High-frequency low-loss MnZn ferrite material and manufacturing method thereof

A technology of ferrite material and manufacturing method, applied in the field of MnZn ferrite material and its manufacturing, can solve the problems of high sintering maximum temperature, deterioration of ferrite performance, lowering production cost and the like, so as to achieve lower sintering temperature and lower production cost, the effect of avoiding abnormal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

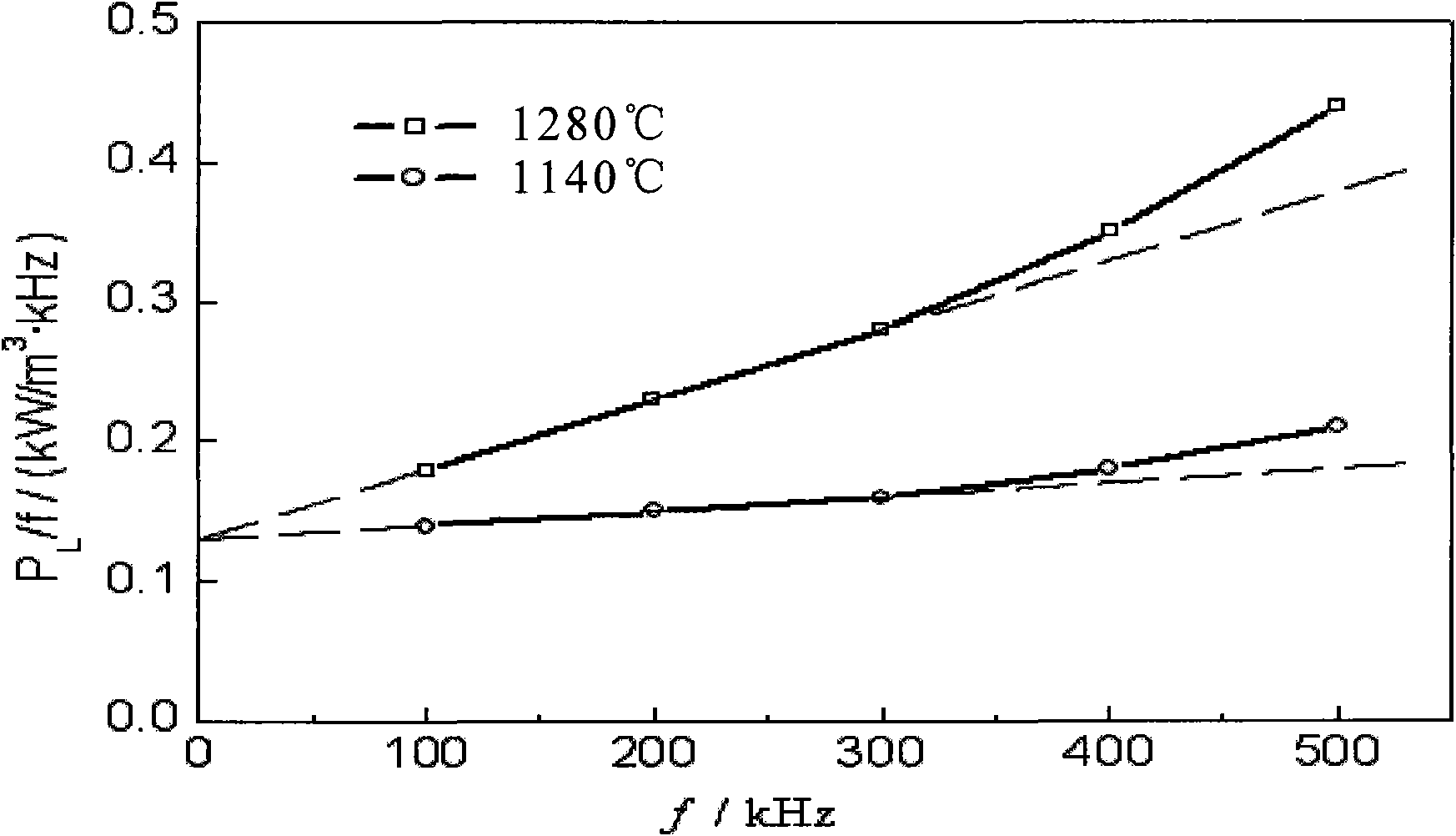

[0031] The main component is 54.6mol% Fe with a sand mill 2 O 3 , 37.9mol% Mn based on Mn 3 O 4 It is mixed with 7.5 mol% of ZnO wet mill and evenly placed in a drying box for drying. Using a box-type resistance furnace, the obtained powder was pre-fired at 820°C for 2 hours. Then put the calcined powder into a ball mill, and based on the total weight of the main component, add an auxiliary component: 0.04wt% of CaCO to the obtained powder 3 , 0.006wt% SiO 2 , 0.035wt% of Nb 2 O 5 , 0.10wt% CoO, 0.04wt% V 2 O 5 , 0.06wt% SnO 2 And 0.03wt% TiO 2 ; Then add 66wt% of deionized water, 1wt% of the dispersant, and 1wt% of the defoaming agent based on the total weight of the main component for ball milling. Ball mill the powder to an average particle size of about 1.0±0.2μm; based on the total weight of the powder after ball milling, add 8wt% polyvinyl alcohol solution to the powder, mix and granulate uniformly, and use a pressure of 50-200MPa The pellets are pressed into green sample...

Embodiment 2-8

[0034] The components and sintering temperatures of Examples 2-8 are shown in Table 1 below, and the implementation steps are the same as in Example 1. The magnetic performance test results of the materials prepared in Examples 2-8 are listed in Table 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com