Lubricating grease for protecting aluminum-conductor steel-reinforced cables and preparation method of lubricating grease

A steel-cored aluminum stranded wire and lubricating grease technology, which is applied in the direction of lubricating compositions and the petroleum industry, can solve the problems of environmental pollution, anti-corrosion oil dripping down, increasing the cost of manufacturers, etc., and achieve the effect of ensuring the protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

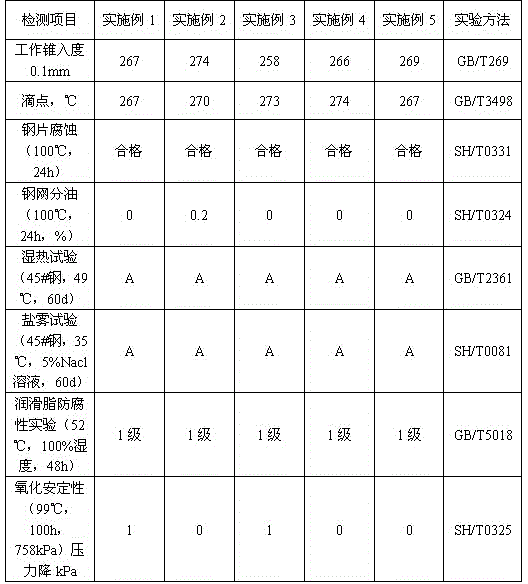

Examples

Embodiment 1

[0020] see figure 1 , the preparation method of a kind of lubricating grease that is used for the protection of steel-cored aluminum stranded wire, it comprises the following steps:

[0021] Add 200g of paraffin-based mineral oil to 1# reactor (the kinematic viscosity at 40°C is 180mm 2 / s), heat up to 50°C, put 16.68g of diphenylmethane diisocyanate into 1# reactor, stir for 45min; add 238.6g of paraffin-based mineral oil to 2# reactor 2 / s), add 11.02g octadecylamine and 11.4g cyclohexylamine, raise the temperature to 80~100℃, and stir for 40min. Slowly add the 2# reactor material into the 1# reactor, react for 1 hour, keep the temperature at 85°C, slowly raise the temperature to 140°C, keep the temperature for 10min, then cool to 110°C, add 10g of ethylene propylene rubber, 2g of dioctyl diphenylamine, Dissolve 10g of barium petroleum sulfonate, 0.3g of carboxylate and amine derivatives, stir at this temperature for 30min, cool to 90°C, homogenize, and serve.

Embodiment 2

[0023] see figure 1 , the preparation method of a kind of lubricating grease that is used for the protection of steel-cored aluminum stranded wire, it comprises the following steps:

[0024] Add 200g polyalphaolefin (40 ℃ kinematic viscosity is 210mm 2 / s), heat up to 50°C, put 16.68g of diphenylmethane diisocyanate into 1# reactor, stir for 45min; add 238.6g of paraffin-based mineral oil to 2# reactor 2 / s), add 11.02g of octadecylamine and 11.4g of cyclohexylamine, raise the temperature to 100°C, and stir for 40min. Slowly add the 2# reactor material into the 1# reactor, react for 1 hour, keep the temperature at 85°C, slowly raise the temperature to 140°C, keep the temperature for 10min, then cool to 110°C, add 10g of ethylene propylene rubber, 2g of dioctyl diphenylamine, Dissolve 10g of barium petroleum sulfonate, 0.3g of carboxylate and amine derivatives, stir at this temperature for 30min, cool to 90°C, homogenize, and serve.

Embodiment 3

[0026] see figure 1 , the preparation method of a kind of lubricating grease that is used for the protection of steel-cored aluminum stranded wire, it comprises the following steps:

[0027] Add 160g of paraffin-based mineral oil to 1# reactor (the kinematic viscosity at 40°C is 260mm 2 / s), heat up to 50°C, put 14.68g of diphenylmethane diisocyanate into 1# reactor, stir for 45min; 2 / s), add 8.02g of octadecylamine and 8.8g of aniline, raise the temperature to 90°C, and stir for 40min. Slowly add the 2# reactor material into the 1# reactor, react for 1 hour, keep the temperature at 80°C, slowly raise the temperature to 135°C, keep the temperature for 10min, then cool to 105°C, add 8g of ethylene propylene rubber, 2g of dioctyl diphenylamine, Dissolve 8g of barium petroleum sulfonate, 0.2g of carboxylate and amine derivatives, stir at this temperature for 30min, cool to 85°C, homogenize, and serve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com