Anti-shock efficient flame-retardant decorative film and preparation method thereof

A decorative film and impact-resistant technology, applied in the field of impact-resistant high-efficiency flame-retardant decorative film and its preparation, to achieve high flatness, prevent the formation of molten droplets, and increase flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

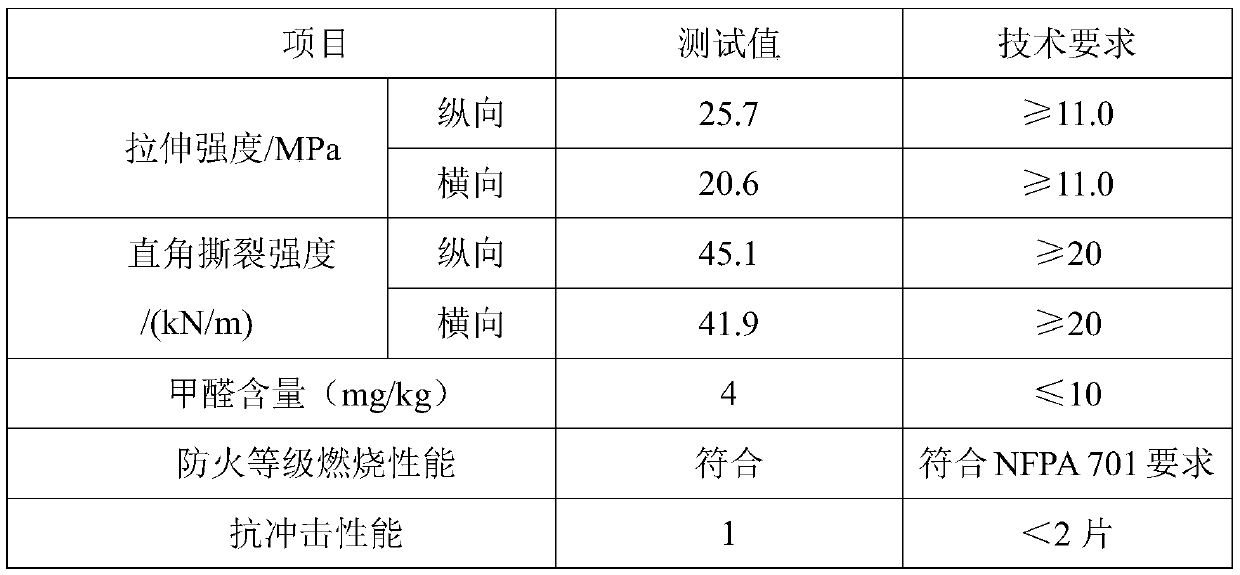

Embodiment 1

[0025] An impact-resistant and high-efficiency flame-retardant decorative film, the decorative film is prepared from the following raw materials in parts by weight: 100 parts of PVC resin powder (S60), 42 parts of DOTP plasticizer, 2 parts of soybean oil, superfine zinc borate resistance 15 parts of flame retardant, 12 parts of antimony trioxide flame retardant, 2 parts of phosphorus flame retardant, 2 parts of formaldehyde absorbent, 3 parts of environmental stabilizer, 2.5 parts of smoke suppressant, 10 parts of nano calcium powder.

[0026] The preparation method of the above-mentioned impact-resistant high-efficiency flame-retardant decorative film includes the following steps: using PVC resin powder as the main raw material, adding plasticizer, composite flame retardant, soybean oil, formaldehyde absorbent, stabilizer, and smoke suppressant , Nano-calcium powder is used as a functional additive, and the decorative film is made by high-speed mixing, molding extrusion, first...

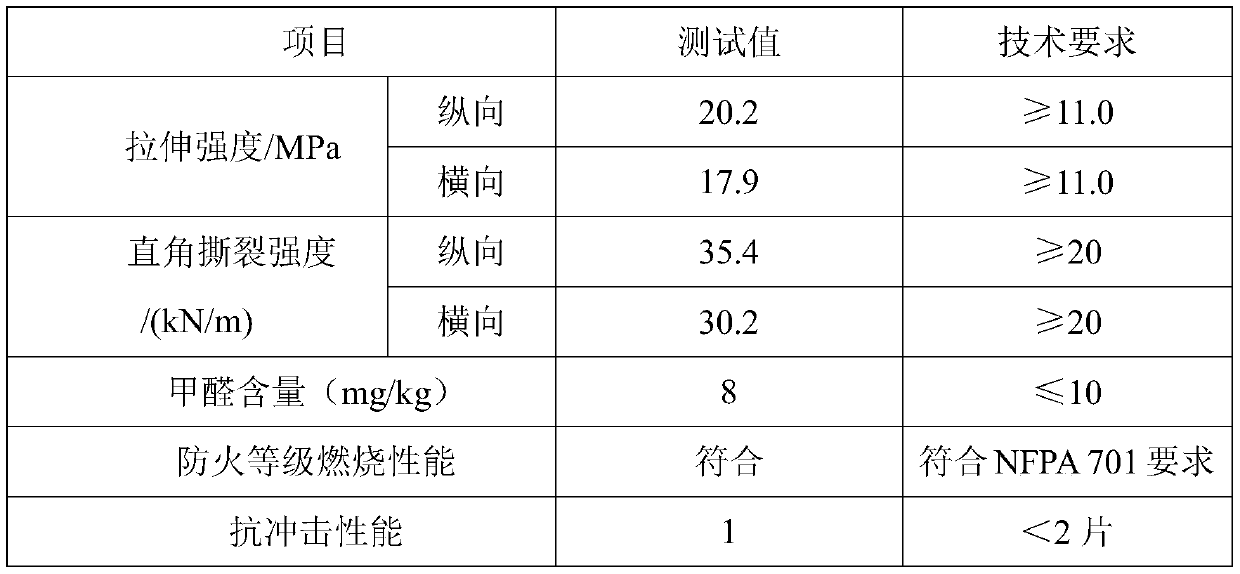

Embodiment 2

[0034] An impact-resistant and high-efficiency flame-retardant decorative film, the decorative film is prepared from the following raw materials in parts by weight: 100 parts of PVC resin powder (S60), 30 parts of DOTP plasticizer, 0.5 part of soybean oil, superfine zinc borate resistance 10 parts of flame retardant, 7.5 parts of antimony trioxide flame retardant, 0.5 part of phosphorus flame retardant, 0.5 part of formaldehyde absorbent, 0.5 part of environmental stabilizer, 0.5 part of smoke suppressant, 5 parts of nano calcium powder.

[0035] The preparation method of the above-mentioned impact-resistant high-efficiency flame-retardant decorative film includes the following steps: using PVC resin powder as the main raw material, adding plasticizer, composite flame retardant, soybean oil, formaldehyde absorbent, stabilizer, and smoke suppressant , Nano-calcium powder is used as a functional additive, and the decorative film is made by high-speed mixing, molding extrusion, fi...

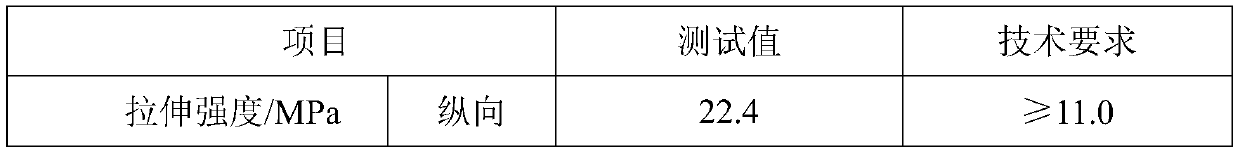

Embodiment 3

[0041] An impact-resistant and high-efficiency flame-retardant decorative film, the decorative film is prepared from the following raw materials in parts by weight: 100 parts of PVC resin powder (S60), 50 parts of DOTP plasticizer, 5 parts of soybean oil, superfine zinc borate resistance 20 parts of flame retardant, 18 parts of antimony trioxide flame retardant, 5 parts of phosphorus flame retardant, 5 parts of formaldehyde absorbent, 5 parts of environmental stabilizer, 5 parts of smoke suppressant, 15 parts of nano calcium powder.

[0042] The preparation method of the above-mentioned impact-resistant high-efficiency flame-retardant decorative film includes the following steps: using PVC resin powder as the main raw material, adding plasticizer, composite flame retardant, soybean oil, formaldehyde absorbent, stabilizer, and smoke suppressant , Nano-calcium powder is used as a functional additive, and the decorative film is made by high-speed mixing, molding extrusion, first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com