MnZn ferrite magnetic isolation shim as well as preparation method and application thereof

A ferrite and magnetic isolation sheet technology, applied in the direction of inductor/transformer/magnet manufacturing, inorganic material magnetism, preventing/reducing unwanted electrical/magnetic effects, etc., can solve the problem of low saturation magnetization and mass production technology problems such as immaturity, to achieve the effect of improving saturation magnetization, suitable for large-scale production, and optimizing microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

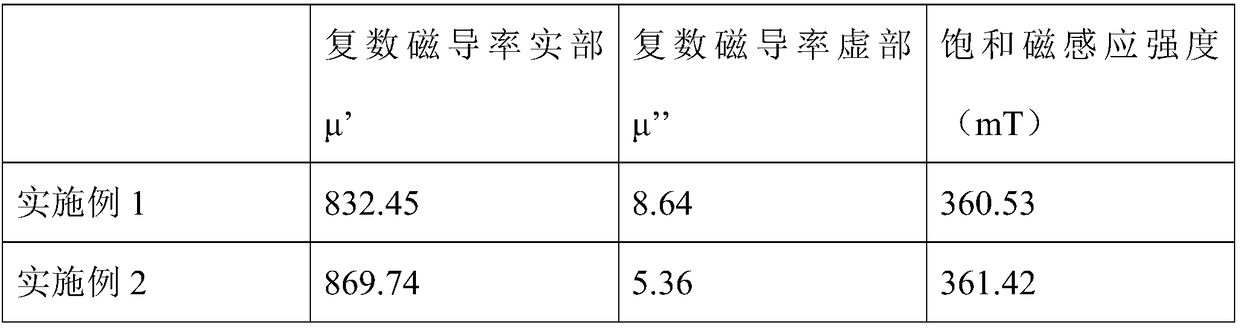

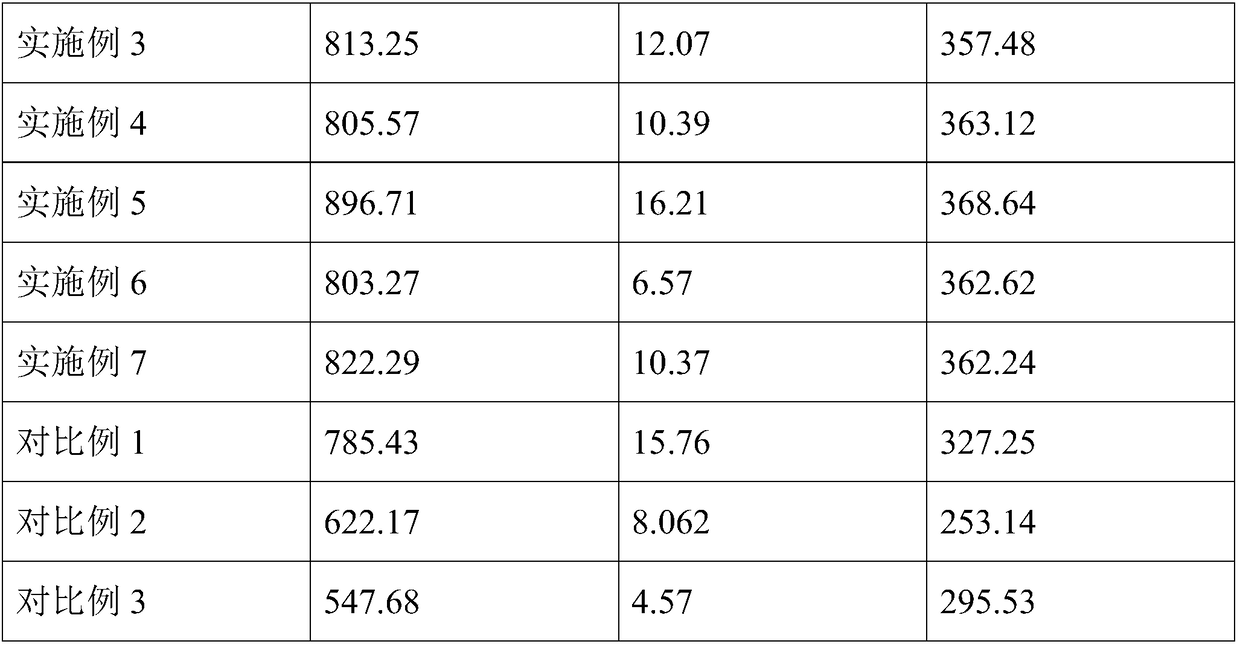

Examples

Embodiment 1

[0091] This embodiment prepares MnZn ferrite magnetic isolation sheet according to the following method:

[0092] 1) Ingredients: respectively select Fe with a purity of 99.5% 2 o 3 , 99% MnO, 99.7% ZnO, the molar ratio of the three is: 51.2:38.5:10.3.

[0093] 2) One-time ball milling and mixing: Put the ball into a ball mill tank with a ball-to-material ratio of 2.5:1, and add deionized water for wet milling. The ball milling time is 45 minutes, and the rotation speed is 160 r / min.

[0094] 3) Pre-burning: put the ground powder into a resistance furnace for pre-burning, the pre-burning temperature is 900° C., and the holding time is 3 hours to obtain the pre-fired powder.

[0095] 4) Secondary ball milling pulping: according to the mass ratio, it is ball: material: pulping solvent = 60:20:7; the amount of adding auxiliary components is CaCO 3 0.035wt%, ZrO 2 0.03wt%, Nb 2 o 5 0.01wt% and SiO 0.05wt%, V 2 o 5 0.02wt%, Co 2 o 3 0.35wt%, Gd (calculated as GdO) 0.05%w...

Embodiment 2

[0103] This embodiment prepares MnZn ferrite magnetic isolation sheet according to the following method:

[0104] 1) Ingredients: respectively select Fe with a purity of 99.5% 2 o 3 , 99% MnO, 99.7% ZnO, the molar ratio of the three is: 51.5:38:10.5;

[0105] 2) One-time ball milling and mixing: Put the ball into a ball mill tank with a ball-to-material ratio of 2.5:1, and add deionized water for wet milling. The ball milling time is 60 minutes, and the rotating speed is 160r / min;

[0106] 3) Pre-burning: put the ground powder into a resistance furnace for pre-burning, the pre-burning temperature is 900° C., and the holding time is 3 hours to obtain the pre-fired powder.

[0107] 4) According to the mass ratio, it is ball: material: pulping solvent=60:20:7; the amount of adding auxiliary components is CaCO 3 0.02wt%, ZrO 2 0.02wt%, Nb 2 o 5 0.03wt% and SiO 0.03wt%, V 2 o 5 0.04wt%, Co 2 o 3 0.25wt%, Gd (calculated as GdO) 0.05%wt; add dispersant castor oil at the sa...

Embodiment 3

[0115] This embodiment prepares MnZn ferrite magnetic isolation sheet according to the following method:

[0116] 1) Ingredients: respectively select Fe with a purity of 99.5% 2 o 3 , 99% MnO, 99.7% ZnO, the molar ratio of the three is: 51.8:37.5:10.7;

[0117] 2) One-time ball milling and mixing: Put the ball into a ball mill tank with a ball-to-material ratio of 2.5:1, and add deionized water for wet milling. The ball milling time is 45 minutes, and the rotating speed is 160r / min;

[0118] 3) Pre-burning: put the ground powder into a resistance furnace for pre-burning, the pre-burning temperature is 900° C., and the holding time is 3 hours to obtain the pre-fired powder.

[0119] 4) According to the mass ratio, it is ball: material: pulping solvent=60:20:7; the amount of adding auxiliary components is CaCO 3 0.025wt%, ZrO 2 0.015wt%, Nb 2 o 5 0.035wt% and SiO 0.025wt%, V 2 o 5 0.015wt%, Co 2 o 3 0.30wt%, Gd (calculated as GdO) 0.08%wt; add dispersant castor oil at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com