Patents

Literature

59results about How to "Uniform light transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photochromic polyurethane laminate

ActiveUS20050233153A1Improve fatigue resistanceGood dimensional stabilityLamination ancillary operationsSynthetic resin layered productsPhotochromic lensThermoplastic polyurethane

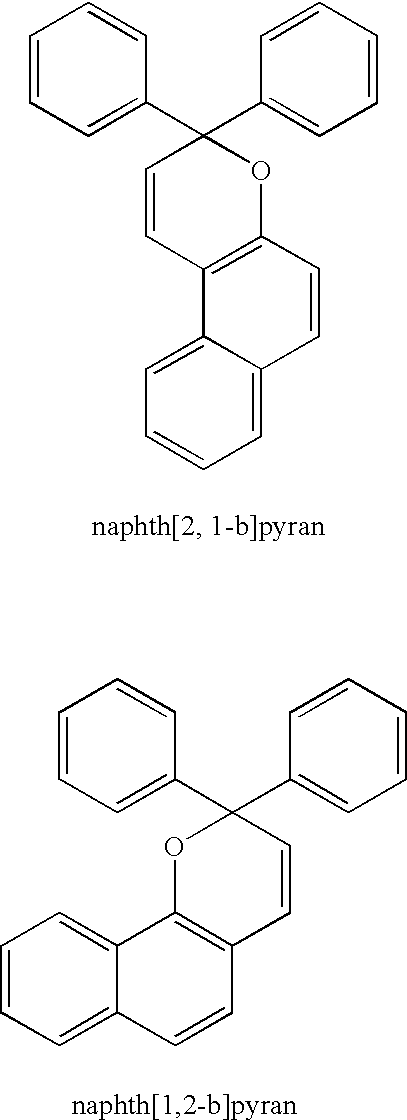

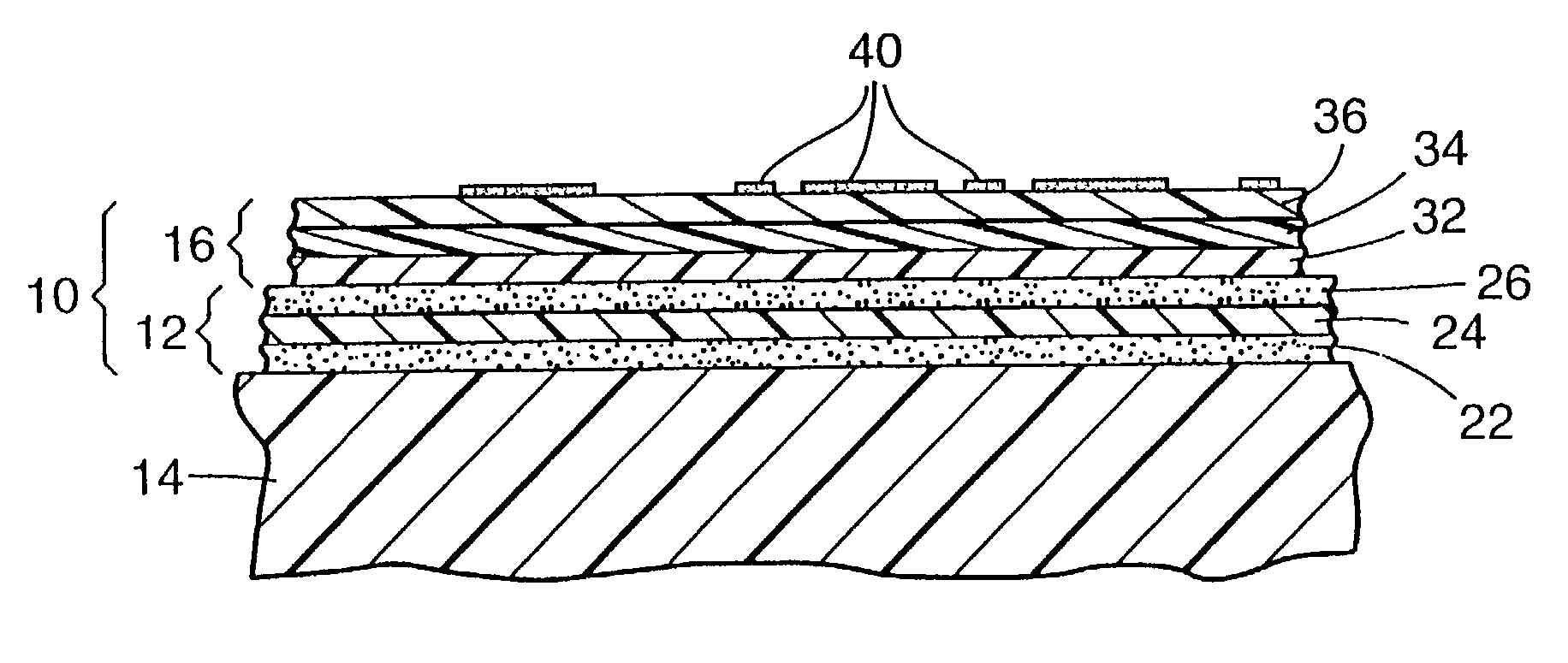

A photochromic polyurethane laminate that is constructed to solve certain manufacturing difficulties involved in the production of plastic photochromic lenses is disclosed. The photochromic laminate includes at least two layers of a resinous material and a photochromic polyurethane layer that is interspersed between the two resinous layers and which contains photochromic compounds. The polyurethane layer is formed by curing a mixture of a solid thermoplastic polyurethane, at least one isocyanate prepolymer, at least one photochromic compound, and a stabilizing system.

Owner:HOYA OPTICAL LABS OF AMERICA INC

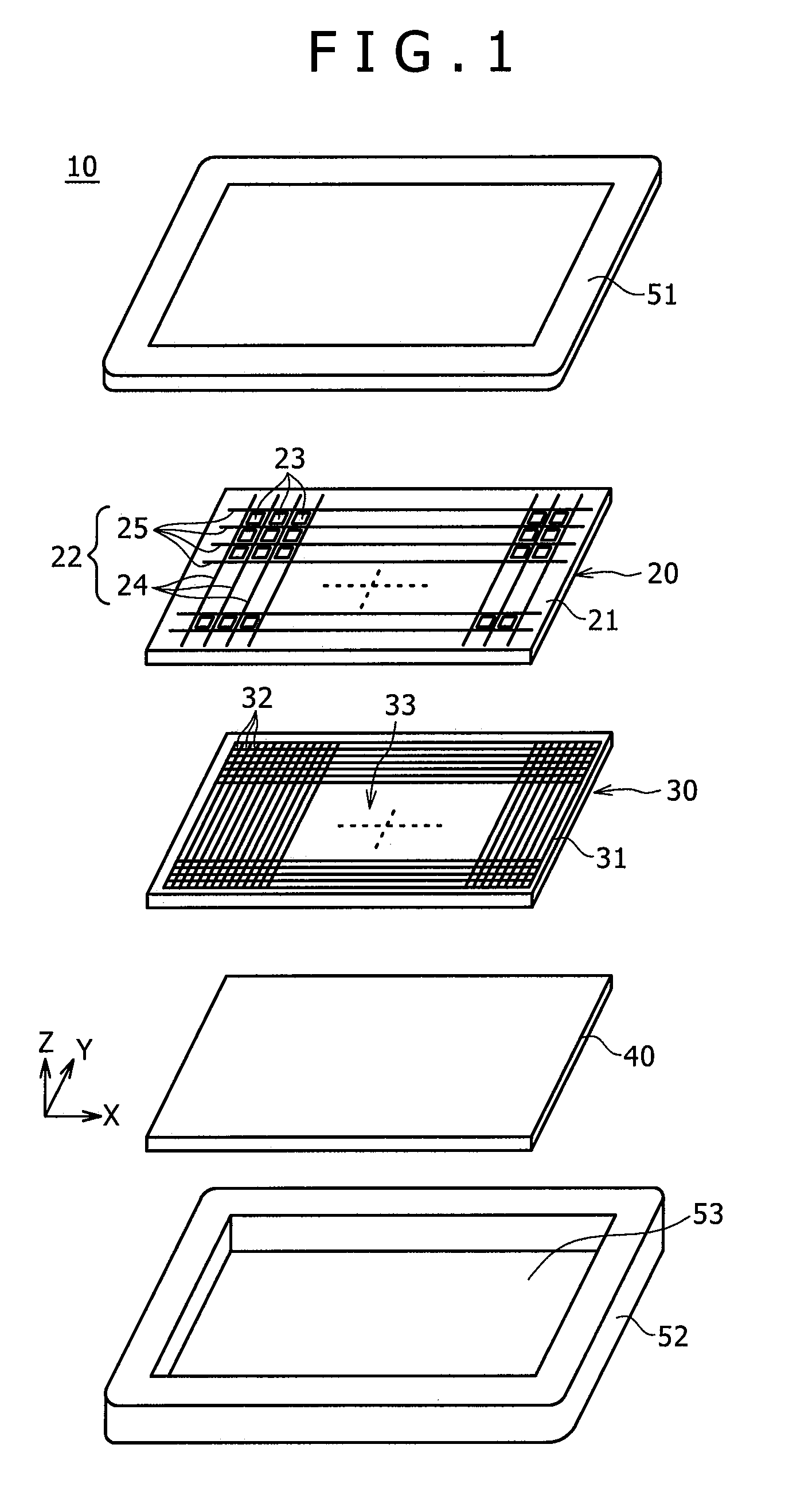

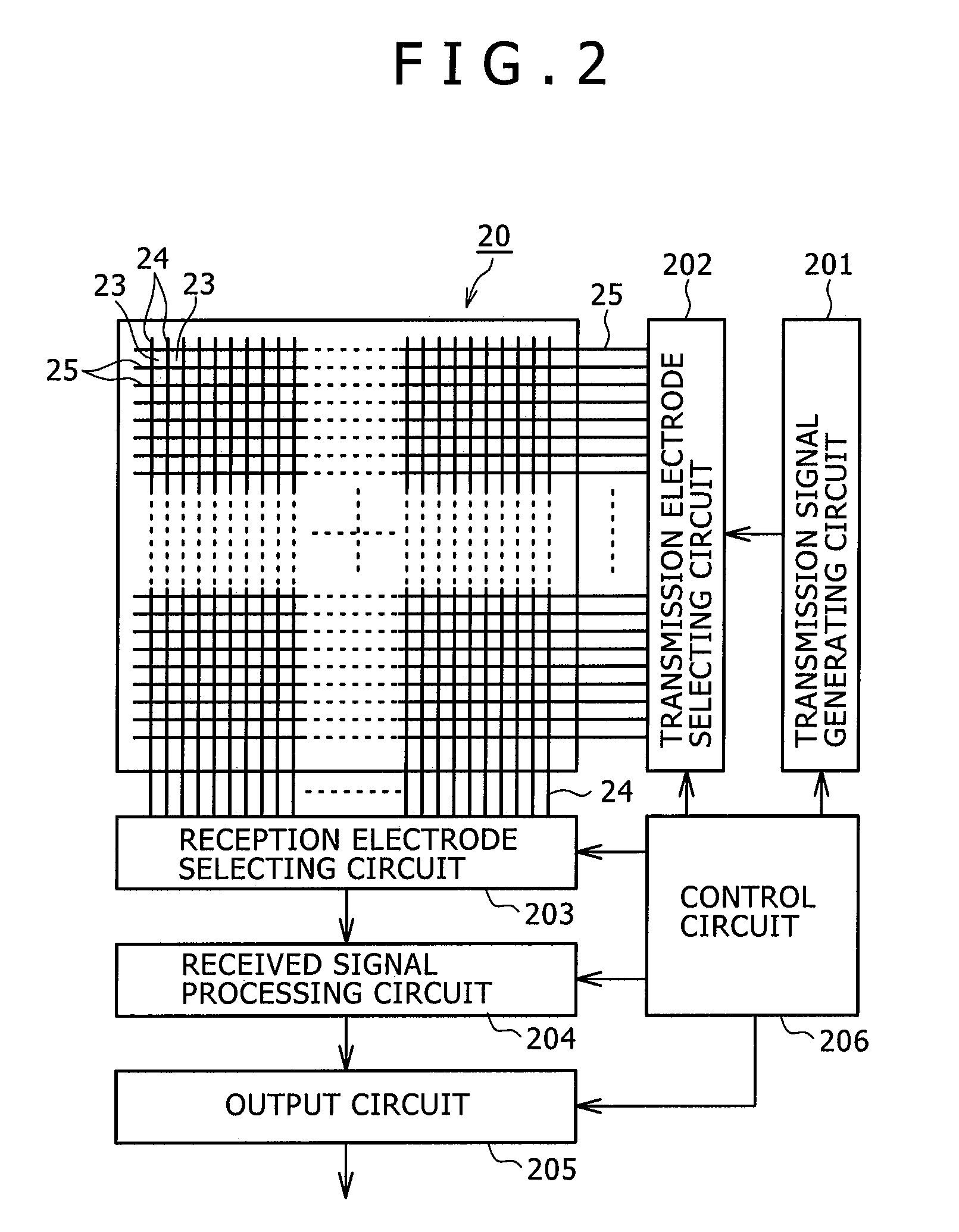

Position detecting sensor and position detector

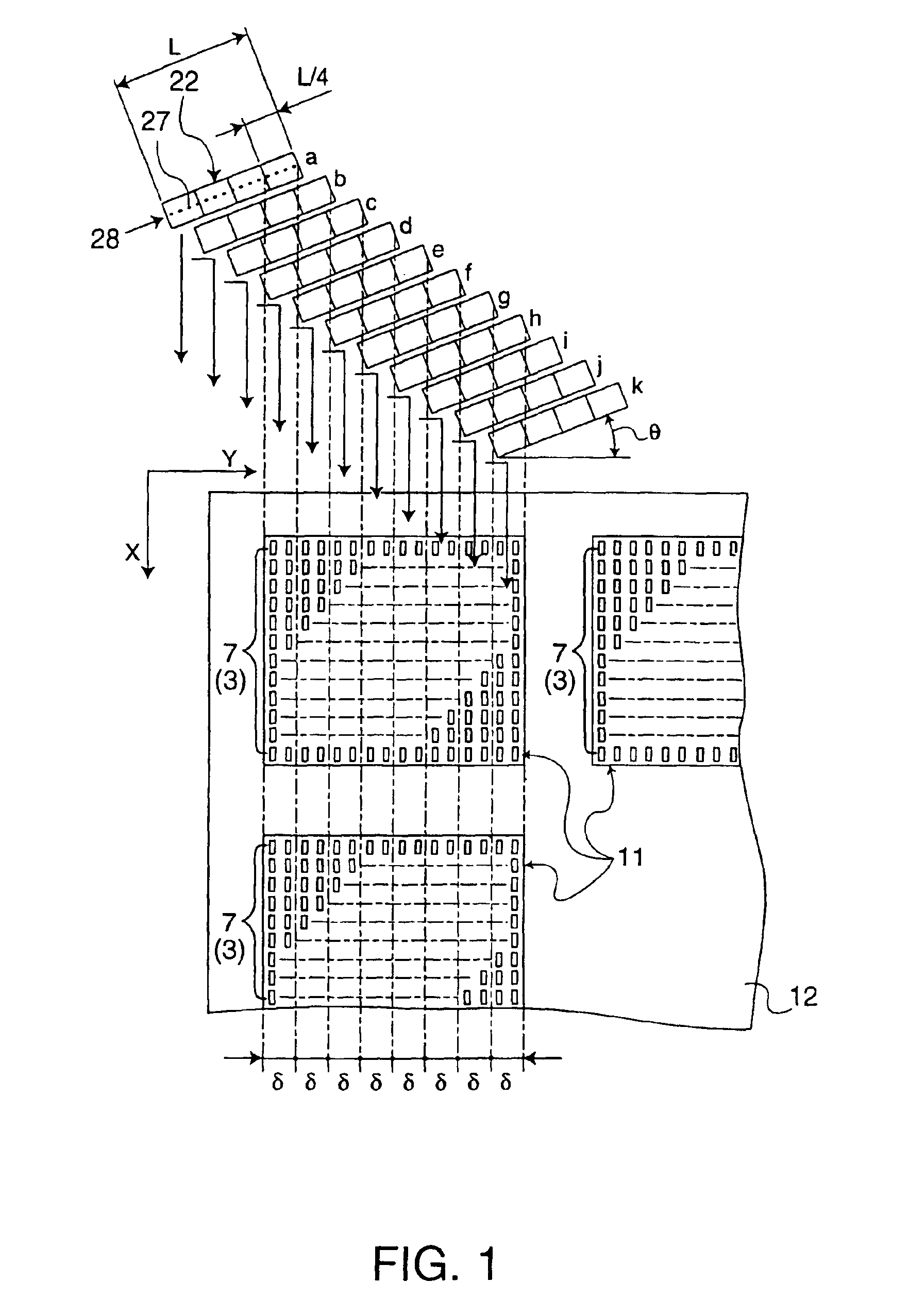

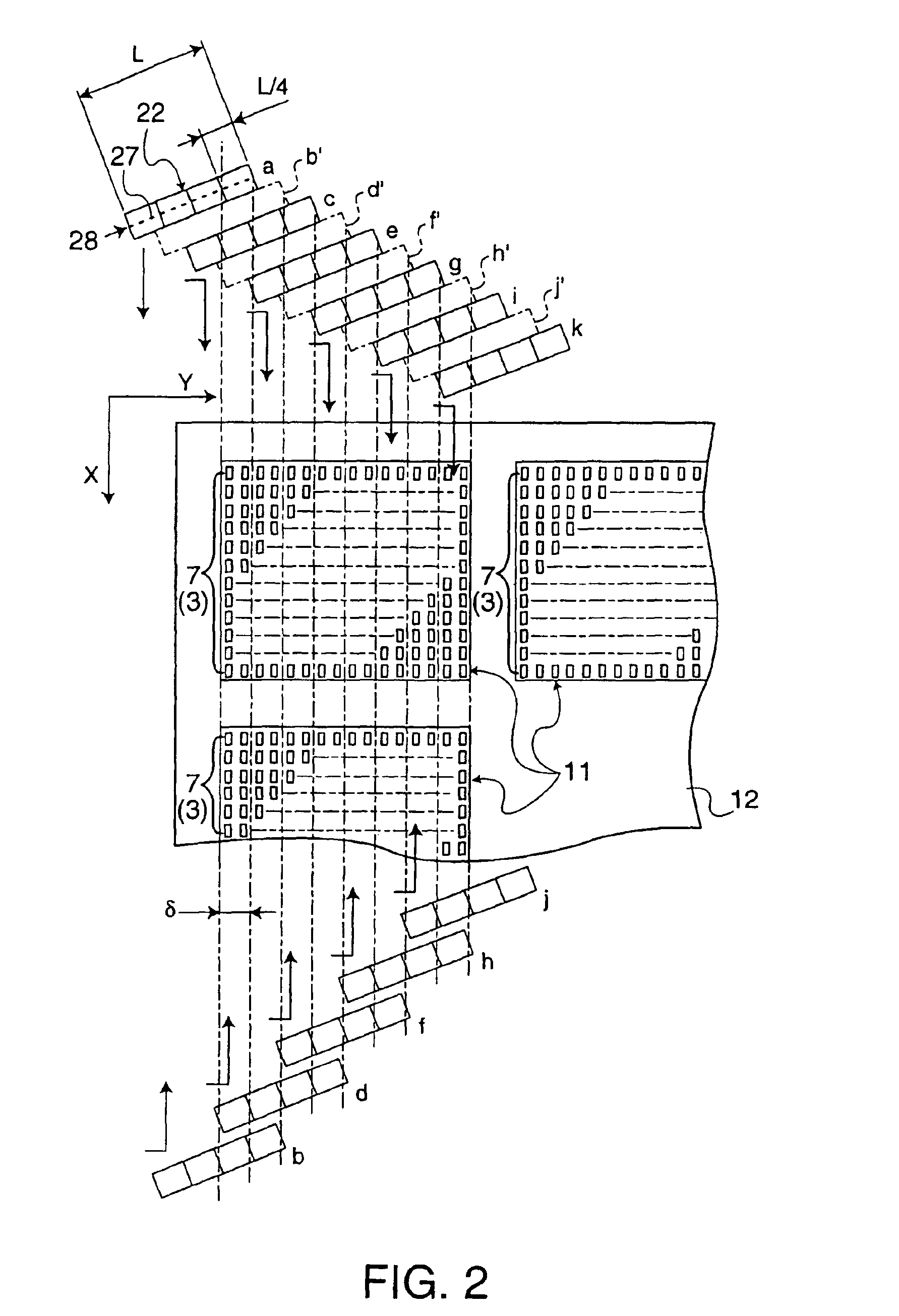

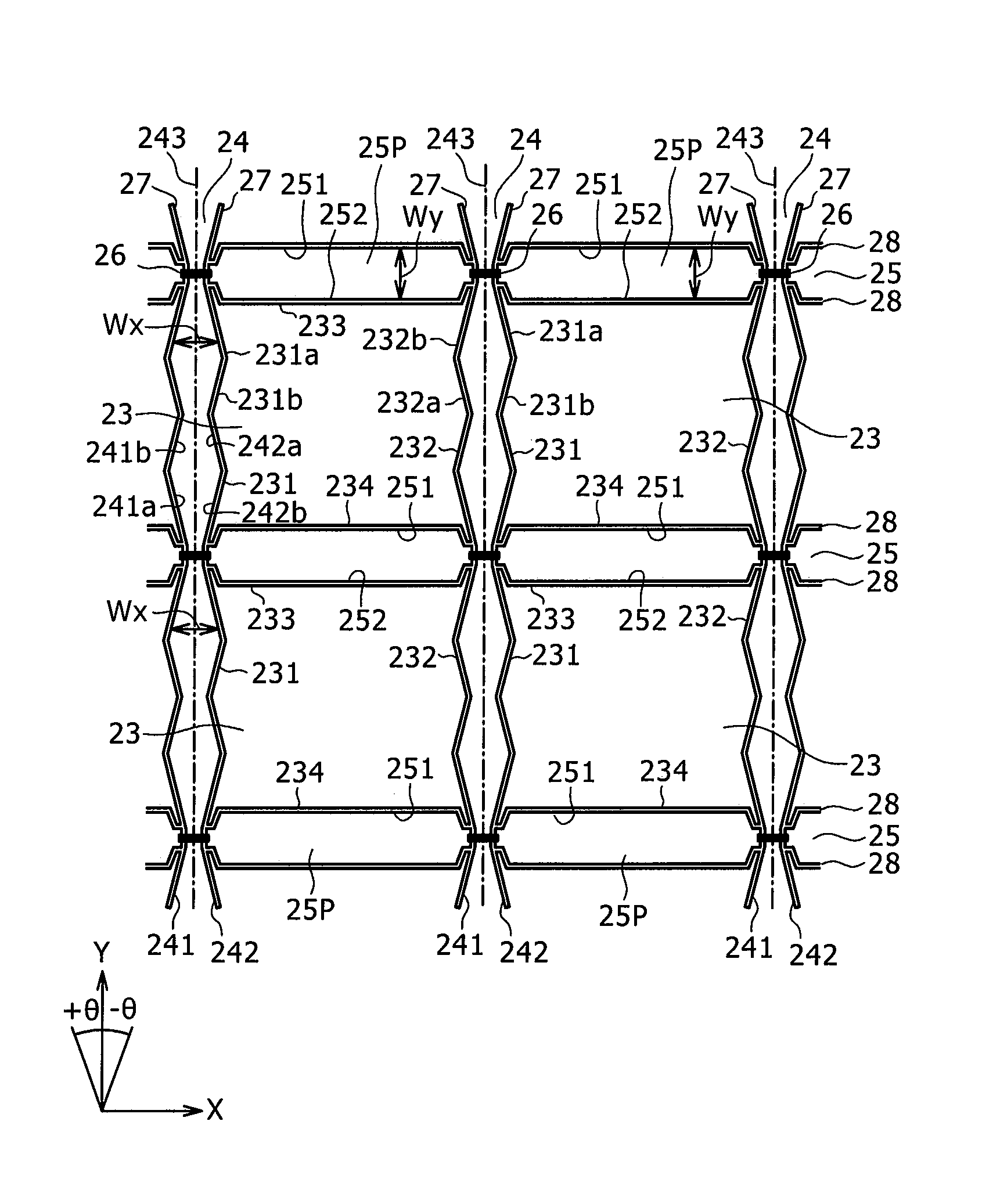

ActiveUS20130016363A1Decrease and prevent generationUniform light transmissionUsing optical meansInput/output processes for data processingDisplay devicePosition detector

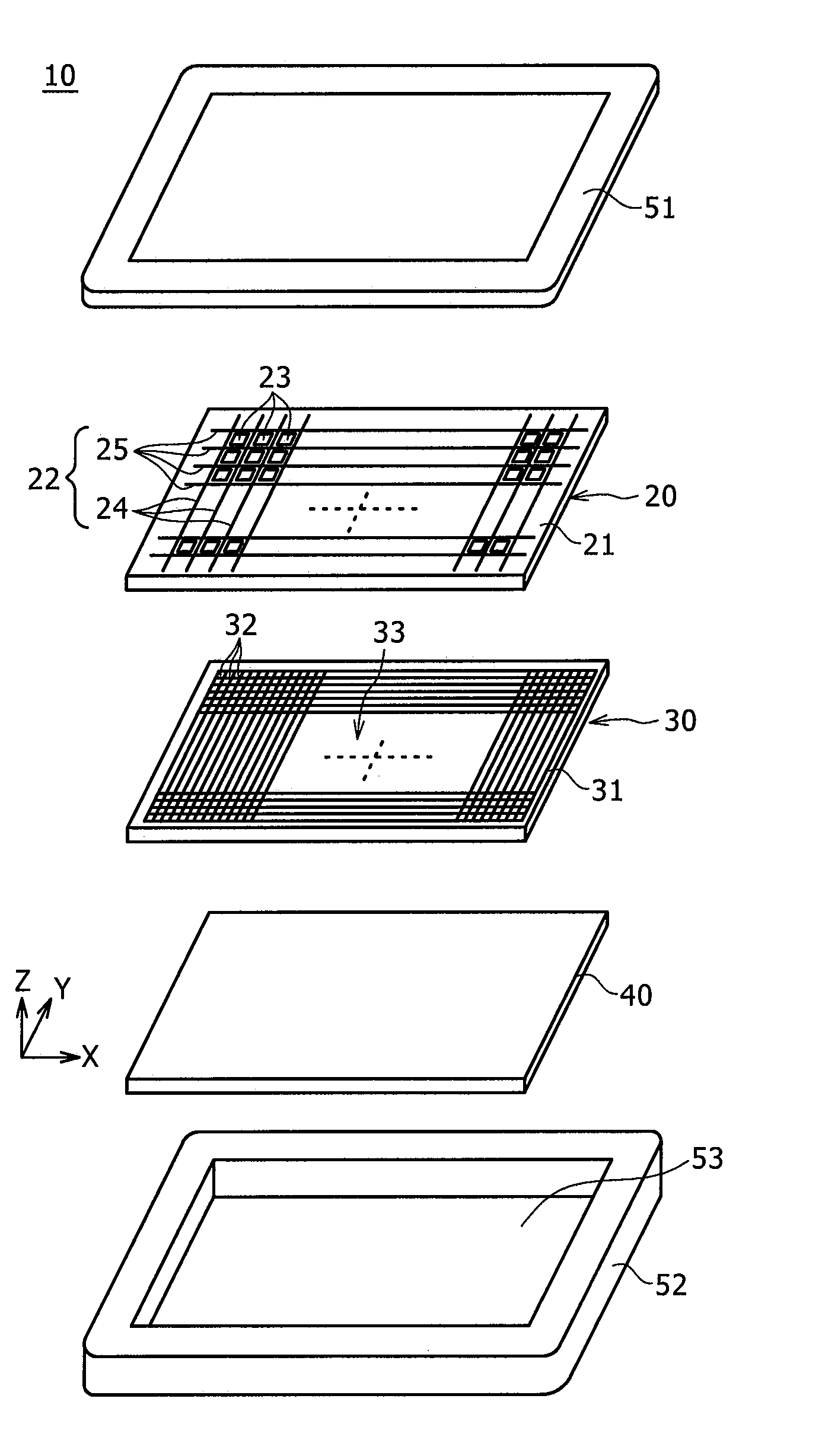

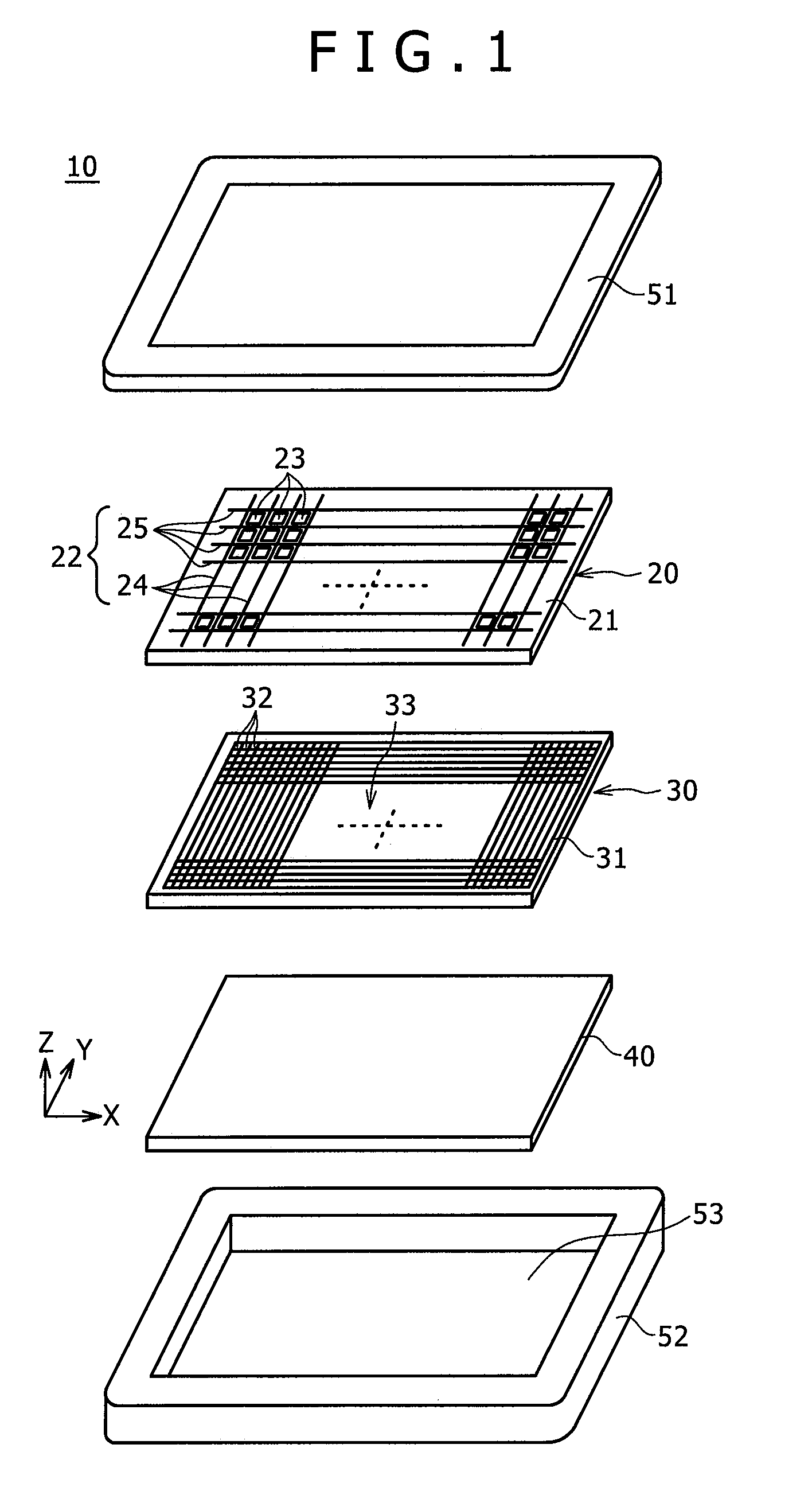

A position detecting sensor includes a grid structure composed of plural electrodes extending in a first direction and plural electrodes extending in a second direction perpendicular to the first direction. The electrodes have light permeability. In a rectangular area defined by four cross-points, where two adjacent electrodes extending in the first direction and two adjacent electrodes extending in the second direction cross each other, a dummy pattern is disposed so as to provide uniform optical characteristics for the sensor. At least some of the electrodes extending in the first direction are shaped to include inclinations relative to the first direction, so as to minimize the Moire effect that may develop between the electrodes and an array of pixels in an overlaid display device. Also, at least some of the electrodes extending in the first direction are shaped to be line-symmetric about a straight line extending in the first direction.

Owner:WACOM CO LTD

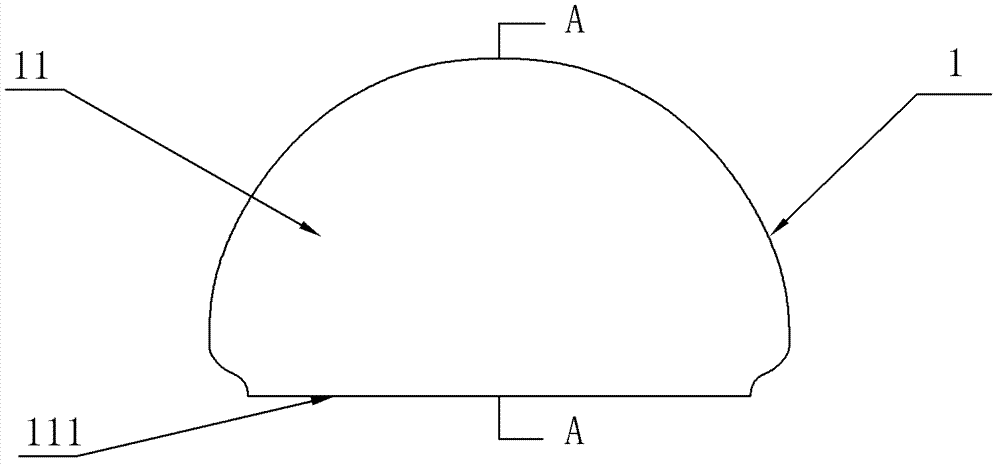

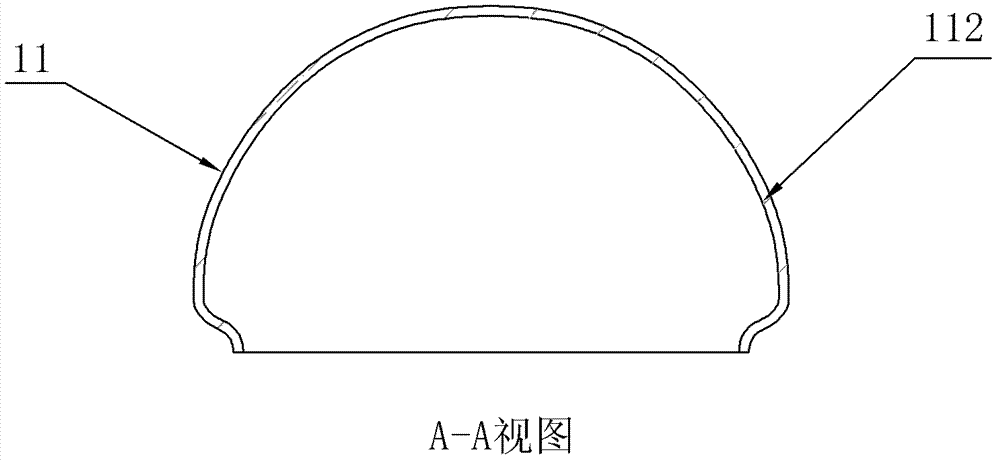

Coat, LED lampshade using it, and PC material

InactiveCN103194109AWith lateral light guiding propertiesHigh light transmittancePoint-like light sourceGlobesTransmittanceSolvent

The invention relates to the electrical design field, and discloses a coat having a high light transmittance and a high astigmatism degree. The coat comprises 1-15% by mass of spherical organic silicon micro-powder, 0-5% by mass of square barium sulfate, 0-15% by mass of an inorganic filler, 20-90% by mass of a resin, 0-40% by mass of a solvent, 0-4% by mass of an assistant and 0-0.5% by mass of a coloring agent, and the spherical organic silicon micro-powder has a high light transmittance and a high astigmatism degree. The invention also discloses an LED lampshade having a high light transmittance and a high astigmatism degree. The LED lampshade comprises the coat and an LED lampshade body, and the coat is coated on the LED lampshade body. The invention also provides a PC material having a high light transmittance and a high astigmatism degree. The PC material is composed of 0.7-1.0% by mass of the spherical organic silicon micro-powder, 0-1.0% by mass of the square barium sulfate and 98-99% by mass of a transparent PC material, and the spherical organic silicon micro-powder has a high light transmittance and a high astigmatism degree. The PC material is used for preparing lampshades or sheets.

Owner:赵宁

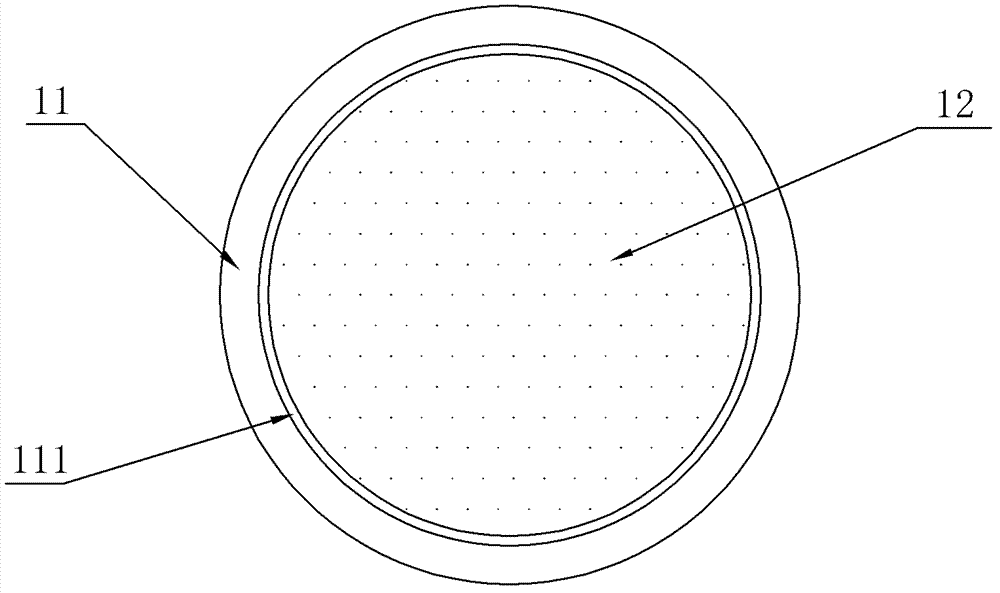

Methods and apparatus for making color filter by discharging a filter material

InactiveUS6939407B2Uniform characteristicsSuppress mutationLiquid surface applicatorsInking apparatusDot matrixFilter material

The present invention provides a method for making a color filter having a plurality of filter elements aligned in a dot-matrix on a substrate. The method has a first-scanning step of moving the inkjet head having a nozzle line including a plurality of nozzles relative to the substrate while selectively discharging a filter material from the plurality of nozzles so as to form filter elements on filter element forming regions of the substrate and a second-scanning step of moving the inkjet head by a second-scanning distance δ in a second-scanning direction. The plurality of nozzles are divided into a plurality of groups and the first-scanning step and the second-scanning step are repeated so that all the nozzle groups scan the same section of the substrate.

Owner:KATEEVA

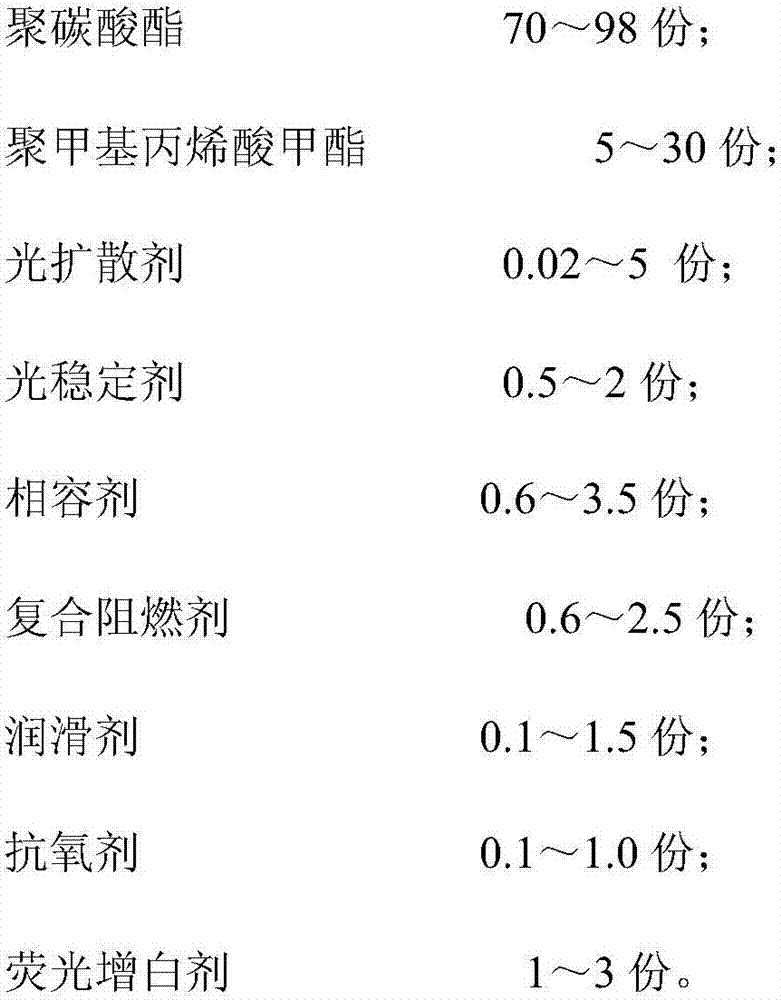

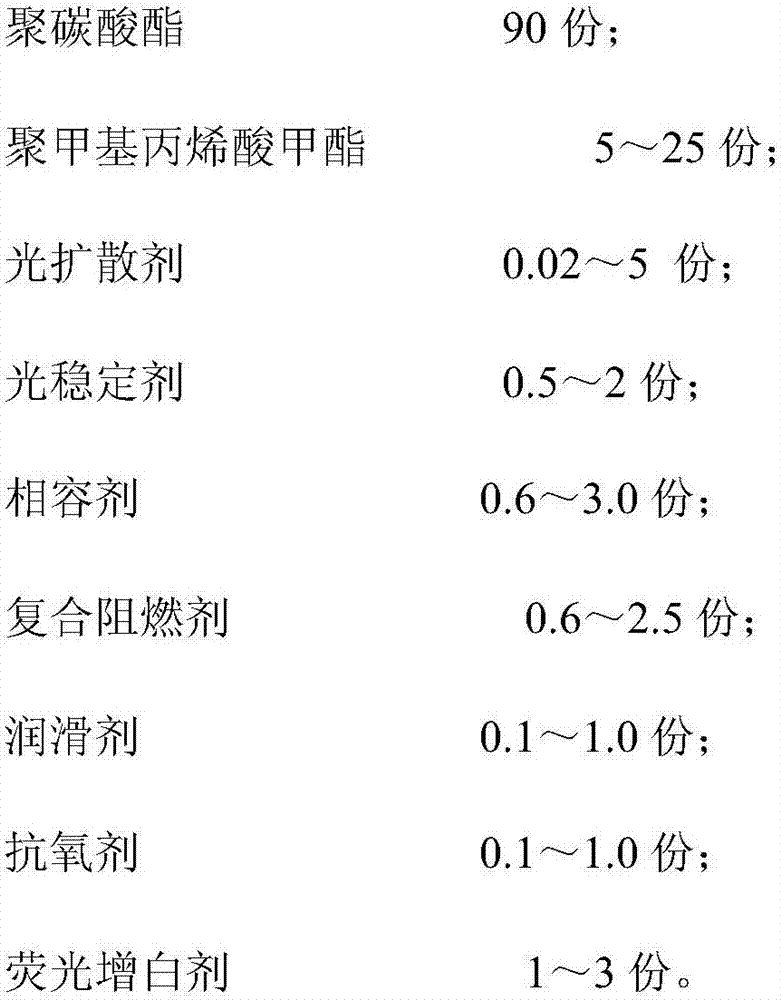

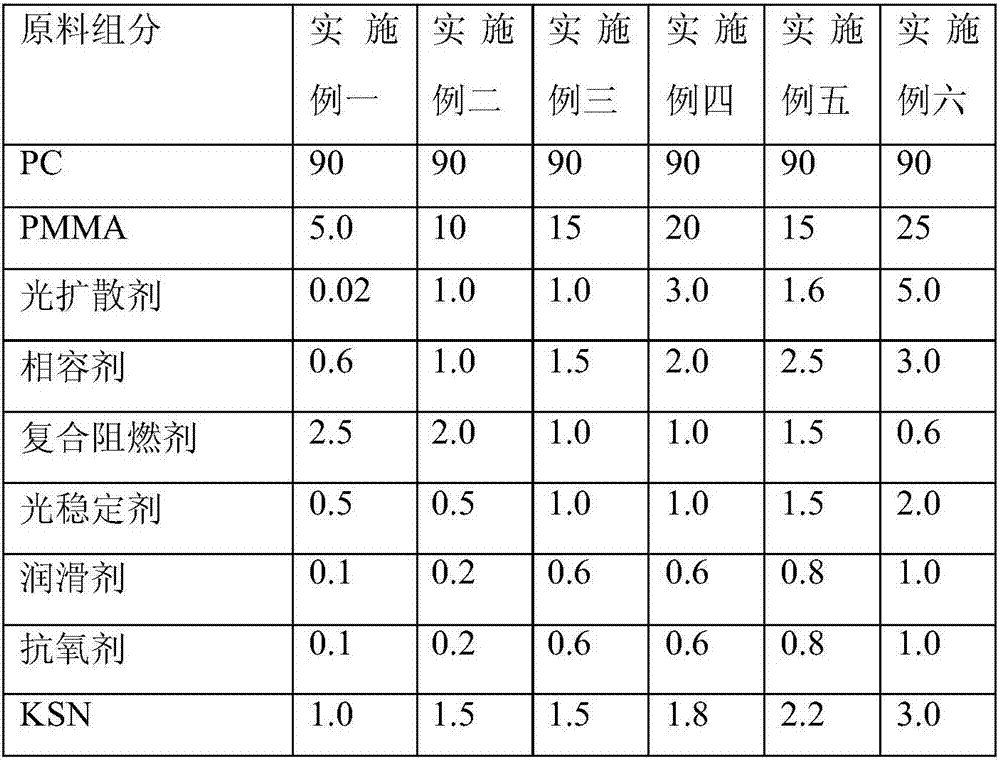

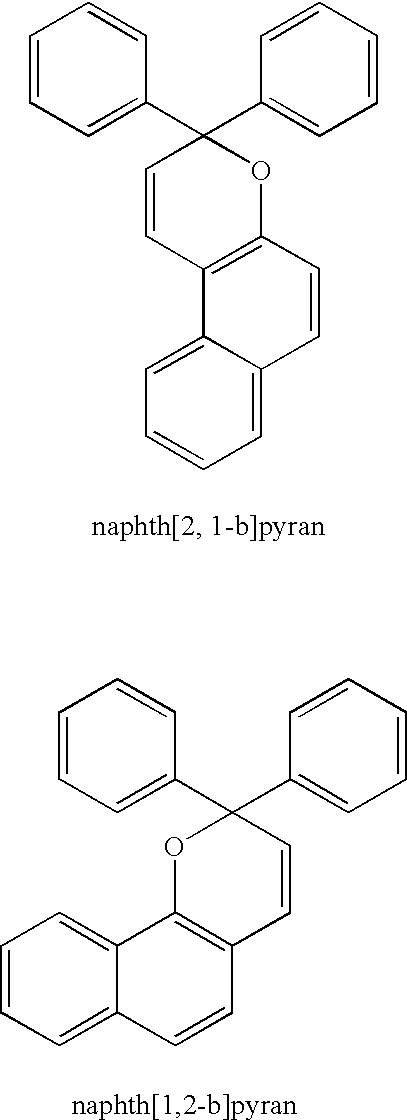

Light-diffusing flame-retardant polycarbonate material for LED lighting, and preparation method thereof

The present invention discloses a light-diffusing flame-retardant polycarbonate material for LED lighting, wherein the light-diffusing flame-retardant polycarbonate material comprises (by weight) the following raw materials. According to the present invention, the organic light diffusing agent is added to the composite substrate, such that the light is soft, the stability is good, the particles are tightly bound, and the uniform system is easily formed; through the matched cooperation of the organic light diffusing agent and the fluorescent brightener, the light transmittance can be improved, and the light diffusion effect can be improved; and the product has the good gloss, the interface combination degree of the matrix resin is enhanced with the compatibilizer, the impact strength is increased, the product has the toughness, and the flame retardant property is provided for the product through the flame retardant agent.

Owner:NINGBO ZHETIE DAPHOON CHEM

Photochromic polyurethane laminate

ActiveUS8298671B2Fine surfaceImprove uniformityLamination ancillary operationsSynthetic resin layered productsPhotochromic lensThermoplastic polyurethane

A photochromic polyurethane laminate that is constructed to solve certain manufacturing difficulties involved in the production of plastic photochromic lenses is disclosed. The photochromic laminate includes at least two layers of a resinous material and a photochromic polyurethane layer that is interspersed between the two resinous layers and which contains photochromic compounds. The polyurethane layer is formed by curing a mixture of a solid thermoplastic polyurethane, at least one isocyanate prepolymer, at least one photochromic compound, and a stabilizing system.

Owner:HOYA OPTICAL LABS OF AMERICA INC

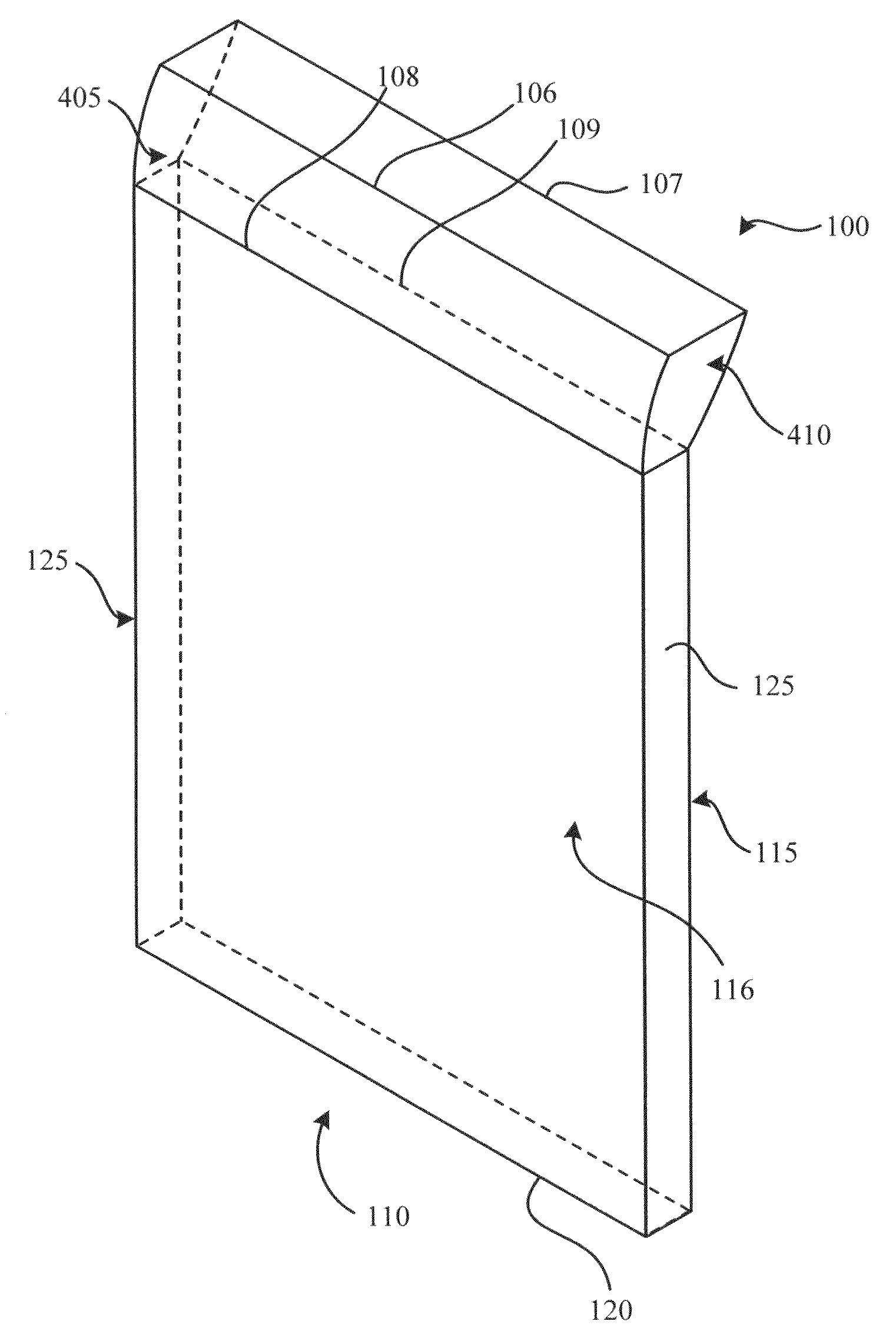

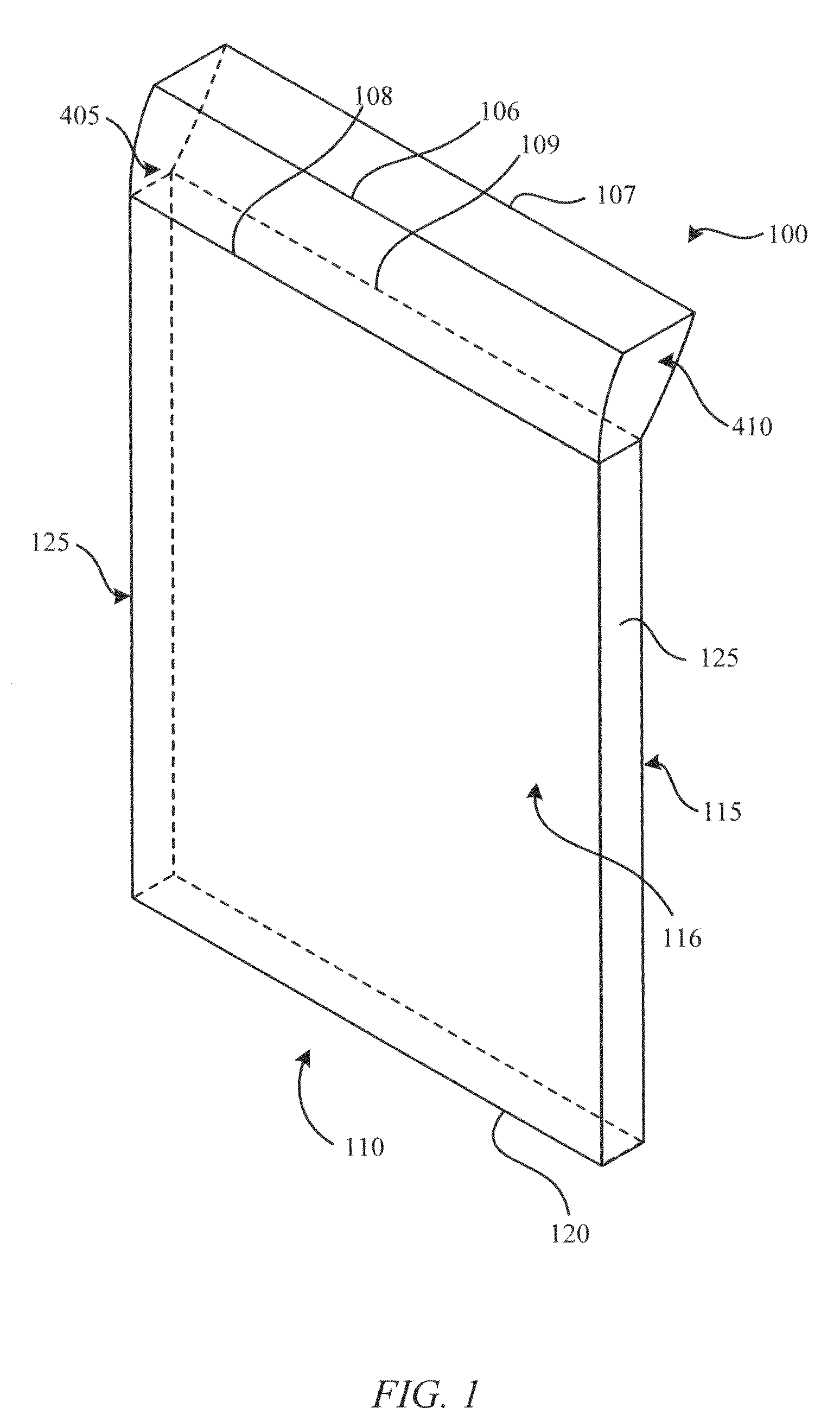

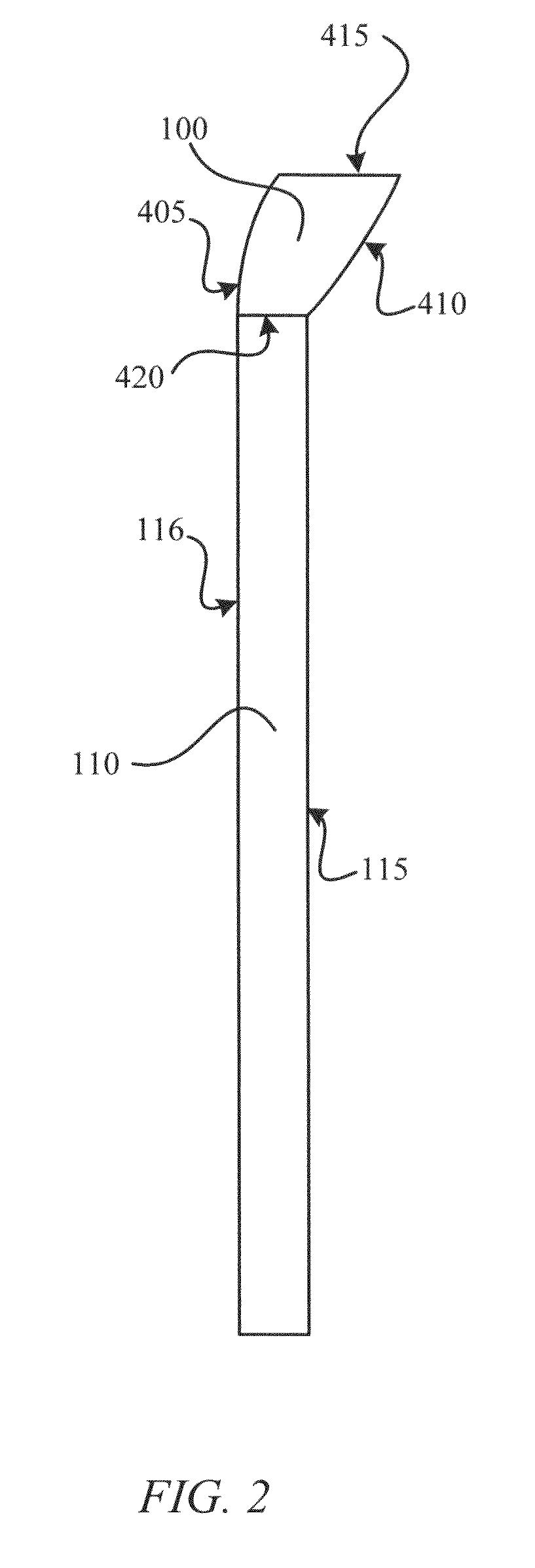

Asymmetric compound parabolic concentrator and related systems

InactiveUS20100028991A1Efficient trackless performanceUniform light transmissionSolar heating energyBioreactor/fermenter combinationsLight guideEngineering

Various embodiments disclosed herein provide for an asymmetric compound parabolic concentrator (ACPC), a liquid light guide, and an algae mixer. These embodiments may be used singularly or in combination, for example, as part of a bioreactor. In various embodiments an ACPC may be used to capture light without the aid of motors or positioning. As such, the ACPC may be used despite seasonal solar variations. The illuminating light guide may be used to guide light, for example, from an exit aperture of an ACPC, through walls substantially perpendicular to the entrance window of the illuminating light guide. In some embodiments, the illuminating light guide may provide substantially uniform light distribution through a vertical profile. Other embodiments include, for example, an algae mixer and bioreactors.

Owner:MIP

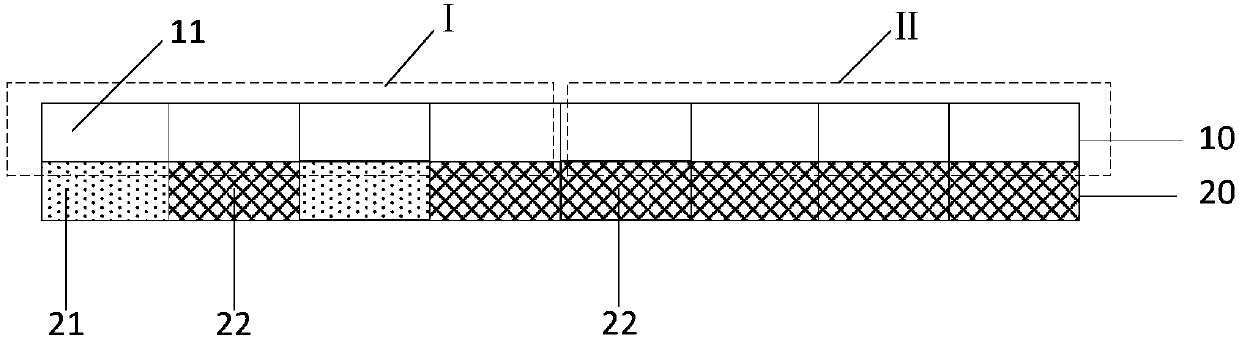

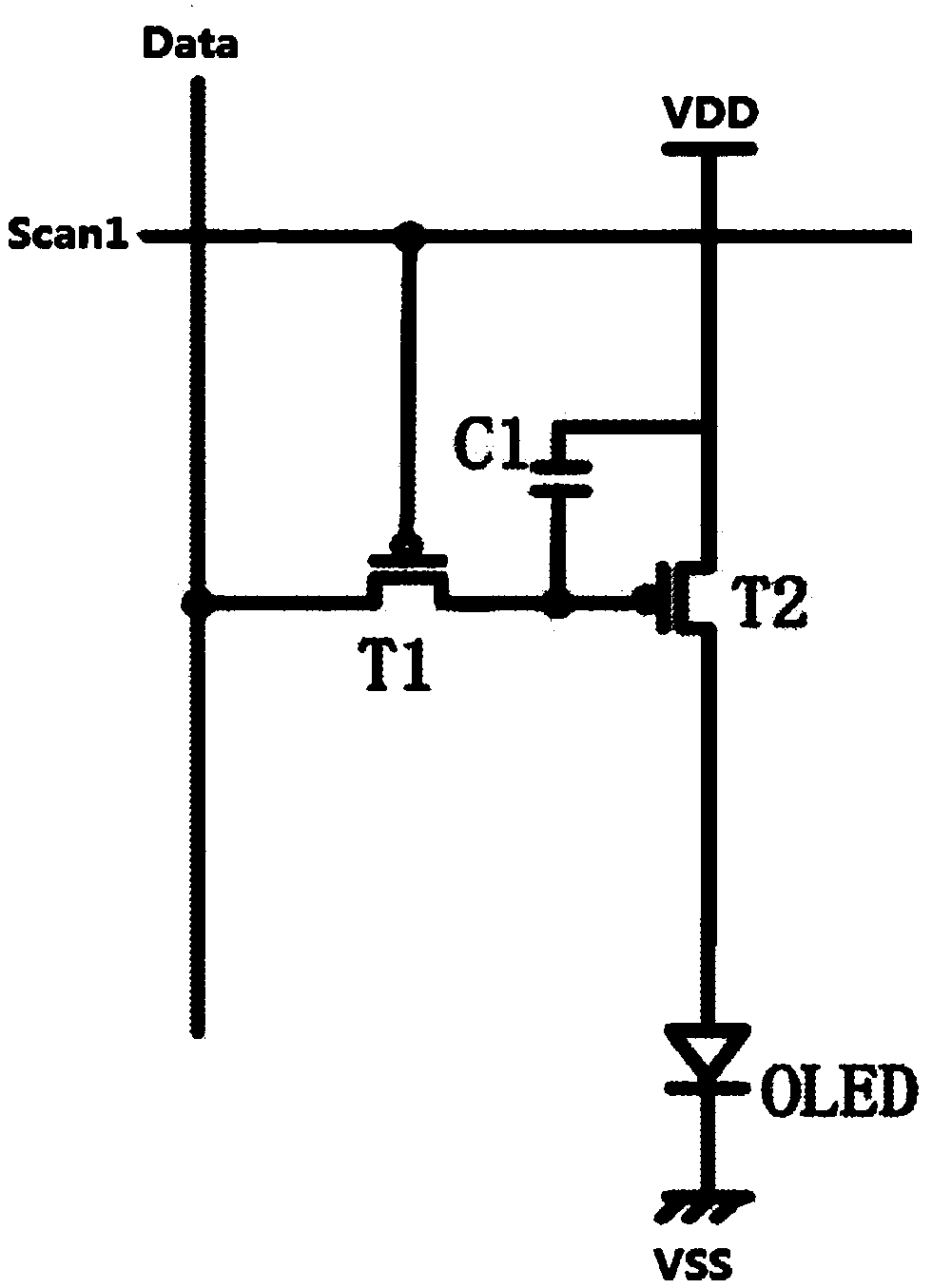

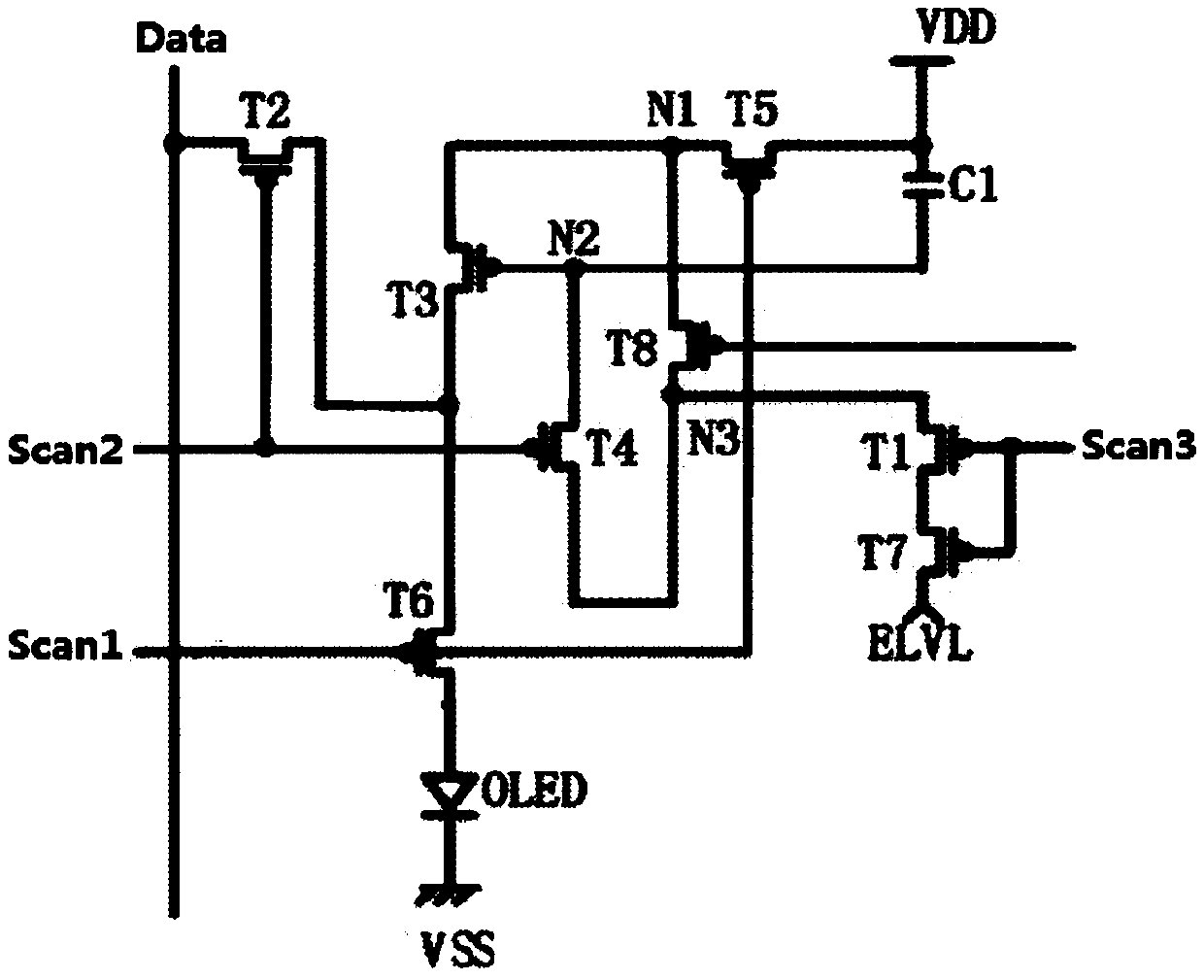

Display device

InactiveCN107863370AHigh light transmittanceChange structureStatic indicating devicesSolid-state devicesElectricityElectrical connection

The invention relates to the display technical field and provides a display device. The display device comprises a display layer and a driving layer in laminated arrangement. The display layer comprises a plurality of display units in array arrangement. The driving layer comprises plurality of driving units in array arrangement. The display units and the driving units are in one-to-one correspondence and are in electrical connection. Light transmittance of the driving units is not totally same. Each element in each driving unit has metal conductivity, the metal has a certain light resistance,and light transmittance of the driving units in the driving layer is set to be not totally same, that is, a light transmitting area is formed by simplifying the structure of a drive circuit in each driving unit, so that light rays are allowed to emit out of the light transmitting area, and an effect of improving the light transmittance of the driving layer is achieved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Image graphic system comprising a highly tacky adhesive and method for using same

InactiveUS20030127181A1Efficient use ofImprove adhesionLamination ancillary operationsPicture framesAdhesiveGraphic system

Owner:3M INNOVATIVE PROPERTIES CO

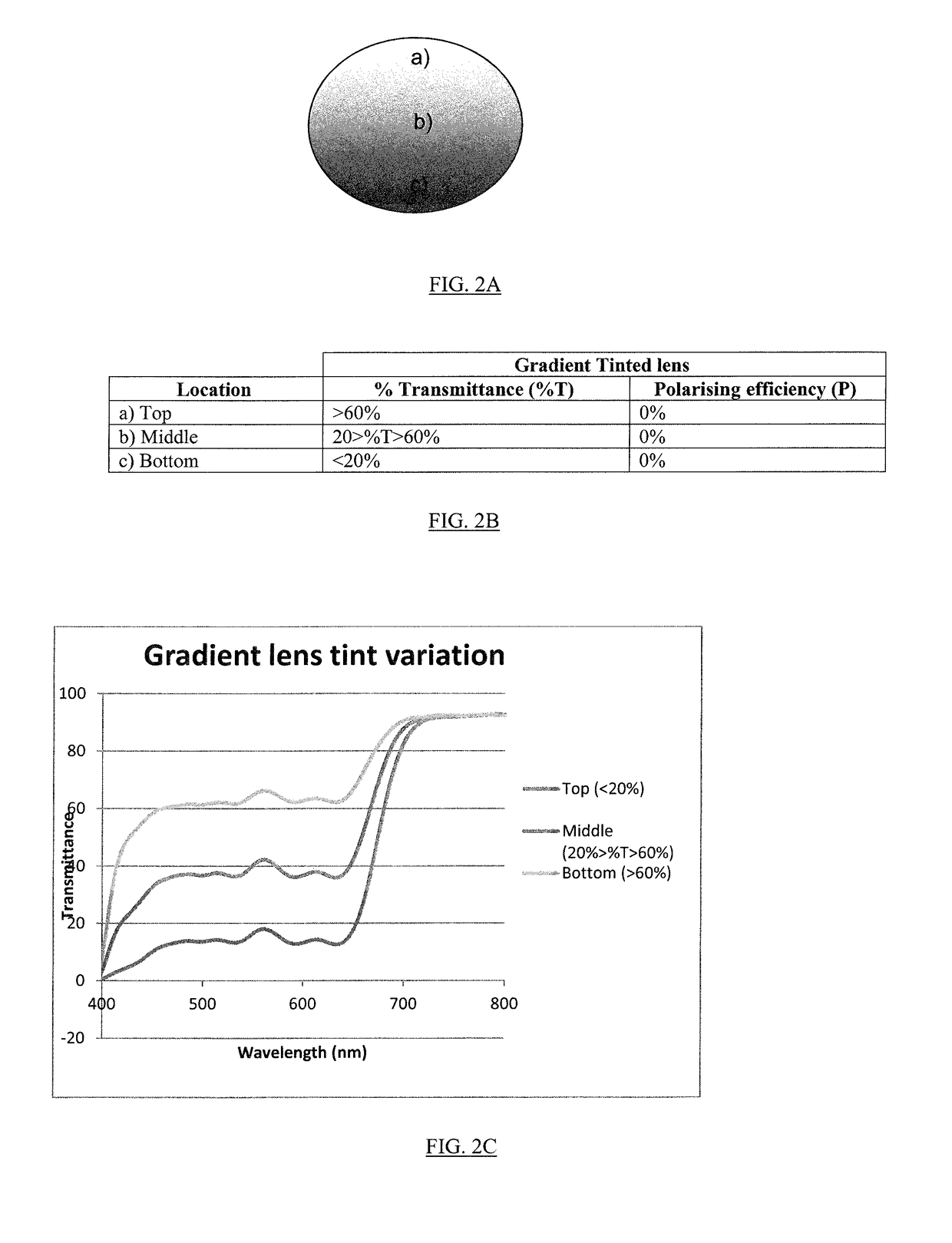

Gradient polarized ophthalmic lens

ActiveUS20170176775A1Reduce polarizationReduce glareSpectales/gogglesOptical articlesLight transmission

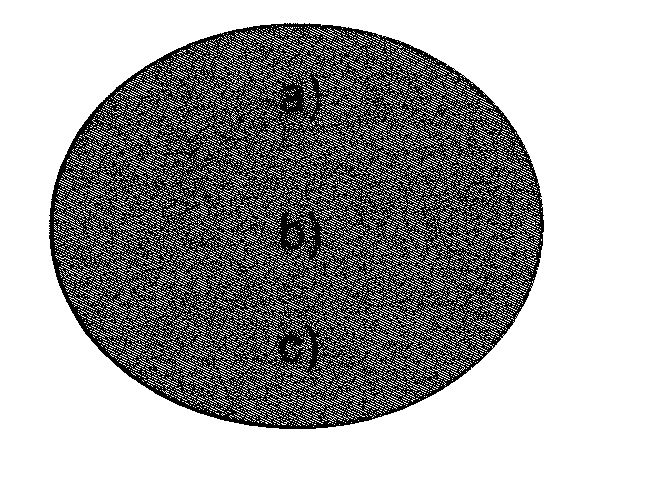

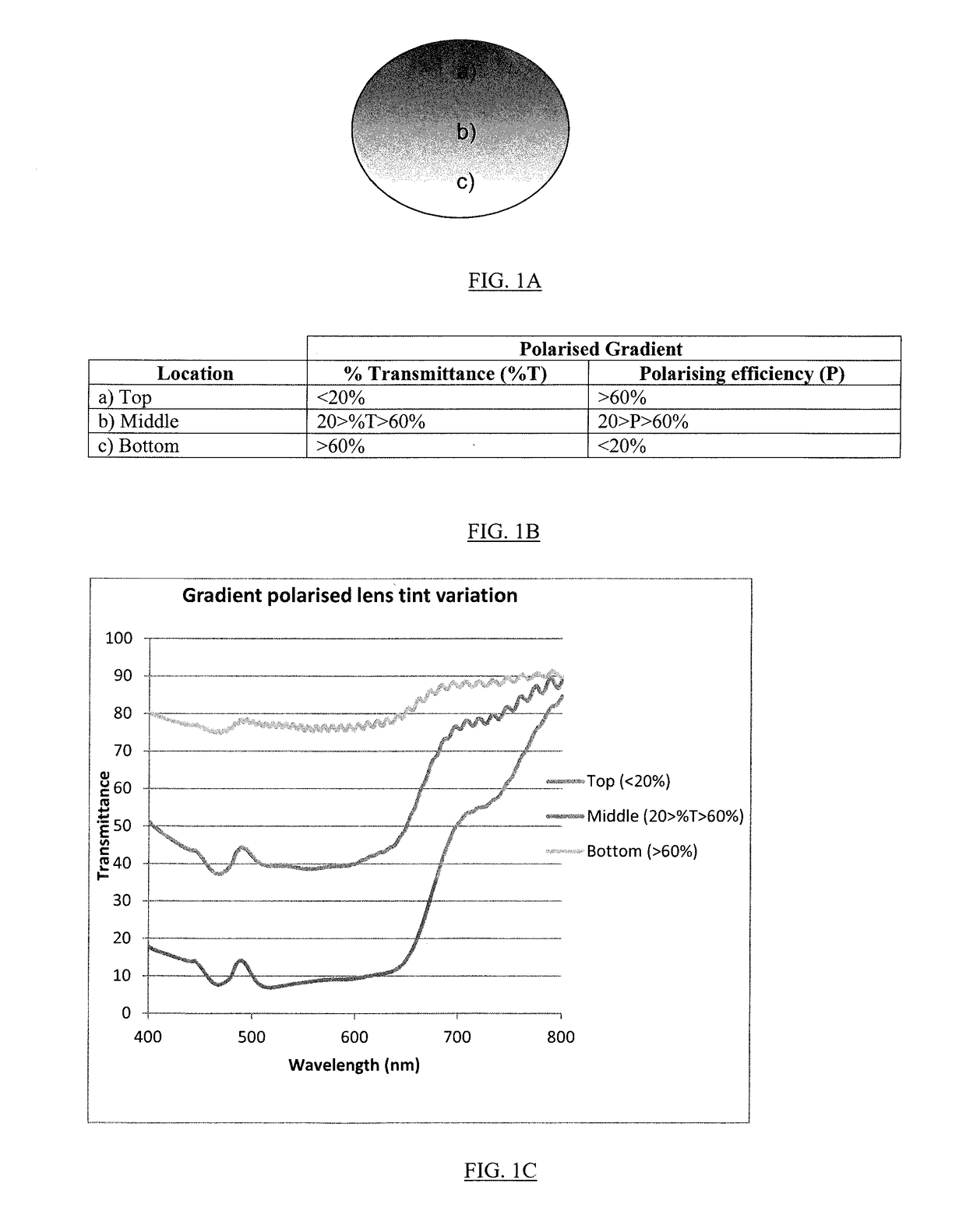

A polarized ophthalmic lens has a polarization gradient with a primary light transmission gradient. The lens also includes a secondary light transmission gradient, the secondary light transmission gradient being complementary to the primary light transmission gradient such that the lens exhibits uniform light transmission.

Owner:CARL ZEISS VISION INT GMBH

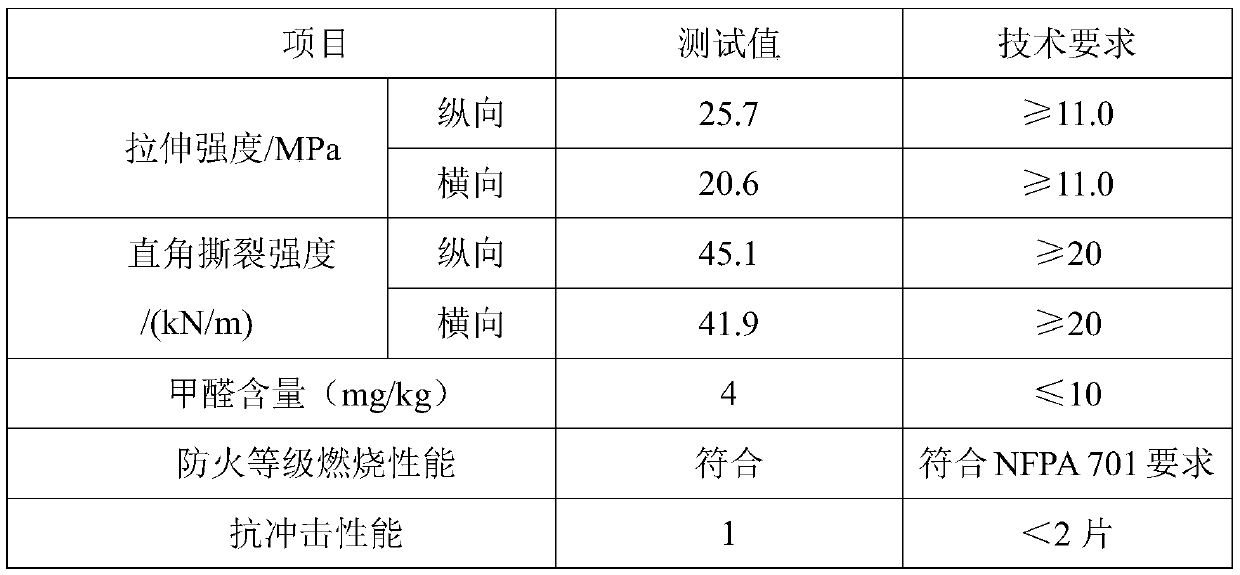

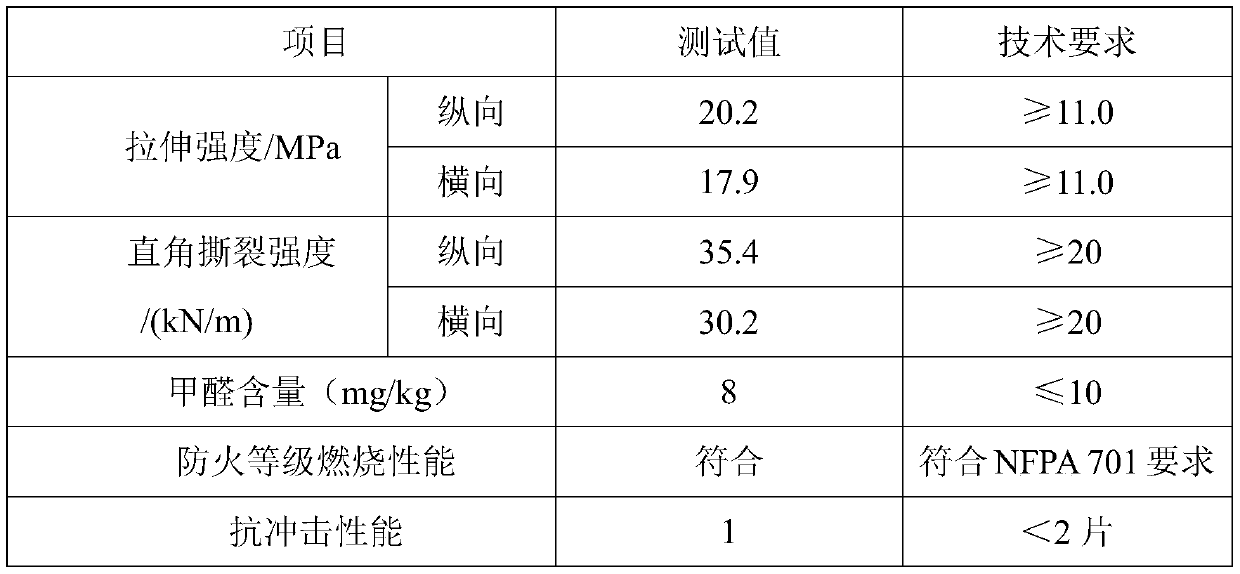

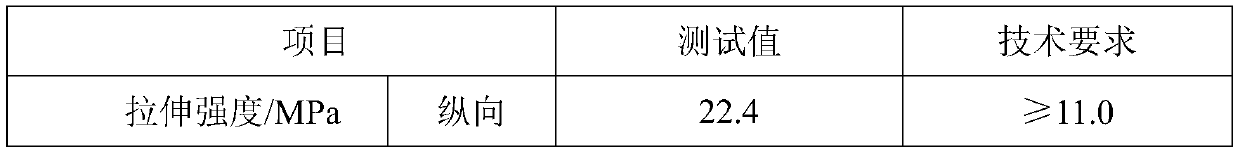

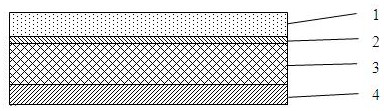

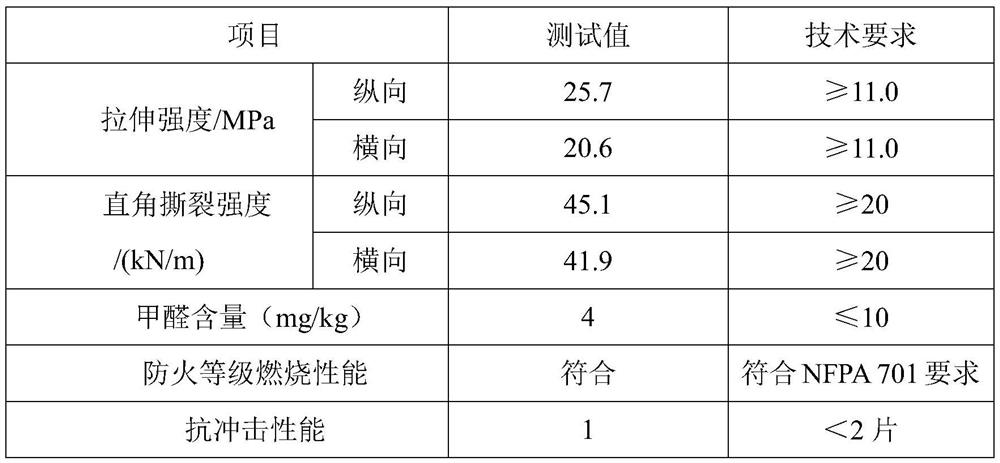

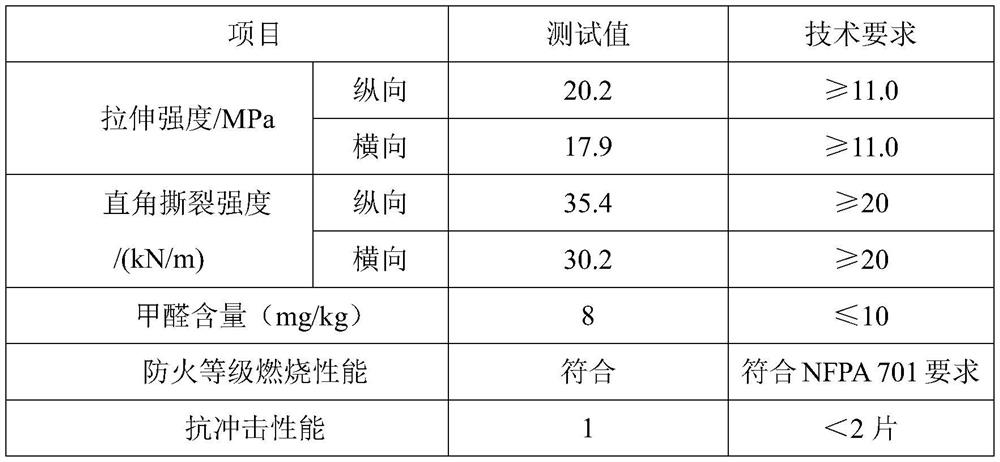

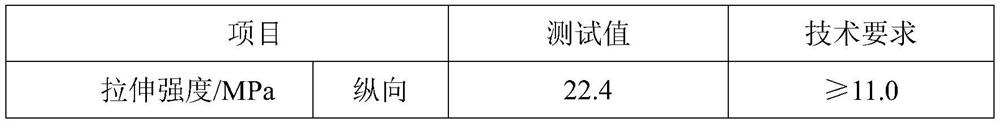

Anti-shock efficient flame-retardant decorative film and preparation method thereof

The invention relates to an anti-shock efficient flame-retardant decorative film and a preparation method thereof. The decorative film is prepared from, by weight, 80-120 parts of PVC resin powder, 30-50 parts of a plasticizer, 0.5-5 parts of soybean oil, 18-45 parts of a composite flame retardant, 0.5-5 parts of a formaldehyde absorbent, 0.5-5 parts of a environment-friendly stabilizer, 0.5-5 parts of a smoke suppressant and 5-15 parts of nano-calcium powder. The PVC resin powder is adopted as the main raw material, and the plasticizer, the composite flame retardant, the soybean oil, the formaldehyde absorbent, the stabilizer, the smoke suppressant and the nano-calcium powder are added as functional auxiliaries. The decorative film is obtained through high-speed stirring and mixing, forming extrusion, first rolling mill plastification, second rolling mill plastification, filtration, calendaring, cooling and reeling. Accordingly, by means of the optimized formula, production process parameters are optimized, the prepared decorative film has the advantages of being excellent in flexibility, efficient flame resistance and environmental friendliness, high in compliance, good in shockresistance and the like, and meanwhile the effect of purifying formaldehyde is achieved; the film has good market prospects.

Owner:浙江明士达股份有限公司

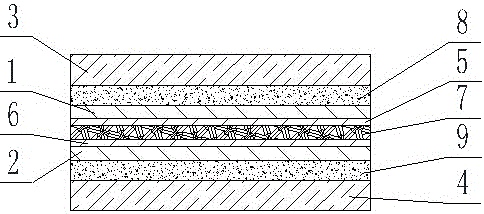

Composite heat insulation dimming glass and preparation method thereof

PendingCN106313794AReduce flatness requirementsGuaranteed fitSynthetic resin layered productsGlass/slag layered productsUltravioletUv absorber

The invention provides composite heat insulation dimming glass and relates to the technical field of optoelectronic products. The composite heat insulation dimming glass comprises a first thin film substrate, a second thin film substrate, a first glass substrate and a second glass substrate, wherein the first thin film substrate and the second thin film substrate are arranged between the first glass substrate and the second glass substrate; a first transparent conducting layer is sputtered on the first thin film substrate, and a second transparent conducting layer is sputtered on the second thin film substrate; a PDLC (polymer dispersed liquid crystal) layer coats the first transparent conducting layer / the second transparent conducting layer; a first transparent adhesive layer coats the first thin film substrate / the first glass substrate, the first thin film substrate and the first glass substrate are fitted together by virtue of the first transparent adhesive layer, a second transparent adhesive layer coats the second thin film substrate / the second glass substrate, and the second thin film substrate and the second glass substrate are fitted together by virtue of the second transparent adhesive layer; and an ultraviolet absorber and an infrared blocking agent are added in the first transparent adhesive layer, and the infrared blocking agent is added in the second transparent adhesive layer.

Owner:HENGSHAN JIACHENG NEW MATERIAL

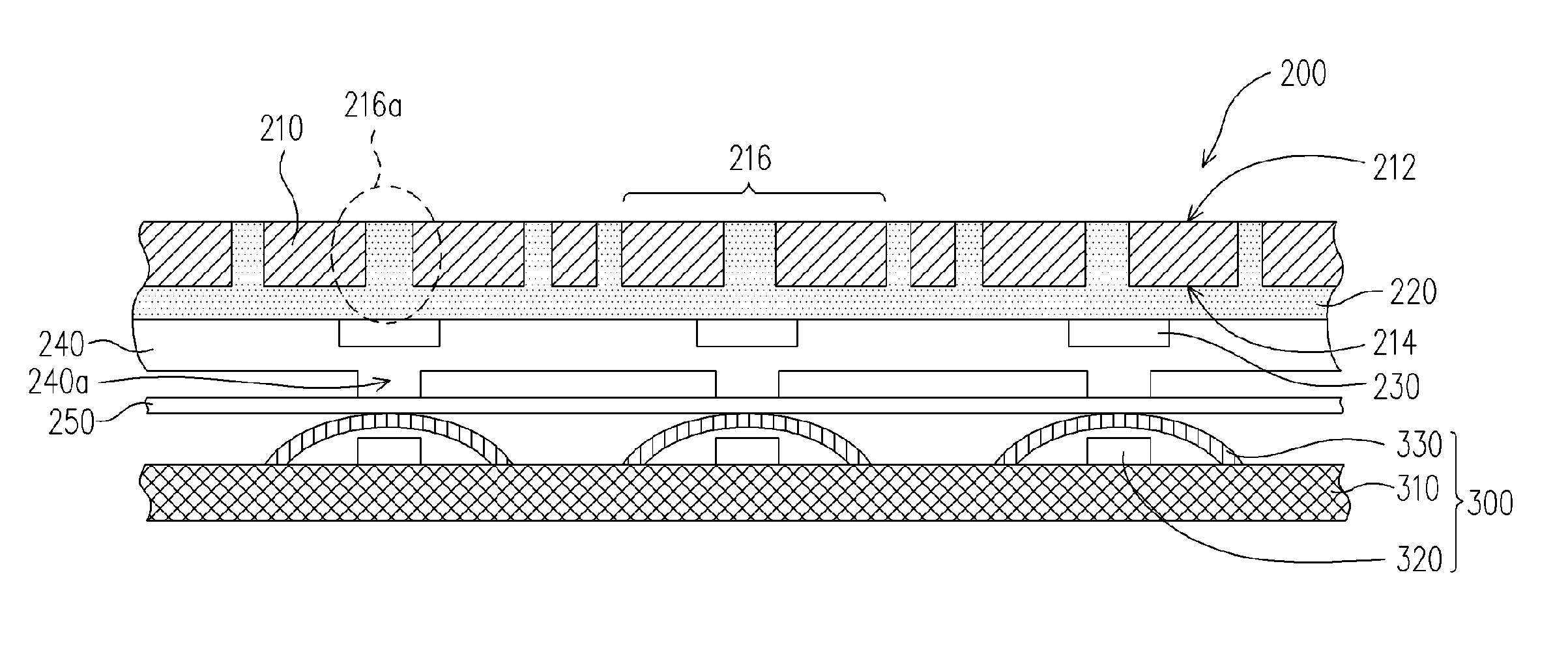

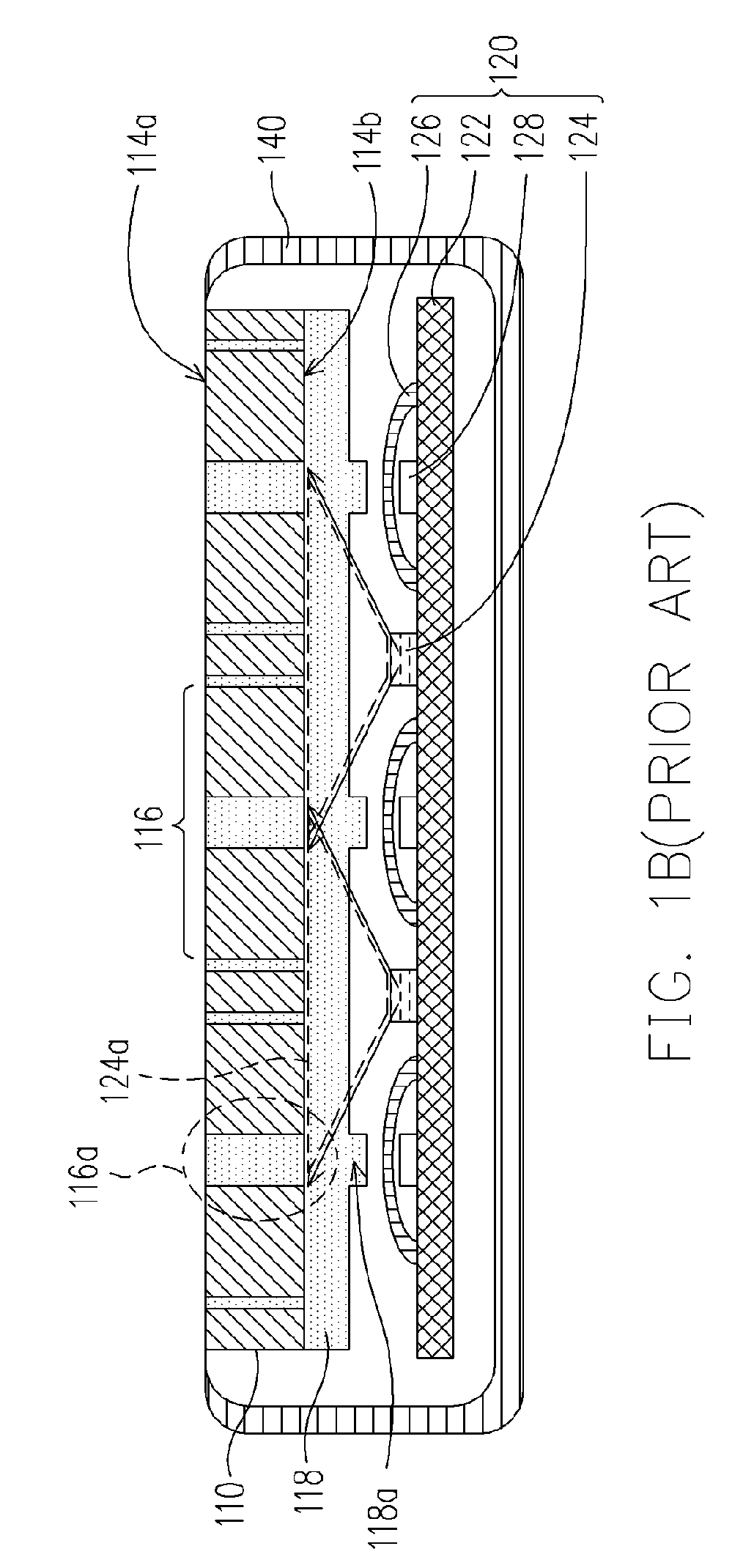

Keypad and manufacturing method thereof

InactiveUS20070023262A1Light transmitting uniformityIlluminating the keypad uniformlyEmergency actuatorsLegendsEngineeringLight emitting device

A method for manufacturing a keypad is provided. First, a patterned metallic sheet is provided. This patterned metallic sheet has a front surface and a rear surface and includes a plurality of key units that can be operated independently. These key units have a plurality of hollow structures thereon. Then, an adhesion-enhancing layer is formed on the rear surface of the patterned metallic sheet. Next, a color layer is formed on the adhesion-enhancing layer. A protruding point layer is formed on the adhesion-enhancing layer to cover the color layer. The protruding point layer has a plurality of protruding points that correspond to the positions of the key units. Finally, a light emitting device layer is disposed on the protruding point layer. The keypad manufactured according the disclosed method has a better light transmitting uniformity.

Owner:SPEED TECH

Preparation method of separators of lithium power batteries

InactiveCN105500724AStable discharge currentUniform pore sizeFlat articlesPolypropyleneLithium-ion battery

The invention relates to a preparation method of separators of lithium power batteries. The method comprises specific operation steps as follows: a, selection of raw materials: raw materials are selected from polypropylene raw materials having the high molecular weight and the narrow molecular weight distribution; b, tape casting and extrusion: tape casting and extrusion are performed, and the thickness is controlled to be uniform; c, cooling stretching and oriented crystallization: melt-extruded polypropylene is subjected to oriented crystallization under the traction of the tape casting roller speed; d, heat treatment crystallization: tape-cast films are placed into a large oven adopting circulating air; e, stretching and hole forming: films subjected to heat treatment recrystallization are sequentially subjected to preheating, multi-point cold stretching, multi-point hot stretching and high-temperature thermoforming. The technical process of the preparation method is simple and reasonable, the obtained separators of the lithium power batteries have the uniform hole diameter, the small hole diameter sinuosity and uniform light transmission, and discharging currents of the lithium power batteries are stable.

Owner:JIANGSU ANREDA NEW MATERIAL

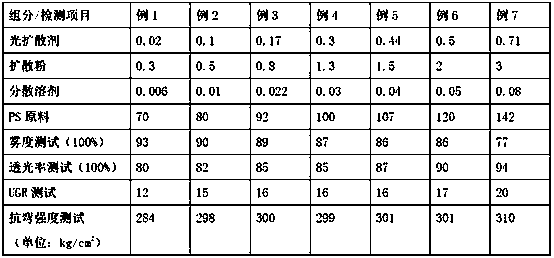

Preparation process of anti-dazzle diffusion plate

InactiveCN108873127AImprove experienceGlare suppressionDiffusing elementsOptical articlesHoneycombHoneycomb like

The invention relates to the technical field of illumination, in particular to a preparation process of an anti-dazzle diffusion plate. The preparation process comprises the steps of the steps of selecting 80 -120 parts of PS raw materials in parts by weight, adding a 0.1 to 0.5 parts light diffusant in parts by weight into the PS raw material, stirring and mixing 0.5 to 2 parts of diffusion powder and 0.01 to 0.05 part of a dispersing agent in parts by weight to form a mixture; adopting an extrusion process, adding the mixture into an extrusion forming machine to be extruded to form a diffusion plate; carrying out embossing on the diffusion plate by adopting an embossing roller with the pattern as convex polygons to make a honeycomb-shaped diffusion plate with a concave polygon pattern, and selecting cutter for cutting the diffusion plate. The honeycomb-shaped diffusion plate can shield light rays in all directions, glare can be effectively inhibited when a user sees from all directions, and the purpose of preventing glare can be achieved. When the anti-dazzle diffusion plate manufactured by adopting the process and the formula is applied to practical application, the light sourceis comfortable and soft, light transmission is uniform, glare is effectively controlled, and user experience is better.

Owner:DONGGUAN XINJU OPTRONICS INC

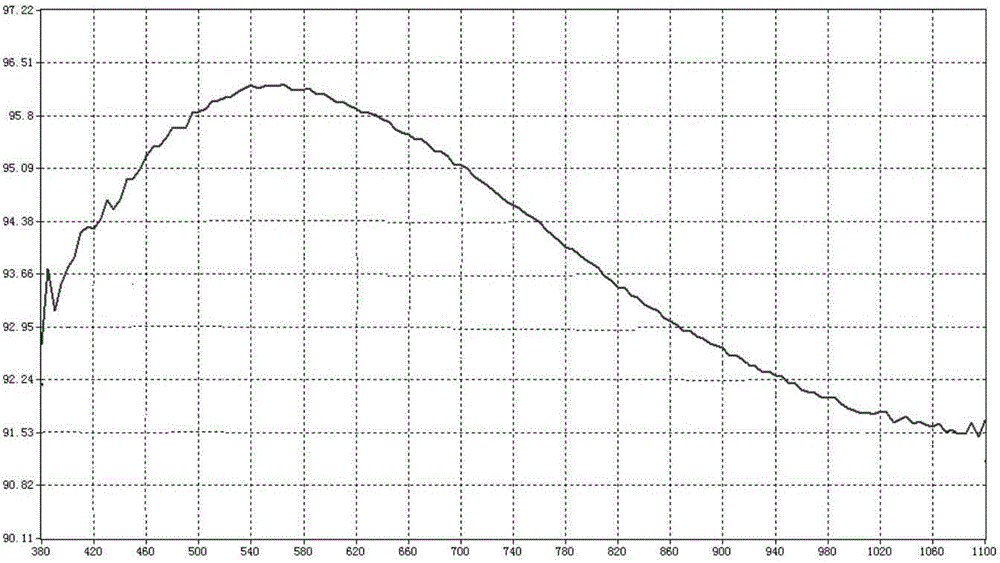

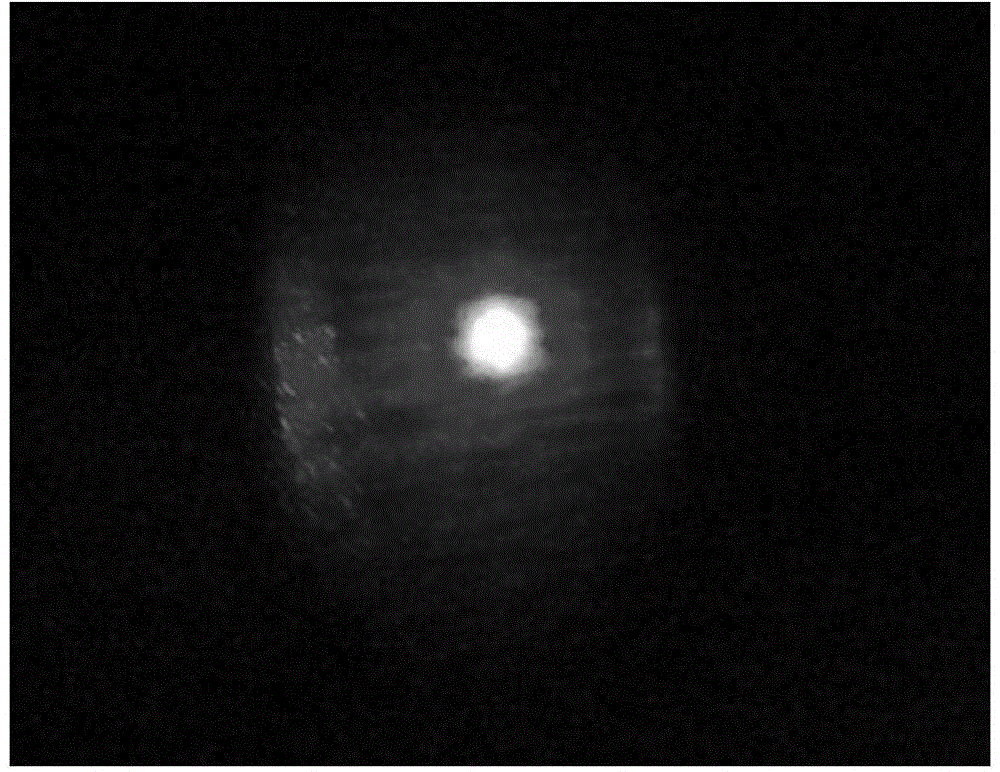

Anti-reflection anti-dazzle liquid for LED glass lampshade and preparation method of anti-reflection anti-dazzle liquid

The invention discloses anti-reflection anti-dazzle liquid for an LED glass lampshade and a preparation method of the anti-reflection anti-dazzle liquid, belonging to the technical field of glass dazzle prevention. The anti-reflection anti-dazzle liquid for the LED glass lampshade is prepared by compounding silica nano-sol and micron-order silica emulsion. The method comprises the following steps: dispersing a silicate ester in an organic solvent, adding 0.1-0.3N of alkaline solution, stirring and reacting for at least 24 hours while controlling the temperature to be 20 DEG C below zero to 25 DEG C, and performing rotary evaporation on the reaction solution after the reaction, thereby obtaining the silica nano-sol; dispersing the micron-order silica particles in the organic solvent, adding 0.5-1g of an organosilicon surfactant, and mechanically stirring, thereby obtaining the micron-order silica emulsion; adding the prepared micron-order silica emulsion into the silica nano-sol, stirring, and reacting, thereby obtaining the uniformly dispersed anti-reflection anti-dazzle liquid for the LED glass lampshade. The anti-dazzle liquid disclosed by the invention can bear high temperature, and the LED glass lampshade treated by utilizing the anti-dazzle liquid is fine in surface structure, high in yield, low in light loss, uniform in light transmission and high in light transmittance.

Owner:YANGZHOU MINGSHENG NEW TECH

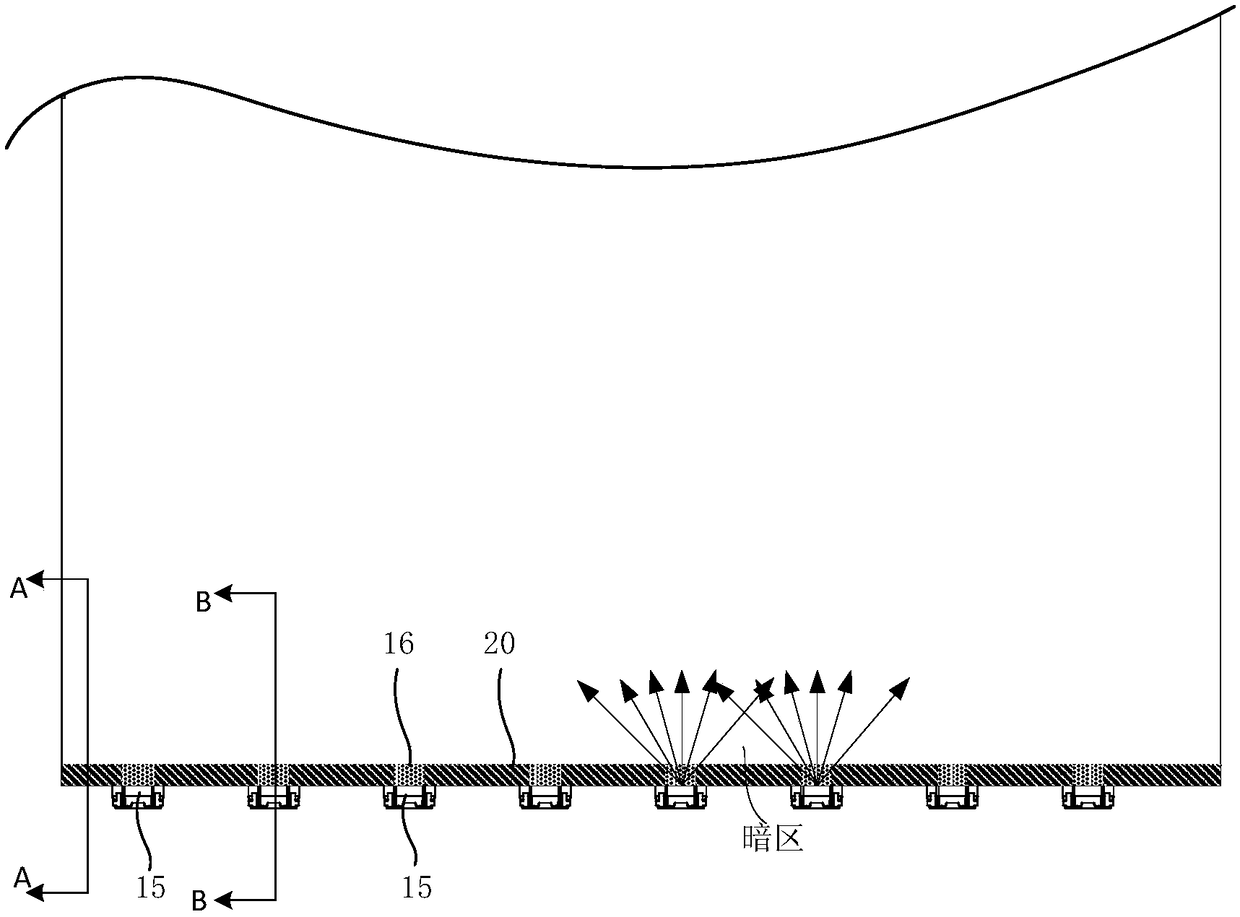

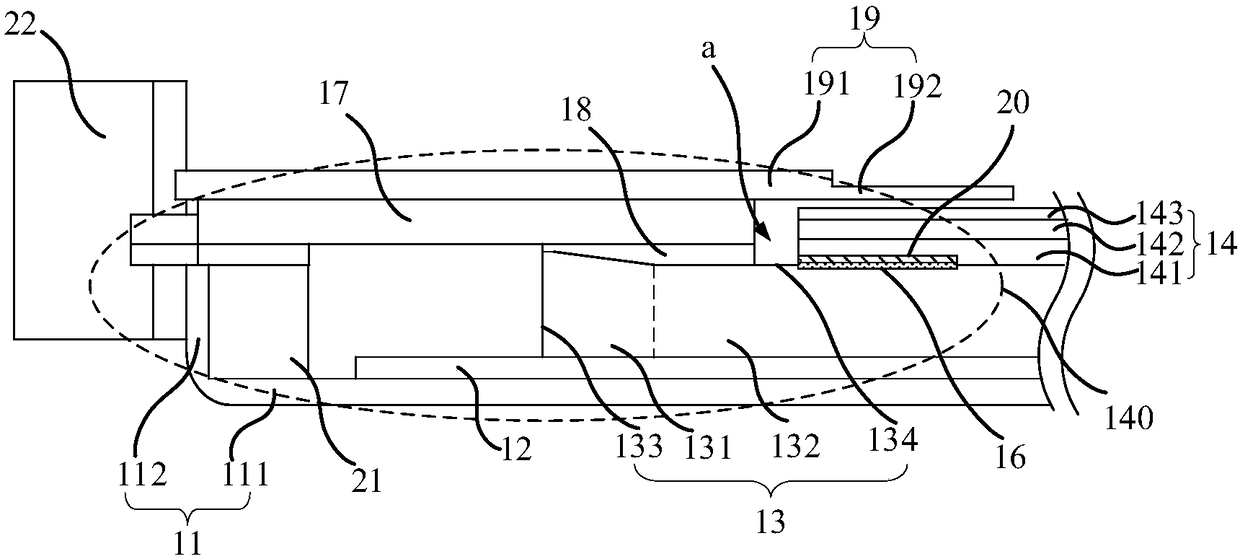

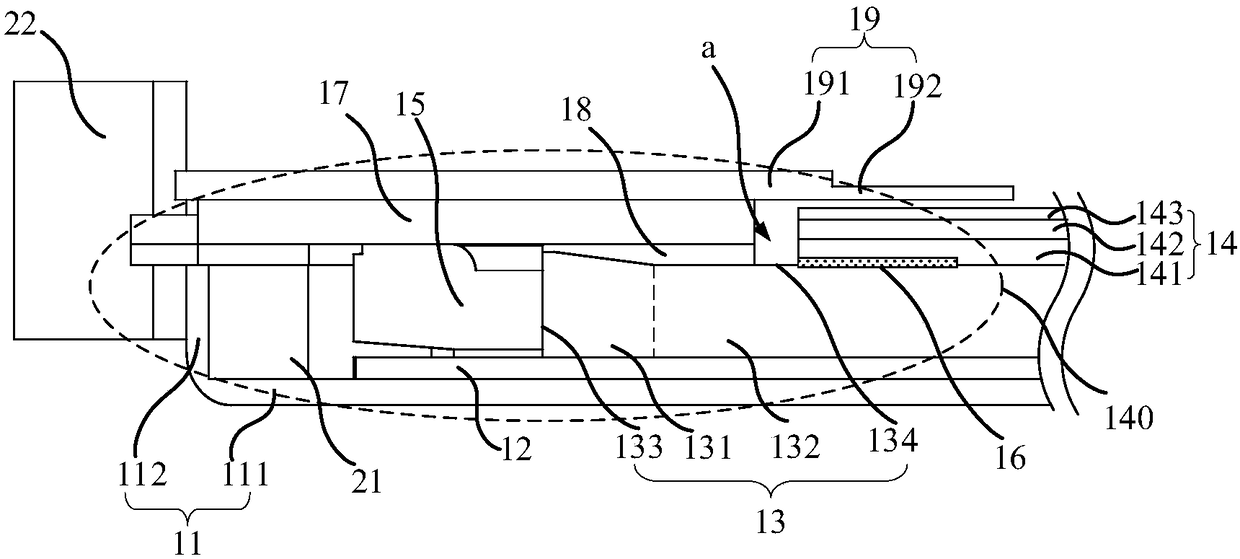

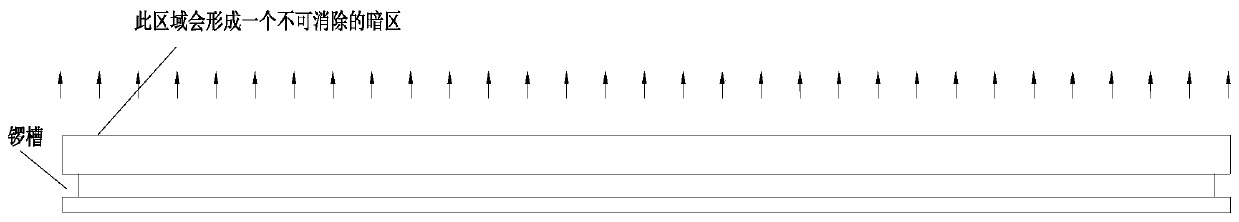

Backlight module and electronic device

ActiveCN108317436AIncrease brightnessPrevent the phenomenon of dark areasMechanical apparatusPoint-like light sourceParallaxLight guide

The invention discloses a backlight module and an electronic device. The backlight module comprises a light guide plate, a plurality of light sources and brightening layers. The light guide plate comprises a light inlet face and a light outlet face. The light sources are arranged on the side, with the light inlet face, of the light guide plate and are arranged at intervals. Each brightening layeris arranged between every two adjacent light sources and used for improving the luminance between the two adjacent light sources, so that it is avoided that a dark area appears between two adjacent light sources. Therefore, the backlight module is uniform in outlet light, and the light and shade parallax is avoided.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

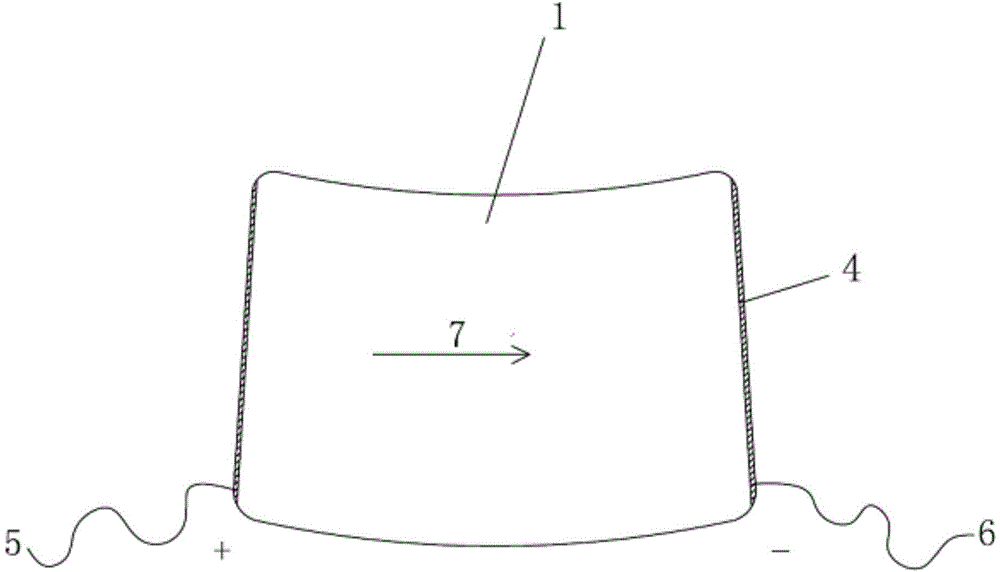

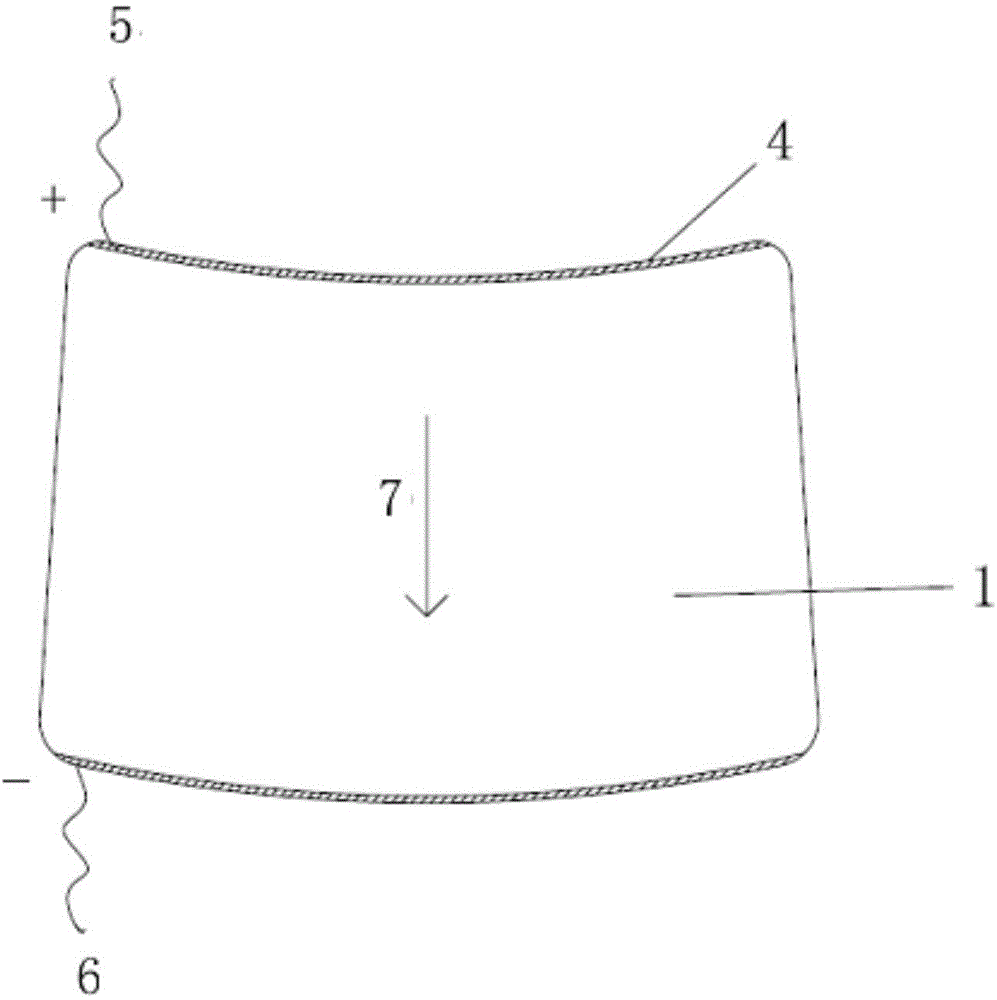

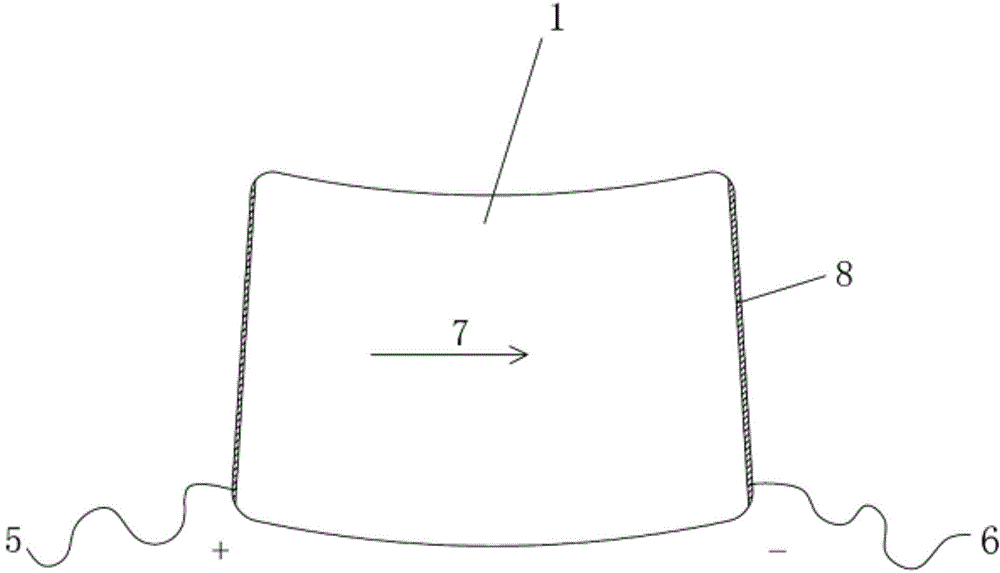

Electrically heated automobile windshield glass

The invention relates to the technology of automobile glass, and discloses an automobile electric heating glass window and a manufacturing method. Firstly, trapezoid cutting, edge polishing and washing are carried out on an FTO conductive glass substrate, and the FTO conductive glass substrate is dried to be used later; secondly, the hot bending and the tempering process are carried out on the processed FTO conductive glass substrate through a die, and after bent glass with the needed strength and curvature is obtained, the edge and two opposite frames of the glass substrate are printed or pasted with conductive metal strips to form the positive electrode and the negative electrode; lastly, the positive electrode metal strip and the negative electrode strip are connected with a power source through an electrical connecting device, and then the automobile electric heating glass window is manufactured. The face heating method is adopted, the automobile glass can be heated more evenly, and bursting caused by uneven heating of the glass is effectively prevented; under the high temperature, the sheet resistance change is very small, the heating performance of the automobile electric heating glass window is changed little even when the automobile electric heating glass window is processed through heating bending and tempering, the appearance of an automobile can be beautified, and the back vision effect of a driver can be improved.

Owner:DALIAN HEPTACHROMA SOLAR TECH CO LTD

Position detecting sensor and position detector

ActiveUS8885178B2Decrease and prevent generationUniform light transmissionUsing optical meansInput/output processes for data processingLocation detectionDisplay device

A position detecting sensor includes a grid structure composed of plural electrodes extending in a first direction and plural electrodes extending in a second direction perpendicular to the first direction. The electrodes have light permeability. In a rectangular area defined by four cross-points, where two adjacent electrodes extending in the first direction and two adjacent electrodes extending in the second direction cross each other, a dummy pattern is disposed so as to provide uniform optical characteristics for the sensor. At least some of the electrodes extending in the first direction are shaped to include inclinations relative to the first direction, so as to minimize the Moire effect that may develop between the electrodes and an array of pixels in an overlaid display device. Also, at least some of the electrodes extending in the first direction are shaped to be line-symmetric about a straight line extending in the first direction.

Owner:WACOM CO LTD

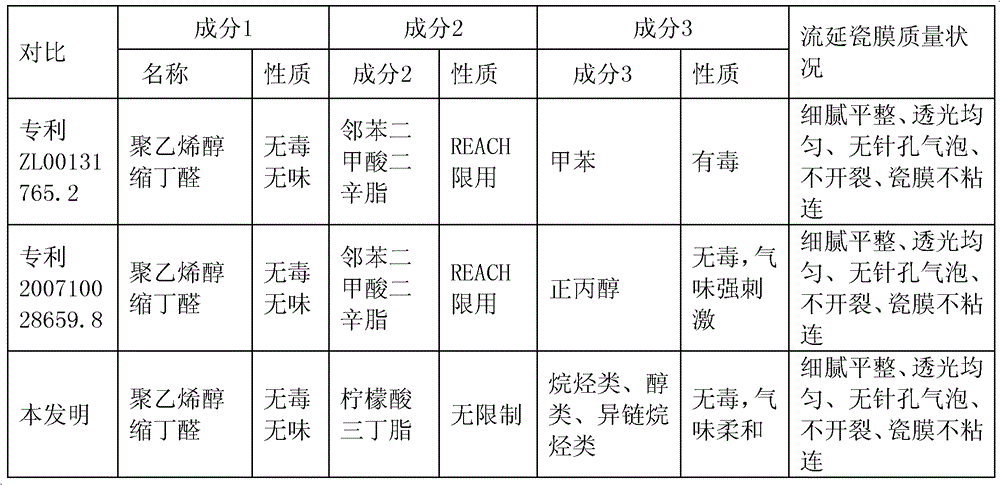

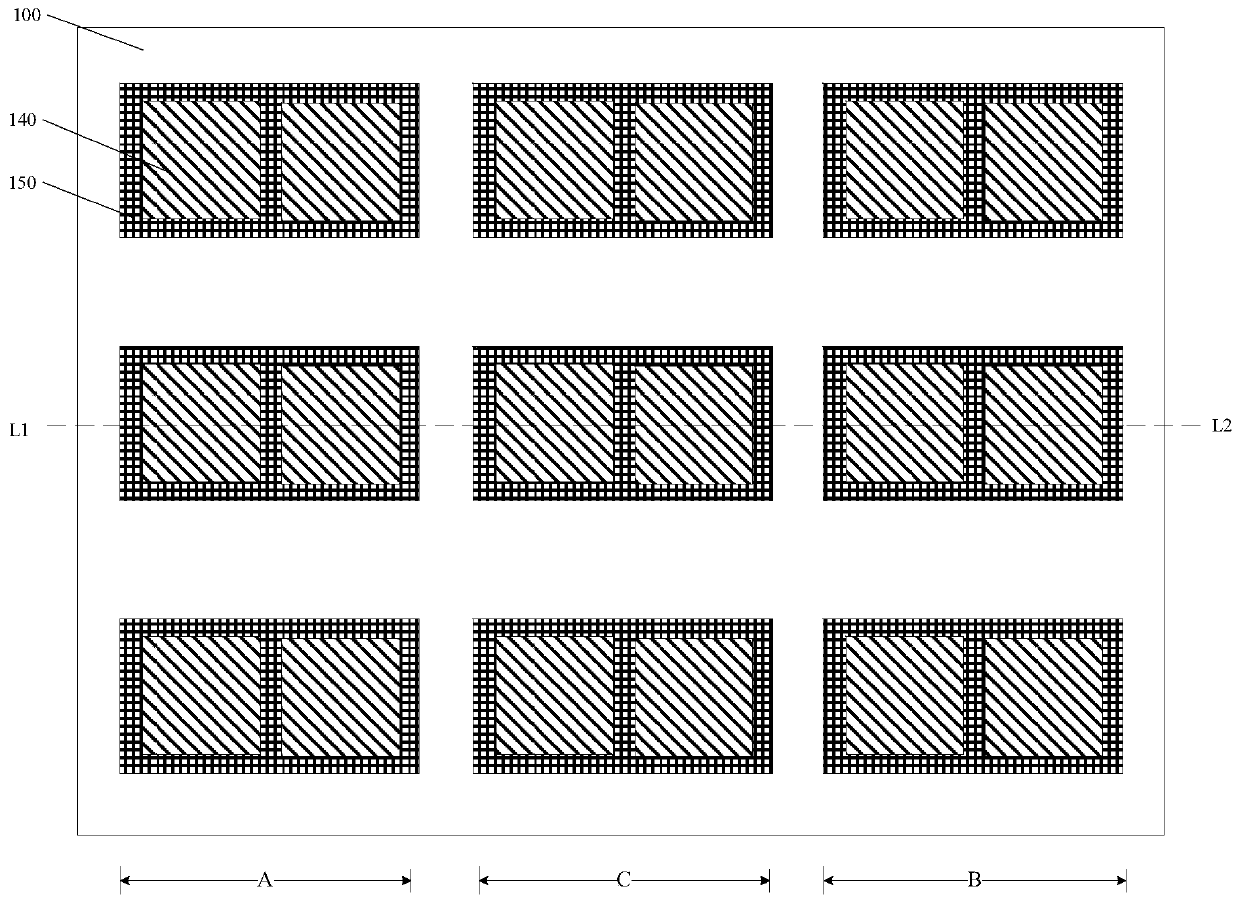

Environment-friendly bonding agent for ceramic sheet tape casting and preparation method of bonding agent

The invention provides an environment-friendly bonding agent for ceramic sheet tape casting and a preparation method of the bonding agent. The bonding agent comprises the following components in percentage by weight: 15%-30% of polyvinyl butyral, 5%-14% of citric acid ester compounds, 56%-80% of solvent formed by selecting at least two of alkanes, alcohols and heterogeneous alkanes. The preparation method comprises the following steps of: adding polyvinyl butyral into the solvent, and stirring until resin is dispersed fully; then adding the citric acid ester compounds and stirring, sealing, standing and defoaming for 4-8 hours; and opening a cover and stirring until the resin is dissolved fully and is of a transparent shape, and sealing and standing for 8-36 hours. The bonding agent has no residual impurity after high-temperature decomposition, has good adhesion stability, is used for tape casting and molding an electronic ceramic film, and is mixed and is subjected to ball milling with ceramic powder materials, thereby obtaining uniformly dispersed ceramic slurry; the ultrathin electronic ceramic film sheet obtained by tape casting technology is neat and smooth, and has no needle holes, no air bubbles, no cracks, no uneven thickness, no adhesion film and other abnormalities; and the finished product film sheet has favorable lamination property and ceramic operation intensity, has tiny volatile flavor, and is friendly.

Owner:广州三则电子材料有限公司

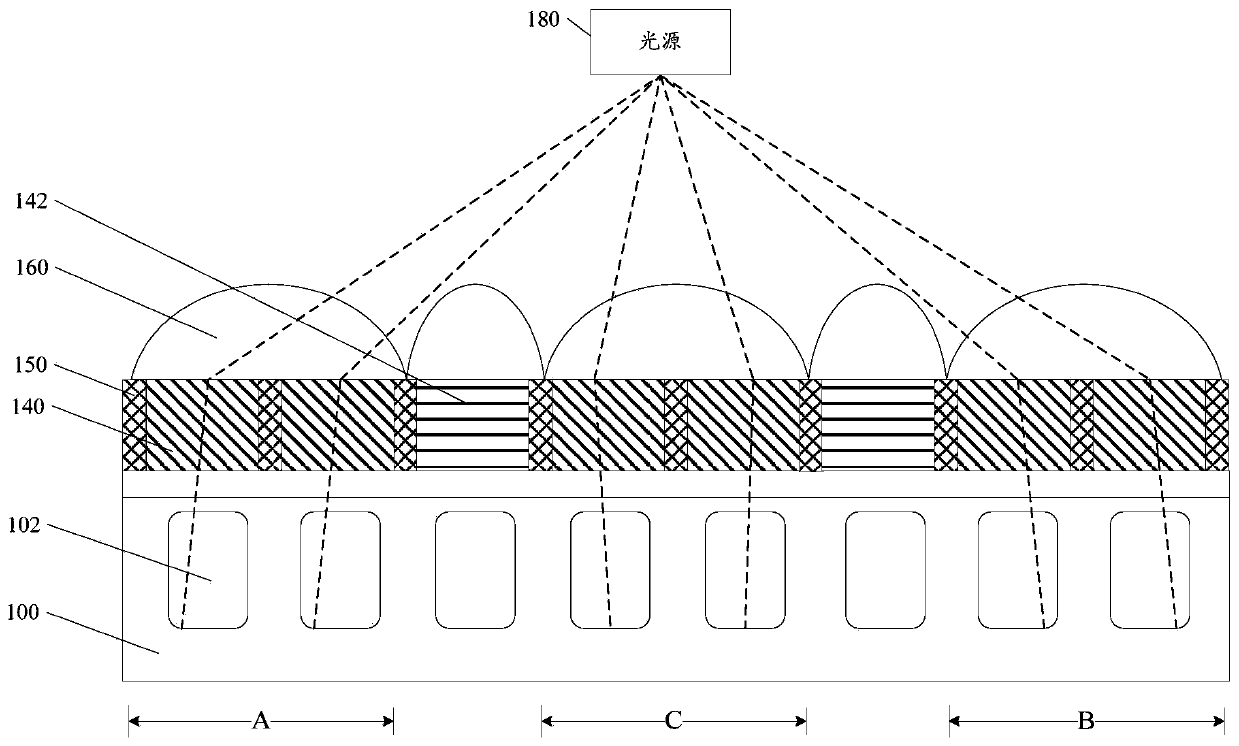

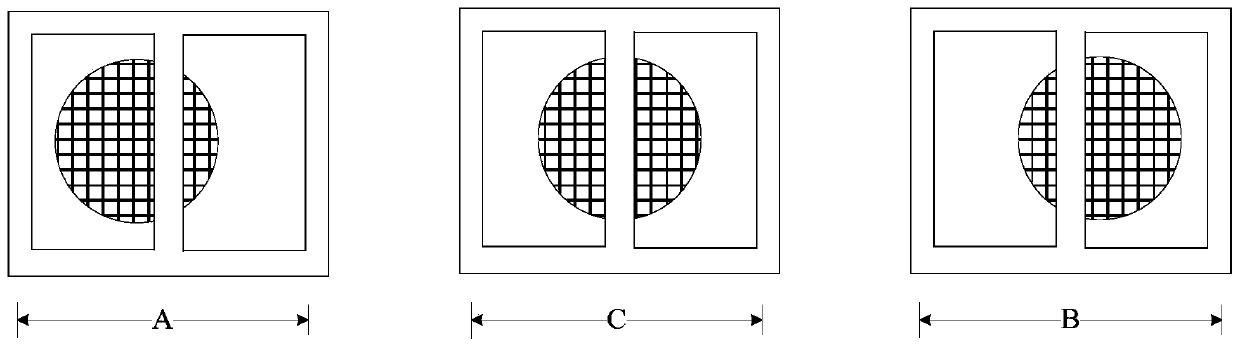

Image sensor and forming method thereof

InactiveCN109887938AAppropriate thicknessFocusRadiation controlled devicesColor filter arrayComputer science

The invention provides an image sensor and a forming method thereof. The image sensor comprises: a semiconductor substrate; a pixel device located in the semiconductor substrate; color filter pairs arranged in rows for PDAF, wherein the color filter pairs are located on the surface of the semiconductor substrate, and each row has a plurality of color filter pairs; in two color filters of each color filter pair, the thickness of the color filter deviating toward the row center of the located row is less than the thickness of the color filter deviating from the row center of the located row; andthe thickness direction is perpendicular to the surface of the semiconductor substrate. The scheme provided by the invention is conducive to compensating the influence caused by the positions of thecolor filters and improving the focusing effect of the PDAF technology.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

Key assembly, key switch assembly and keyboard

The invention discloses a keyboard that comprises a key assembly, a key switch assembly and a semi-transparent film. The key assembly includes a transparent material layer, a non-transparent film, and a transparent elastomer layer. The key switch assembly consists of a substrate, at least a protrudent switch, and a light guide film (LGF). And the semi-transparent film is arranged between the transparent material layer and the LGF or is arranged at the upper surface of the transparent material layer, so that light that is refracted by a light guide lattice in a refraction region towards a corresponded light-transmitting pattern region can be shielded at least. According to the keyboard provided in the invention, a light guide lattice that is on an LGF in a refraction region can not be seen from the surface of a pattern; and light transmission in a light-transmitting pattern region is uniform; therefore, user experience is improved. In addition, the invention also brings forward a key assembly and a key switch assembly.

Owner:BYD CO LTD

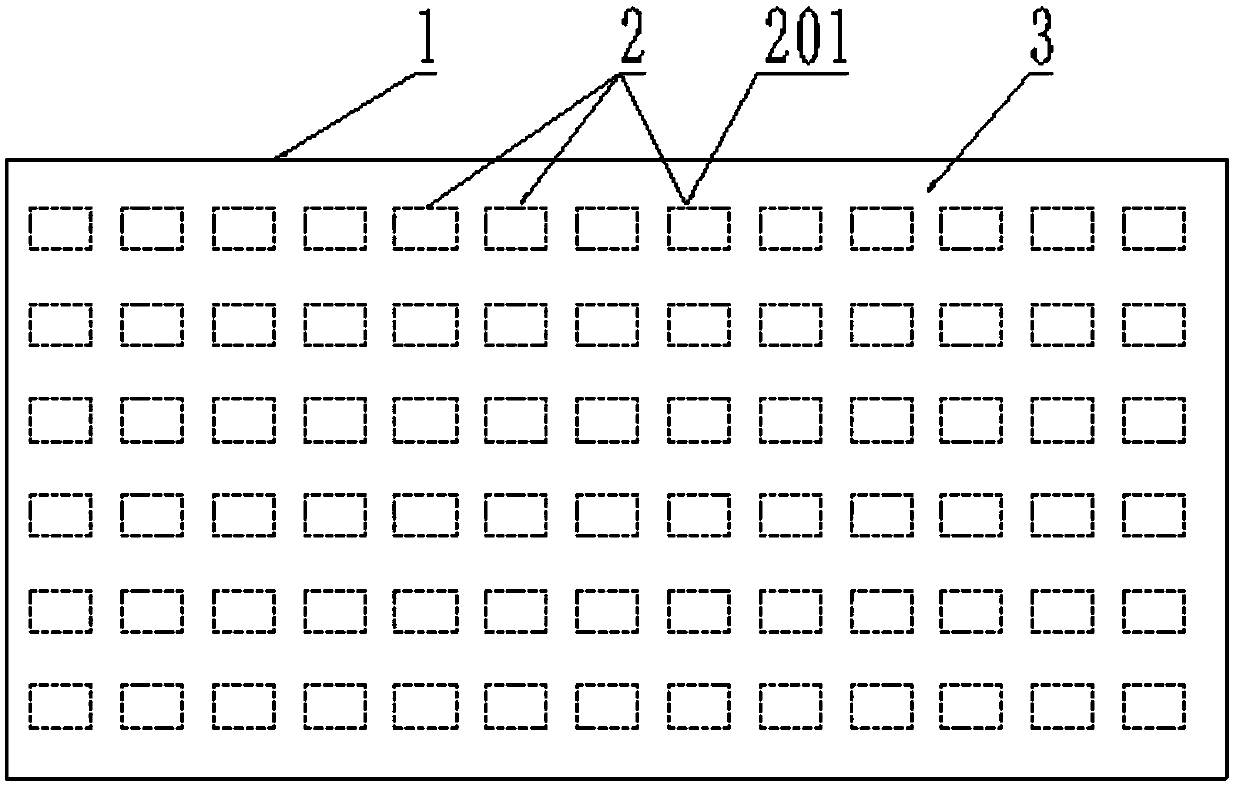

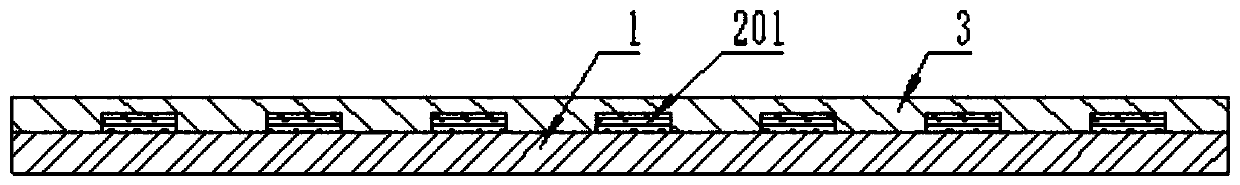

LED lamp panel and preparation method thereof, and display device

InactiveCN110534627AUniform light transmissionRealize thin and light developmentSolid-state devicesSemiconductor devicesAdhesiveDisplay device

The invention provides an LED lamp panel. The LED lamp panel comprises: a circuit board; a LED chip array arranged on the circuit board and comprising a plurality of LED chips, wherein the LED chip array is electrically connected with the circuit board; and a packaging layer, wherein the packaging layer covers the LED chip array, wherein the packaging layer comprises a packaging adhesive. Based onthe LED lamp panel provided by the invention, the invention further provides a preparation method of the LED lamp panel and a display device. According to the LED lamp panel and the preparation method thereof and the display device, the LED lamp panel is high in light emitting efficiency, good in heat dissipation, small in LED chip size and uniform in light emitting, a thick and heavy traditionaltelevision backlight diaphragm can be removed, the light mixing distance is reduced, the ultrathin module design is achieved, and light and thin development of a backlight module is facilitated.

Owner:HISENSE VISUAL TECH CO LTD

Fully-compatible ink-jet printing flame-retardant forward-blowing lamp sheet

PendingCN112521646AFast ink absorptionHigh color reproductionFireproof paintsDuplicating/marking methodsPolymer scienceWeather resistance

The invention discloses a fully-compatible ink-jet printing flame-retardant front-spraying lamp sheet which is characterized in that a back coating is arranged on the back surface of a base material,a bottom coating agent layer is arranged on the front surface of the base material, and a fully-compatible ink-jet printing flame-retardant coating is arranged on the bottom coating agent layer; the fully-compatible ink-jet printing flame-retardant coating is prepared from flame-retardant modified acrylic resin emulsion, and a halogen-free flame retardant, an anti-dripping agent, a smoke suppressor, a leveling agent and an anti-foaming agent are added; the bottom coating agent layer is made of a water-based two-component polyurethane binder; the base material is a transparent PET film; the lamp sheet has the advantages that various ink printing can be compatible; the coating is high in ink absorption speed, capable of adapting to high-speed printing and high in color rendition degree; thelamp sheet is waterproof, ultraviolet-proof, not easy to fade, super-strong in weather resistance, high-temperature-resistant, low-temperature-resistant, high in flatness, high in tensile strength andlong in service life; the lamp sheet is white, fine, semitransparent and uniform in light transmittance, and the light transmittance reaches 50-60%; the flame retardant property is good, the fire isextinguished immediately after leaving the fire, no obvious molten drops exist, and less combustion smoke is generated.

Owner:江苏耐斯数码科技股份有限公司

A kind of impact-resistant high-efficiency flame-retardant decorative film and its preparation method

The invention relates to an impact-resistant and high-efficiency flame-retardant decorative film and a preparation method thereof. The decorative film is prepared from the following raw materials in parts by weight: 80-120 parts of PVC resin powder, 30-50 parts of plasticizer, and 0.5-5 parts of soybean oil , 18-45 parts of composite flame retardant, 0.5-5 parts of formaldehyde absorbent, 0.5-5 parts of environmental stabilizer, 0.5-5 parts of smoke suppressant, and 5-15 parts of nano-calcium powder. Using PVC resin powder as the main raw material, adding plasticizers, composite flame retardants, soybean oil, formaldehyde absorbents, stabilizers, smoke suppressants, and nano-calcium powders as functional additives, through high-speed stirring and mixing, molding extrusion, The decorative film is produced by first rolling machine plasticizing, second rolling machine plasticizing, filtering, calendering, cooling, and coiling. The present invention optimizes the production process parameters by optimizing the formula, and the prepared decorative film has the characteristics of excellent flexibility, high-efficiency flame retardancy, environmental protection, high compliance, good impact resistance, etc., and also has the effect of purifying formaldehyde , has a good market prospect.

Owner:浙江明士达股份有限公司

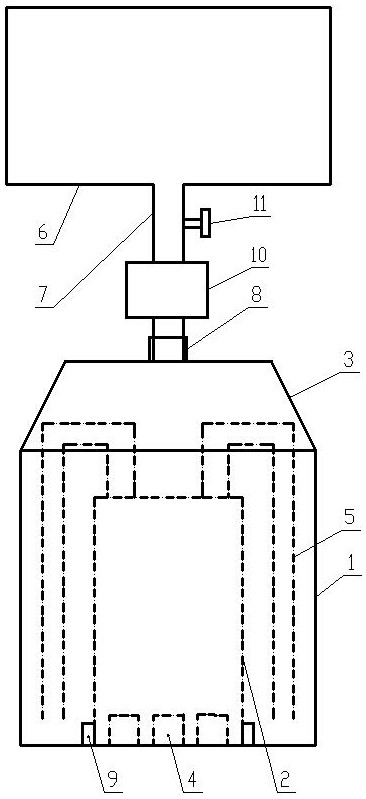

Tourism souvenir and using method thereof

InactiveCN110949050AAchieve lightingEasy to viewMechanical apparatusLighting elementsLight irradiationLight guide

The invention discloses a tourism souvenir and a using method thereof, and belongs to the technical field of the souvenirs. The tourism souvenir comprises a hollow cylinder body and a view mechanism which is in threaded connection with the interior of the hollow cylinder body. The tourism souvenir is arranged in an up-down spiral storage form so that the view mechanism can be conveniently retracted into the hollow cylinder body for storage and then carried, customers can be effectively attracted for purchase, when the view mechanism is rotated out of the hollow cylinder body, the tourism souvenir can be conveniently displayed, at night, a control switch is turned on, light irradiation is performed through an LED illumination lamp post, light is conducted through a light guide column, so that lighting of a scenic spot pattern is achieved, meanwhile, uniform light transmission of the hollow cylinder body 1 is achieved through light diffusion, then the hollow cylinder body serves as a bedside lamp to be used, through cooperation of a first optical fiber bundle, an optical fiber connector and a second optical fiber bundle, light display of a plurality of optical fiber light guide lampposts is achieved, and the ornamental value and the practicability of the tourism souvenir in the low light environment are effectively enhanced.

Owner:ZHENGZHOU INST OF TECH

Modified polyethylene plastic particle for fruit tree cap bag

The invention relates to a modified polyethylene plastic particle for a fruit tree cap bag, which is characterized in that reflecting agents carboxymethyl cellulose and kieselguhr, a dispersant lubricant and a light absorber carbon black are added into the base material polyethylene to prepare the polyethylene plastic film with high light transmission uniformity; the added toughener can enhance the toughness and low temperature resistance of the product; and the manufacturing cost is low. According to the invention, the product cost is low, the material has the advantages of high toughness and low loss tendency, and the fruit cultivated by using the fruit tree cap bag has the advantages of uniform color and regular shape.

Owner:薛申生

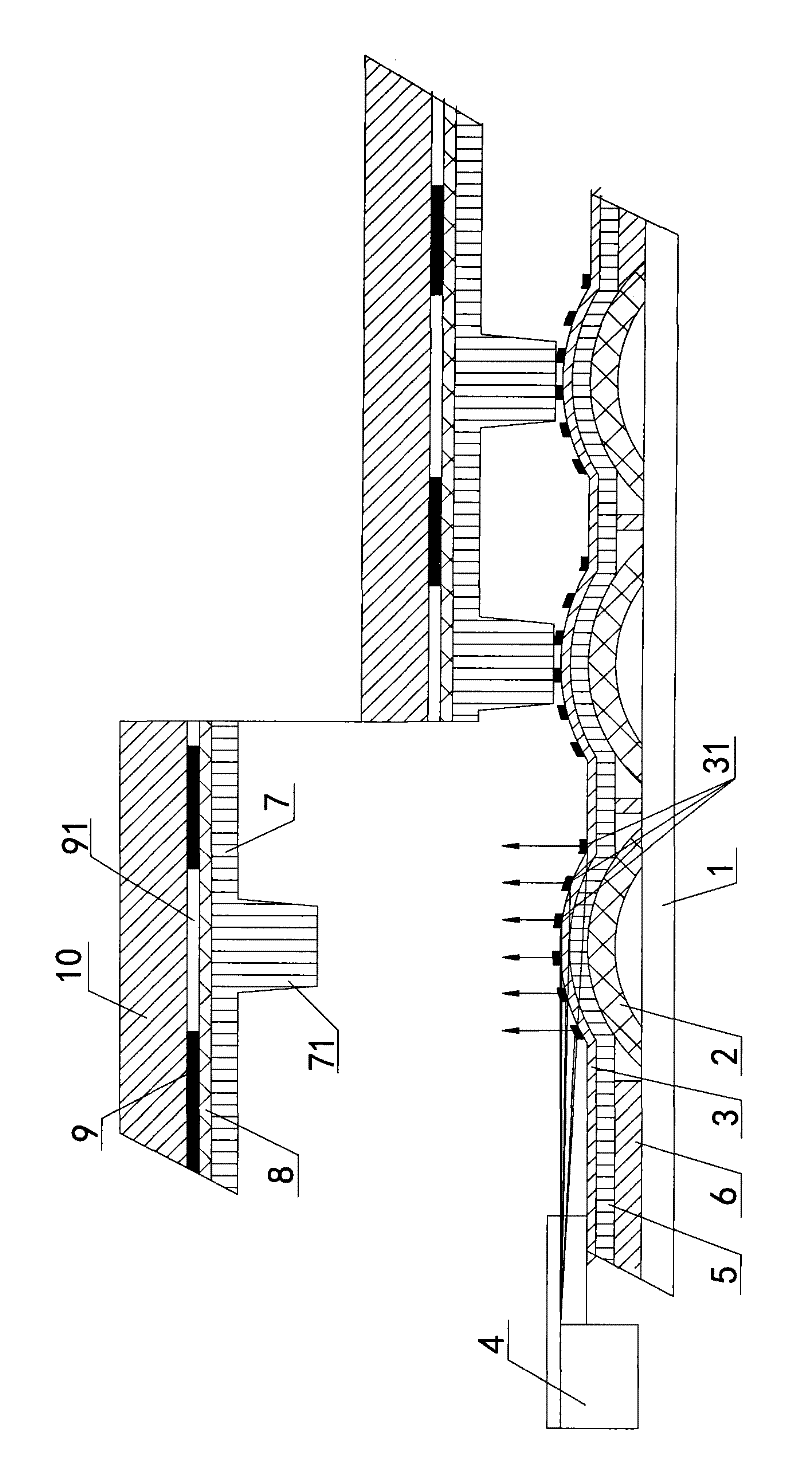

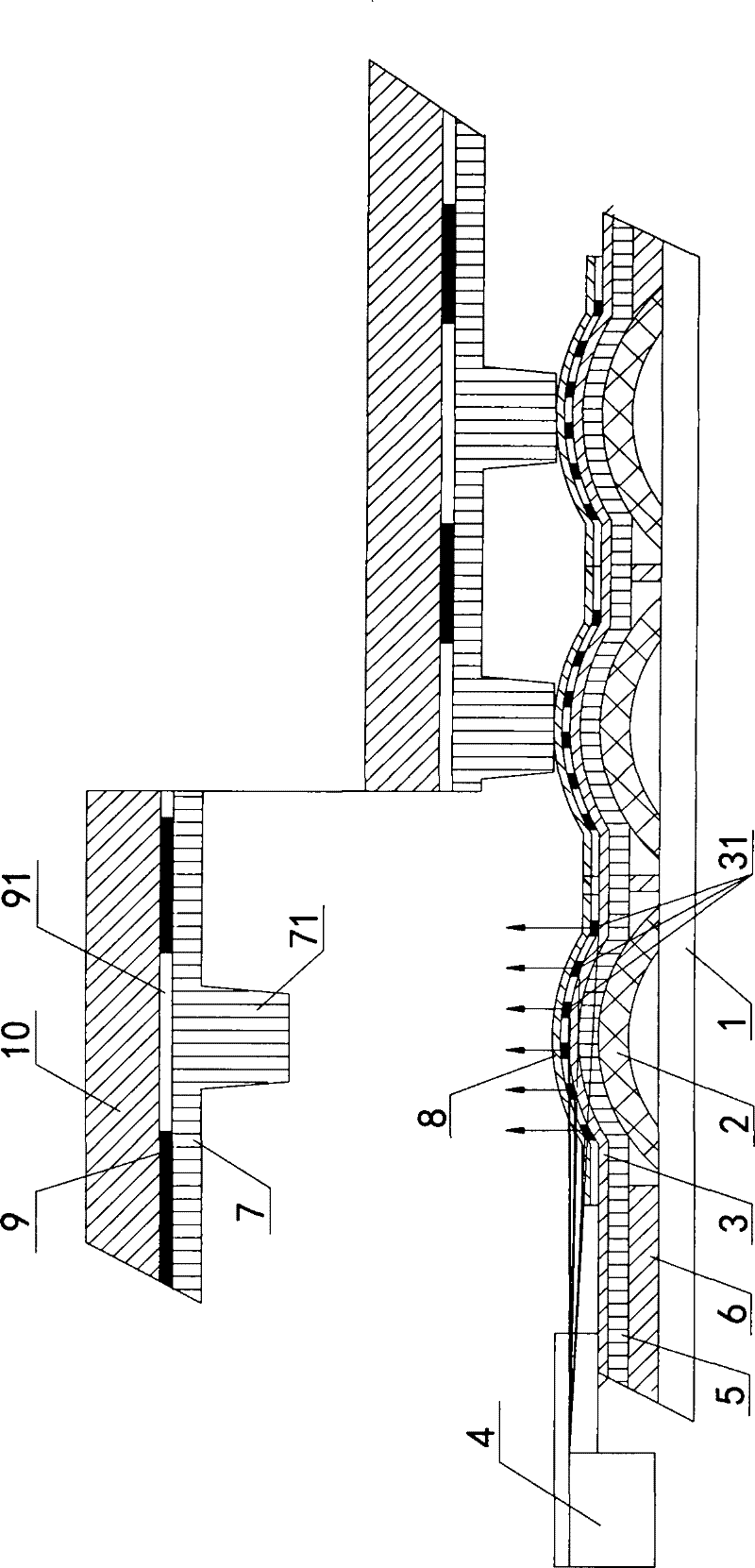

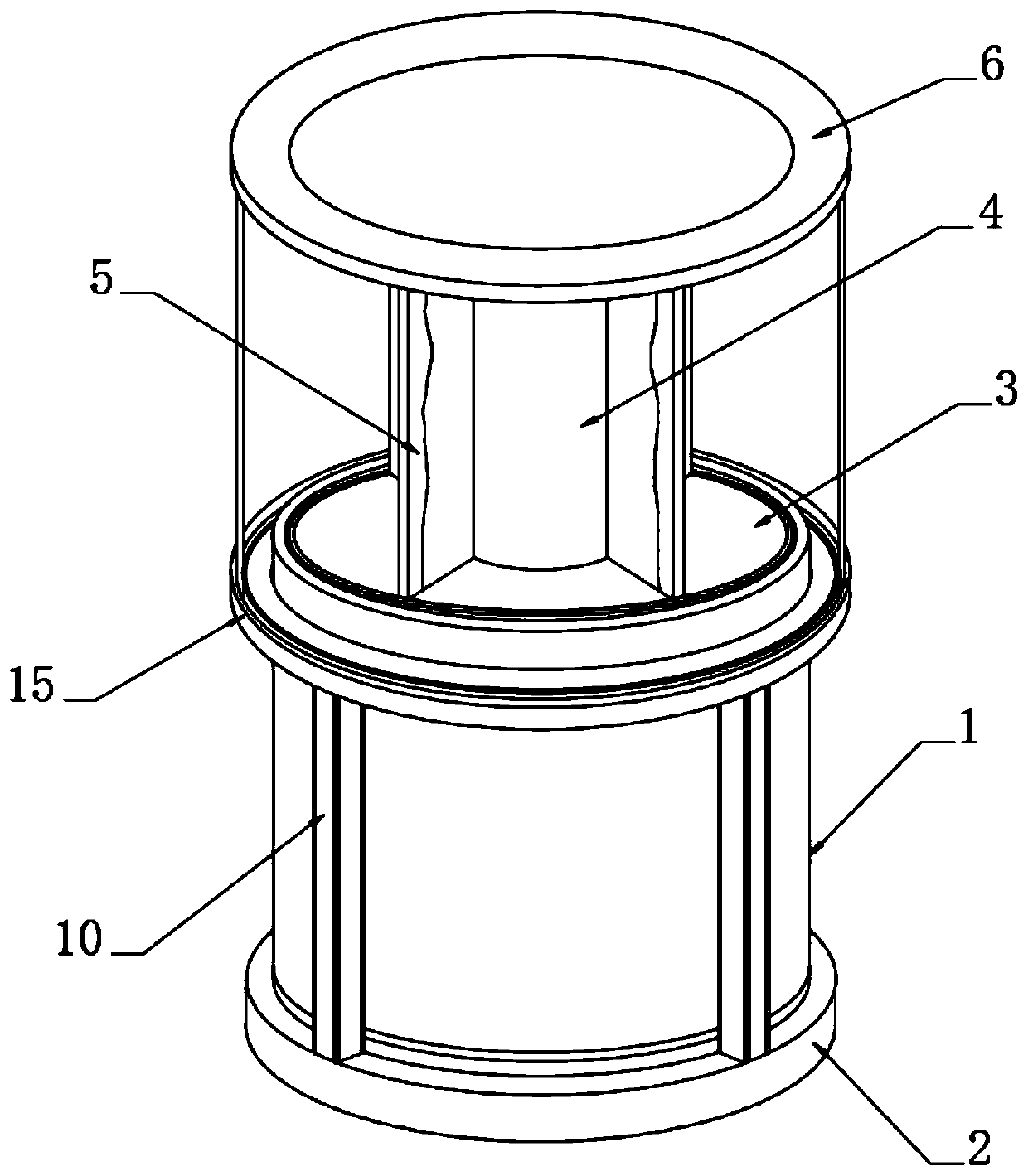

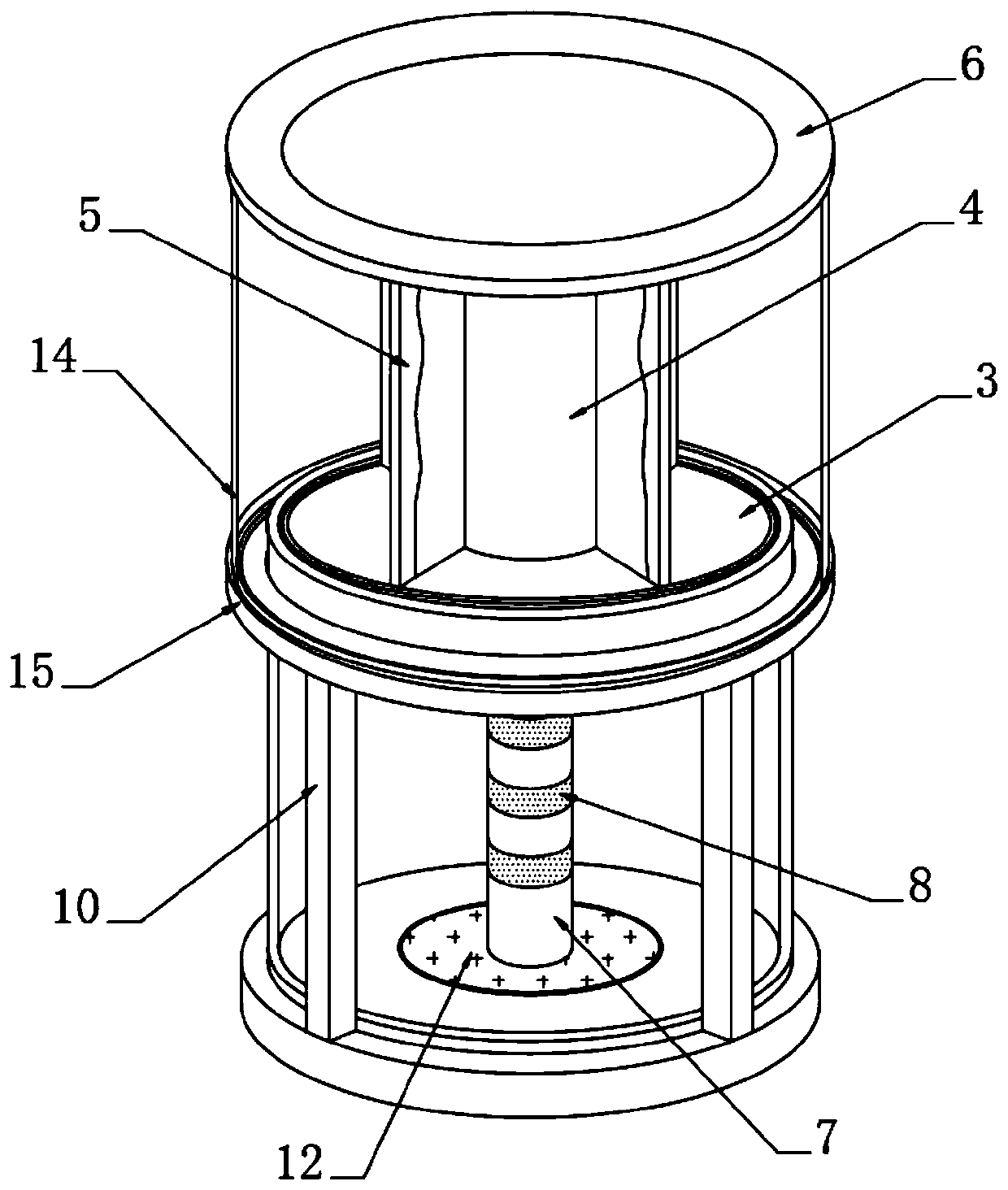

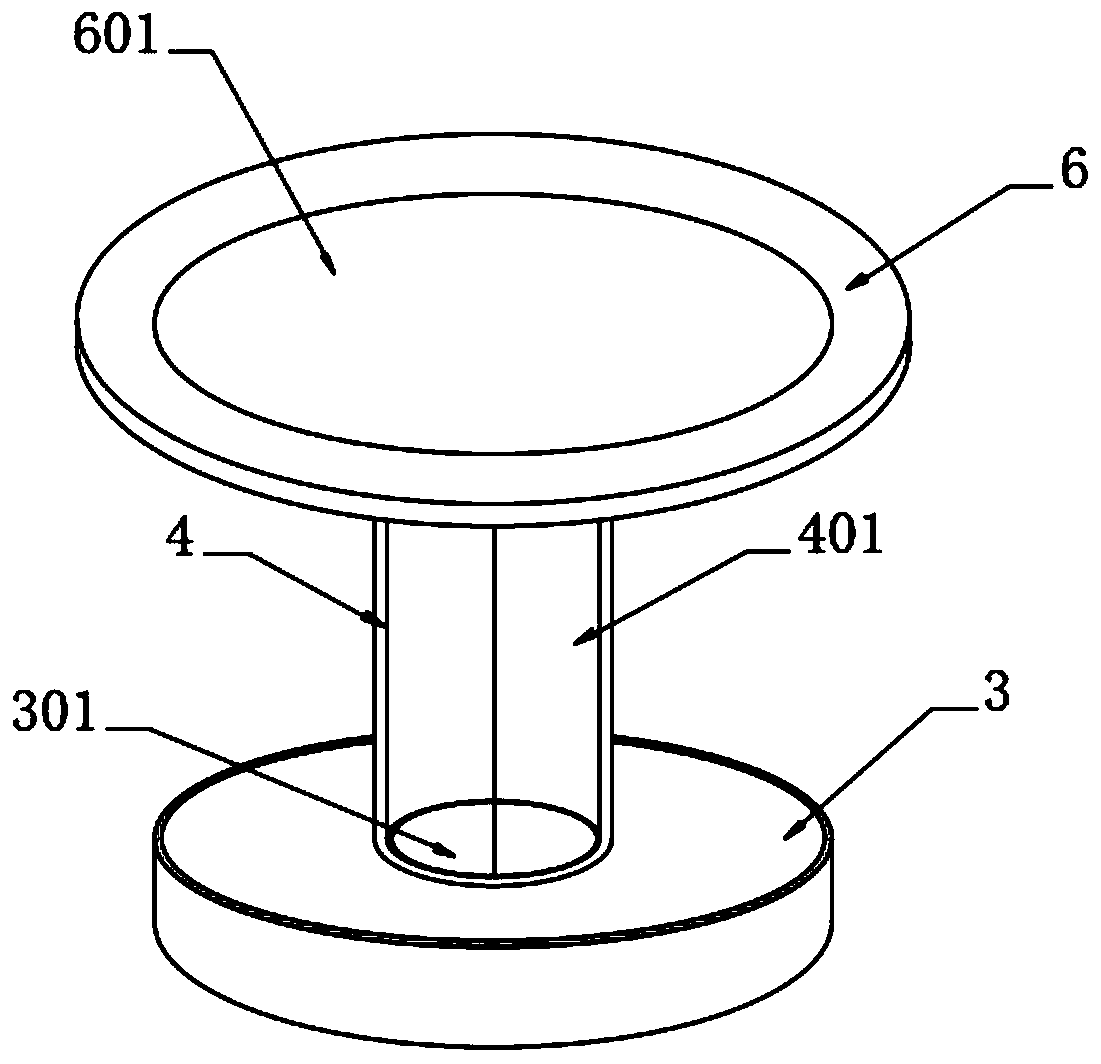

Novel pump-free internal circulation type photosynthetic biological hydrogen production reactor

ActiveCN112266848AReduce consumptionCompact structureBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringMechanical engineering

The invention provides a novel pump-free internal circulation type photosynthetic biological hydrogen production reactor. The novel pump-free internal circulation type photosynthetic biological hydrogen production reactor comprises an outer reaction barrel, an inner reaction barrel and a gas collecting device, wherein a barrel cover is arranged at the top of the outer reaction barrel; the inner reaction barrel is arranged in the outer reaction barrel; an outer annular reaction chamber is formed between the inner reaction barrel and the outer reaction barrel; an inner circular reaction chamberis formed in the inner reaction barrel; the edge of the lower end of the inner reaction barrel is in contact with the bottom of the outer reaction barrel; a liquid permeating hole is formed in the lower part of the inner reaction barrel; a gas guide pipe is arranged at the top of the inner reaction barrel; an outlet of the gas guide pipe extends into the bottom of the outer annular reaction chamber; an exhaust port is formed in the barrel cover; and a gas inlet of the gas collecting device is connected with the exhaust port in the barrel cover. The novel pump-free internal circulation type photosynthetic biological hydrogen production reactor is simple and compact in structure and convenient to operate; the reactor is designed to be cylindrical, so that light is uniformly transmitted, andthe occupied area is small; and gas produced by the reactor is guided into reaction liquid again, so that stirring aerodynamic force is provided for the reaction liquid, energy consumption is effectively reduced, and low-energy-consumption and high-efficiency hydrogen production is realized.

Owner:HENAN AGRICULTURAL UNIVERSITY

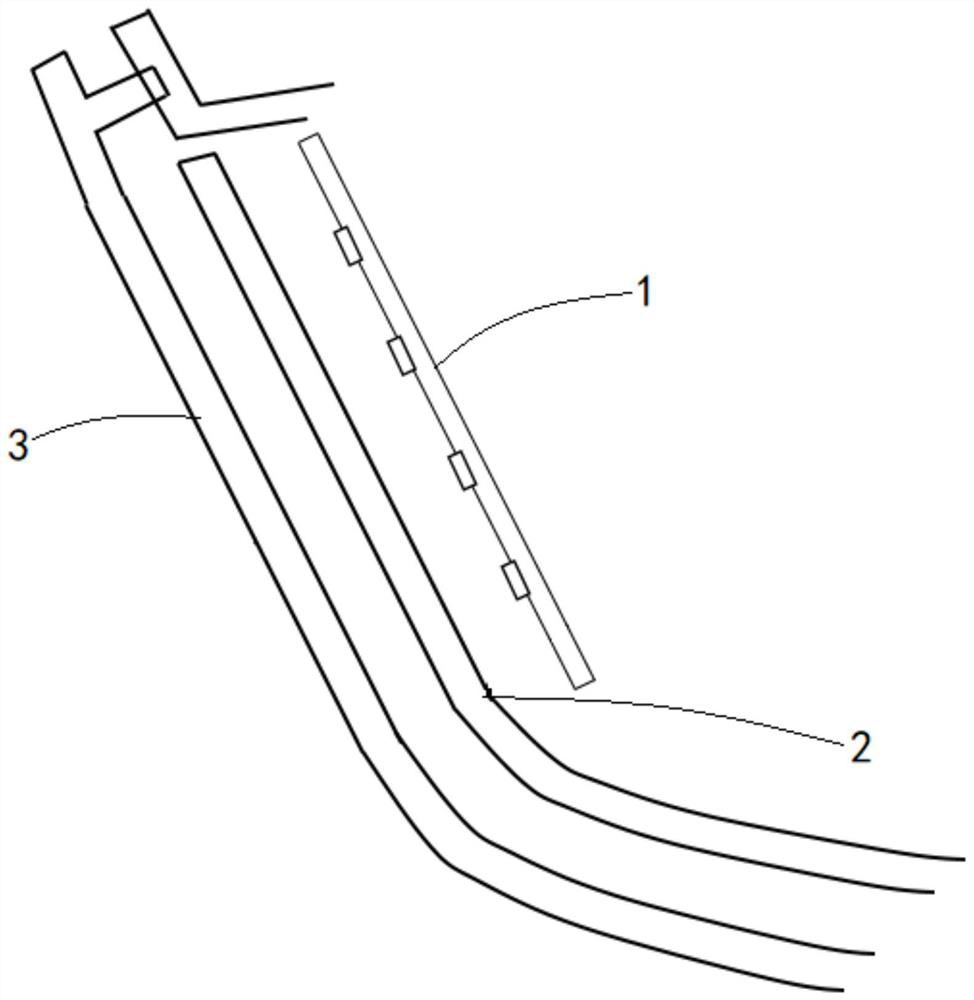

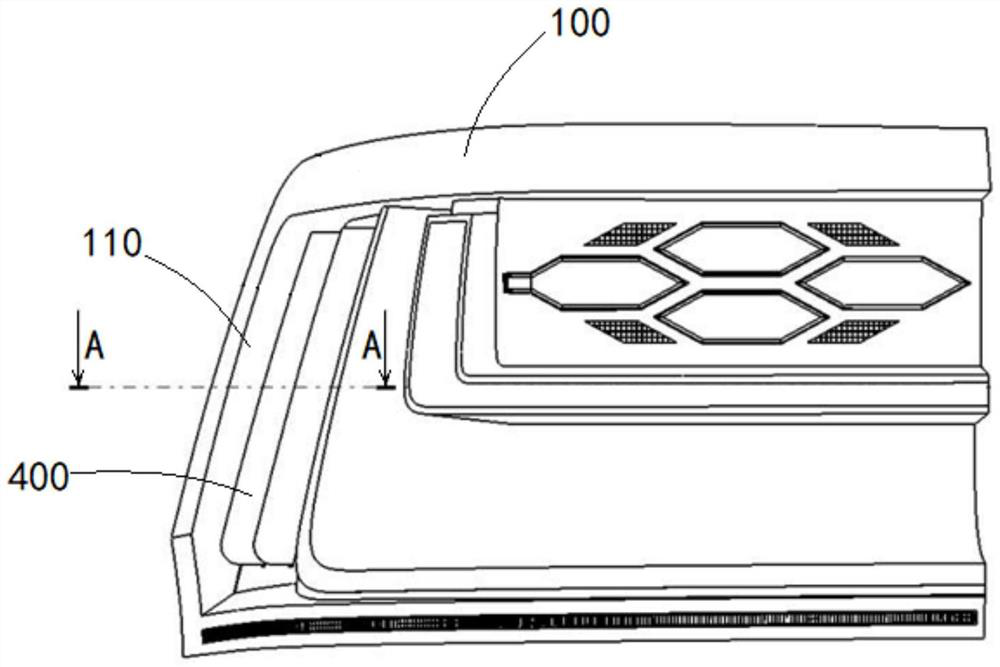

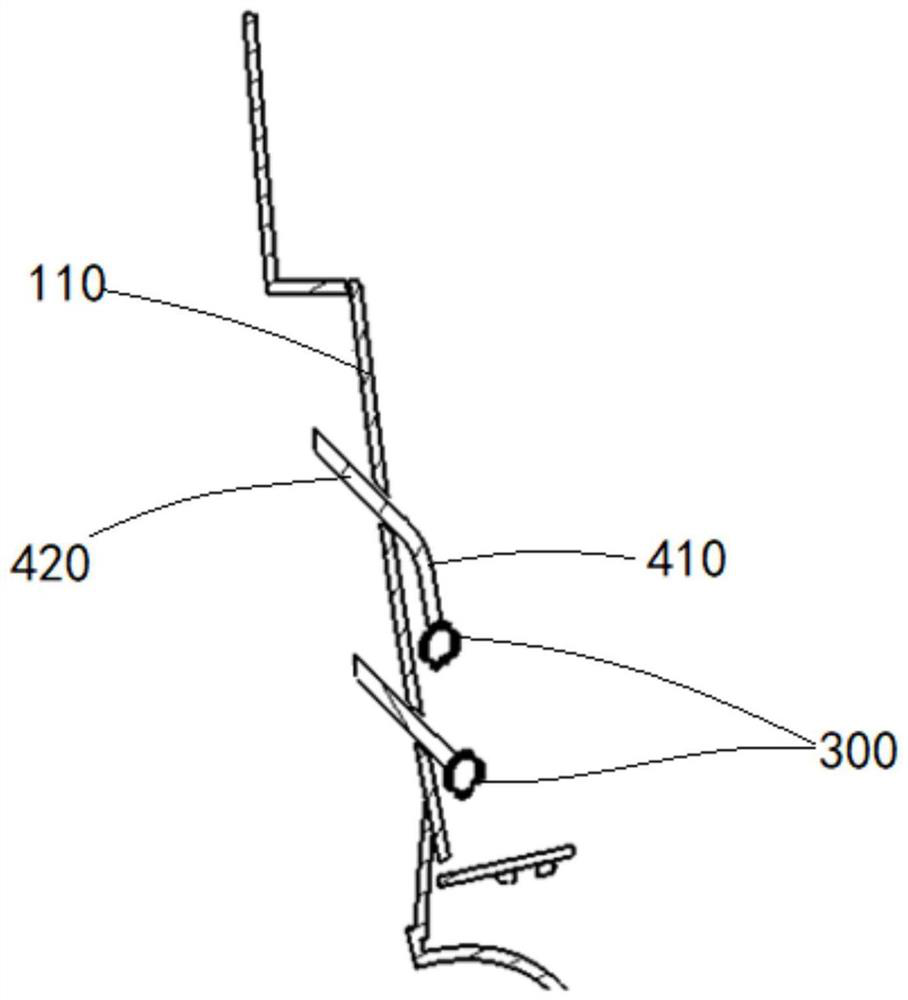

Light emitting device and vehicle

PendingCN111765428AAvoid dependenceSave spaceVehicle headlampsOptical signallingLight guideEngineering

The present invention relates to a light emitting device comprising: a shell, a light-emitting component which is arranged in the shell and used for emitting light, a light guide part which is arranged in the shell and close to the side edge of the shell, wherein the end of the light guide part faces the light-emitting component and is used for allowing light emitted by the light-emitting component to enter, and then the light is guided out in the light guide direction, and a light uniformizing part which is installed on the side edge of the shell in a penetrating mode and comprises a light inlet part arranged inside the shell and a light outlet part arranged outside the shell, wherein the light inlet part is located in the light guide direction of the light guide part so that light guidedout by the light guide part can enter the light uniformizing part, and the light outlet part is used for evenly diffusing the light entering the light uniformizing part and uniformized by the light uniformizing part outwards. According to the embodiment, the occupied space in the automobile lamp is very small, and layout and design of a light-emitting form can be conducted in a narrow space, theside surface of the car lamp can emit light uniformly, and the product has a three-dimensional uniform light-emitting effect in the side surface area.

Owner:HASCO VISION TECHNOLOGY CO LTD

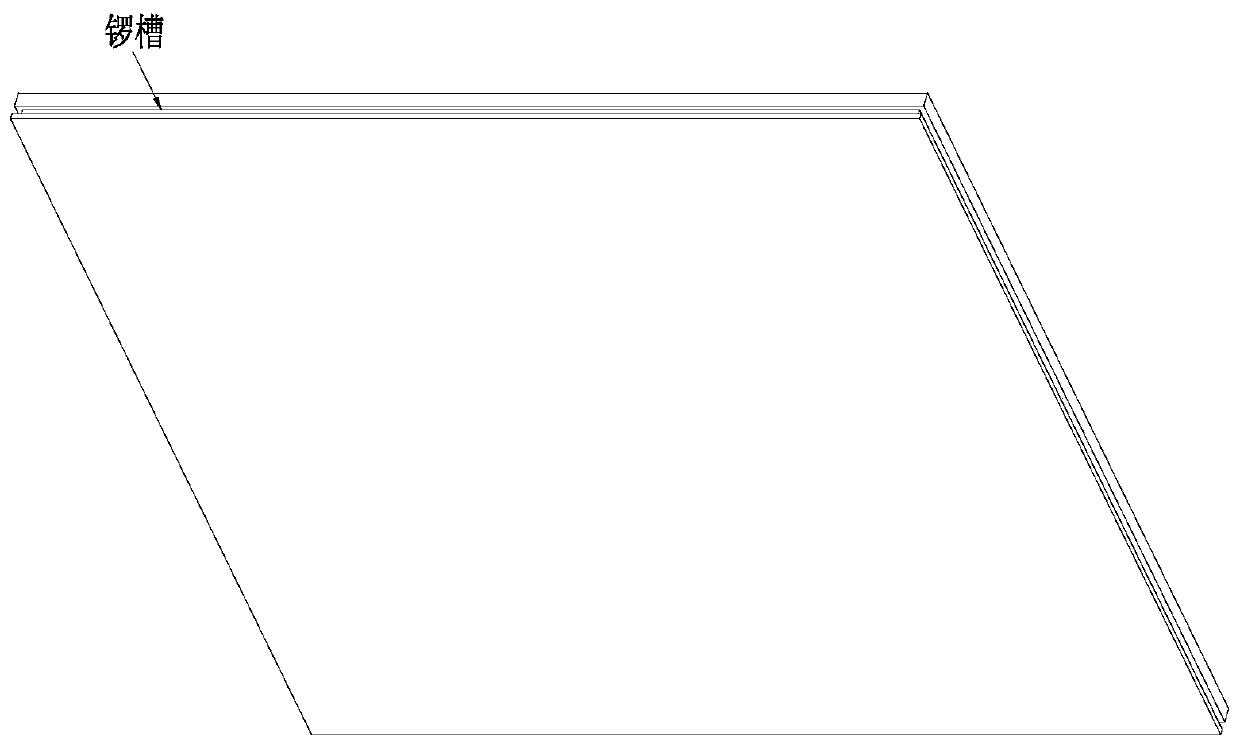

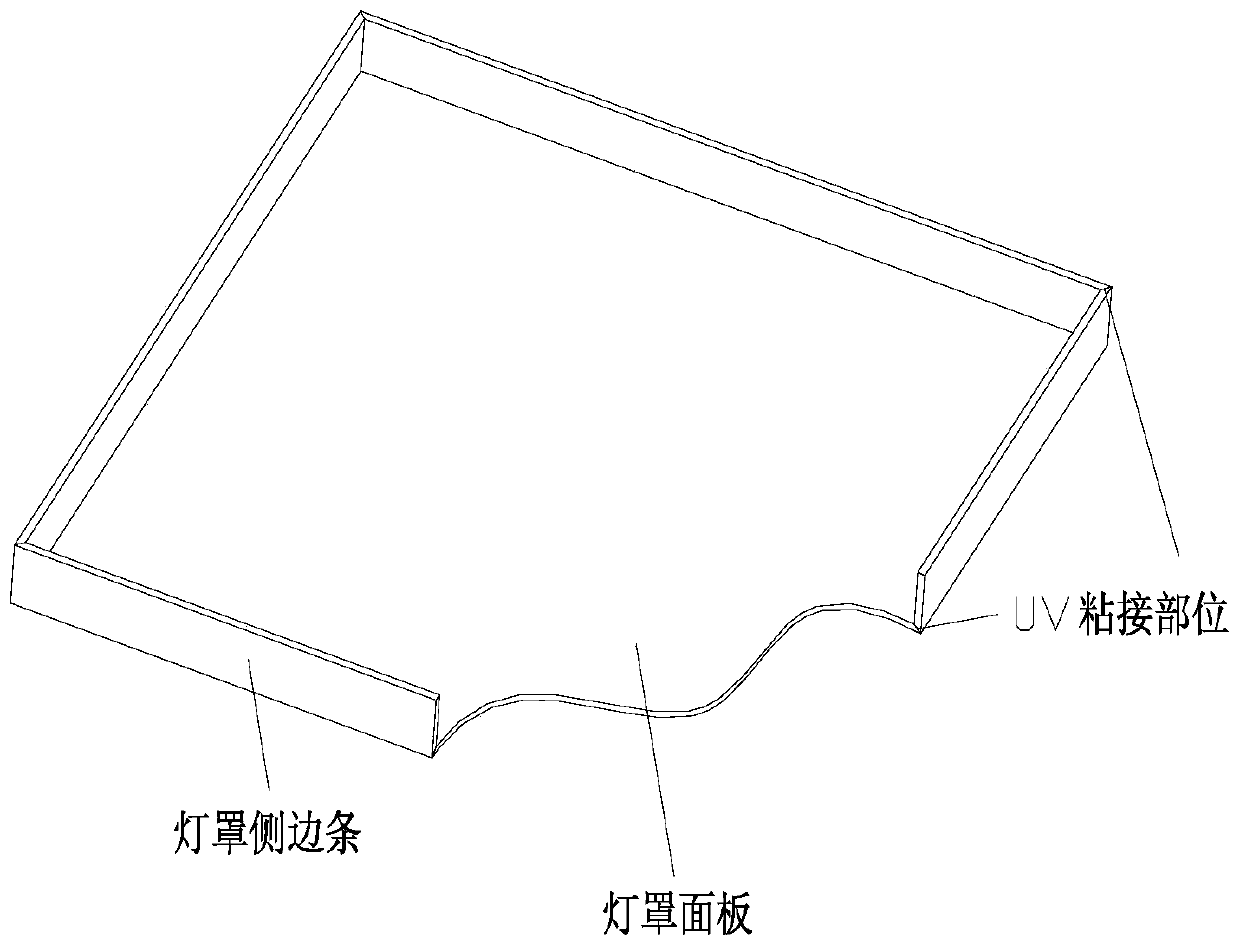

Process method for producing sharp-edge integrated lampshade and lampshade made by using same

PendingCN110887018AAchieve sharp edge effectDimensionally stableGlobesHigh volume manufacturingStructural engineering

The invention discloses a process method for producing a sharp-edge integrated lampshade and a lampshade made by using the same. The method comprises the following steps that rough shape cutting is conducted, wherein a plastic plate is milled or stamped into a blank material, a diffusion agent is added into the blank material, and the machined plastic plate can serve as a diffusion plate for a light diffusion effect; square notches are formed in the four corners of the blank material, and four side edges are formed in the portions, between the adjacent notches, of the blank part; bending is conducted, wherein the side edges are sequentially bent to form a box-shaped semi-finished lampshade; after the side edges are bent, a side butting structure is formed between the adjacent side edges ofthe box-shaped semi-finished lampshade, and gaps exist at the positions where the adjacent side edges are butted; seam sealing is conducted, wherein edge strips stick to the inner surfaces of the adjacent side edges of the box-shaped semi-finished product lampshade, or the adjacent side edges are welded with a plastic welding rod, the gaps are sealed, and the two sides of the edge strips are attached to the adjacent side edges; and rounded corner repairing and polishing are conducted. According to the lampshade with the structure and the process, it can be guaranteed that the lampshade realizes the sharp-edge effect, the lampshade is clean and tidy in whole, stable in size and uniform and consistent in light transmission, does not loosen and crack for a long time, does not crack, and meets the requirements of mass stability and consistency of mass production products.

Owner:GUANGZHOU LUMBENCY LIGHTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com