High-performance PZT modified piezoelectric ceramic prepared at low temperature

A piezoelectric ceramic and piezoelectric ceramic sheet technology, applied in the field of piezoelectric ceramic materials, can solve the problems of deterioration of the electrical properties of ceramics, affecting the reliability of multi-layer devices, etc., and achieve the effects of good piezoelectric properties and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

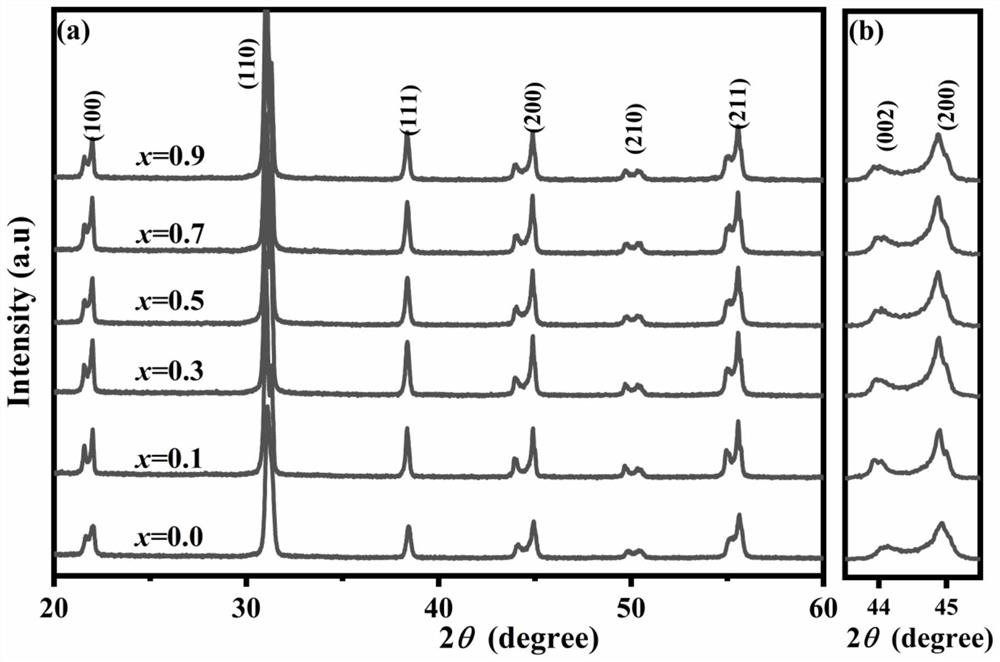

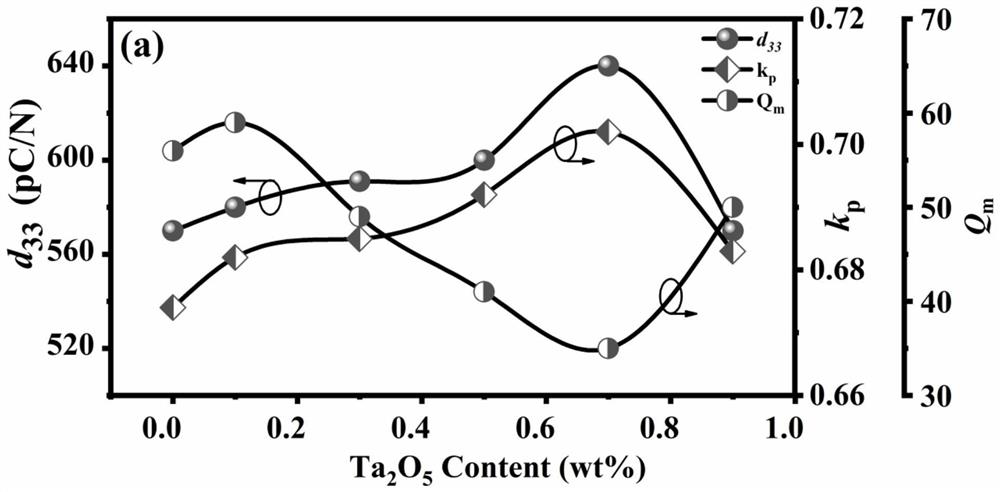

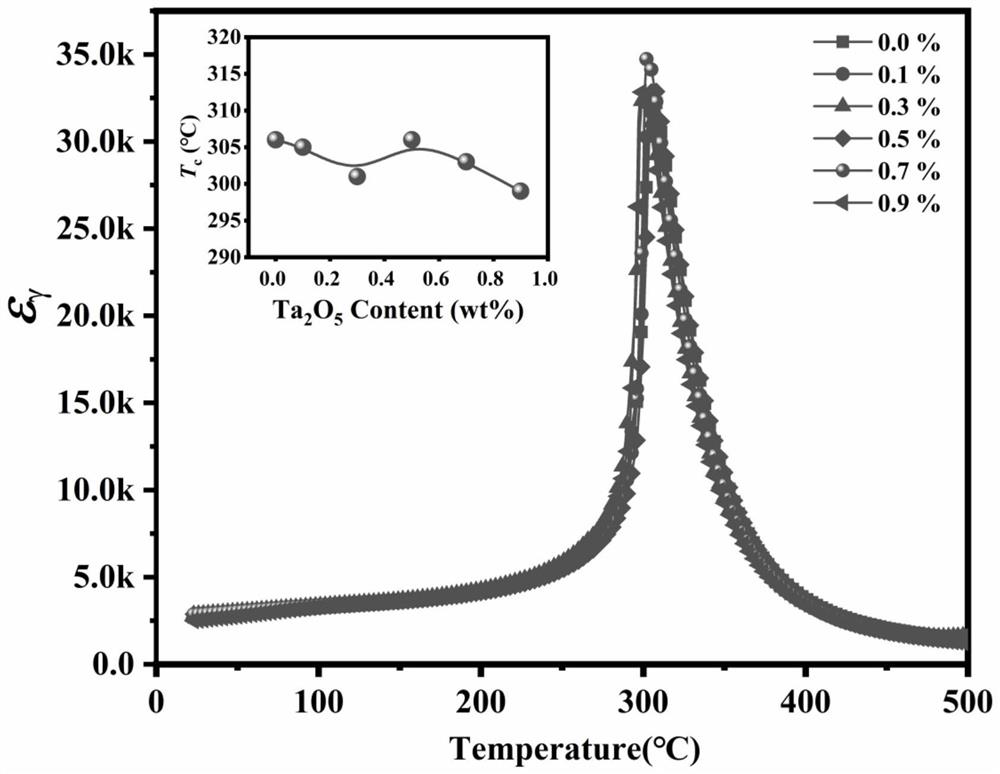

[0019] The XRD patterns of the prepared high-performance PZT modified piezoelectric ceramics prepared at low temperature are shown in figure 1 , figure 1 It is shown that the PZT piezoelectric ceramic is a pure perovskite phase; the ZJ-3 type quasi-static state of the Institute of Acoustics, Chinese Academy of Sciences is used. d 33 meter, the measured piezoelectric coefficient of d 33 See image 3 , which is 322 pC / N; the change of dielectric constant with temperature was measured by using Agilent 4980A precision impedance meter connected to a temperature-controlled furnace, which can be obtained from Figure 4 The Curie temperature of the obtained sample was 171 °C.

Embodiment 2

[0021] The XRD patterns of the prepared high-performance PZT modified piezoelectric ceramics prepared at low temperature are shown in figure 1 , figure 1 It is shown that the PZT piezoelectric ceramic is a pure perovskite phase; the ZJ-3 type quasi-static state of the Institute of Acoustics, Chinese Academy of Sciences is used. d 33 meter, the measured piezoelectric coefficient of d 33 See image 3 , which is 513 pC / N; the change of dielectric constant with temperature was measured by using Agilent 4980A precision impedance meter connected to a temperature-controlled furnace, which can be obtained from Figure 4 The Curie temperature of the obtained sample was 178 °C.

Embodiment 3

[0023] The XRD patterns of the prepared high-performance PZT modified piezoelectric ceramics prepared at low temperature are shown in figure 1 , figure 1 It is shown that the PZT piezoelectric ceramic is a pure perovskite phase; the ZJ-3 type quasi-static state of the Institute of Acoustics, Chinese Academy of Sciences is used. d 33 meter, the measured piezoelectric coefficient of d 33 See image 3 , which is 608 pC / N; the change of dielectric constant with temperature was measured by using Agilent 4980A precision impedance meter connected to a temperature-controlled furnace, which can be obtained from Figure 4 The Curie temperature of the obtained sample was 173 °C. Its SEM image see figure 2 , showing that the grain size is uniform and the grains are relatively dense.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric coefficient | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

| Piezoelectric coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com