A boron-doped diamond electrode with high conductivity, long life and high specific surface area, its preparation method and application

A high specific surface area, diamond electrode technology, applied in the direction of electrodes, chemical instruments and methods, electrolytic components, etc., can solve the problems of unfavorable solution mass transfer, strong oxidizing active groups, small specific surface area, low electrode efficiency, etc., to achieve low Effects of residual stress, increase in specific surface area, and increase in adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Planar (Al 2 O 3 -Fe composite)

[0059] (1) Flat Al 2 O 3 -Pretreatment of Fe substrate: ultrasonically clean the surface with acetone and anhydrous ethanol for 10 minutes to remove oil stains and impurities on the surface, and immerse it in dilute hydrochloric acid with a mass fraction of 50% for 10 minutes to obtain a stepped surface of the substrate. Ultrasonic cleaning with ethanol for 15min to remove residual acid on the surface;

[0060] (2) Due to the thermal expansion adaptation problem between the substrate surface and the boron-doped diamond layer, in order to facilitate the deposition of boron-doped diamond, a layer of transition layer metal was sputtered on the pretreated substrate surface by a magnetron sputtering method. Titanium Ti layer, adjust sputtering power 80W, deposition time 30min, the thickness of Ti layer is about 10μm;

[0061] (3) The processed Al 2 O 3 - The Fe / Ti substrate is placed in the suspension of nanocrystalline and...

Embodiment 2

[0065] Example 2: Planar Porous (TiC-Cr Composite)

[0066] (1) Pretreatment of porous TiC-Cr substrate: ultrasonic cleaning with acetone and absolute ethanol for 10 min to remove surface oil and impurities, immersion in dilute hydrochloric acid with a mass fraction of 15% for 20 min, to obtain micro-etched pits on the surface of the substrate, Then ultrasonically clean with absolute ethanol for 15min to remove residual acid on the surface;

[0067] (2) Since there is no thermal expansion adaptation problem between the ceramic phase contained in the substrate and the boron-doped diamond, and Cr is a good substrate for depositing boron-doped diamond, there is no need to deposit a transition layer on its surface. The TiC-Cr substrate is placed in a suspension of nanocrystalline and microcrystalline diamond mixed particles, and shaken in ultrasonic waves for 30 minutes to disperse uniformly, and the surface is obtained with microcrystalline and nanocrystalline diamond particles a...

Embodiment 3

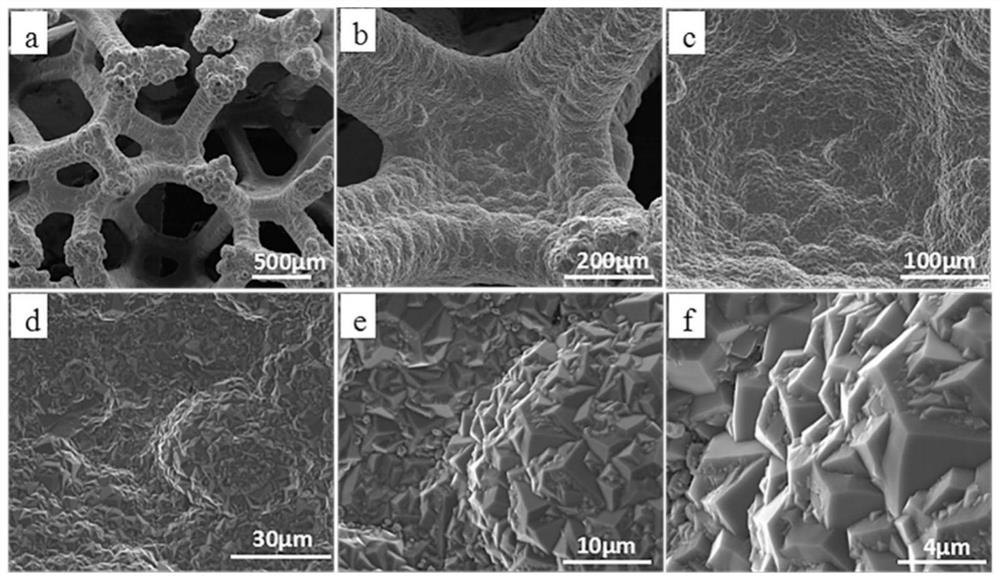

[0071] Example 3: Three-dimensional porous (Al 2 O 3 -Ni composite material)

[0072] (1) Pretreatment of the substrate: ultrasonically clean the surface with acetone and anhydrous ethanol for 10 minutes to remove oil stains and impurities on the surface, immerse it in dilute hydrochloric acid with a mass fraction of 15% for 20 minutes, and obtain micro-etched pits on the surface of the substrate. Ultrasonic cleaning with ethanol for 15min to remove residual acid on the surface;

[0073] (2) Due to the thermal expansion adaptation problem between the substrate surface and the boron-doped diamond layer, in order to facilitate the deposition of boron-doped diamond, a layer of transition layer metal was sputtered on the pretreated substrate surface by a magnetron sputtering method. Titanium Ti layer, adjust sputtering power 80W, deposition time 30min, the thickness of Ti layer is about 10μm;

[0074] (3) Use hot wire CVD to deposit boron-doped diamond film, keep the distance b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com