Metallic oxide electrode for organic wastewater processing and preparation thereof

A technology for organic wastewater treatment and oxidation, applied in the direction of electrochemical water/sewage treatment, electrodes, electrolysis process, etc., can solve the problems of high cost, complicated preparation process, long cycle, etc., and achieve low production cost, good electrical conductivity, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

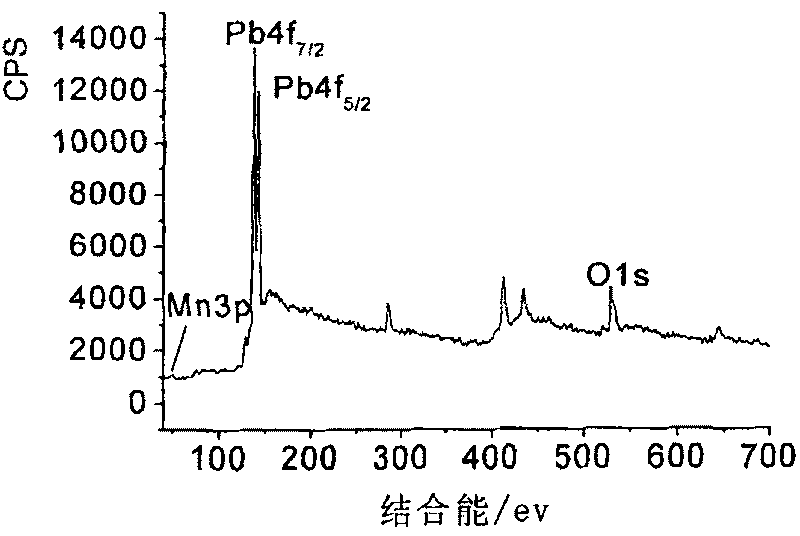

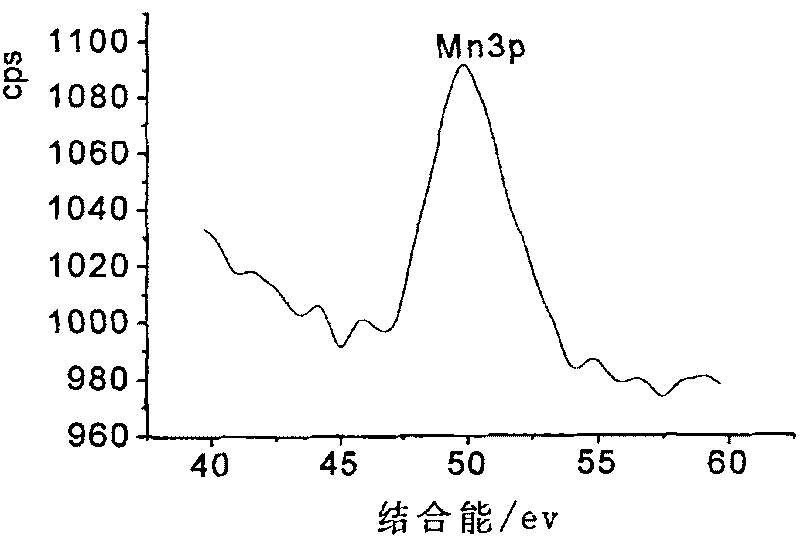

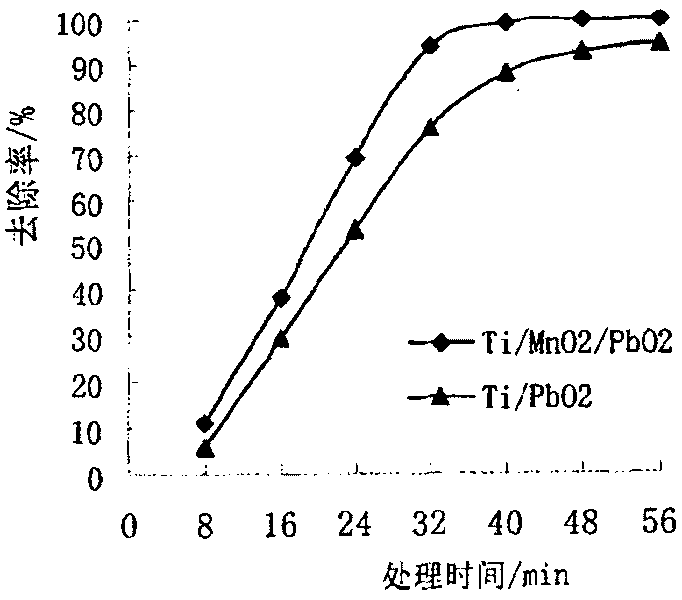

[0022] A metal oxide composite electrode for waste water treatment and its preparation method: Firstly, the industrial pure titanium plate is polished successively with 120-mesh and 600-mesh sandpaper, washed, put into acetone solution, and washed by ultrasonic oscillation for 20-30 minutes. 10-20% NaOH solution, 10-20% H 2 SO 4 solution and a saturated oxalic acid solution were boiled and etched for 1-1.5 hours respectively, and then rinsed with distilled water to obtain a pretreated titanium metal substrate.

[0023] Then two titanium plates were symmetrically distributed on both sides of the pretreated titanium metal substrate as cathodes, and placed together on the MnSO 4 120~140g / L,H 2 SO 4 In the 30-50g / L mixed solution, adopt the anode electrodeposition method, under the conditions of agitator stirring and temperature of 80-90°C, the anode current density is 5-10mA / cm 2 Deposit for 25 to 30 minutes; take it out and bake at 400 to 450°C for 1 to 1.5 hours to obtain T...

Embodiment 2

[0027] A metal oxide composite electrode for wastewater treatment and its preparation method: Firstly, the industrial pure titanium plate is polished successively with 120-mesh and 600-mesh sandpaper, washed and put into acetone solution, and washed by ultrasonic oscillation for 20-30 minutes . In turn, the mass percentage is 20-30% NaOH solution, 20-30% H 2 SO 4 solution and saturated oxalic acid solution were boiled and etched for 1.5-2 hours respectively, and then rinsed with distilled water to obtain a pretreated titanium metal substrate.

[0028] Then two titanium plates were symmetrically distributed on both sides of the pretreated titanium metal substrate as cathodes, and placed together on the MnSO 4 140~160g / L,H 2 SO 4 In the 50-60g / L mixed solution, the anode electrodeposition method is adopted, under the conditions of agitator stirring and temperature of 90-100°C, the anode current density is 10-15mA / cm 2Deposit for 20 to 25 minutes; take it out and bake at 450...

Embodiment 3

[0032] A metal oxide composite electrode for wastewater treatment and its preparation method: Firstly, the industrial pure titanium plate is polished successively with 120-mesh and 600-mesh sandpaper, washed and put into acetone solution, and washed by ultrasonic oscillation for 30-40 minutes . In turn, the mass percentage is 30-40% NaOH solution, 30-40% H 2 SO 4 solution and saturated oxalic acid solution were boiled and etched for 1.5-2 hours respectively, and then rinsed with distilled water to obtain a pretreated titanium metal substrate.

[0033] Then two titanium plates were symmetrically distributed on both sides of the pretreated titanium metal substrate as cathodes, and placed together on the MnSO 4 160~180g / L,H 2 SO 4 In the 60-80g / L mixed solution, the anode electrodeposition method is adopted, under the conditions of aeration and stirring and a temperature of 90-100°C, the anode current density is 15-20mA / cm 2 Deposit for 10 to 20 minutes; take it out and bake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com