Special-shaped cable and preparation method thereof

A cable and special-shaped technology, which is applied in the field of special-shaped cables and their preparation, can solve the problems of not being able to meet the needs of product connection, and achieve the effect of eliminating eddy current effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

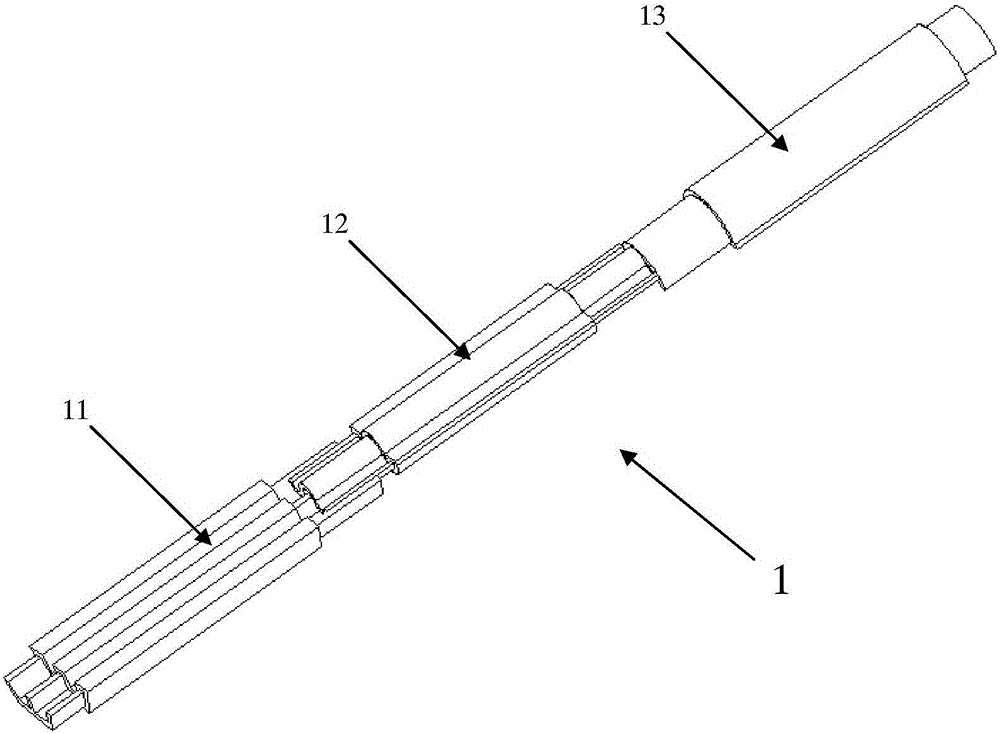

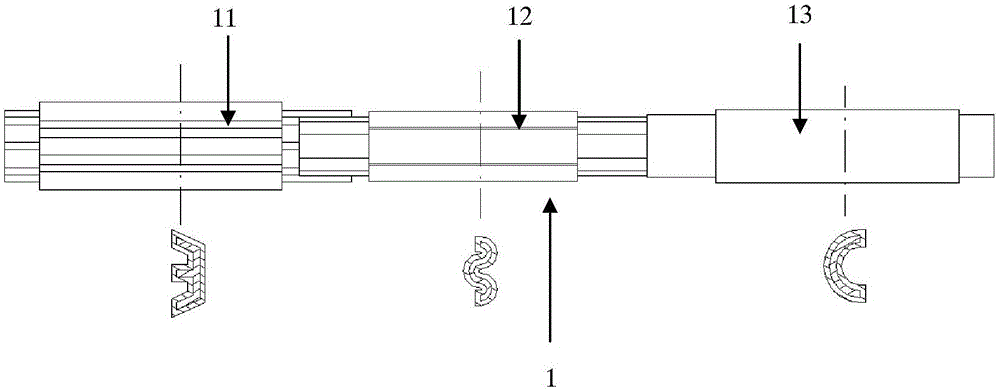

[0102] Such as figure 1 with 2 Shown is the first specific implementation of the technical solution. The guide core of the cable 1 of this embodiment is composed of three guide core segments with different shapes (respectively the first guide core segment 11, the second guide core segment 12 and the second core guide segment 12). The third guide core segment 13) is connected end to end.

[0103] In this embodiment, the cross-section of the first core segment is W-shaped, the cross-section of the second core segment is wave-shaped, and the cross-section of the third core segment is arc-shaped. The upper surface of the rear end of the first core segment is in contact with the lower surface of the front end of the second core segment, and the rear end of the second core segment is in contact with the front end of the third core segment . Each guide core section is coated with an insulating layer made of PVC material.

[0104] In this embodiment, the cross-sectional shapes of ...

Embodiment 2

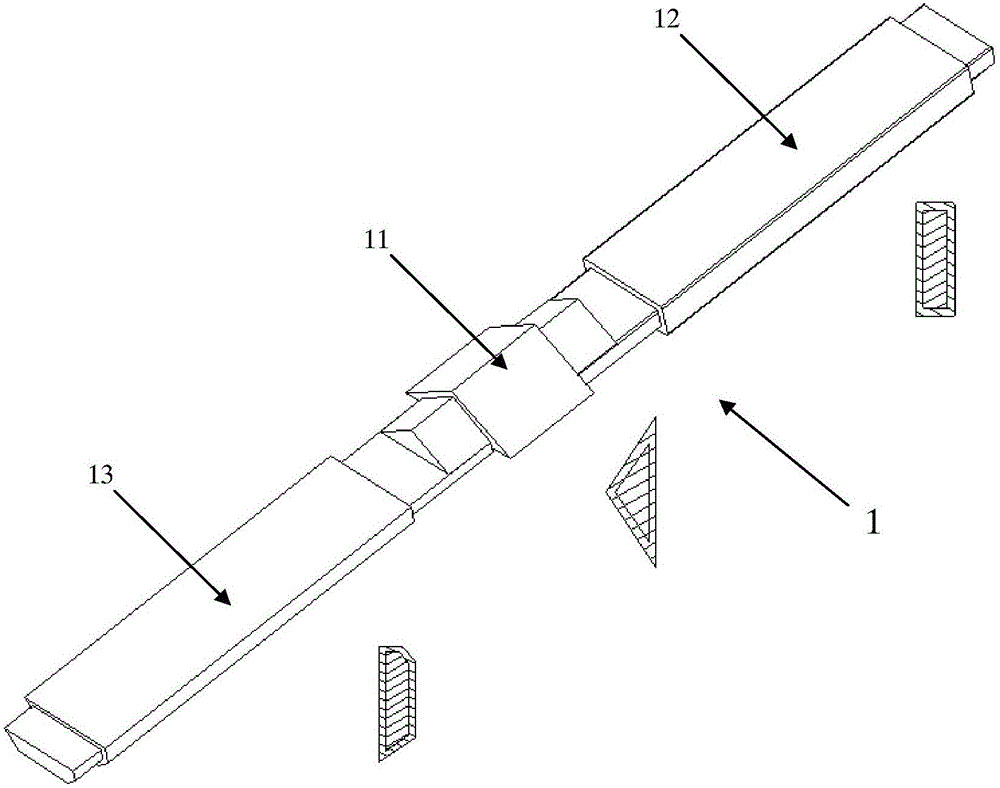

[0112] Such as image 3 Shown is the second specific implementation of the technical solution. The difference between this embodiment and Embodiment 1 is that the three sections of the cable 1 in this embodiment are polygonal core segments with different shapes, specifically: the cross section of the first core segment 11 is triangular in shape, and the second The cross-section of the guide core segment 12 is quadrilateral, and the cross-section of the third core guide segment 13 is pentagonal. The lower end of the rear end of the first core segment abuts against the upper end of the front end of the second core segment, and the lower end of the front end of the first core segment abuts against the upper end of the rear end of the third core segment. The other implementation conditions are the same as those in the first embodiment, and will not be repeated in this embodiment.

[0113] In this embodiment, the cross-sectional shape of the guide core segment is set in different...

Embodiment 4

[0118] Such as Figure 5 Shown is the fourth specific implementation of the technical solution. The guide core of the cable 1 in this embodiment is not connected by two or three guide core segments of the same shape or material, but by three guide core segments of different shapes or materials. Specifically, the first core segment 11 is a flexible elliptical stranded core segment, the second core segment 12 is a solid core segment with an octagonal cross-sectional area, and the third core segment 13 is a quadrilateral cross-sectional area. flexible stranded core section. The lower end of the rear end of the first core segment is connected to the upper end of the front end of the second core segment by welding, and the upper end of the rear end of the second core segment is connected to the lower end of the front end of the third core segment. connected by welding. As one of the preferred implementations, the welding method is ultrasonic welding. The upper and lower end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com