Patents

Literature

164results about How to "Efficient flame retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

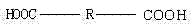

Preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol

The invention discloses a preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol. The preparation method is characterized by comprising following steps: taking binary acid, dihydric alcohol, halogen-free phosphorous copolymer fire retardant and catalyst to be put into a reaction kettle, stirring and warming up, filling nitrogen to empty, reacting for 2 to 8h when the temperature reaches 125 to 155 DEG C, then warming up to 180 DEG C, vacuumizing to ensure the air pressure to be 100 to 5000 Pa, controlling reaction temperature to be 180 to 245 DEG C, after reacting for 2 to 4h, sampling at an interval of 10 to 40 min to test acid value, stopping heating when the acid value is reduced below 2 mgKOH / g, and stirring for cooling so as to obtain the reaction type halogen-free phosphorous flame retardant polyester polyol. The reaction type halogen-free phosphorous flame retardant polyester polyol is applied to synthesis of rigid or soft polyurethane foamed plastic, and the prepared polyurethane foamed plastic has excellent flame retardant property, and the limit oxygen index can be up to more than 32%.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

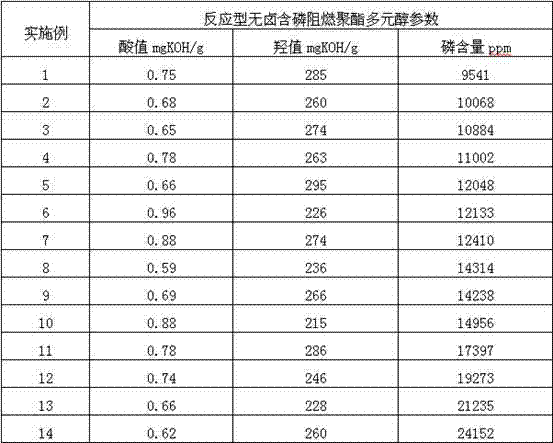

Preparation and application methods of lignin-based flame retardant

The invention provides preparation and application methods of a lignin-based flame retardant, and relates to a flame retardant. The flame retardant is prepared from the following raw materials: lignin, isocyanate, 9,10-dihydro-9-oxa-phenanthrene-10-oxide (DOPO). The preparation method specifically comprises the following steps: performing reaction on the lignin and the isocyanate at certain temperature; performing reaction with the DOPO at certain temperature; finally, drying the obtained product in a vacuum drying box, and smashing the product, thus obtaining the flame retardant. According to the flame retardant, hydroxyl on the lignin is reacted with the isocyanate; meanwhile, with a phosphate structure, the flame retardant has a good flame retarding effect; benzene ring structures contained in the lignin and the DOPO can enhance the mechanical property of the material. The invention further provides a preparation method of flame retarding polyurethane. The method comprises the steps of performing reaction on polyatomic alcohol and the isocyanate at certain temperature till the system is sticky, adding the phosphorus-containing lignin-based flame retardant and other auxiliaries, and performing thermal curing and molding. The obtained flame retarding polyurethane can be used as an adhesive, a coating, a foaming material, a terrace coating material and the like.

Owner:CHANGCHUN UNIV OF TECH

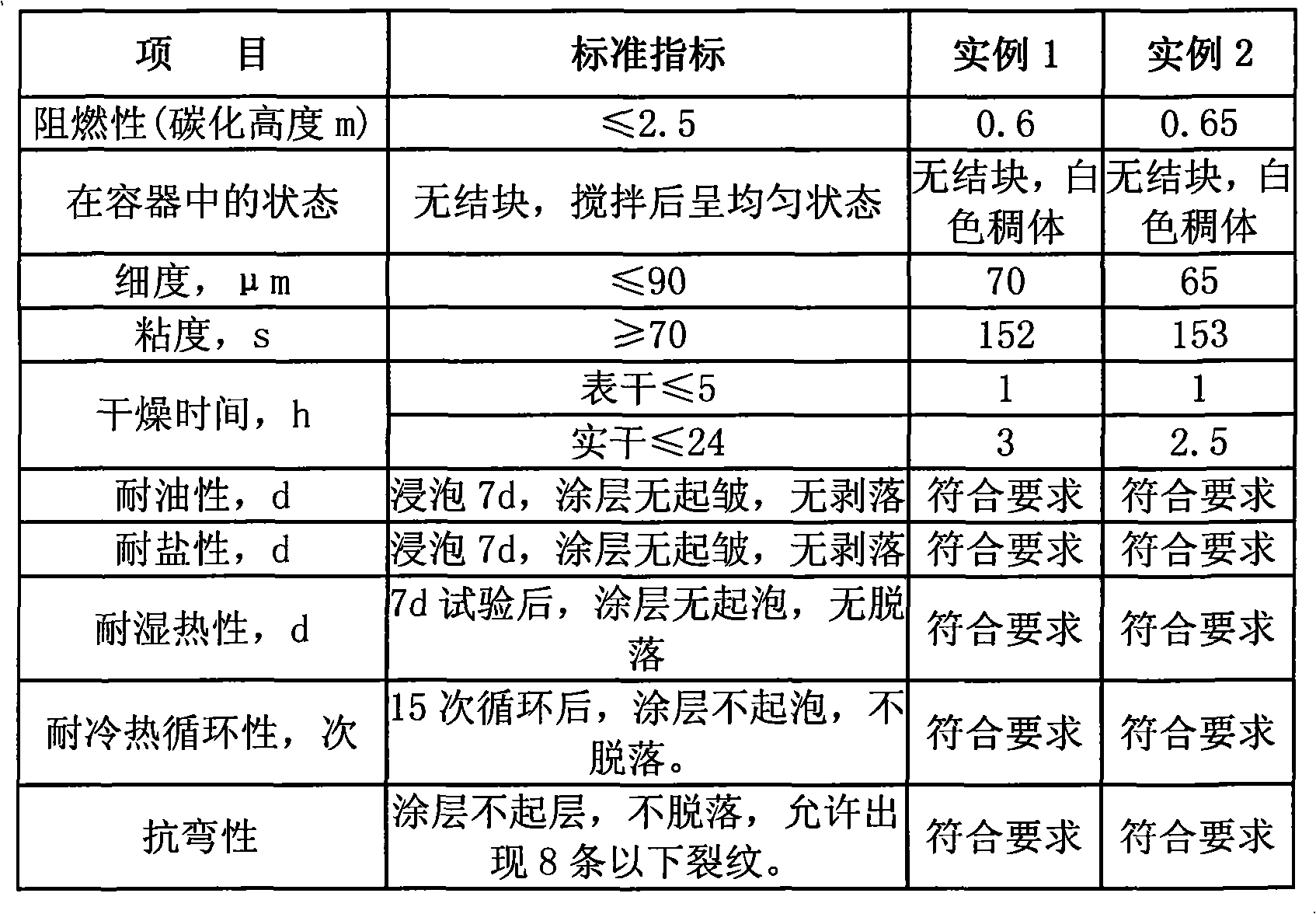

Environment-friendly cable fireproof paint and manufacturing method thereof

InactiveCN101654579AEliminate fire hazardsHarm reductionFireproof paintsInsulated cablesWater basedFire risk

The invention relates to a manufacturing method of fireproof paint, in particular to environment-friendly cable fireproof paint and a manufacturing method thereof. The environment-friendly cable fireproof paint comprises the following initial raw materials in parts by weight: 1-50 parts of water, 10-90 parts of elastic acrylic based emulsion, 1-10 parts of stuffing, 10-90 parts of flame retardant,1-10 parts of melamine, 1-10 parts of rutile type titanium pigment, 1-10 parts of dipentaerythritol, 1-10 parts of thixotropic agent and 1-10 parts of thickening agent. The environment-friendly cablefireproof paint is water-based fireproof paint, has the advantages of no halogen, innocuity, no corrosion, safety, environmental protection, high-effective flame retardance, volume increase in case of fire, convenient construction and the like, radically eliminates the fire risks due to the solvent volatilization of solvent type paint in production and construction, and reduces the harm to peopleand the pollution to environment caused by harmful organic solvents.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

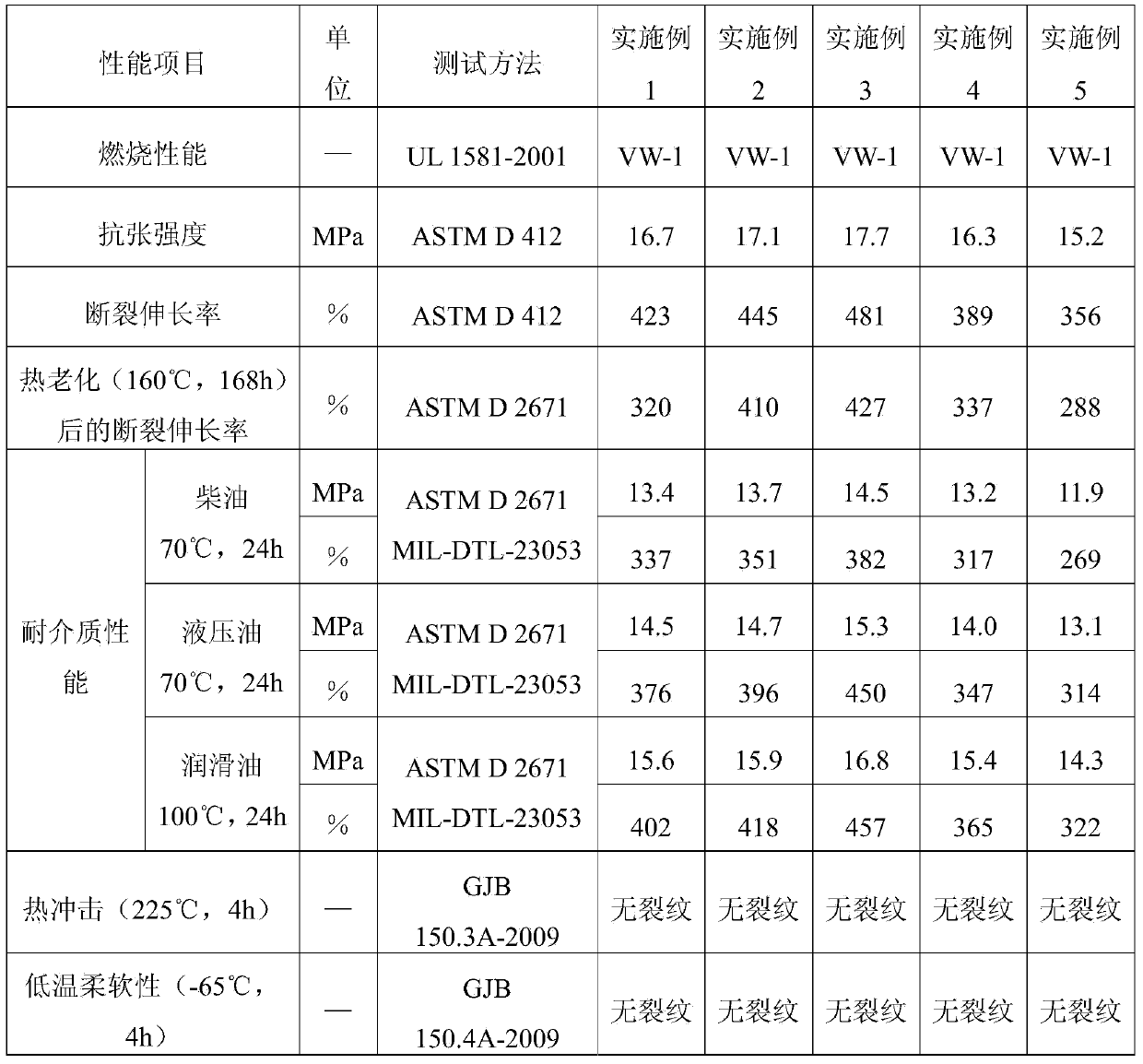

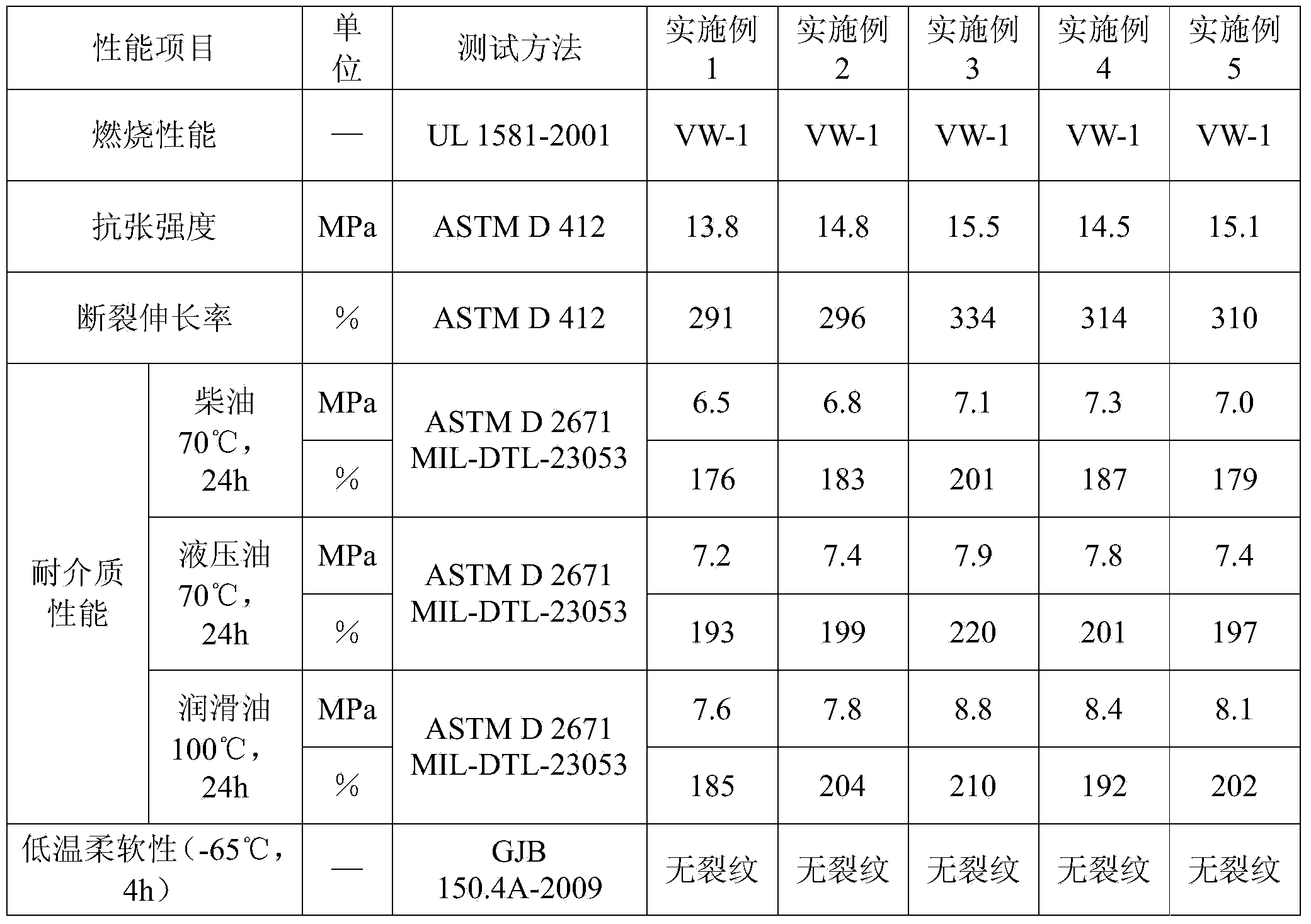

Thermoplastic polyester elastomer heat-shrinkable casing tube for automobile wire harness as well as preparation method and application of heat-shrinkable casing tube

The invention discloses a thermoplastic polyester elastomer heat-shrinkable casing tube for an automobile wire harness as well as a preparation method and an application of the heat-shrinkable casing tube. The heat-shrinkable casing tube comprises the following components in parts by weight: 50-80 parts of a thermoplastic polyester elastomer, 30-60 parts of halogen-containing resin, 5-15 parts of black masterbatch, 5-30 parts of diantimony trioxide, 0-100 parts of a flame retardant, 3-15 parts of a flame retardant synergist, 1-4 parts of a thermal stabilizer, 0.5-4 parts of an antioxidant, 0.5-2 parts of a silicone aid and 1-2.5 parts of a sensitizer. The preparation method comprises the following steps: mixing the thermoplastic polyester elastomer, the halogen-containing resin, the black masterbatch, diantimony trioxide, the flame retardant, the flame retardant synergist, the thermal stabilizer, the antioxidant and the silicone aid, adding the sensitizer, mixing, granulating, extruding to form a tube, performing irradiation crosslinking, stretching by expanding, shaping by cooling, flattening, and marking. The heat-shrinkable casing tube has the advantages of relatively low price, high-efficiency flame retardance, excellent mechanical property, low pollution, high-temperature oil resistance, acid-base corrosion resistance and capability of being applied in a severe working environment.

Owner:广州凯恒科塑有限公司

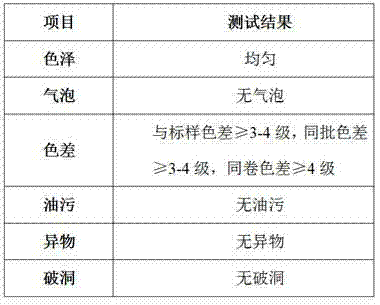

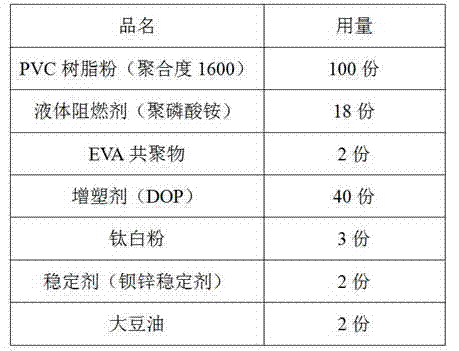

High brightness flame retardant decorative film

The invention relates to a high brightness flame retardant decorative film, which is prepared by steps of temperature-rising agitation, banburying, filtration, four-roller rolling, primary embossing of mirror surface, non-adhesive pasting process of mirror surface, cooling, reeling and the like by taking PVC (polyvinyl chloride) resin powder and plasticizer as main materials and adding functionalassistants such as a liquid flame retardant, an EVA (ethylene vinyl acetate)-grafted copolymer, soybean oil, a stabilizer and the like. The high brightness flame retardant decorative film of the inveiton has excellent properties such as durable mirror-surface luster, efficient flame retardancy, good strength, size stability and the like.

Owner:ZHEJIANG BOTAI PLASTIC

High-temperature oil-resistant and flame-retardant chlorinated polyethylene heat-shrinkable tubing as well as preparation method and application thereof

The invention discloses high-temperature oil-resistant and flame-retardant chlorinated polyethylene heat-shrinkable tubing as well as a preparation method and an application thereof. The heat-shrinkable tubing comprises the following components: chlorinated polyethylene, resin A, resin B, a polymer compatibilizer, black masterbatch, antimonous oxide, a flame retardant synergist, a halogen-free flame retardant, a thermal stabilizer, hydrotalcite, an antioxidant, a sensitizer and a silicone additive. The method comprises the following steps: firstly, banburying the antimonous oxide, the flame retardant synergist, the halogen-free flame retardant and hydrotalcite; adding and banburying the chlorinated polyethylene, the resin A, the resin B, the polymer compatibilizer, the black masterbatch, the thermal stabilizer, the antioxidant and the silicone additive; finally adding a sensitizer and banburying, and then palatalizing, and extruding to form the tubing; and carrying out irradiation crosslinking, expanding drawing, cooling sizing, and marking, so as to obtain the high-temperature oil-resistant and flame-retardant chlorinated polyethylene heat-shrinkable tubing. The high-temperature oil-resistant and flame-retardant chlorinated polyethylene heat-shrinkable tubing has the advantages of being low in price, efficient, flame-retardant, excellent in mechanical property, low in pollution, high in high-temperature oil resistance, and good in resistance to acid and alkali corrosion, and can be applied to a bad working condition.

Owner:广州凯恒科塑有限公司

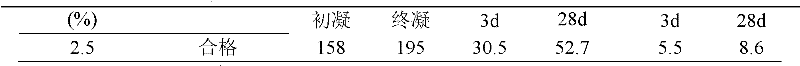

Environment-friendly high-performance waterproof flame-retardant plastering mortar and preparation method thereof

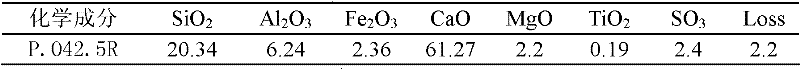

The invention relates to environment-friendly high-performance waterproof flame-retardant plastering mortar, which is prepared by mixing the following components of: P.O42.5R cement, modified phosphogypsum, redispersible latex powder, limestone powder, ceramic microspheres, modified expandable graphite, a water-retaining agent, a toughening agent and a water repellent in a mass ratio of (1-2):(0.4-0.9):(0.1-0.4):(0.1-0.5):(0.5-1):(0.25-1.5):(0.005-0.04):(0.005-0.01):(0.005-0.03). The environment-friendly high-performance waterproof flame-retardant plastering mortar has a great significance for high-efficiency flame retardance, heat insulation, water prevention, permeation resistance, composite heat preservation, energy conservation, the recycling of the phosphogypsum and the reduction in the pollution of solid wastes to environment, and has the advantages of low cost and high strength.

Owner:WUHAN UNIV OF TECH

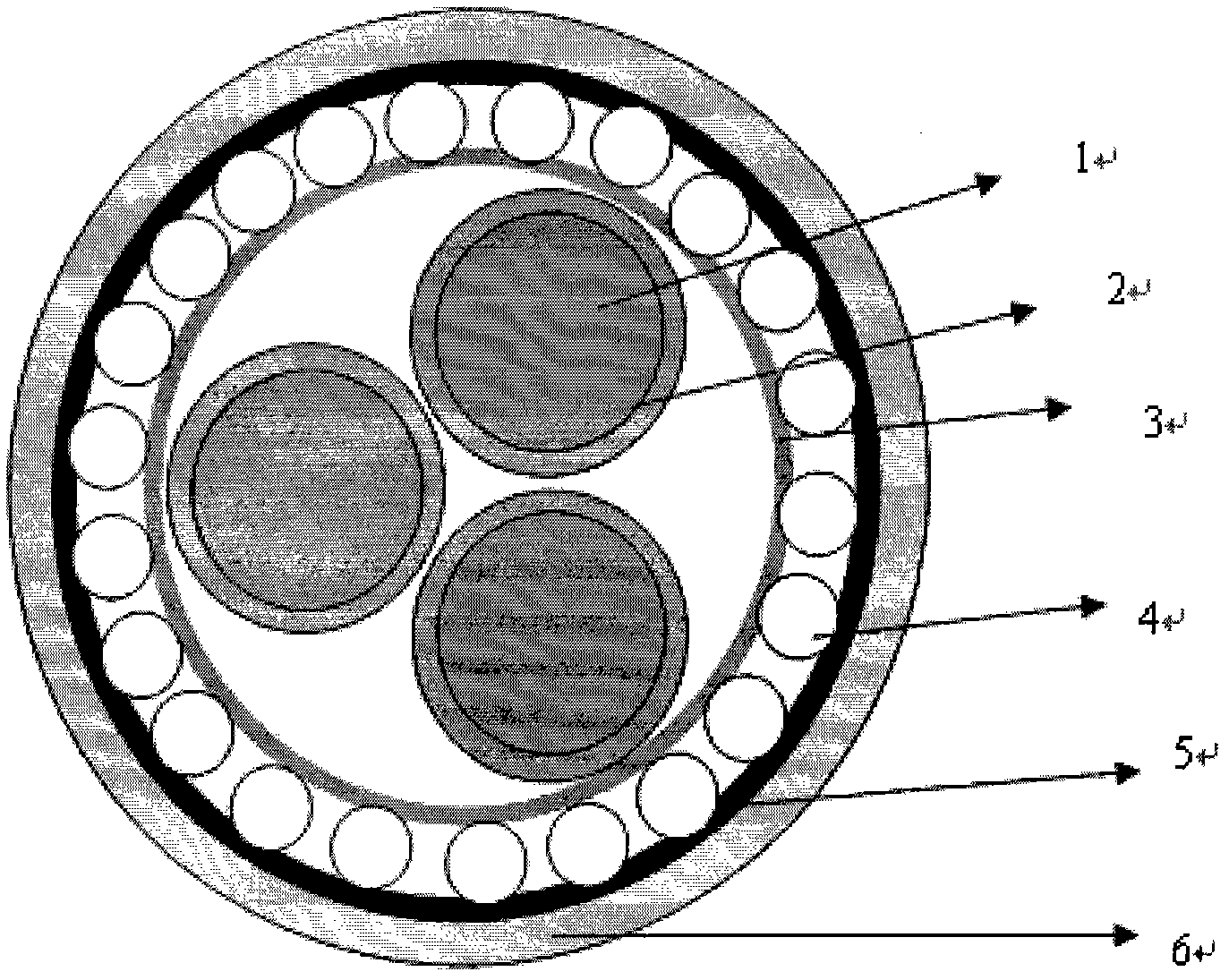

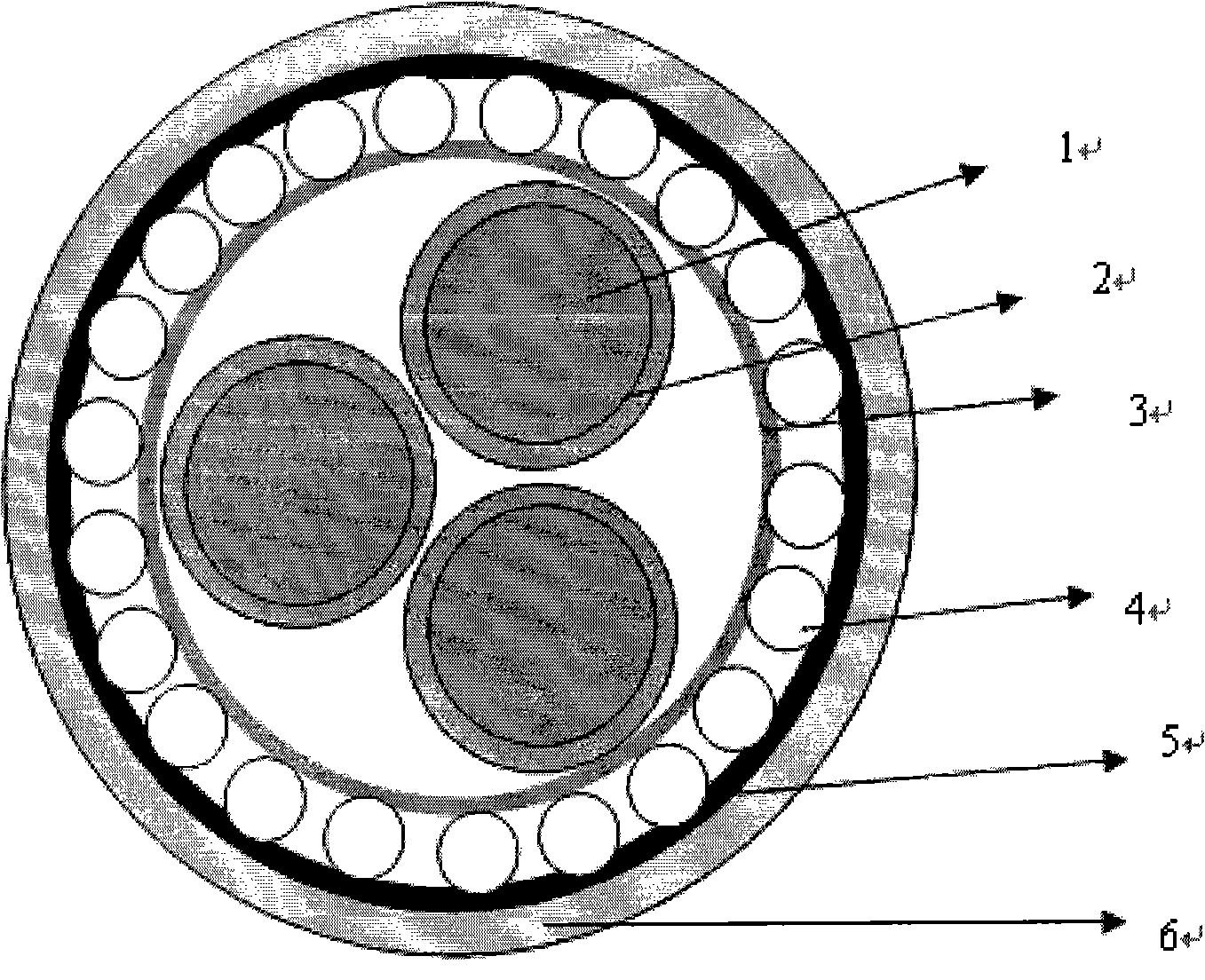

Cleaning-type oil-resistant cable

InactiveCN102082004ALarge leakage currentWear-resistantClimate change adaptationInsulated cablesCopper conductorCross-link

The invention belongs to the technical field of electrical wire and cable production processes, and particularly relates to a cleaning-type oil-resistant cable. Conductors (1) are copper conductors, the structures of the conductors adopt a first type or a second type, a cross-linked polyethylene insulating layer (2) is extruded on the conductors (1) respectively by applying a warm water cross-linking technology to serve as a cable core, an inner lining layer (3) is arranged outside the cable core, an armor layer (4) is armored by back-twist type galvanized fine steel wires, aluminum-plastic composite tapes are longitudinally coated and welded outside the armor layer (4) to form a water and tide blocking layer (5), and a flame-retardant jacket layer (6) made of a butyronitrile material is arranged at the outermost layer. With a double-layer co-extrusion mode to extrude, the arrangement of the high-strength water and tide blocking layer capable of longitudinally preventing tension in the overall cable and a process of double-layer co-extrusion protection layers, the cleaning-type oil-resistant cable has not only very strong resistance to abrasion and oil, but also better resistance to cleaning, thereby the quality stability of the oil-resistant cable is improved and a new technical field is developed for the development of the cleaning-type oil-resistant cable.

Owner:HENAN HUATAI SPECIAL CABLE

High-effective bio-based flame-retarding agent containing furan ring, and synthesis method and application of the flame-retarding agent

ActiveCN109280219AHigh yieldThe synthesis process is simpleGroup 5/15 element organic compoundsFuranSynthesis methods

The invention discloses a high-effective bio-based flame-retarding agent containing furan ring, and a synthesis method and an application of the flame-retarding agent. In the invention, with a bio-based compound containing furan ring and a phosphorus-containing compound being raw materials, the bio-based flame-retarding agent containing furan ring is prepared under protection by inert gas. The flame-retarding agent is very low in influence on thermo-stability of a resin matrix and can effectively improve crystallization property of the resin matrix, thereby improving mechanical strength and modulus of the material. When being applied to polymers, the flame-retarding agent has outstanding flame-retarding effect and can achieve flame retarding just by a less addition amount. The flame-retarding agent can alleviate thermal performance loss of a flame-retarding composite material and significantly improve crystallization and increase crystallization speed of the polymer matrix, thus significantly enhancing mechanical performance of the composite material. The flame-retarding agent can catalyze degradation of polylactic acid mainly in the manner of breaking molecular chains to form low-molecular-weight oligomers, then heat generated during combustion is released in the form of molten drops, thus achieving the flame retarding object.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Non-halogen fire retardant for terylene polyester chips and its production technology

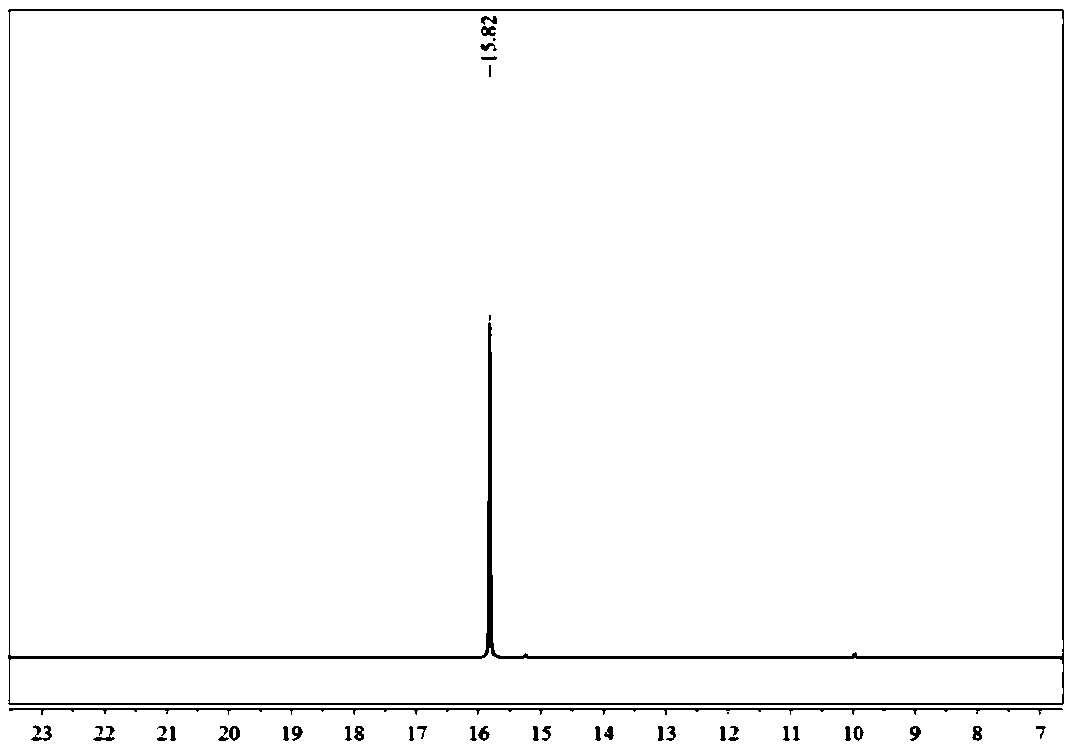

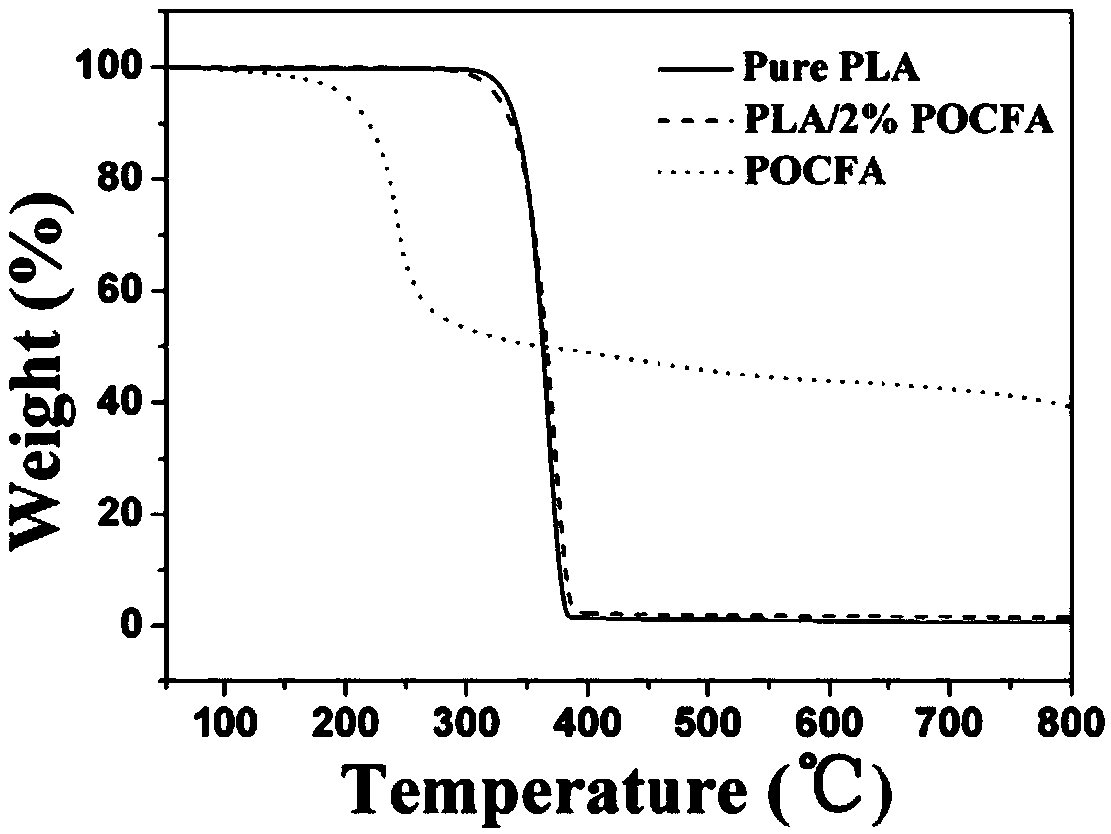

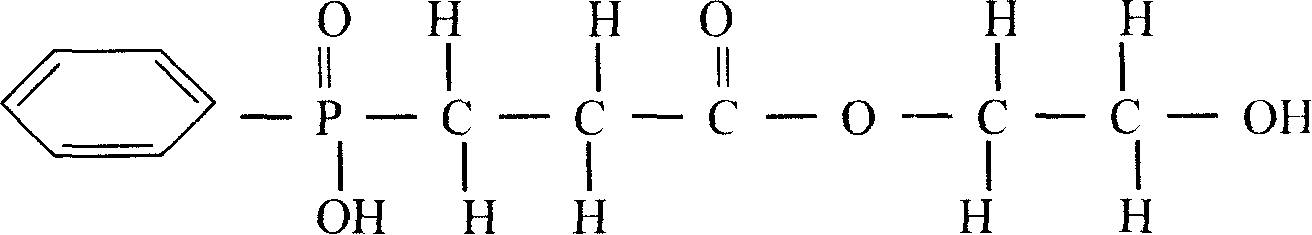

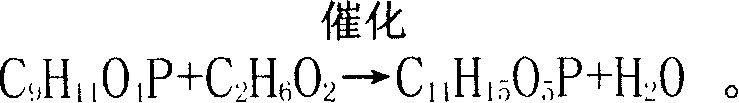

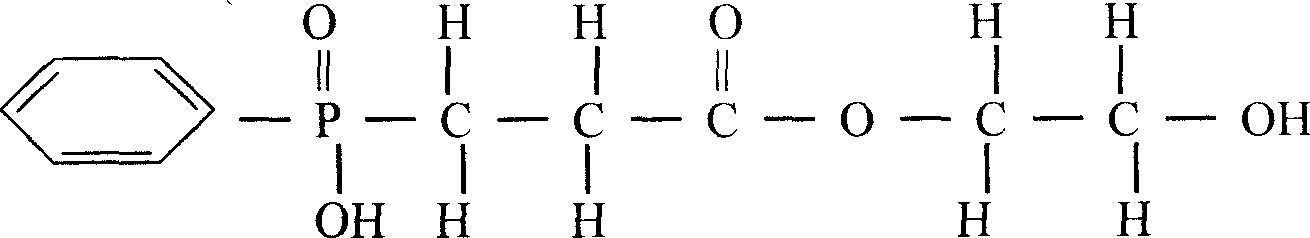

A non-halogen fire retardant for terylene polymer chips used to prepare polyester fibres is prepared from ethanediol (C2H6O2) and 2-carboxyethyl phenylphosphoric acid (C9H11O4P) through adding catalyst, stirring, heating, negative-pressure reaction, and cooling.

Owner:南通联华阻燃科技有限公司

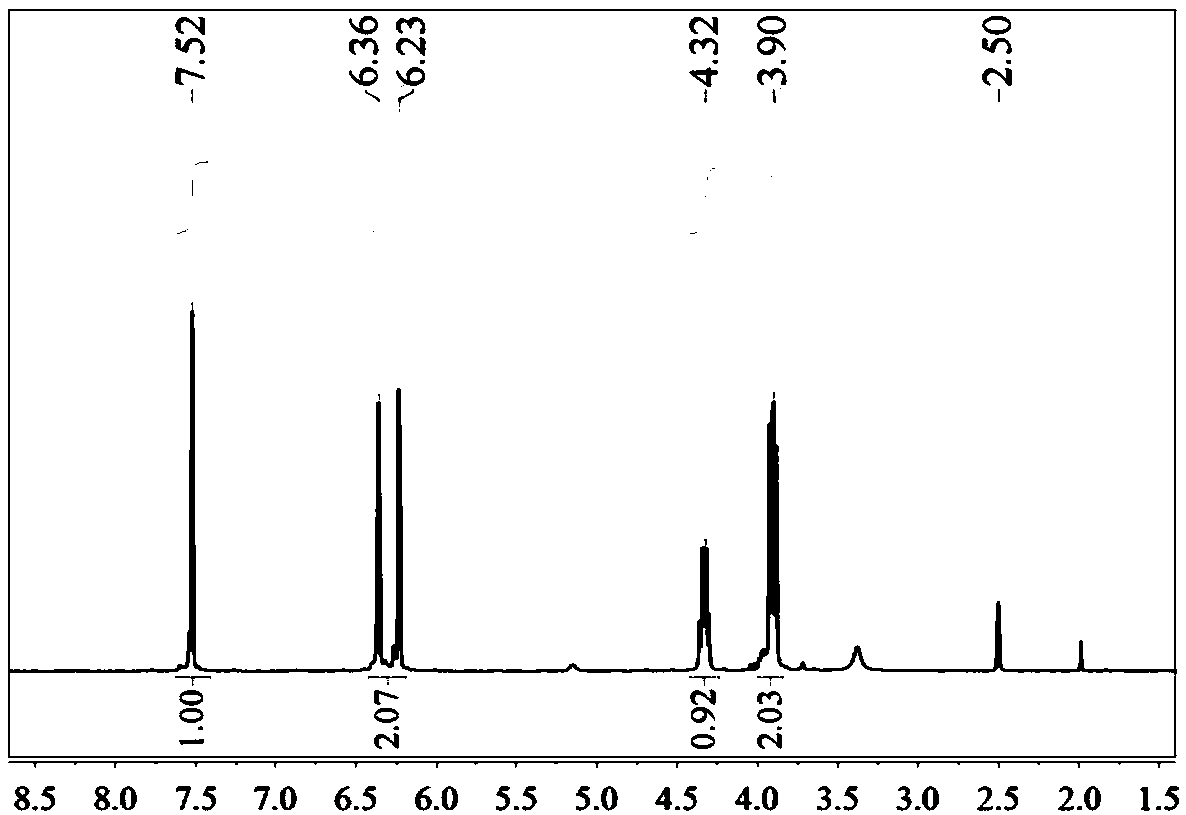

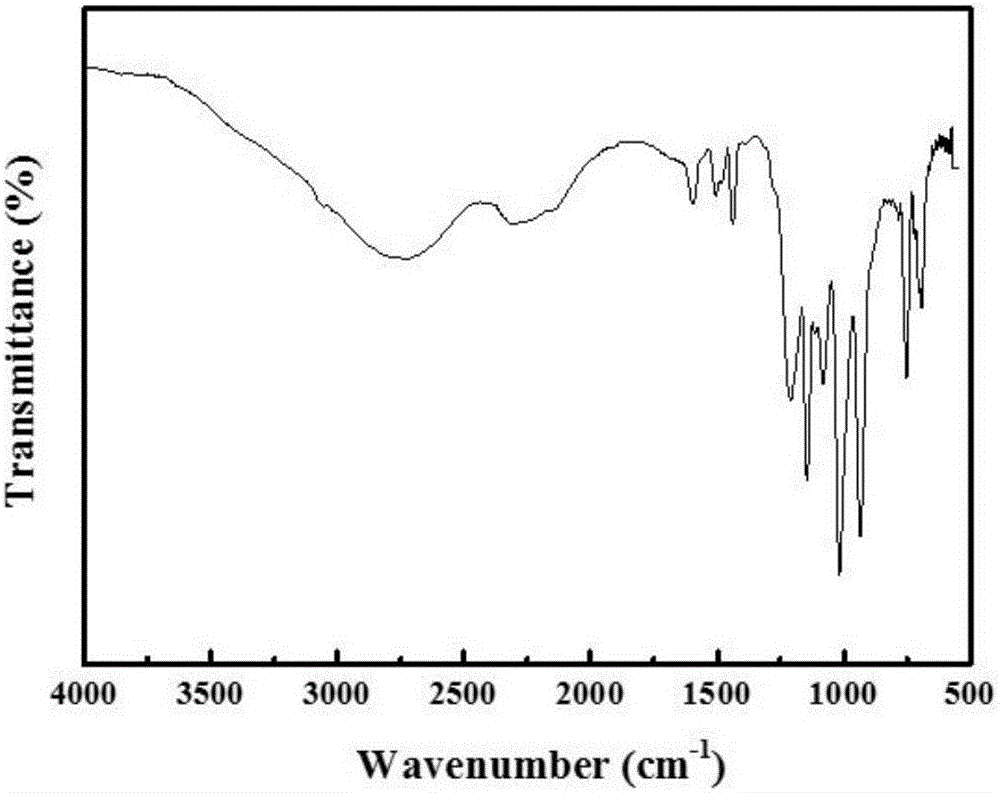

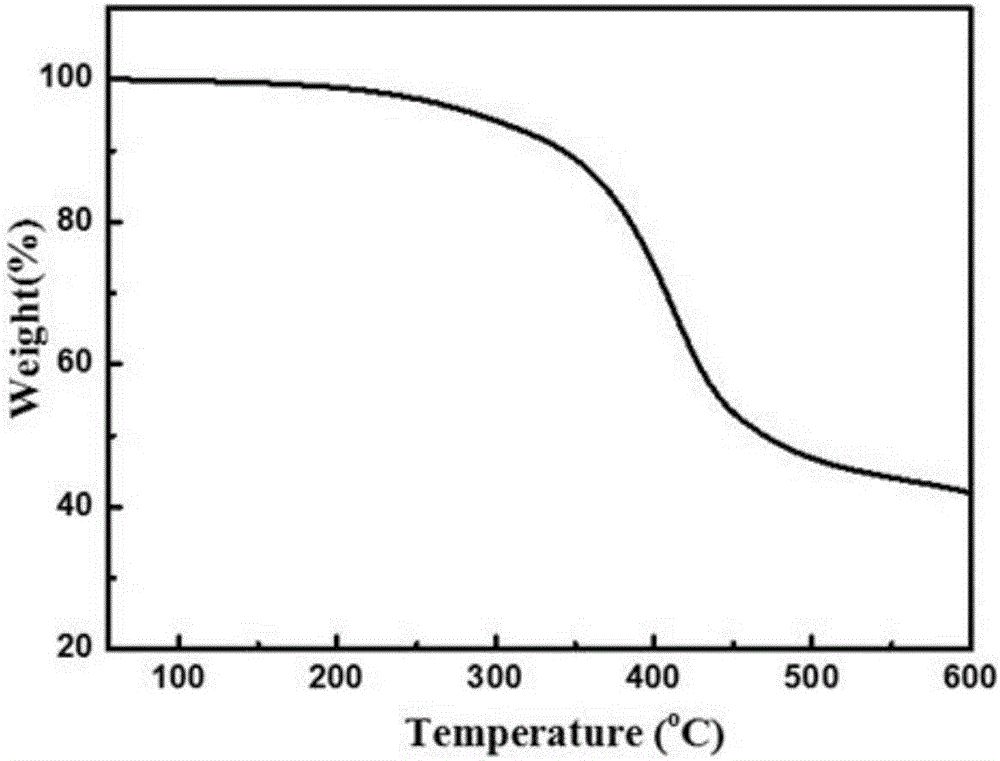

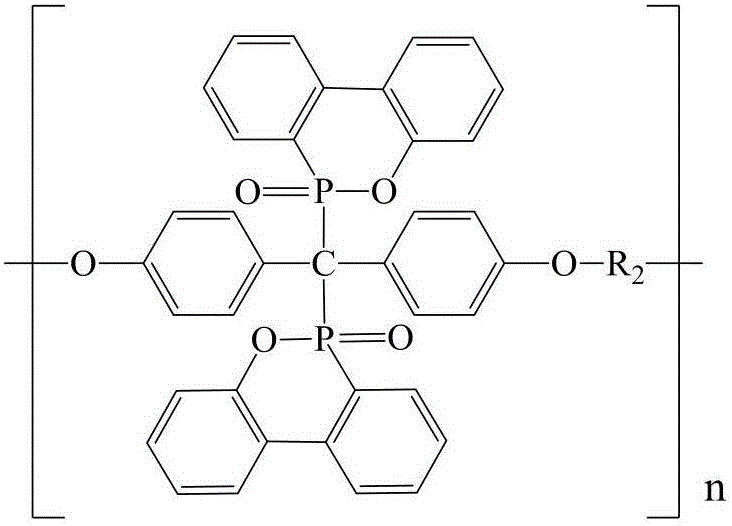

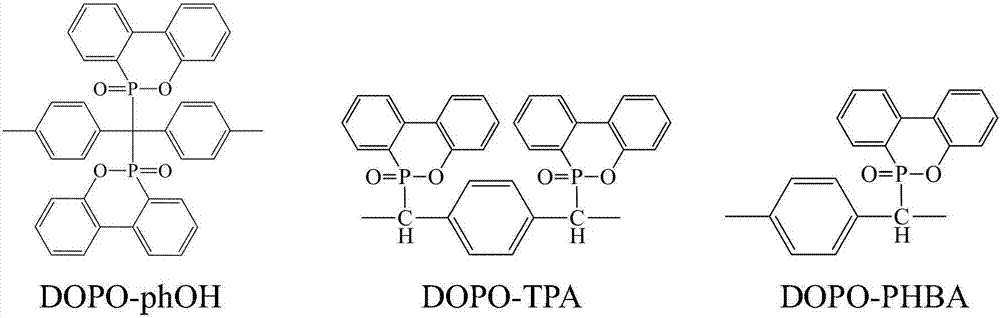

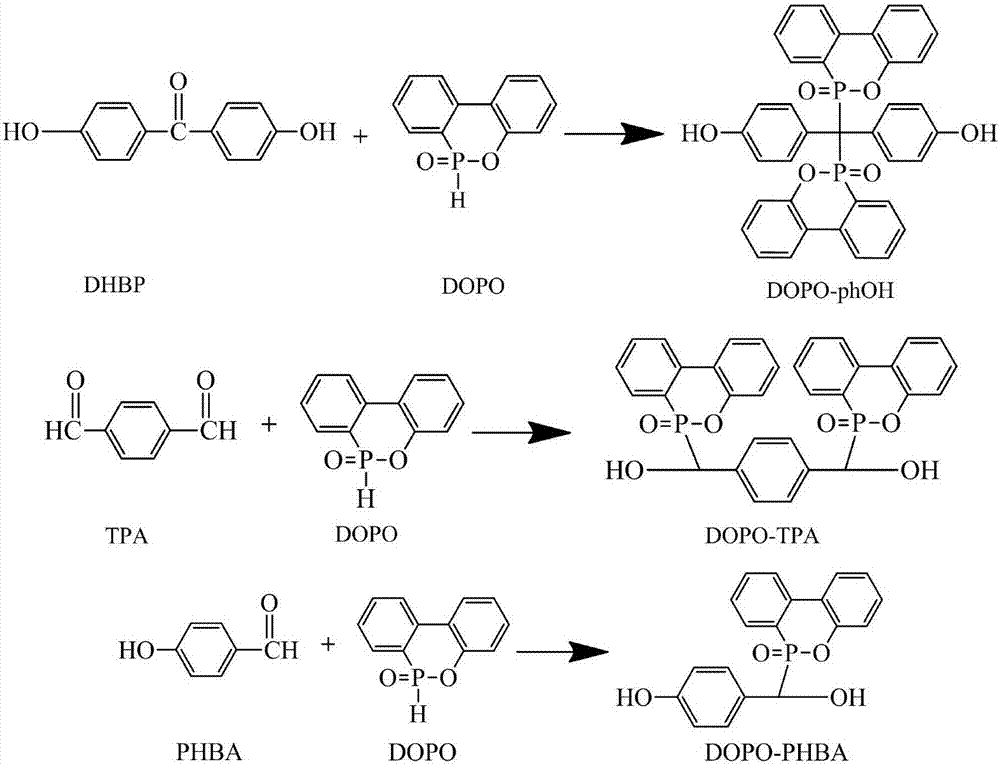

Preparation method for polyphosphoester fire retardant with dual-DOPO as branch chain

The invention belongs to the technical field of a phosphorus-containing fire retardant and specifically relates to a preparation method for a polyphosphoester fire retardant with dual-DOPO as a branch chain. The method comprises the following steps: under the protection of inert gases, reacting 4,4'-dyhydroxyl benzophenone with phenyldichlorophosphate, phenyl dichlorophosphate or pentaerythritol diphosphate diphosphoryl chloride in an anhydrous acetonitrile solvent till no halogen hydride gas is emitted, thereby acquiring a polymerized fire retardant midbody; performing heating for reaction on the midbody, initiator and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide at the temperature of 130-160 DEG C; and performing melt grafting reaction, reducing the reaction temperature to 50-70 DEG C, adding ethyl alcohol, stirring and flowing back, performing suction filtration and drying, thereby acquiring the fire retardant. According to the invention, the difficulty of the traditional process that a highly polymerized fire retardant cannot be acquired under the effect of larger steric hindrance in the process of polymerizing after compounding micro-molecule midbody can be overcome; the compounded fire retardant has higher molecular weight and narrower molecular weight distribution; and the compounded fire retardant has excellent compatibility with substance, is difficult to migrate and has excellent durability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Environmental-friendly water-based fire extinguishing agent and its preparation method

InactiveCN102350032ANot easy to cause pollutionLeave quicklyFire extinguisherWater basedAntiseptic Agent

The invention relates to an environmental-friendly water-based fire extinguishing agent, which comprises: deionized water, an antiseptic agent, a metal antirust agent, a halogen-free fire retardant, a hydrocarbon surfactant, a high efficiency chelating agent, 2-5 parts of an osmotic agent and a high efficiency corrosion inhibitor. The preparation method of the water-based fire extinguishing agentconsists of the steps of: adding deionized water into a dispersing cylinder according to the weight part, then adding the antiseptic agent, the metal antirust agent, the halogen-free fire retardant and the hydrocarbon surfactant, and stirring the mixture uniformly till completely salvation of the mixture; then adding the high efficiency chelating agent, the osmotic agent and the high efficiency corrosion inhibitor, stirring them uniformly till semi-clarity, thus obtaining the finished product. Containing a halogen free fire retardant, the fire extinguishing agent of the invention can be biologically degraded 100%, thus having no pollution to surrounding equipment and space. Containing an osmotic agent, the fire extinguishing agent in the invention can penetrate articles in fire hazards ofclass A, and can penetrate into the inside of combustible articles, so that even if the fire is not completely put out due to a large fire, the part injected with the agent can effectively block a fire source and control the spreading speed of a fire. Therefore, the fire extinguishing agent provided in the invention has excellent flame resistance.

Owner:广东卫斯理化工科技有限公司

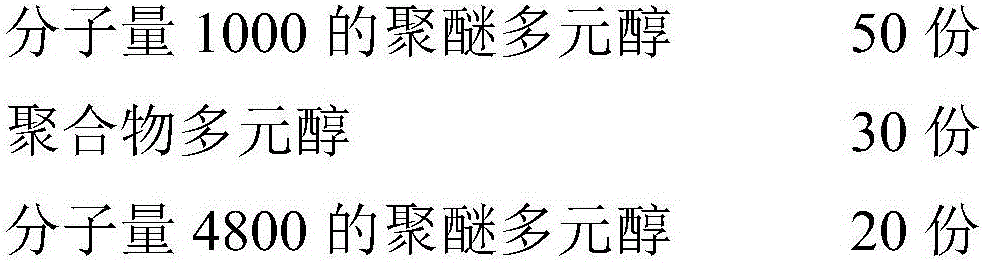

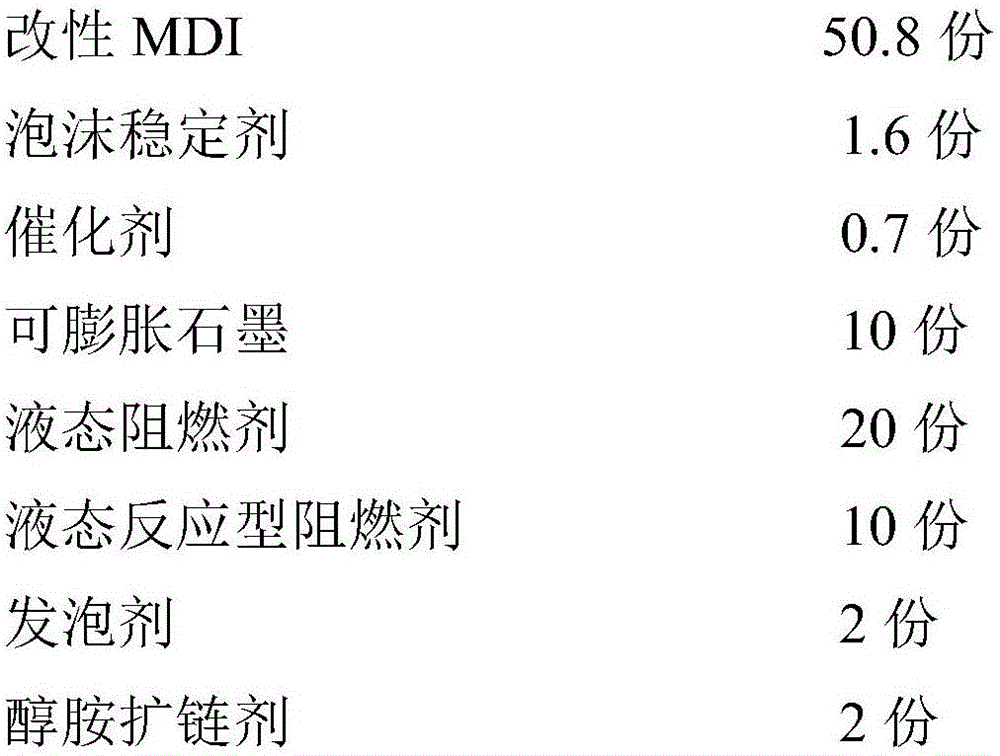

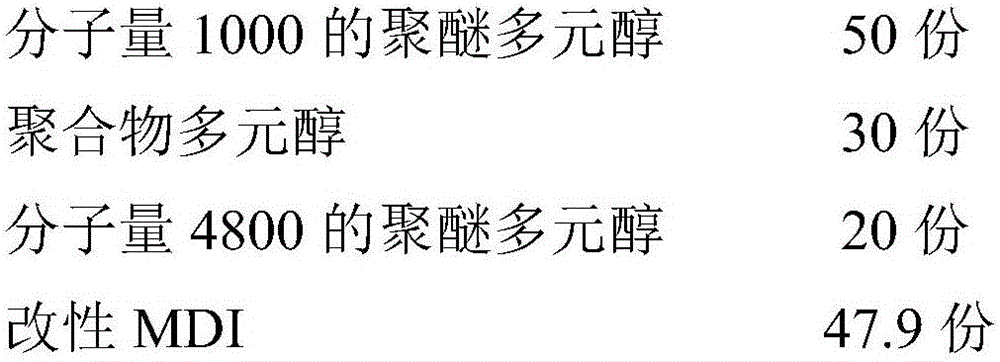

High-efficiency flame-retardant slow-resilient polyurethane sponge and preparation method thereof

The invention relates to the field of sponge products, and in particular to slow-resilient polyurethane sponge and a preparation method. The high-efficiency flame-retardant slow-resilient polyurethane sponge is prepared from the following raw materials in parts by weight: on the basis of 100 parts of two types of polyether glycol and one polymer polycol, 30 to 70 parts of modified MDI, 0.5 to 3.0 parts of foam stabilizer, 0.1 to 1 part of catalysts, 1.0 to 4.0 parts of foaming agents, 0.5 to 3.0 parts of alcohol amine chain extender, 0 to 20 parts of melamine, 5 to 30 parts of expandable graphite, 10 to 20 parts of liquid flame retardant, and 0 to 15 parts of liquid reaction flame retardant. The expandable graphite is used as a solid flame retardant to be added into a slow-resilient polyurethane sponge system, so that the consumption of the liquid flame retardant is reduced, the flame retardant performance of the slow-resilient sponge is greatly improved, and the physical performance is good.

Owner:GLORY HOME FURNISHING JIAXING +1

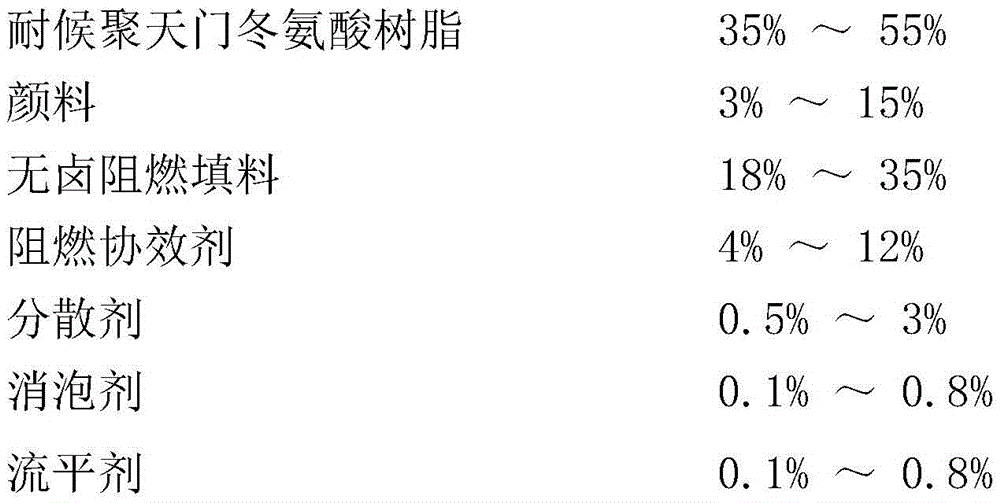

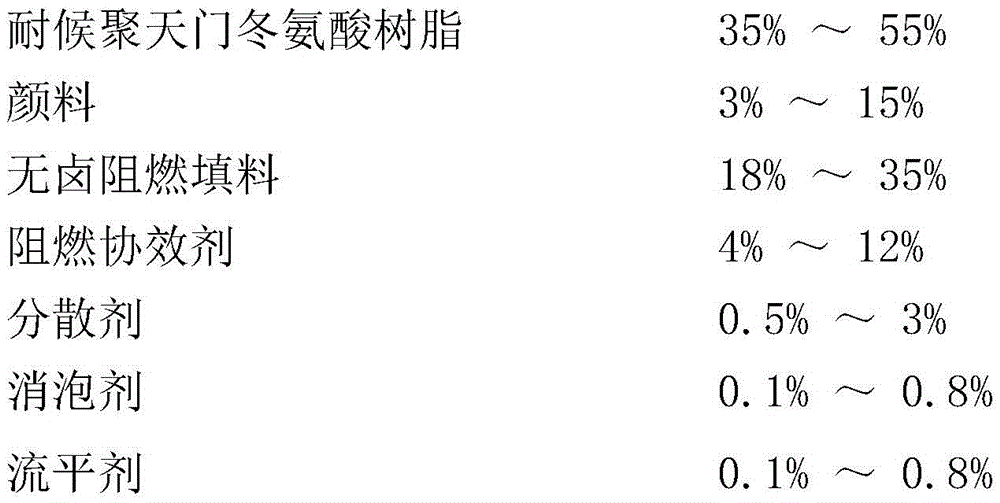

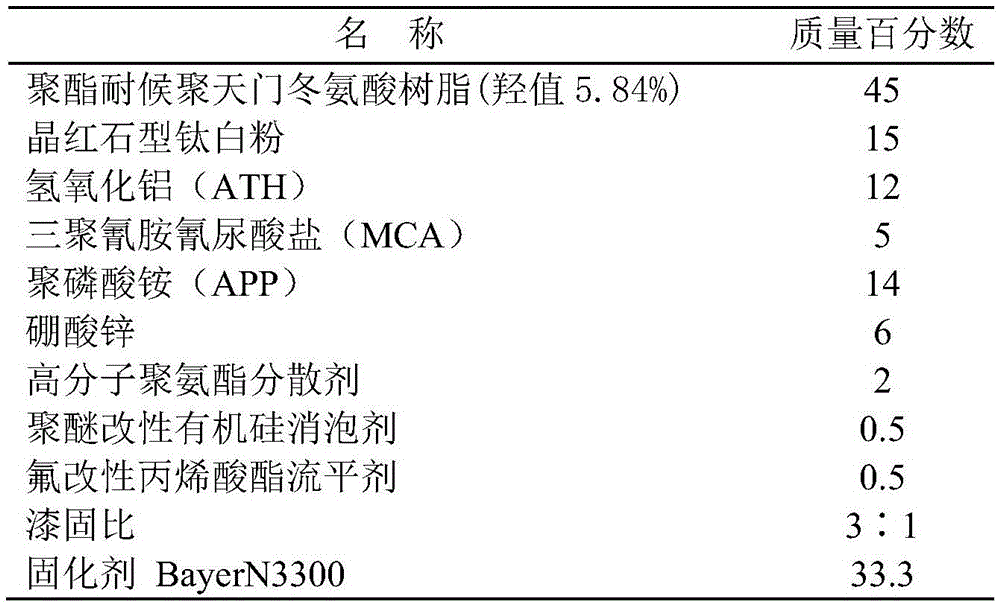

Weather-proof halogen-free flame retardant insulation polyurea coating

InactiveCN105602424AEfficient flame retardantDoes not produce irritating hydrogen halide toxic substancesFireproof paintsPolyurea/polyurethane coatingsSolvent freeSolvent

The invention relates to a double-component weather-proof halogen-free flame retardant insulation polyurea coating. A halogen-free flame retardant compounded form weather-proof polyaspartic acid resin is adopted as a component A, and a solvent-free polyisocyanate curing agent is adopted as a component B, wherein a ratio of the component A to the component B is (2.5 to 4): 1. The weather-proof halogen-free flame retardant insulation polyurea coating is green and environment-friendly, free of discharge of solvent, high in insulation strength, good in flexibility and resistant to wear and impact, and has the breakthrough voltage being larger than 15kV / mm; the flame retardant is environment-friendly and halogen-free, and has the inflammable level of S2 upon flame retardance according to a DIN5510 standard; meanwhile, the weather-proof halogen-free flame retardant insulation polyurea coating is simple in construction and good in self leveling property, has a smooth surface and wide practical applicability, and is especially suitable for flame retardance and insulation in an pantograph mounting region of an urban rail vehicle.

Owner:广东四方威凯新材料有限公司

Flame-retardant modified natural rubber material and preparation method thereof

The invention relates to a rubber material and a preparation method thereof, in particular to a flame-retardant modified natural rubber material and a preparation method thereof. The flame-retardant modified natural rubber material is composed of a polyphosphamine (PPA) flame retardant, natural rubber (NR), epoxidized natural rubber (ENR), stearic acid, zinc oxide, a promoter CZ, an antiager 4010, carbon black and paraffin. The preparation method includes: grafting the efficient PPA flame retardant which is self-prepared onto an ENR matrix to perform flame-retardant modification on the ENR; adding the ENR after being subjected to flame-retardant modification and various rubber processing auxiliaries into the NR through mixing; utilizing high compatibility of the ENR and the NR to realize uniform dispersion of the flame retardant in the NR matrix. The natural rubber material prepared by adopting the method has excellent flame retardancy, mechanical performance and good thermostability, and the problem of lowering in mechanical performance due to the fact that the flame retardant is added into the rubber matrix is improved substantially. The flame-retardant modified natural rubber material is suitable for tires, natural rubber plates, pipes, wires and cables and automobile rubber parts.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

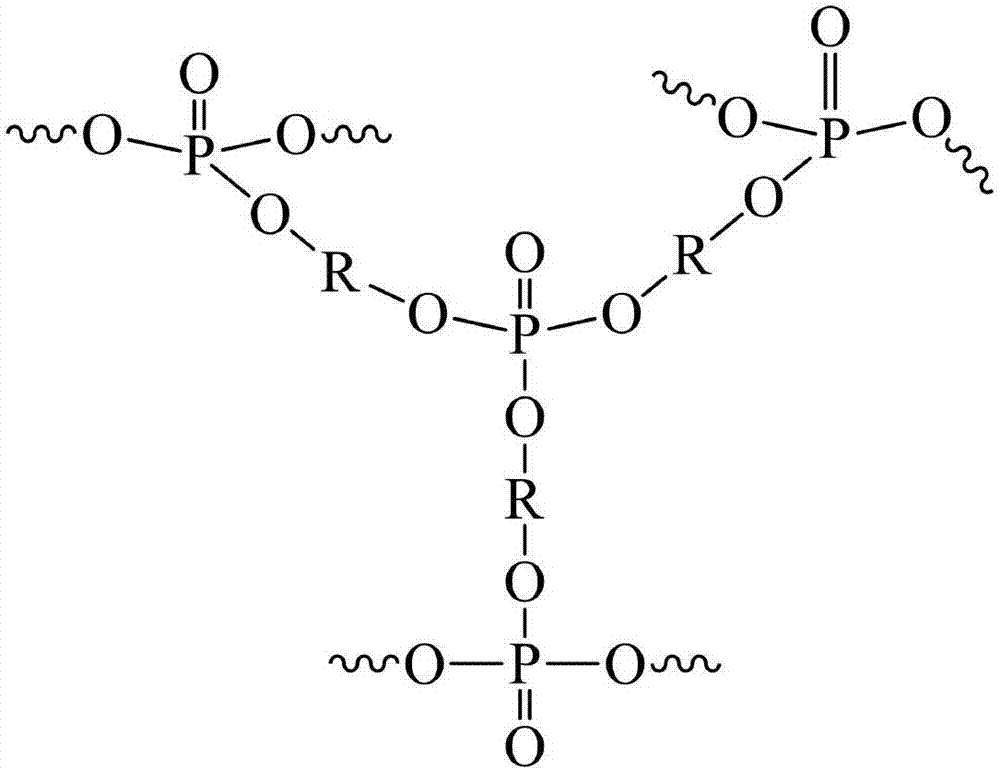

Halogen-free DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene 10-oxide)-based hyperbranched structure phosphate flame retardant and preparation method thereof

InactiveCN107501566AHigh flame retardant efficiencySolve the problem of low phosphorus contentCombustionPolymer science

The invention relates to a halogen-free DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene 10-oxide)-based hyperbranched structure phosphate flame retardant and a preparation method thereof and belongs to the technical field of phosphorus-containing flame retardants. According to the method, the hyperbranched structure phosphate flame retardant with high phosphorus content is prepared from two phosphorus-containing monomers, namely, a DOPO-based intermediate and phosphorus oxychloride serving as reaction units, and the purpose of increasing the phosphorus content of the flame retardant is achieved while the macromolecular flame retardant is obtained. The defects of poor compatibility of a micromolecular phosphorus-containing flame retardant and low phosphorus content of conventional hyperbranched flame retardants are effectively overcome. The synthesized flame retardant has the advantages of high phosphorus content, high molecular weight, high combustion efficiency, good compatibility with a flame-retardant substrate, low probability of migration and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Process for preparing flame-resistance insoluble drip insulating padding

ActiveCN1752318AImprove flame retardant performanceSolve the droplet problemFibre treatmentNon-woven fabricsPolyesterCotton fibre

The present invention relates to a prepartion method of flame-retardant fibre flocculus. Its main raw material includes phosphorus series flame-relardand polyester staple fibre and cotton fibre or viscose staple fibre, and its preparation process includes the following steps: mixing fibres, opening, air-mixing, air-conveying, storing, carding, web-laying, covering, needling, impregnating, mangling and oven drying, said invention also provides the concrete requirements and concrete operation method of every step.

Owner:PETROCHINA CO LTD

Efficient flame-retardant and smoke-suppressant agent for wood-based composite material and preparation method thereof

ActiveCN105295405AInhibitionEfficient flame retardant effectNon-macromolecular adhesive additivesWood impregnation detailsMontmorilloniteMagnesium Sulfate whiskers

The invention discloses an efficient flame-retardant and smoke-suppressant agent for a wood-based composite material and a preparation method thereof. The efficient flame-retardant and smoke-suppressant agent is prepared from 55-65 parts of inrumescent flame retardant, 2-6 parts of organic montmorillonite, 15-25 parts of nano-metal hydroxide and 10-20 parts of magnesium sulfate whisker. The preparation method includes the following steps that 1, the inrumescent flame retardant is synthesized and prepared; 2, the organic montmorillonite is synthesized and prepared; 3, the nano-metal hydroxide and the magnesium sulfate whisker are prepared; 4, the efficient flame-retardant and smoke-suppressant agent is prepared. The adopted raw materials including the inrumescent flame retardant, the organic montmorillonite, the nano-metal hydroxide and the magnesium sulfate whisker achieve multiple synergistic flame-retardant effects including synergistic flame retardant of the inrumescent flame retardant and the organic montmorillonite (the inrumescent flame retardant-nano synergy) and synergistic flame retardant of the organic montmorillonite and the nano-metal hydroxide (nano-nano synergy); the advantages of being high in flame-retardant, environment-friendly and smoke-suppressant efficiency, low in smoke and poison and the like. The technology is simple, industrialization is easy, and cleanliness and non-pollution can be achieved.

Owner:贵州恒力源林业科技有限公司

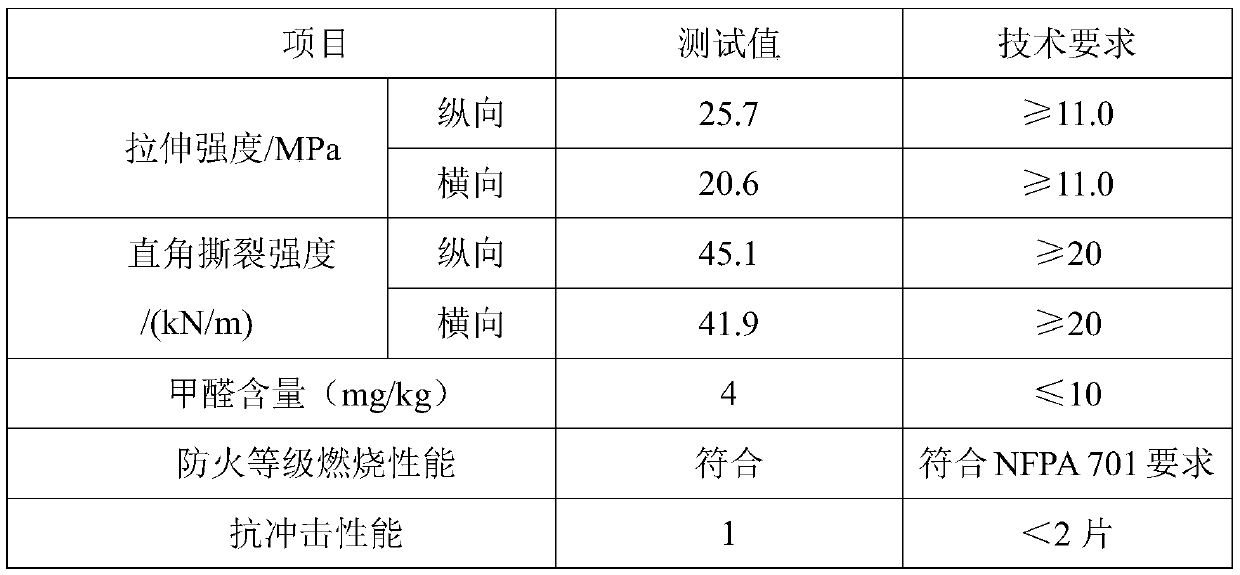

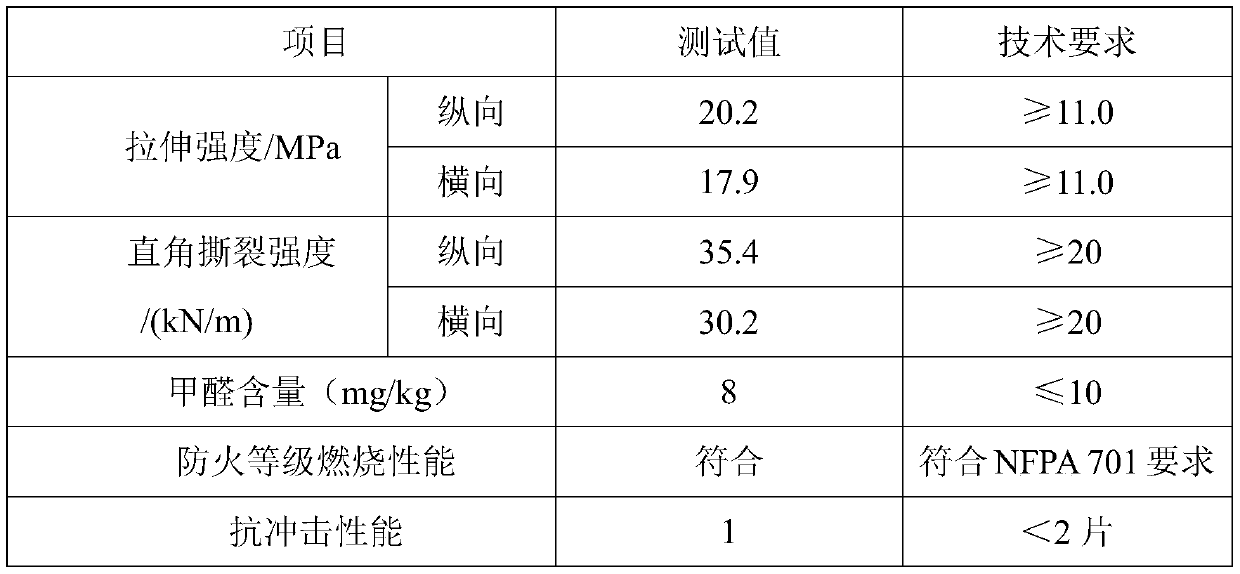

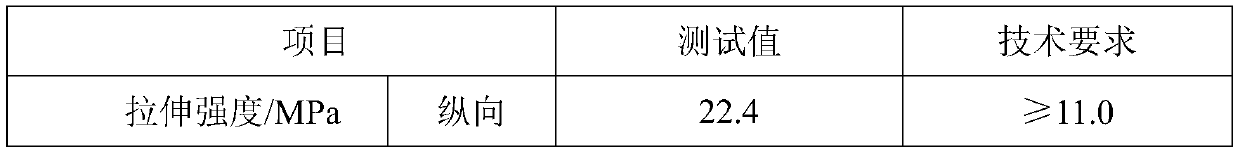

Anti-shock efficient flame-retardant decorative film and preparation method thereof

The invention relates to an anti-shock efficient flame-retardant decorative film and a preparation method thereof. The decorative film is prepared from, by weight, 80-120 parts of PVC resin powder, 30-50 parts of a plasticizer, 0.5-5 parts of soybean oil, 18-45 parts of a composite flame retardant, 0.5-5 parts of a formaldehyde absorbent, 0.5-5 parts of a environment-friendly stabilizer, 0.5-5 parts of a smoke suppressant and 5-15 parts of nano-calcium powder. The PVC resin powder is adopted as the main raw material, and the plasticizer, the composite flame retardant, the soybean oil, the formaldehyde absorbent, the stabilizer, the smoke suppressant and the nano-calcium powder are added as functional auxiliaries. The decorative film is obtained through high-speed stirring and mixing, forming extrusion, first rolling mill plastification, second rolling mill plastification, filtration, calendaring, cooling and reeling. Accordingly, by means of the optimized formula, production process parameters are optimized, the prepared decorative film has the advantages of being excellent in flexibility, efficient flame resistance and environmental friendliness, high in compliance, good in shockresistance and the like, and meanwhile the effect of purifying formaldehyde is achieved; the film has good market prospects.

Owner:浙江明士达股份有限公司

PU (polyurethane) daub and preparation method thereof

The invention relates to the field of daub materials, in particular to PU (polyurethane) daub and a preparation method thereof. The PU daub mainly comprises a component A and a component B, wherein the component A is mainly prepared from polyether polyols, MDI and a flame retardant; the component B is mainly prepared from polyether polyols, a curing agent, a flame retardant, an antifoaming agent, a dispersing agent, a leveling agent and a surfactant. During usage of the PU daub, the component A and the component B are mixed, the obtained PU daub has the characteristics that the PU daub has better mechanical properties and better waterproofness, and is capable of being cured at the normal temperature, flame-retardant, non-toxic and the like, and is applicable to insides and outsides of sea ships. The technology of the preparation method of the PU daub is simple and easy to implement.

Owner:BEIJING HAIYUEXING SCI & TECH CO LTD

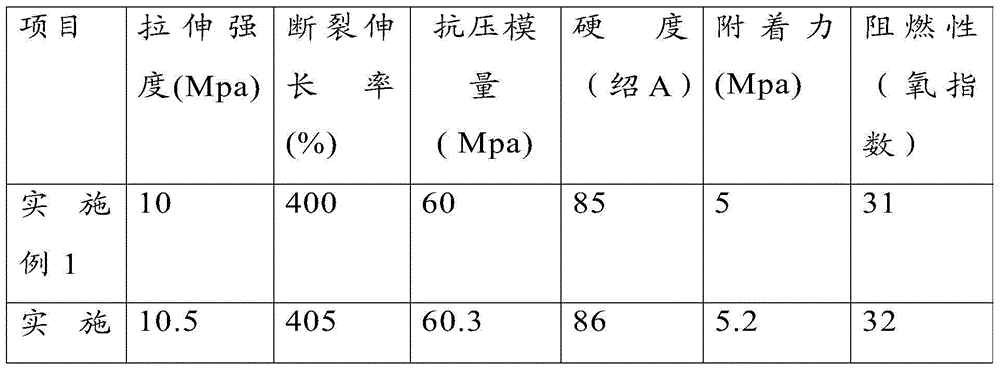

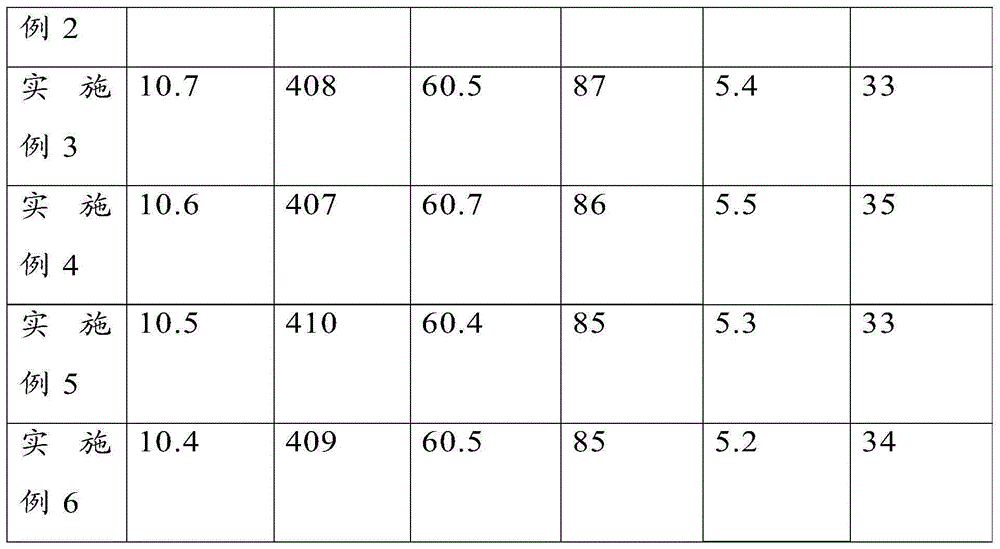

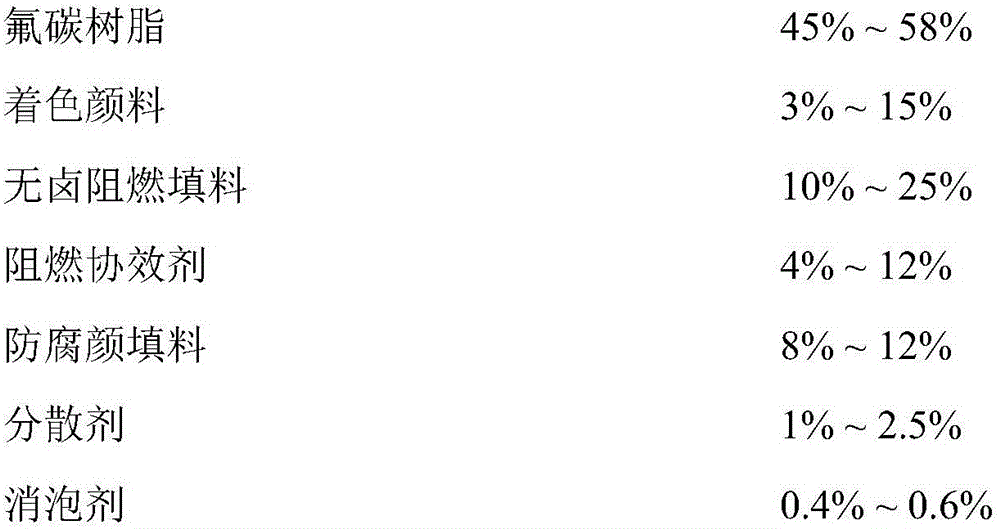

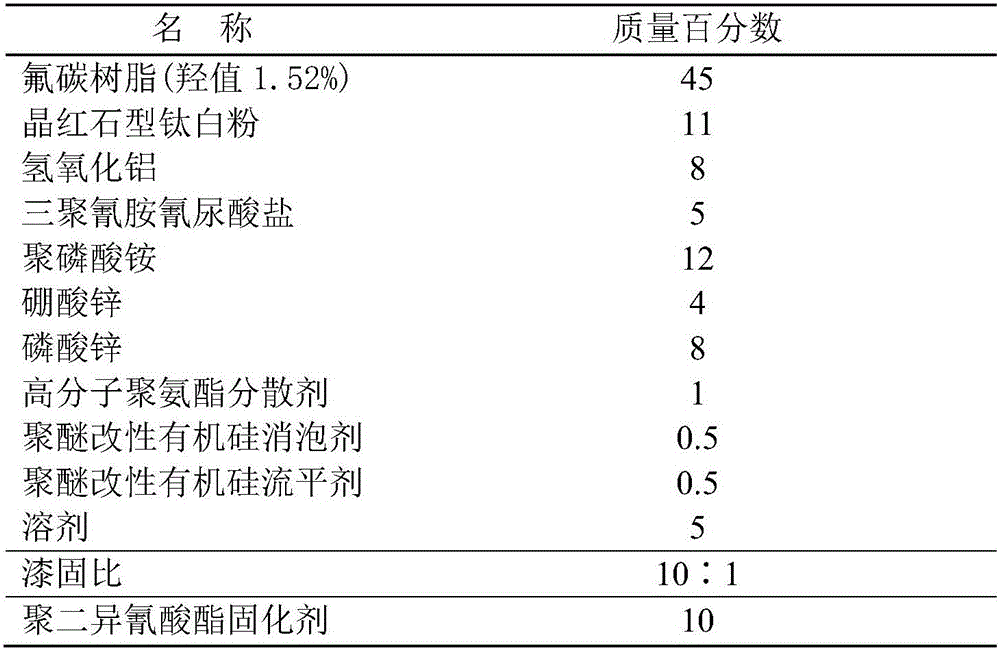

Weather-proof, halogen-free, flame-retardant, anti-corrosion and insulating fluorine-carbon coating

ActiveCN105733376AStrong adhesionGood temperature resistanceFireproof paintsAnti-corrosive paintsCarbon coatingFluorocarbon Resins

The invention provides a weather-proof, halogen-free, flame-retardant, anti-corrosion and insulating fluorine-carbon coating. Fluorine-carbon resin is compounded with a halogen-free flame retardant, wherein the fluorine-carbon resin accounts for 45% to 58%, and the halogen-free flame-retardant filler accounts for 10% to 25%. The weather-proof, halogen-free, flame-retardant, anti-corrosion and insulating fluorine-carbon coating is high in adhesive force, good in temperature resistance, high in low-temperature drying speed and the like, has excellent flame-retardant performance, electrical insulating performance, anti-corrosion and damp-proof performance and excellent ultraviolet light resistance, has high applicability, and is especially suitable for the field of flame-retardant, anti-corrosion and insulating operation on the surface of electrical equipment.

Owner:广东四方威凯新材料有限公司

High molecular fire retardant extinguisher and its compounding process

The macromolecular flame-retardant fire-extinguishing agent is made up by using water soluble substrate containing anion group through the processes of cross-linking and grafting, adding correspondent flame-retardant active substrate, and mixing them with water. It is high in fire-extinguishing effect, and its performance is stable and cost is low.

Owner:罗萌

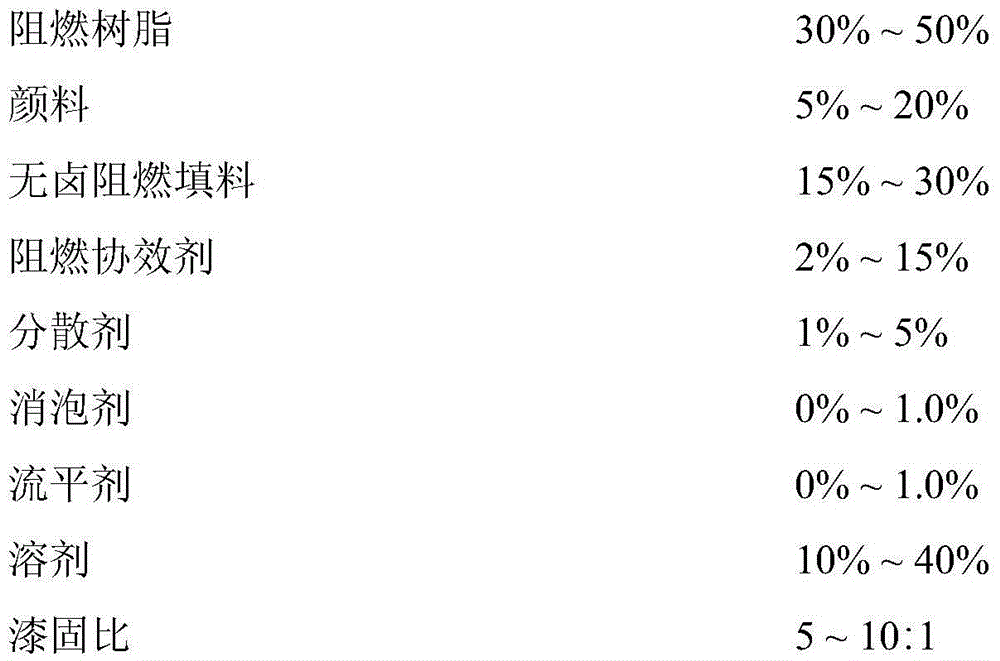

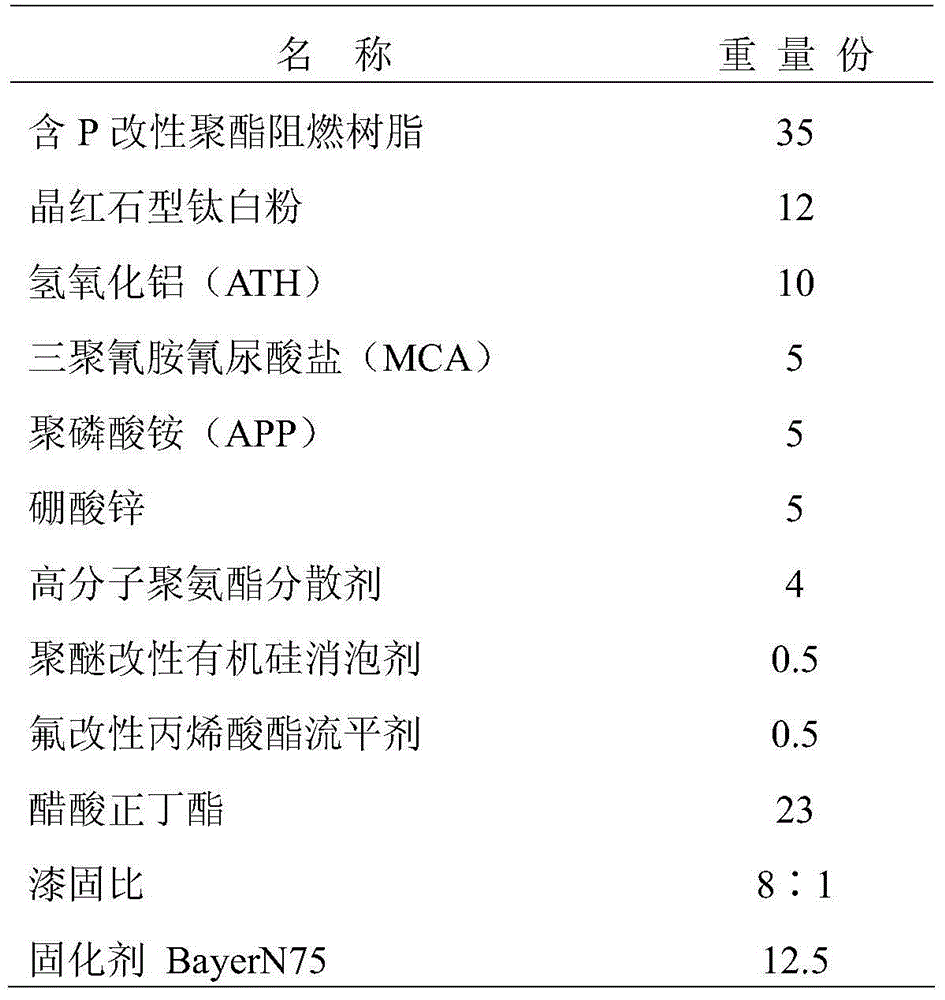

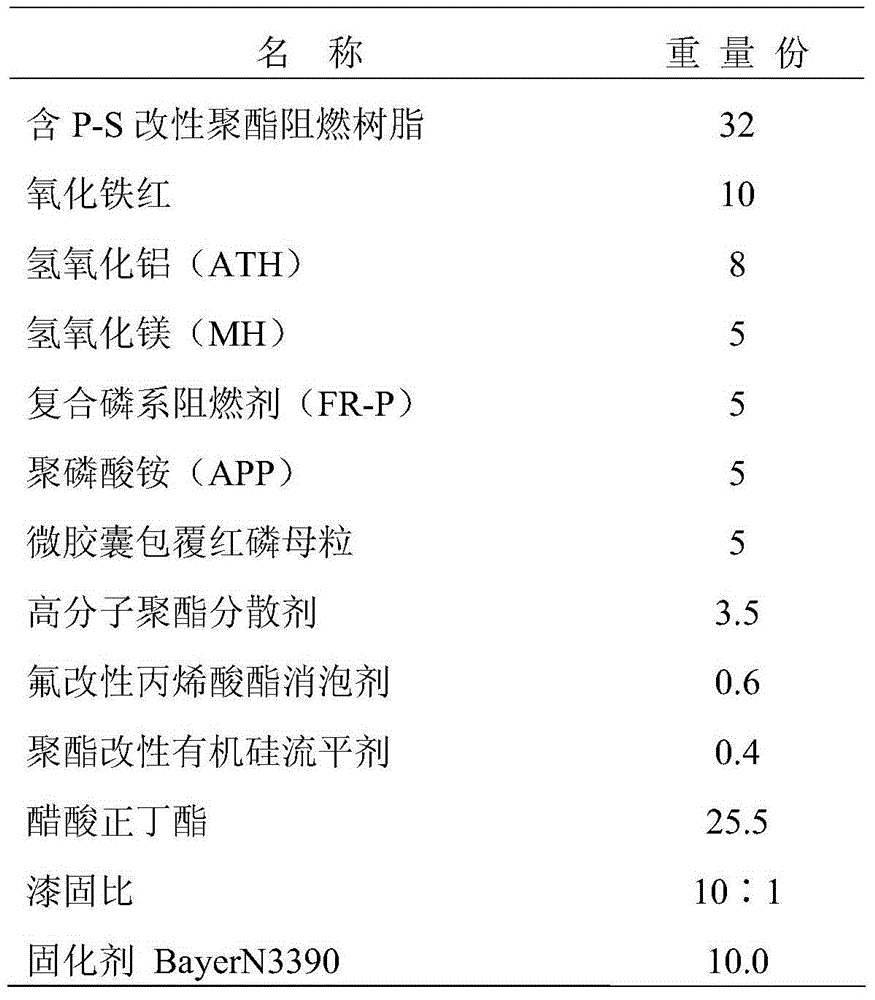

Reactive halogen-free flame retardant polyester paint

InactiveCN104449263AEfficient flame retardantHigh strengthFireproof paintsPolyester coatingsPolyester resinUltimate tensile strength

The invention discloses a reactive halogen-free flame retardant polyester paint. A little of halogen-free flame retardant is compounded by adopting halogen-free flame retardant polyester resin; the percentage of the halogen-free flame retardant polyester resin is 30%-50%; and the percentage of the halogen-free flame retardant filler is 15%-30%. The reactive halogen-free flame retardant polyester paint disclosed by the invention has the advantages of high strength and good flexibility; the flame retardant is environment-friendly and halogen-free; a little additive is added; the flame retardant grade (UL-941.6mm) can reach the UL-94 V-0 grade; meanwhile, the reactive halogen-free flame retardant polyester paint has the advantages of high liquidity, smooth surface, high impact strength, low cost and relatively good practical application.

Owner:常州市弘可利办公用品有限公司 +1

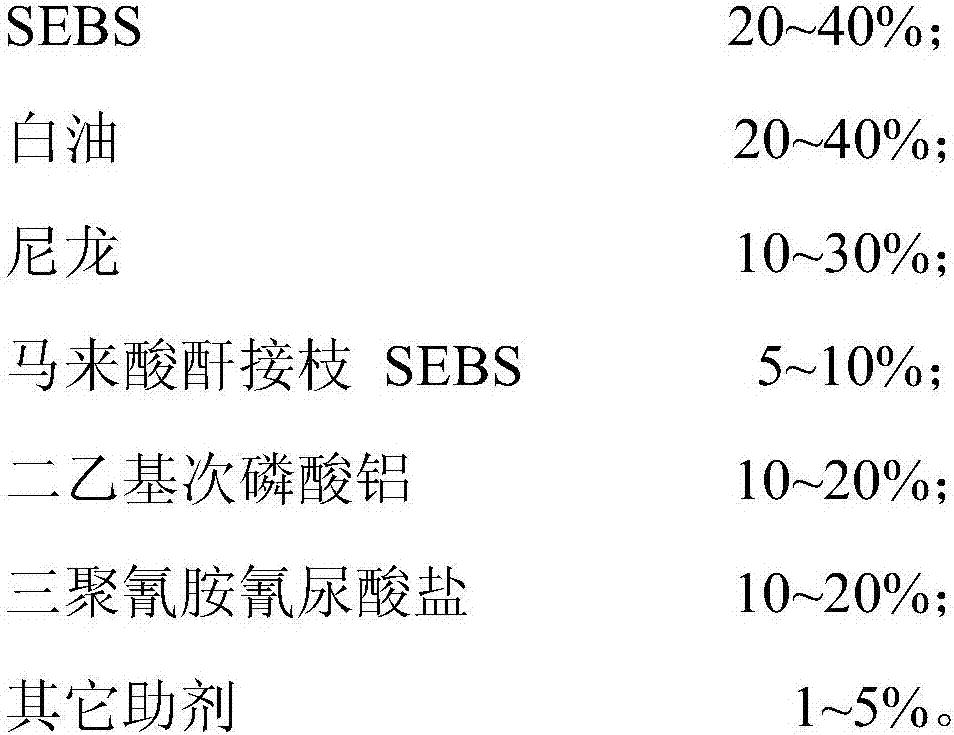

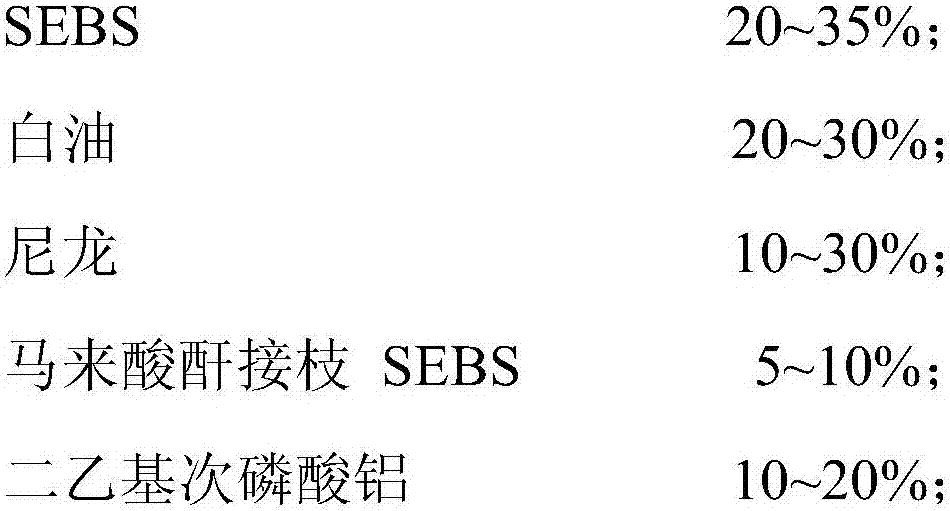

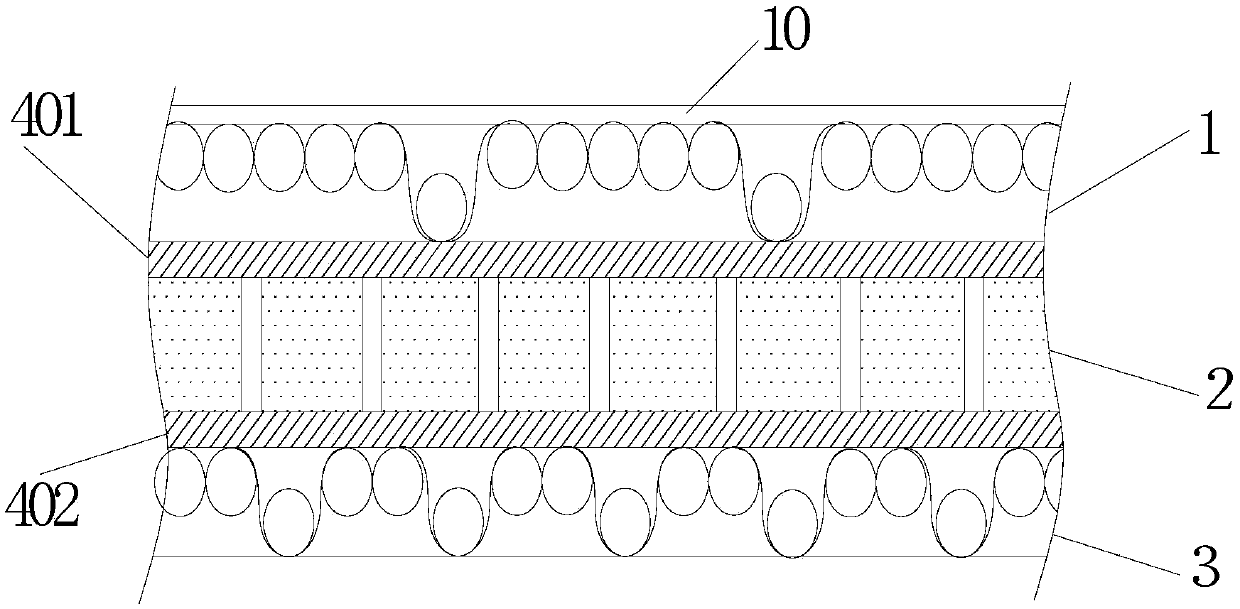

Wear-resisting, high-flame-retarding, halogen-free and flame-retarding thermoplastic elastomer composition for electric wires and cables and preparation method thereof

The invention discloses a wear-resisting, high-flame-retarding, halogen-free and flame-retarding thermoplastic elastomer (TPE) composition for electric wires and cables. The wear-resisting, high-flame-retarding, halogen-free and flame-retarding thermoplastic elastomer composition is prepared from the following raw materials in percentage by weight: 20 percent to 40 percent of SEBS (styrene hydride-butadiene-styrene block copolymer), 20 percent to 40 percent of white oil, 10 percent to 30 percent of nylon, 5 percent to 10 percent of maleic anhydride grafted SEBS, 10 percent to 20 percent of diethyl aluminum hypophosphite, 10 percent to 20 percent of melamine cyanurate and 1 percent to 5 percent of other auxiliary agents. Aiming at the problem that the wearing-resisting performance of a conventional halogen-free and flame-retarding TPE electric wire and cable material based on the SEBS and polyolefin is poor, the invention provides the wear-resisting, high-flame-retarding, halogen-free and flame-retarding thermoplastic elastomer composition; the nylon and the TPE material are compounded by utilizing an excellent wear-resisting property of the nylon so as to improve the wear-resisting property of the TPE; the invention also accidentally finds out that the nylon is coordinated with a diethyl hypophosphite flame-retarding system, and efficient flame retarding is realized under the condition that a PPO (Polyphenylene Oxide) component does not need to be added.

Owner:JIANGSU LISIDE NEW MATERIAL

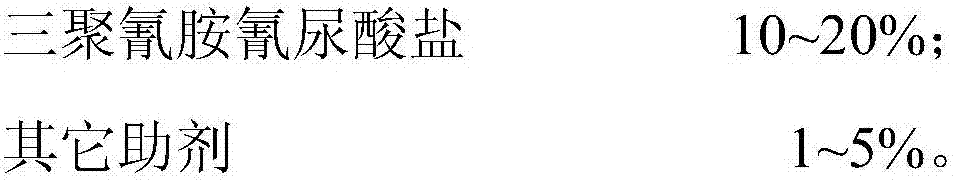

Efficient flame-retardant heat insulation composite fabric and application

ActiveCN109664582AImprove insulation effectNo pollution in the processPhysical treatmentSynthetic resin layered productsAdhesiveCeramic coating

The invention provides an efficient flame-retardant heat insulation composite fabric and an application. The efficient flame-retardant heat insulation composite fabric comprises a surface fabric, a middle layer and a lining fabric, modacrylic and Lenzing flame-retardant viscose fiber blended yarns serve as warp yarns of the surface fabric, aramid fiber 1313, aramid fiber 1414 and conductive fiberblended yarns are weft yarns, a surface layer is further provided with a nano-ceramic coating, the middle layer is mixture of aerogel and polyurethane, one or two of silicon-nitrogen flame-retardant viscose fibers, aramid fibers 1313, polysulfonamide and polyimide fibers are blended to form the lining fabric, and the middle layer is arranged between the surface layer and a lining layer and fittedwith the surface layer and the lining layer through flame-retardant adhesives. The efficient flame-retardant heat insulation composite fabric is used for manufacturing a flame-retardant heat insulation garment. The efficient flame-retardant heat insulation composite fabric is high in washing fastness by the aid of plasma treatment, the nano-ceramic coating and the middle layer of aerogel and shapememory polyurethane mixture are arranged, flame-retardant heat insulation effects are long and high, and the efficient flame-retardant heat insulation composite fabric has antibacterial health care functions and is widely applied.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

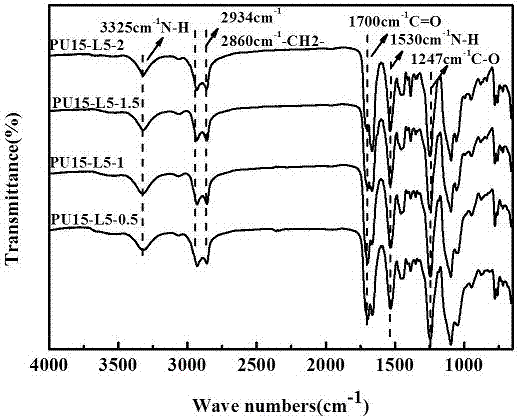

Halogen-free phosphonate flame-retardant modified waterborne polyurethane coating agent and preparation method thereof

The invention relates to a halogen-free phosphonate flame-retardant modified waterborne polyurethane coating agent and a preparation method thereof, and discloses a halogen-free phosphonate flame-retardant modified waterborne polyurethane coating agent. The halogen-free phosphonate flame-retardant modified waterborne polyurethane coating agent is prepared by substituting a phosphonate modified flame-retardant polyol part for diisocyanate and polyol, performing chain extension by using a hydrophilic chain extender and neutralizing by using a salt-forming agent, wherein the diisocyanate accounts for 20 to 45 weight percent, the polyol accounts for 15 to 40 weight percent, the phosphonate modified flame-retardant polyol accounts for 15 to 40 weight percent, the hydrophilic chain extender accounts for 2 to 9 weight percent and the salt-forming agent accounts for 1 to 4 weight percent. The halogen-free phosphonate flame-retardant modified waterborne polyurethane coating agent and the preparation method thereof have the advantages that a free flame retardant is not provided and formaldehyde release is avoided; and fabric with the flame-retardant coating has excellent mechanical property and flame-retardant performance, is environment-friendly, non-toxic and low-smoke, and has high application value.

Owner:浙江枫翎新材料科技有限公司

Preparation method and application of halogen-free environment-friendly flame retardant

InactiveCN102964376AAvoid pollutionAvoid harmPhosphorus organic compoundsEnvironmental resistancePhosphate

The invention discloses a preparation method and an application of a halogen-free environment-friendly flame retardant, and belongs to the technical field of macromolecular compounds and solves the problem of environment pollutions caused in the process of burning halogen flame retardants. The preparation method of the halogen-free environment-friendly flame retardant comprises the following steps of: mixing pentaerythritol, boric acid and phosphoric acid in a mole ratio of 1:(0.3-1.8):(0.5-2), reacting at a temperature of 100-180 DEG C, stirring and reacting for 3-7 hours to generate pentaerythritol phosphate borate; and adding melamine in a mole ratio of melamine to pentaerythritol of (1-3.2):1 and a solvent in a weight ratio of solvent to the total material of to (1-2):1 into the pentaerythritol phosphate borate, reacting at a temperature of 80-140 DEG C, stirring and reacting for 1.5-5 hours to generate pentaerythritol phosphate borate melamine salt suspension, filtering and drying. The application of the halogen-free environment-friendly flame retardant comprises processes of adding the halogen-free environment-friendly flame retardant and accessory ingredients into a rubber-plastic material, mixing and forming to instantly obtain anti-flaming rubber-plastic products. The halogen-free environment-friendly flame retardant can be widely applied to the rubber-plastic products.

Owner:SHIJIAZHUANG QIHONG RUBBER PLASTIC PROD

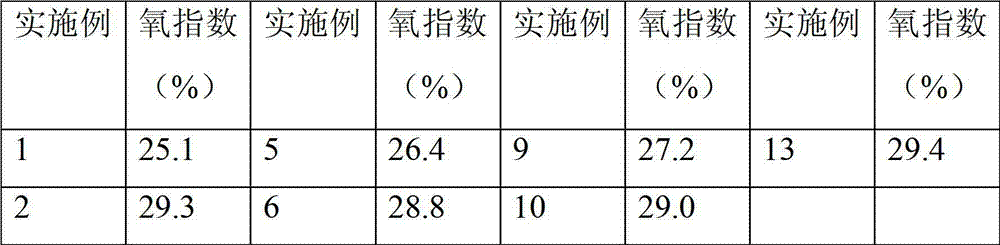

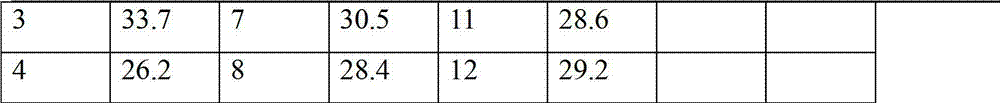

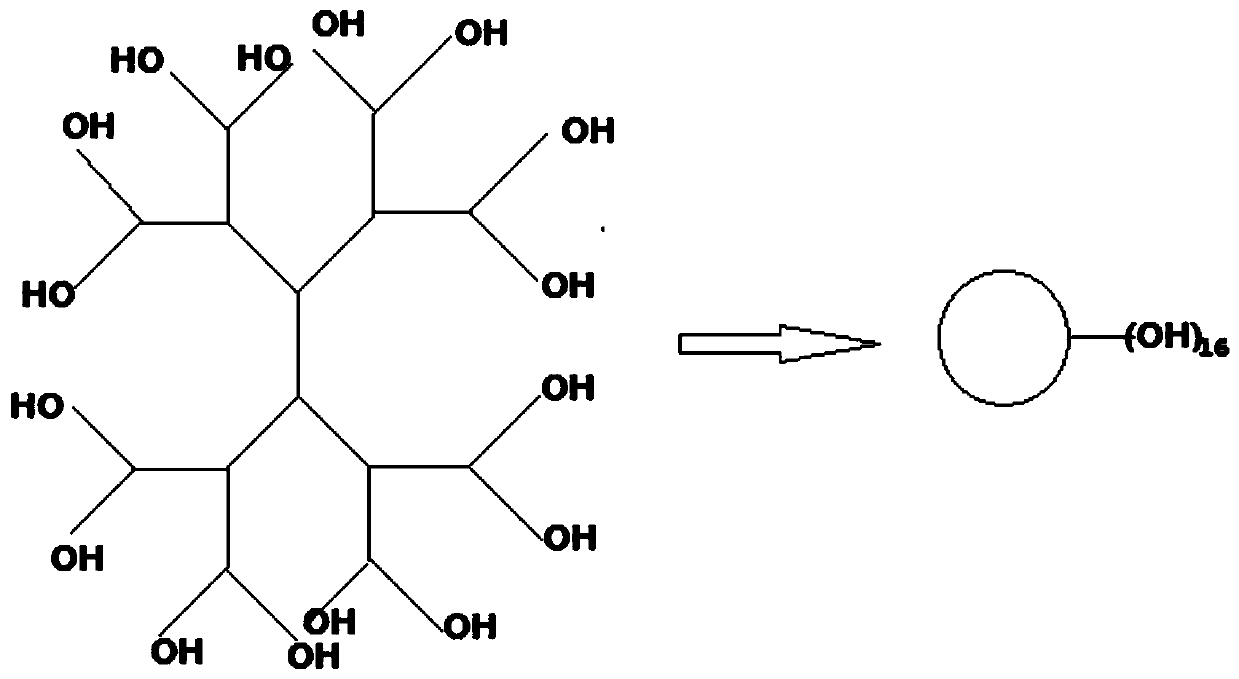

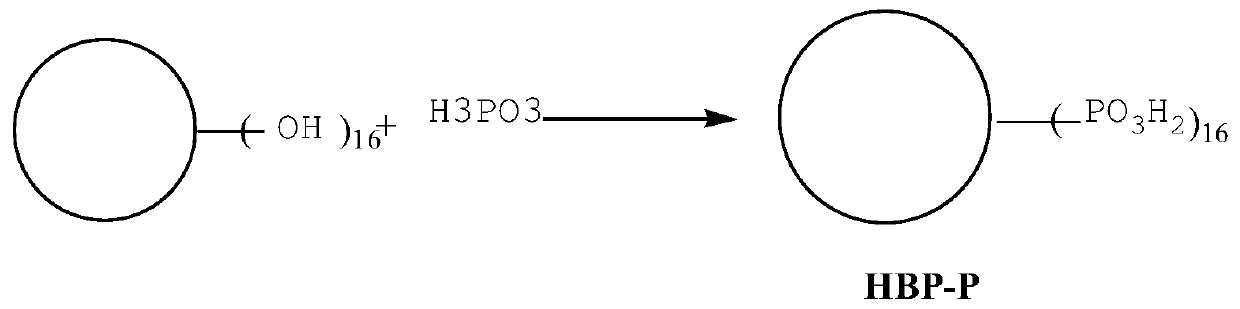

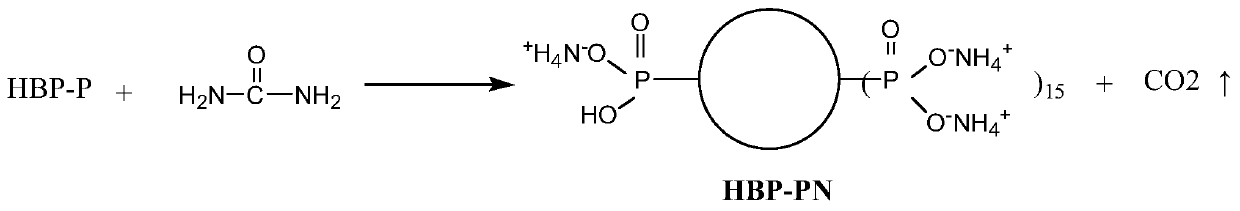

Preparation methods for hyperbranched polyester based phosphorus-nitrogen type flame retardant and flame-retardant fabrics

ActiveCN110016130AEfficient flame retardantImprove washing resistanceHeat resistant fibresVegetal fibresWater bathsReflux

The invention provides a preparation method for a hyperbranched polyester based phosphorus-nitrogen type flame retardant. The method is characterized by comprising the following steps: (1) dissolvinghyperbranched polyester into deionized water to prepare a hyperbranched polyester solution; and adding orthophosphorous acid, carrying out sustained stirring, carrying out a reaction under water-bathconditions, then, carrying out separation and purification to prepare phosphorus-containing hyperbranched polyester, and carrying out baking in a vacuum baking oven for later use; and (2) dissolving the phosphorus-containing hyperbranched polyester into deionized water, adding urea, carrying out a reaction under condensation reflux conditions, and then, carrying out separation and purification toobtain phosphorus-nitrogen containing hyperbranched polyester, namely the hyperbranched polyester based phosphorus-nitrogen type flame retardant. Then, flame-retardant cotton fabrics are produced in apadding and baking manner. According to the flame-retardant finishing agent provided by the invention, raw materials and a process flow are friendly to environments and human bodies, no formaldehydeis released in both a flame-retardant finishing process of the cotton fabrics and a use process of the flame-retardant fabrics, and the cotton fabrics have excellent washing resistance while efficientflame retardance is obtained.

Owner:DONGHUA UNIV

Modified graphene containing inflaming-retarding corrosion-resisting coating

InactiveCN105949832AImprove adhesionImprove interface propertiesFireproof paintsAnti-corrosive paintsHydrotalciteGraphene

The invention relates to a modified graphene containing inflaming-retarding corrosion-resisting coating. Laminar hydrotalcite-like compounds and modified graphene cooperate with an intercalator for modification, and the high-corrosion-resistance coating is prepared. The modified graphene is added, therefore, the adhesive force of an inorganic coating to metal can be promoted, the interface attribute of the coating is improved, the coating has good corrosion-preventing performance on a thick coating, and excellent corrosion resistance of the coating can still be kept for a thin coating.

Owner:张哲夫

Compound fire extinction material used for coal mine, and preparation method thereof

ActiveCN108498998AEfficient flame retardantFire fastFire extinguisherSafety equipmentsPolyvinyl butyralSodium Bentonite

The invention provides a compound fire extinction material used for a coal mine. The fire extinction material is prepared from the following ingredients in parts by weight: 12-15% of sandy soil, 5-7%of vermiculite, 3.2-3.5% of pyrophyllite, 2.7-3.5% of bentonite, 1.7-2.0% of nano-silica, 1.2-1.5% of sodium carboxymethylcellulose, 0.5-0.6% of hydroxyethyl cellulose, 1.1-1.3% of silicate mixture, 0.6-0.7% of melamine cyanurate, 0.3-0.6% of phosphoric acid, 0.1-0.3% of sodium alginate, 0.1-0.3% of Tween-80, 0.1-0.3% of polyvinyl butyral, 0.1-0.2% of chitosan and the balance of water, wherein thetotal amount of above raw materials is 100%. According to the compound fire extinction material prepared with the preparation method, a multilayer structure can be formed on the surface of coal, in addition, the coal can be cooled in a targeted way so as to perform the efficacies on thermal insulation, oxygen insulation, smoke inhibition and the like, effects on efficiently resisting flame and quickly carrying out fire extinction are achieved, and the flame resistance of the material is greatly improved.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com