 - 90 g / L of the sodium citrate, 5 - 20 g / L of the ammonium sulfate, 0.11 - 1.10 ml / L of the hydroxypropyl pavement agent, and 0.001 - 0.10 g / L of the PS reagent. According to the deep hole nickel electroplating plating solution, the electroplating operation of the irregular deep hole in a battery shell is realized.

Owner:CENT IRON & STEEL RES INST

Gradient-boron-doped diamond strengthened metal matrix composite and preparation method and application thereof

ActiveCN111778506AImprove thermal conductivitySmall coefficient of thermal expansionSemiconductor/solid-state device detailsVacuum evaporation coatingLinear configurationMetal matrix composite

The invention discloses a gradient-boron-doped diamond strengthened metal matrix composite and a preparation method and application thereof. The composite includes gradient-boron-doped diamond strengthened bodies, and metal matrices, and the gradient-boron-doped diamond strengthened bodies include diamond strengthened bodies, and gradient-boron-doped diamond modified layers arranged on the surfaces of the diamond strengthened bodies. The configuration of the diamond strengthened bodies include one or more of a zero-dimensional particle configuration, a one-dimensional linear configuration, a two-dimensional piece-shaped configuration, and a three-dimensional continuous network skeleton configuration. The coupling of the gradient-boron-doped diamond strengthened bodies with different dimensions can greatly improve the mass of diamonds on the composite, and improve the heat conductivity. In addition, according to the added gradient-boron-doped diamond strengthened bodies, the gradient-boron-doped diamond modified layers account for less, so that the heat conductivity of the diamonds can not be affected, and the humidity between the diamonds and metal can be greatly improved.

Owner:CENT SOUTH UNIV

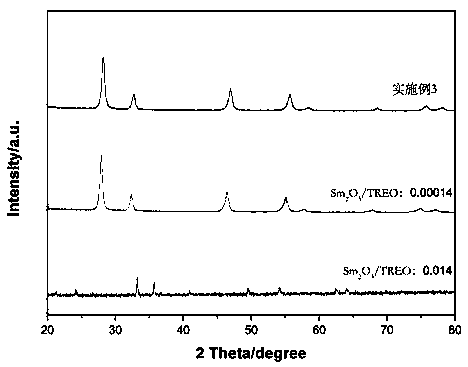

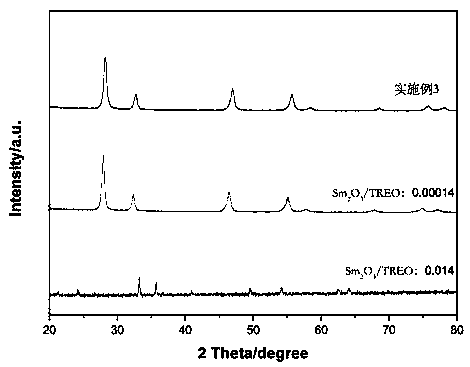

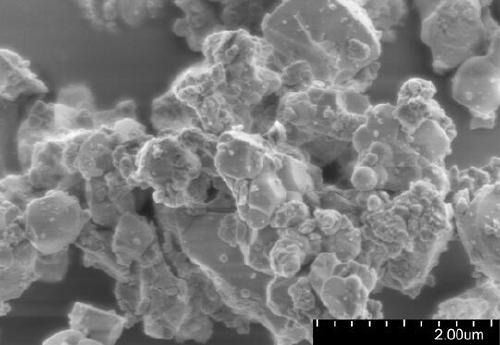

Samarium-containing rare earth polishing powder and preparation process thereof

ActiveCN107556922AEvenly distributedSharp edgePolishing compositions with abrasivesRare earthSamarium

The invention discloses samarium-containing rare earth polishing powder. According to the molar ratio, the samarium-containing rare earth polishing powder comprises the following components that Sm2O3 / TREO is equal to 1.4*10<-4>-0.014, La2O3 / TREO is equal to 0.06-0.12, Pr7O11 / TREO is equal to 8.6*10<-6>-0.0047, Nd2O3 / TREO is equal to 2.97*10<-5>-0.0074, and the balance of CeO2 / TREO is equal to 0.27-0.46. The rare earth polishing powder is obtained by the following steps: by adopting the samarium-containing rare earth salt solution as a main material, adding a fluorine-containing precipitant solution into the material, controlling the fluorine content in a product by regulating the concentration of fluorine ions in a precipitant, and then washing, drying, calcining, crushing and grading andthe like. Different from other production processes, the process is mainly characterized by introducing samarium element into the rare earth material and introducing fluorine element into the precipitant, and has the advantages of simple preparation process and wide material source and the like. The prepared rare earth polishing powder prepared is uniform in grain, obvious in edge and corner andfast in cutting speed.

Owner:甘肃稀土新材料股份有限公司

Hydrazine hydrate chemical nickel plating solution and preparation method and nickel plating method thereof

ActiveCN109852952AMeet environmental protection requirementsEasy to addLiquid/solution decomposition chemical coatingSuperimposed coating processAcetic acidSodium Hypophosphite Monohydrate

The invention discloses a hydrazine hydrate chemical nickel plating solution and a preparation method and nickel plating method of the hydrazine hydrate chemical nickel plating solution, and belongs to the technical field of chemical nickel plating. The problems that in the prior art, a sodium hypophosphite chemical nickel plating solution and the environment are damaged and polluted by the element phosphorus in the nickel plating solution, and the speed is low when hydrazine hydrate is adopted for chemical nickel plating are solved. The hydrazine hydrate chemical nickel plating solution is prepared from nickel sulfate, hydrazine hydrate, sodium citrate, potassium sodium tartrate, cobalt sulfate and lead acetate. The hydrazine hydrate chemical nickel plating solution and the preparation method and nickel plating method of the hydrazine hydrate chemical nickel plating solution are suitable for chemical nickel plating of matrix materials.

Owner:ZHEJIANG INNUOVO MAGNETICS +1

Machining method of forge piece jaw base

InactiveCN103990941AHarm reductionImprove mechanical propertiesPositioning apparatusMetal-working holdersMechanical propertyMachining

The invention relates to the technical field of equipment manufacturing industries, in particular to a machining method of a forge piece jaw base. According to the technical scheme, the method comprises the steps that A forging is carried out, wherein (1) blanking, (2) heat treatment, (3) prepressing, (4) forging and pressing, (5) pushing out and (6) cooling are included; and B turning is carried out. The method has the advantages that air holes, sand holes and damage caused by the holes are reduced; the mechanical property of metal is improved, and the internal structure of the metal is improved; labor productivity is improved; precision die forging is used, so the forge piece size is proper, and waste during cutting machining is lowered; and crystalline grains are relatively small, even, compact and suitable for following mechanical cutting machining, organization preparation is achieved for final heat treatment, and part using performance can be well improved.

Owner:HUNAN QIANYUE MACHINERY MFG

High-frequency low-loss MnZn ferrite material and manufacturing method thereof

The invention provides a high-frequency low-loss MnZn ferrite material, which comprises main components and auxiliary components, wherein the main components are 53-56 mol percent of ferric oxide, 34-41 mol percent of manganese oxide and 6-10 mol percent of zinc oxide, the content of manganese oxide is measured by Mn; the auxiliary components are at least three selected from CaCO3, SiO2, Nb2O5, CoO, V2O5, SnO2 and TiO2, and based on the total weight of the main components, the auxiliary components comprise: 0.02-0.08 weight percent of CaCO3, 0.002-0.01 weight percent of SiO2, 0.02-0.06 weightpercent of Nb2O5, 0.03-0.20 weight percent of CoO, 0.01-0.05 weight percent of V2O5, 0-0.20 weight percent of SnO2 and 0-0.10 weight percent of TiO2. The invention also provides a manufacturing method of the high-frequency low-loss MnZn ferrite material.

Owner:江门江益磁材有限公司

Preparation method of Ni-B/B4C nano composite plating through pulse electrodeposition

InactiveCN113061945AImprovement and increase in hardnessLow densityElectrolytic coatingsActive agentSurface-active agents

The invention discloses a preparation method of Ni-B / B4C nano composite plating through pulse electrodeposition. The preparation method comprises the steps that S1, a steel sheet base body is pretreated; S2, an electroplating solution is prepared, wherein the electroplating solution comprises the following components according to the concentration: 240 g / L of nickel sulfate, 45 g / L of nickel chloride, 30 g / L of boric acid, 0.5 g / L of saccharin, 3 g / L of dimethylamine borane, 0.1 g / L of a surfactant and 1-5 g / L of B4C nano particles; S3, an electrodeposition process is conducted, specifically, the pretreated base body is put into the prepared electroplating solution to be subjected to electrodeposition; the technological parameters in the pulse electroplating process are as follows: the pulse frequency is 1000 Hz, the duty ratio is 40%, the time is 30 min, and the magnetic stirring rate is 400 rmp; and S4, after electrodeposition is finished, the surface of a plated part is subjected to ultrasonic cleaning through ethyl alcohol and pure water in sequence. The Ni-B / B4C nano composite plating prepared by the method has excellent corrosion resistance, higher microhardness and lower friction coefficient, and the comprehensive performance of the Ni-B / B4C nano-composite plating is remarkably improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

High-speed train aluminum alloy supporting groove and preparation method thereof

InactiveCN113444938AIncreased strain hardening rateHigh strengthUltimate tensile strengthCorrosion resistant

The invention provides a high-speed train aluminum alloy supporting groove aluminum alloy and a preparation method thereof, and mainly relates to the field of aluminum alloys. The method comprises the following steps: providing an aluminum alloy which comprises the following components in percentage by weight: 5.0-7.5wt% of Zn, 2.0-3.5wt% of Mg, 1.0-2.5 wt% of Ag, 0.3- 0.6wt% of Sc, 0.6-0.8 wt% of Zr, less than 0.02 wt% of impurity elements and the balance of Al; The high-speed train aluminum alloy supporting groove aluminum alloy has the beneficial effects that on the premise that the mechanical strength of the aluminum alloy is guaranteed, the corrosion resistance is good, and the maintenance cost of a high-speed train is greatly reduced.

Owner:SHANDONG NANSHAN ALUMINUM

Preparation method for polycrystalline mercury iodide film seed crystal layer

InactiveCN103820851ASolve the removal problemAvoid pollutionPolycrystalline material growthSingle crystal growth detailsVapour phase epitaxyMercury(II) iodide

The invention belongs to the field of chemical liquid phase deposition, particularly relates to a preparation method for a polycrystalline mercury iodide film seed crystal layer and solves the problems that the pollution of solvent and reaction by-products are difficult to remove during solution precipitation in the prior art. According to the preparation method for the polycrystalline mercury iodide film seed crystal layer, provided by the invention, yellow mercury oxide (HgO) and hydroiodic acid (HI) are used as basic materials, and the reaction rate between the HgO and (HI) is controlled by adjusting the concentration of the HI added into a system, so that fine mercury iodide particles are generated. The generated fine mercury iodide particles deposit on a substrate (electrode) material to form a layer of homogeneous film, so that directional crystal nucleuses are provided for gas phase epitaxial growth, thereby increasing one-way growth probability of the film.

Owner:XIAN TECHNOLOGICAL UNIV

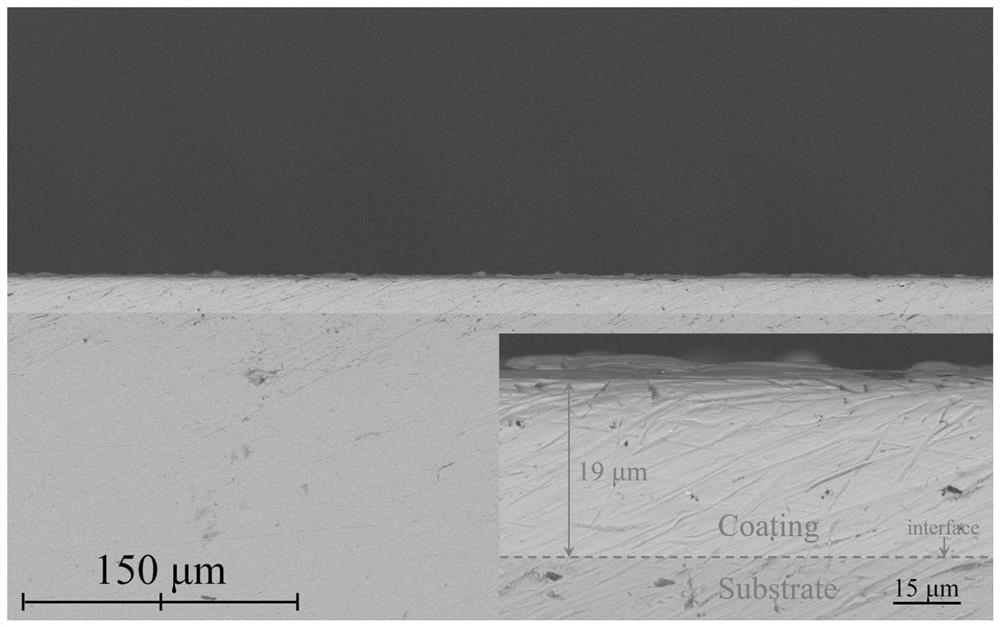

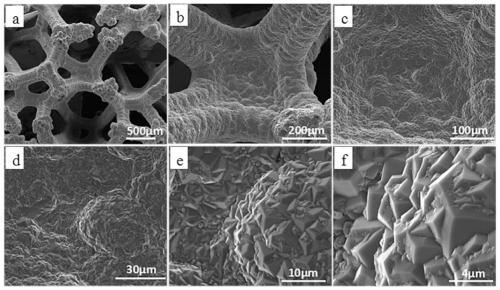

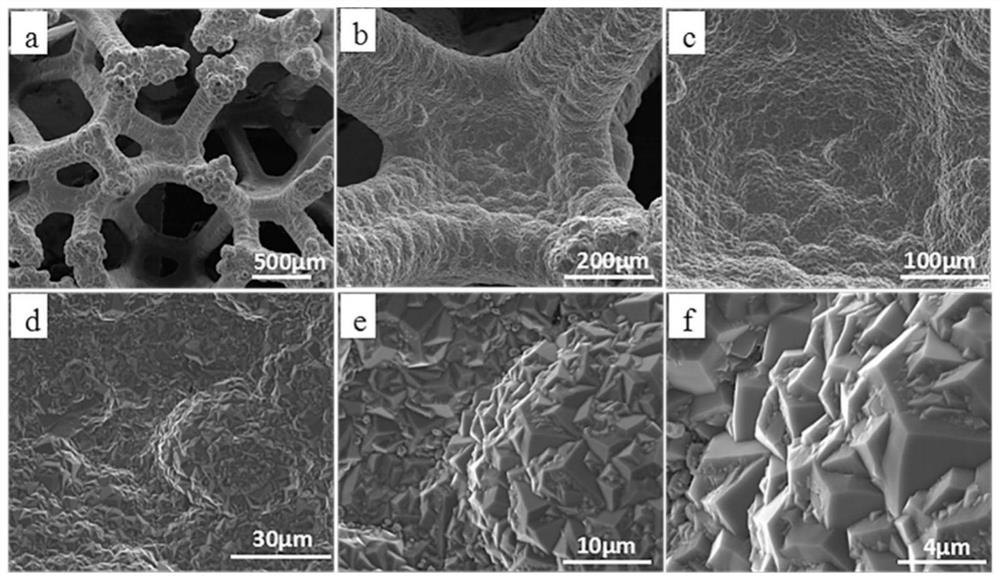

Boron-doped diamond electrode with high conductivity, long service life and high specific surface area and preparation method and application thereof

ActiveCN111519163AImprove adhesionTightly combinedWater contaminantsMaterial analysis by electric/magnetic meansDiamond electrodesHigh conductivity

The invention discloses a boron-doped diamond electrode with high conductivity, a long service life and a high specific surface area. The boron-doped diamond electrode is prepared by taking an etchedsubstrate as an electrode matrix; or arranging a transitional layer on the surface of the etched substrate as the electrode matrix and then arranging a boron-doped diamond layer on the surface of theelectrode matrix, wherein the boron-doped diamond layer comprises a boron-doped diamond bottom layer, a boron-doped diamond middle layer and a boron-doped diamond top layer with different boron contents; the boron-doped diamond bottom layer in contact with the matrix is taken as a conducting layer, the boron-doped diamond middle layer is taken as an anti-corrosive layer, the boron-doped diamond top layer is taken as a strong electro-catalytically active layer, the substrate is a composite material composed of a metal phase and a ceramic phase, and the metal phase is distributed continuously inthe composite material. The boron-doped diamond electrode has high conductivity, low residual stress, long service life and high specific surface area, and the degradation efficiency is improved greatly when being applied to degrading wastewater.

Owner:NANJING DAIMONTE TECH CO LTD

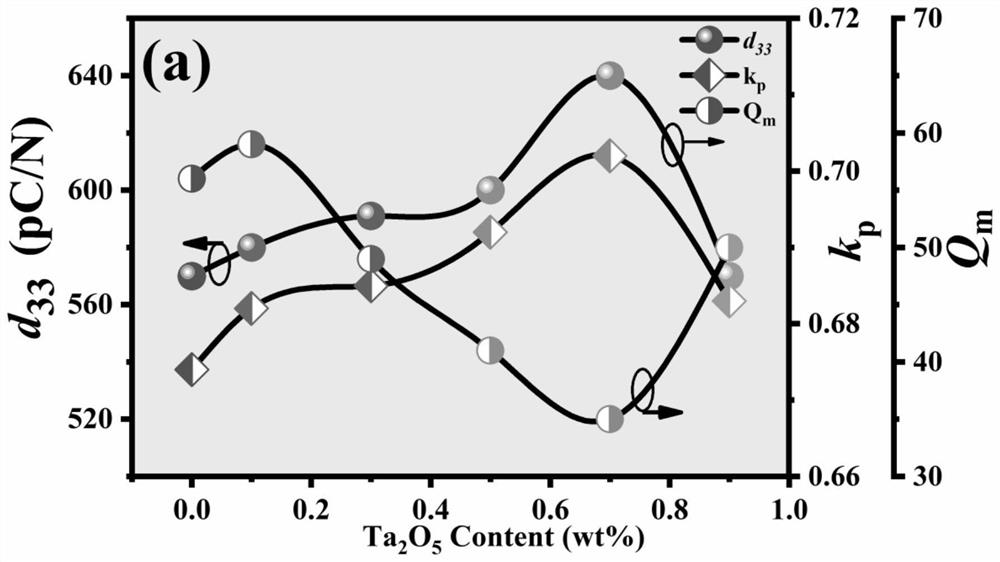

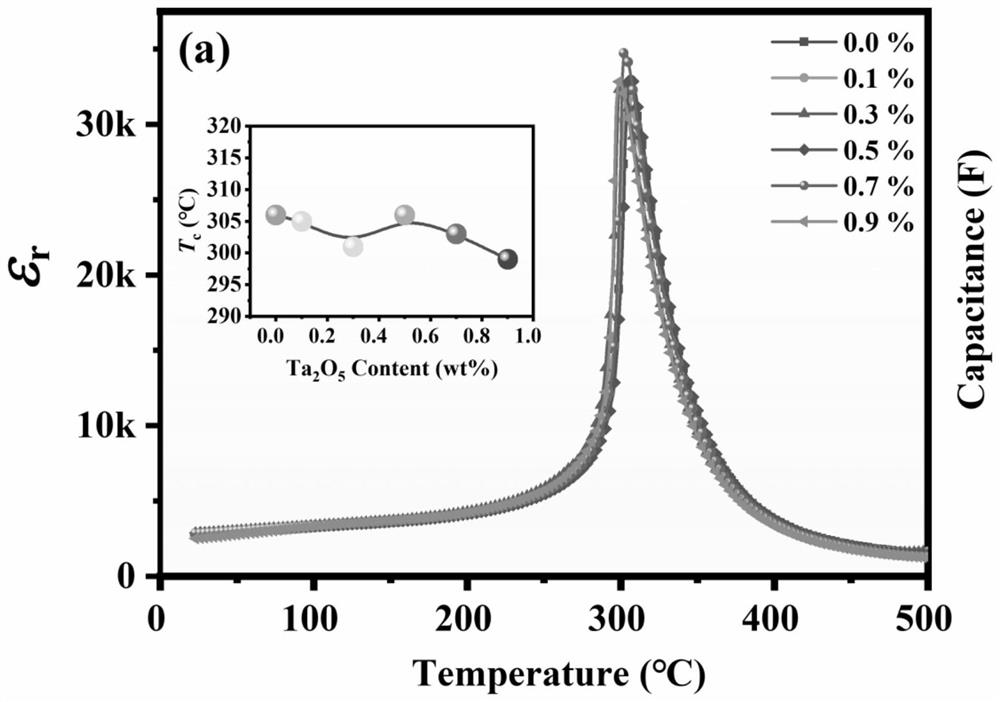

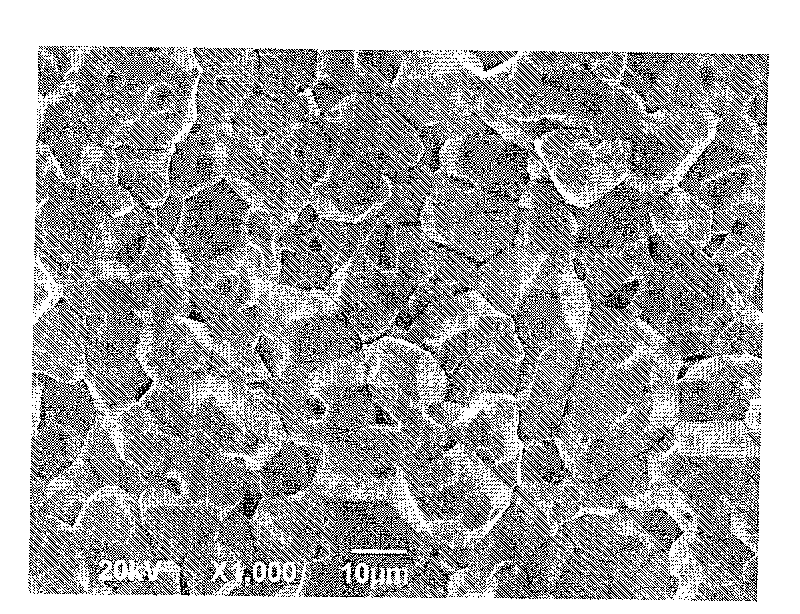

High-performance lithium-calcium-tantalum-nickel-zinc-niobium-magnesium-tungsten modified PZT piezoelectric ceramic prepared at low temperature

PendingCN114644524ALower sintering temperatureExcellent piezoelectric propertiesSolid state reaction methodMagnesium

The general formula of the piezoelectric ceramic is Pb1-x-yLixCayTauu [(Ni, Zn) 1 / 3Nb2 / 3] v (Mg1 / 2W1 / 2) w (Ti, Zr) 1-u-v-wO3, 0.001 < = x < = 0.005, 0.001 < = y < = 0.005, 0 < = u < = 0.005, 0.01 < = v < = 0.05, and 0.01 < = w < = 0.05. PZT modified piezoelectric ceramic powder sintered at the low temperature of 850-950 DEG C is prepared by adopting a solid-phase reaction method, and then the ceramic material is prepared through the processes of granulation, tabletting, glue discharging, sintering, silver firing, polarization and the like. The result shows that the PZT modified ceramic material prepared at the sintering temperature of 850-950 DEG C is compact in crystal grain, uniform in crystal grain, sufficient in crystallization and obvious in liquid-phase sintering characteristic, and the piezoelectric property is greatly improved.

Owner:SICHUAN UNIV

A samarium-containing rare earth polishing powder and its preparation process

ActiveCN107556922BEvenly distributedSharp edgePolishing compositions with abrasivesPhysical chemistryEngineering

A samarium-containing rare earth polishing powder, the composition of which is calculated by molar ratio: Sm 2 o 3 / TREO=1.4×10 ‑4 ~0.014, La 2 o 3 / TREO=0.06~0.12, Pr 7 o 11 / TREO=8.6×10 ‑6 ~0.0047, Nd 2 o 3 / TREO=2.97×10 ‑5 ~0.0074, the balance is CeO 2 / TREO=0.27~0.46. The rare earth polishing powder uses samarium-containing rare earth salt solution as the main raw material, adds fluorine-containing precipitant solution to the raw material, controls the fluorine content in the product by adjusting the fluoride ion concentration in the precipitant, and then washes, dries and calcines , crushing and grading processes. The main difference between this process and other production processes is that samarium element is introduced into the rare earth raw material, and fluorine element is introduced into the precipitant, which has the advantages of simple preparation process and wide source of raw materials. The prepared rare earth polishing powder has uniform crystal grains, obvious edges and corners, and fast cutting speed.

Owner:甘肃稀土新材料股份有限公司

A boron-doped diamond electrode with high conductivity, long life and high specific surface area, its preparation method and application

ActiveCN111519163BImprove adhesionTightly combinedWater contaminantsMaterial analysis by electric/magnetic meansDiamond electrodesActive layer

The invention discloses a boron-doped diamond electrode with high conductivity, long service life and high specific surface area. The boron-doped diamond electrode uses an etched substrate as an electrode base; or on the surface of an etched substrate After the transition layer is set as the electrode base, a boron-doped diamond layer is set on the surface of the electrode base. The boron-doped diamond layer includes a boron-doped diamond bottom layer with different boron content, a boron-doped diamond middle layer, and a boron-doped diamond layer. Top layer; wherein, the boron-doped diamond bottom layer in contact with the substrate is used as a conductive layer, the boron-doped diamond middle layer is used as a corrosion-resistant layer, the boron-doped diamond top layer is used as a strong electrocatalytic active layer, and the substrate is a metal phase and A composite material composed of ceramic phases, the metal phase is continuously distributed in the composite material; the boron-doped diamond electrode obtained in the present invention has high electrical conductivity, low residual stress, long life, and high specific surface area, and when it is applied to degrade wastewater, the degradation efficiency is greatly improved promote.

Owner:NANJING DAIMONTE TECH CO LTD

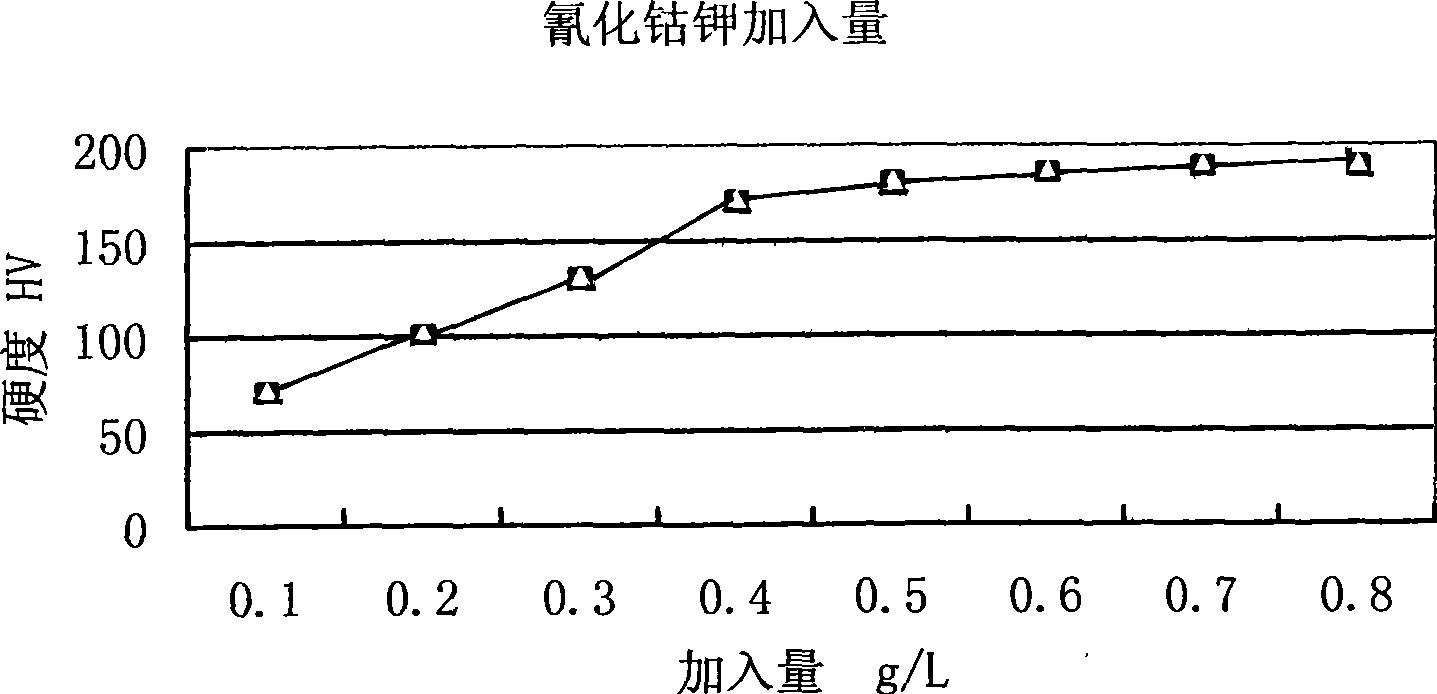

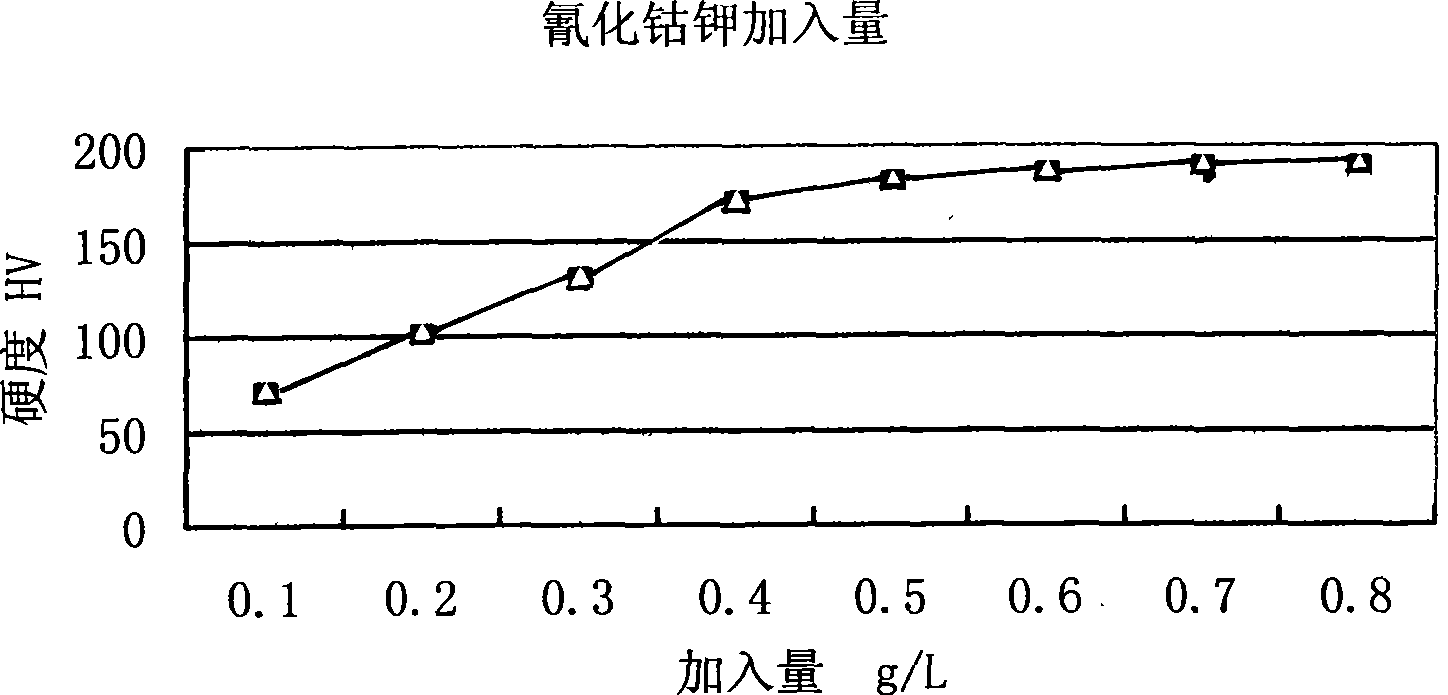

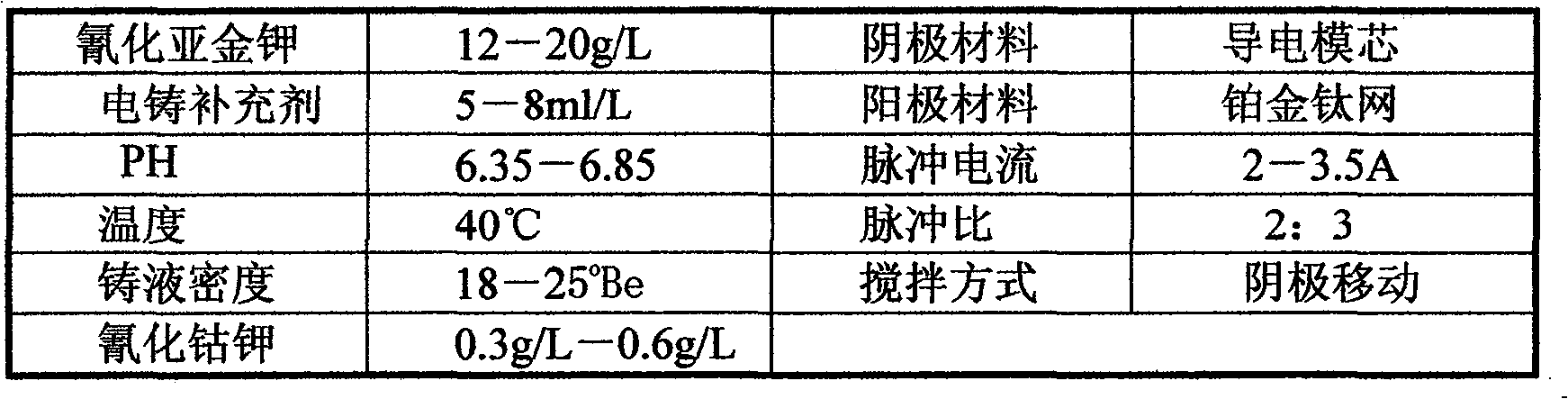

Gold electroforming technique

The invention discloses a new process for electroforming gold, comprising the following steps: A. adding deionized water, make-up salt and make-up solution to a electroforming cylinder; B. heating liquid in the electroforming cylinder to 40 DEG C to 45 DEG C; adjusting the pH value of the liquid to 6.35 to 6.85; C. adding electroforming main salt potassium gold cyanide and electroforming replenisher to the electroforming cylinder, keeping the content of gold in a range from 10g / L to 12g / L; D. hanging a cast coated with conducting layer as a cathode on a hanging unit, and putting it into the electroforming cylinder; E adding hard gold replenisher, keeping the content of the replenisher in a range from 0.3g / L to 0.6g / L; and F. electrolyzing gold from plating solution under current function, and attaching the electrolyzed gold to the above cast. The invention aims to overcome low hardness, low yield of gold artwork manufactured by current electroforming gold process, and provide a electroforming gold process which can effectively increase hardness of gold artwork and improve yield of gold artwork by time.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC +2

High-performance PZT modified piezoelectric ceramic prepared at low temperature

PendingCN114573343ALower sintering temperatureExcellent piezoelectric propertiesPelletizingSolid state reaction method

The general formula of the piezoelectric ceramic is Pb1xyLixCayTauu [(Ni, Zn) 1 / 3Nb2 / 3] v (Mg1 / 2W1 / 2) w (Ti, Zr) 1uvwO3, x is greater than or equal to 0.1 and less than or equal to 0.5, y is greater than or equal to 0.1 and less than or equal to 0.5, u is greater than or equal to 0.1 and less than or equal to 0.9, v is greater than or equal to 0.01 and less than or equal to 0.10, and w is greater than or equal to 0.01 and less than or equal to 0.10. PZT modified piezoelectric ceramic powder sintered at the low temperature of 850-950 DEG C is prepared by adopting a solid-phase reaction method, and then the ceramic material is prepared through the processes of granulation, tabletting, glue discharging, sintering, silver firing, polarization and the like. Results show that the PZT modified ceramic material prepared at the sintering temperature of 850-950 DEG C is compact in crystal grains, uniform in crystal grains, sufficient in crystallization and obvious in liquid-phase sintering characteristic, and the piezoelectric property is greatly improved.

Owner:SICHUAN UNIV

Method for preparing PZN based multi-element composite perovskite type piezoelectric ceramics

The invention discloses a method for preparing PZN based multi-element composite perovskite type piezoelectric ceramics. In the preparation method, a precursor is synthesized by the following steps: weighing, mixing and grinding B-site ion oxides except ZrO2 and TiO2 in stoichiometric ratio; and finally cofiring to obtain the precursor. The method disclosed by the invention has an obvious advantage in preparation of PZN based three-element and multi-element composite perovskite type piezoelectric ceramics, and can effectively inhibit the formation of pyrochlore phase in the PZN based ceramic preparation process, thereby improving the PZN content of a solid solution and obtaining perovskite ceramics.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

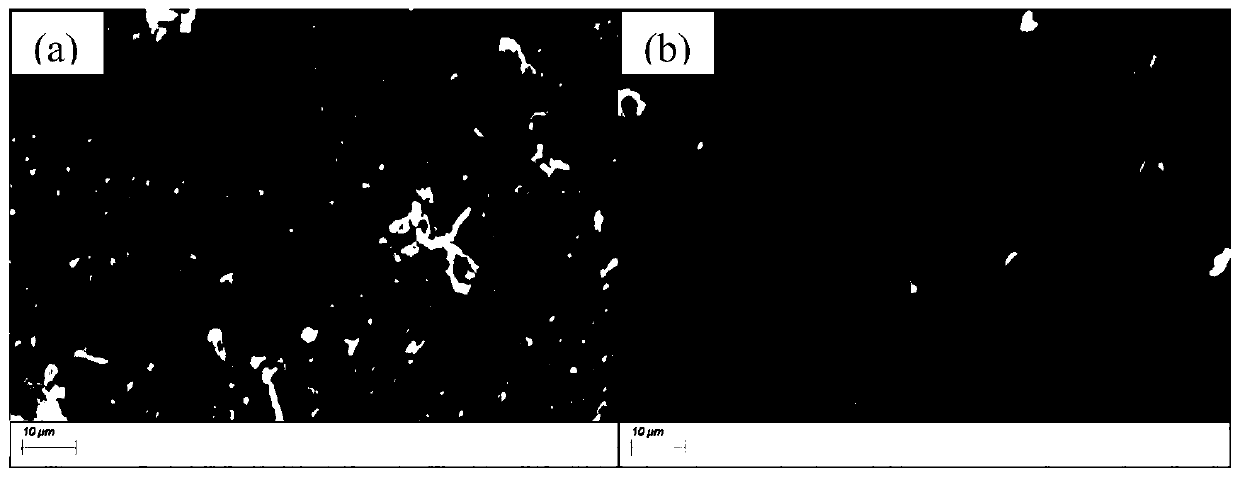

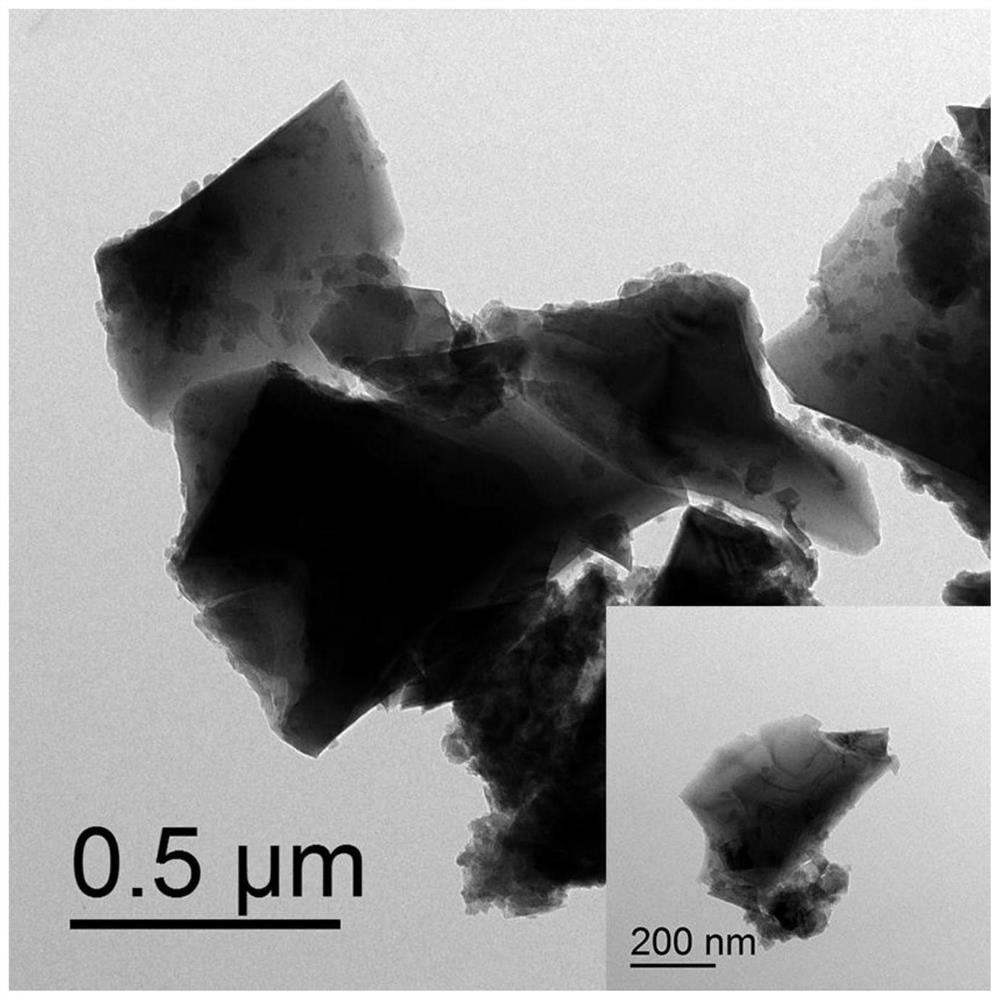

Method for preparing lanthanum yttrium hafnate-based titanium dioxide composite photocatalyst

InactiveCN102125829AUniform and dense grainWell coveredMetal/metal-oxides/metal-hydroxide catalystsTransmission electron microscopyTitanium tetrachloride

The invention discloses a method for preparing a lanthanum yttrium hafnate-based titanium dioxide composite photocatalyst, and belongs to the technical field of photocatalyst preparation. The preparation method comprises the following steps of: (1) preparing lanthanum yttrium hafnate powder by adopting a conventional known method; (2) adding the lanthanum yttrium hafnate powder into titanium tetrachloride or titanium tetrafluoride solution, and dispersing the system into suspension by using ultrasonic wave; (3) placing the suspension in an electron beam generating device, and performing electron beam irradiation of certain dose, wherein the irradiation dose is 70 to 280KGy; (4) sealing the suspension, putting the sealed suspension in a baking oven, and reacting for 20 hours at the temperature of 60 DEG C; and (5) washing, drying and finally obtaining the lanthanum yttrium hafnate-based titanium dioxide composite photocatalyst. The lanthanum yttrium hafnate-based titanium dioxide composite photocatalyst prepared by the method has high photocatalysis activity by detection. Detected by a transmission electron microscope (TEM), nano titanium dioxide crystals are densely and uniformly loaded on a lanthanum yttrium hafnate matrix.

Owner:上海奇葩环境科技有限公司

Wide temperature ultra-low loss MnZn soft magnetic ferrite material and preparing method thereof

The present invention relates to wide-temperature ultra-low-loss MnZn soft magnetic ferrite material and method for manufacturing, and belongs to electronic material technology field. The main constituent is calculated by oxide with molar percentage: 65-75mol%Fe2O3, 13-20mol%ZnO, 0.0001-0.5mol%TiO2, allowance being Mn3O4; weight percentage ofdoping agent: 0.01-0.1wt%CaO, 0.01-0.09wt%Nb2O5, 0.01-0.1wt%V2O5, 0.001-0.1wt%ZrO2, and 0.05-1wt%Co2O3. Grain of wide-temperature ultra-low-loss MnZn soft magnetic ferrite material of the invention is uniform and dense, and average grain dimension is about 12-18Mum.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

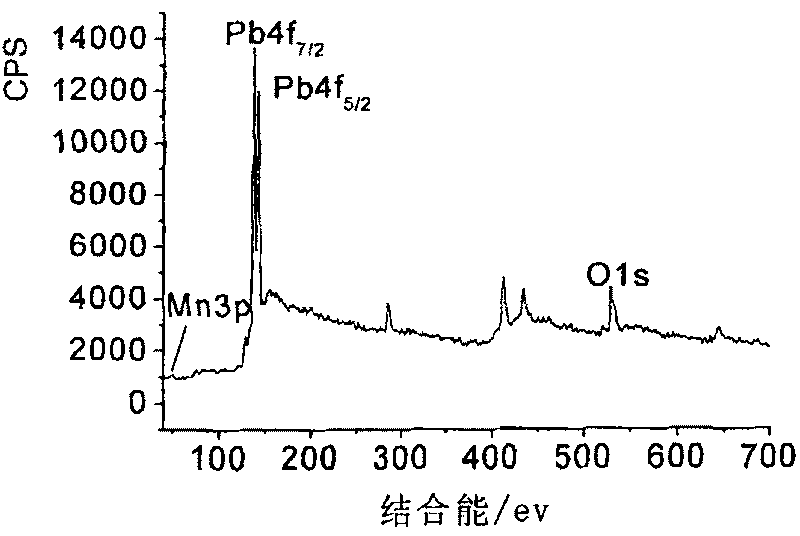

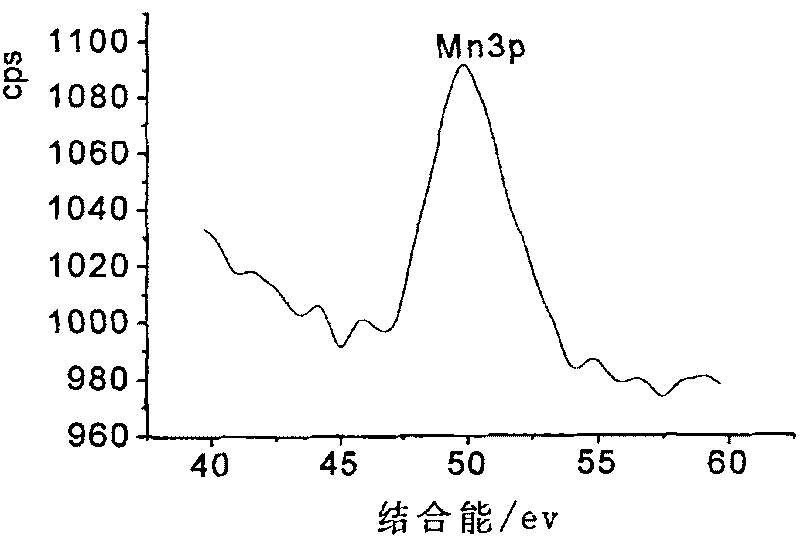

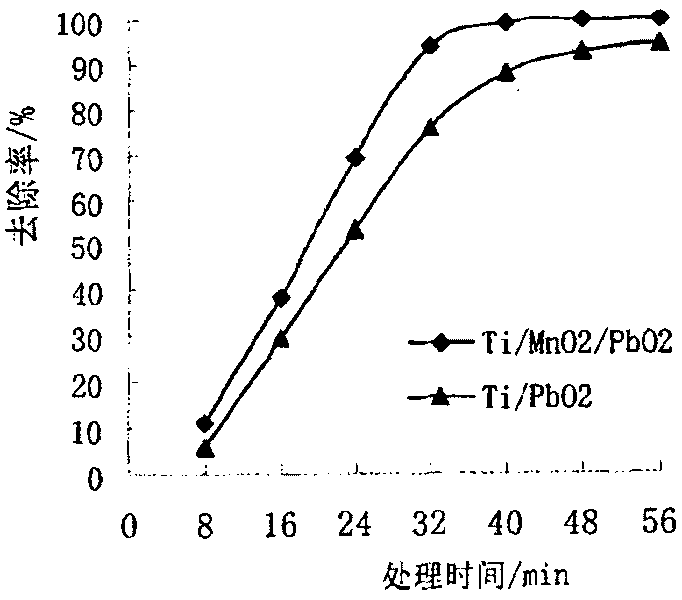

Metallic oxide electrode for organic wastewater processing and preparation thereof

InactiveCN101298342BImprove stabilityExtended service lifeWater/sewage treatment by electrochemical methodsElectrodesHigh activityTitanium plate

The invention relates to a metal oxide electrode used for the treatment of organic wastewater and a production method thereof. The technical proposal the following steps of: sequentially boiling and etching the industrially pure titanium sheet that is ground and washed in an alkali solution, acid solution and saturated oxalic acid solution respectively, then taking out and washing with a distilledwater to obtain a pre-treated metallic matrix of titanium; placing cathode titanium plates at two dies of the metallic matrix of titanium symmetrically and placing the both into a mixture of MnSO4 and H2SO4, then calcining after deposited by the anode electro-deposition process to obtain Ti / MnO2 electrode; the titanium plate cathode and the Ti / MnO2 electrode are placed in the mixture of Pb(No3)2,Cu(NO3)2, NaF and HNO3, then power is supplied by two stage during the anode electro-deposition process to obtain the Ti / MnO2 / PbO2 composite electrode. The production method provided by the inventionis simple and the manufacturing cost is low; the metal oxide electrode produced by the invention can be used for the treatment of organic wastewater and is characterized by high activity, good conductivity, strong anodic oxidation resistance and long service life.

Owner:WUHAN UNIV OF SCI & TECH

A special-shaped cable and its preparation method

ActiveCN106653163BDistribute stressAvoid force breakingDetails of conductive coresManufacturing wire harnessesEngineeringAbnormal shaped

Owner:CHANGCHUN JETTY AUTOMOTIVE PARTS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com