Hydrazine hydrate chemical nickel plating solution and preparation method and nickel plating method thereof

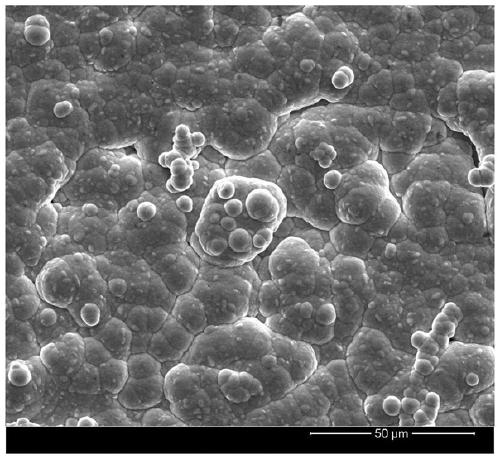

A technology of electroless nickel plating and hydrazine hydrate, which is applied in the direction of liquid chemical plating, superimposed layer plating, coating, etc., can solve the problems of damage, pollution, low speed of hydrazine hydrate electroless nickel plating, etc., and achieve simple process and durable Erosion is good, the effect of solving the problem of deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also discloses a preparation method of the above-mentioned hydrazine hydrate alkaline electroless nickel plating solution, comprising the following steps:

[0052] Step 1, measure various raw materials according to the concentration of each component in the electroless nickel plating solution;

[0053] Step 2, dissolving nickel sulfate with deionized water to obtain solution A;

[0054] Step 3, dissolving sodium citrate and potassium sodium tartrate with deionized water to obtain solution B, slowly adding solution A to solution B, mixing evenly and stirring to obtain solution C;

[0055] Step 4, adding cobalt sulfate and lead acetate into solution C respectively, and fully stirring to obtain solution D;

[0056] Step 5. Use 5wt% sodium hydroxide solution to adjust the pH value of solution D to above 9, add hydrazine hydrate, stir and mix evenly, add deionized water to close to the capacity of the volumetric flask, and then use a small amount of so...

Embodiment 1

[0070] Contents of each component in a kind of hydrazine hydrate alkaline electroless nickel plating solution of the present embodiment are as shown in table 1:

[0071] The content of each component in the hydrazine hydrate alkaline electroless nickel plating bath of table 1

[0072]

[0073]

[0074] The preparation method of a kind of hydrazine hydrate alkaline electroless nickel plating bath of the present embodiment specifically comprises the following steps:

[0075] Step 1, take by weighing 3kg nickel sulfate, 8kg sodium citrate, 1.2kg potassium sodium tartrate, 0.6kg cobalt sulfate, 0.5g lead acetate and 6L hydrazine hydrate according to the content of each component in Table 1;

[0076] Step 2. Add 20L of deionized water into container A, add 3kg of nickel sulfate under stirring, and stir until completely dissolved;

[0077] Step 3. Add 30L of deionized water into container B, add 8kg of sodium citrate and 1.2kg of sodium potassium tartrate under stirring, and ...

Embodiment 2

[0087] Each component content is as shown in table 2 in a kind of hydrazine hydrate alkaline electroless nickel plating bath of the present embodiment:

[0088] Content of each component in table 2 hydrazine hydrate alkaline electroless nickel plating bath

[0089] nickel sulfate

25g / L

Hydrazine hydrate

70ml / L

Sodium citrate

60g / L

8g / L

10g / L

lead acetate

10mg / L

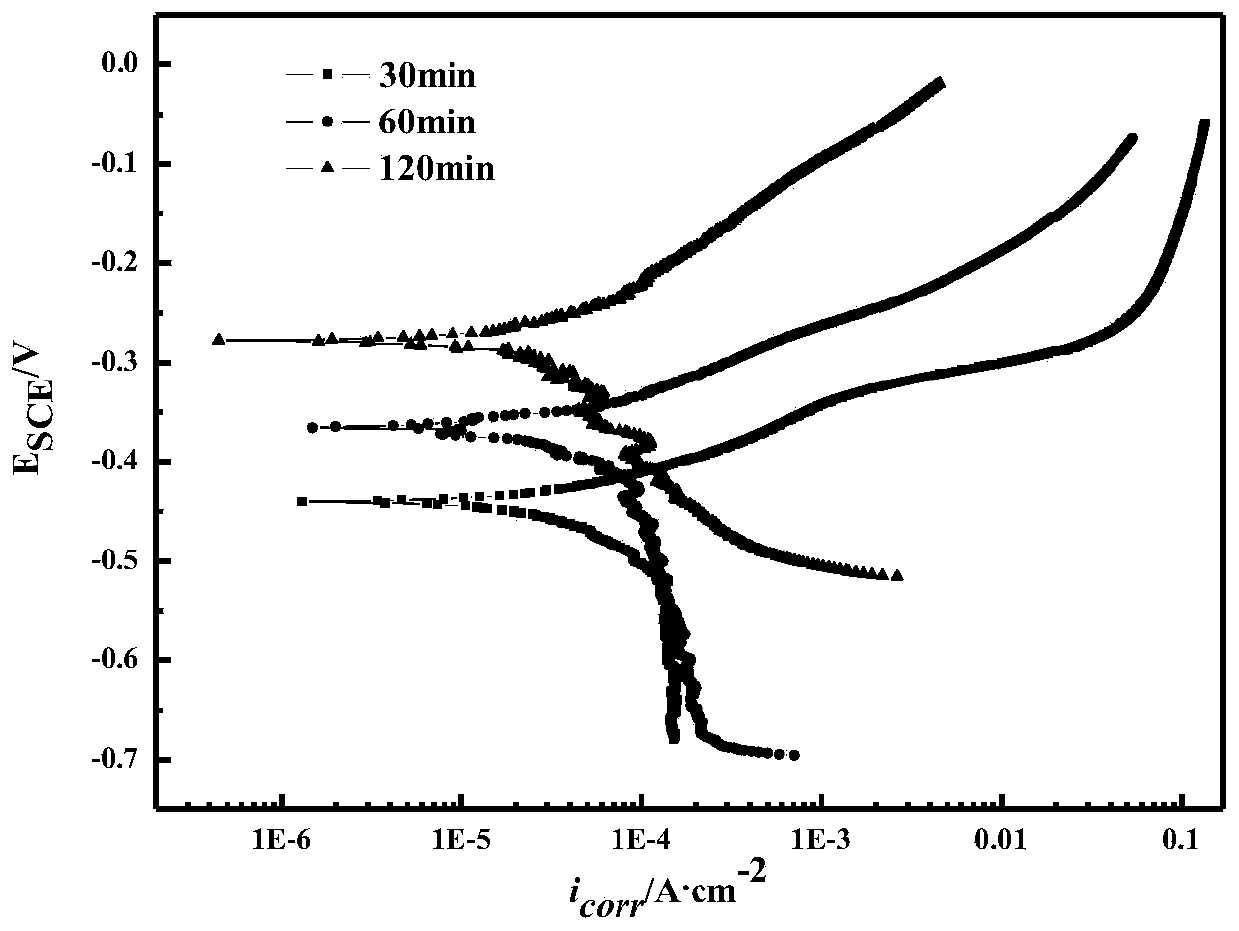

[0090] The preparation method of plating solution is with embodiment 1, and the nickel plating method of the present embodiment specifically comprises the following steps:

[0091] Step 1. The iron matrix material is subjected to pretreatment processes such as grinding corners → cleaning → degreasing → water washing → degreasing → water washing → pickling → cleaning;

[0092] Step 2, hanging the pretreated sample into a plating tank equipped with an electroless nickel plating solution;

[0093] Step 3, p...

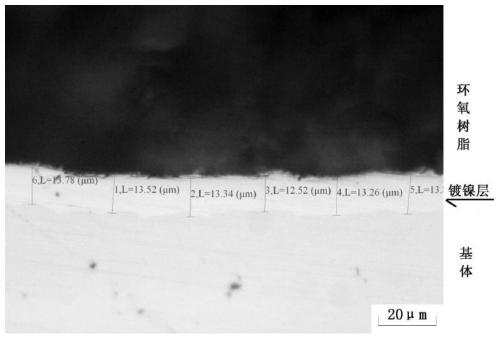

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com