Light-diffusing flame-retardant polycarbonate material for LED lighting, and preparation method thereof

A flame-retardant polycarbonate and LED lighting technology, which is applied in the field of polymer materials, can solve the problems of single comprehensive performance of materials, low light transmission, and difficult to diversify the use of lamps, etc., achieve high surface hardness and improve mechanical strength , the effect of less smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

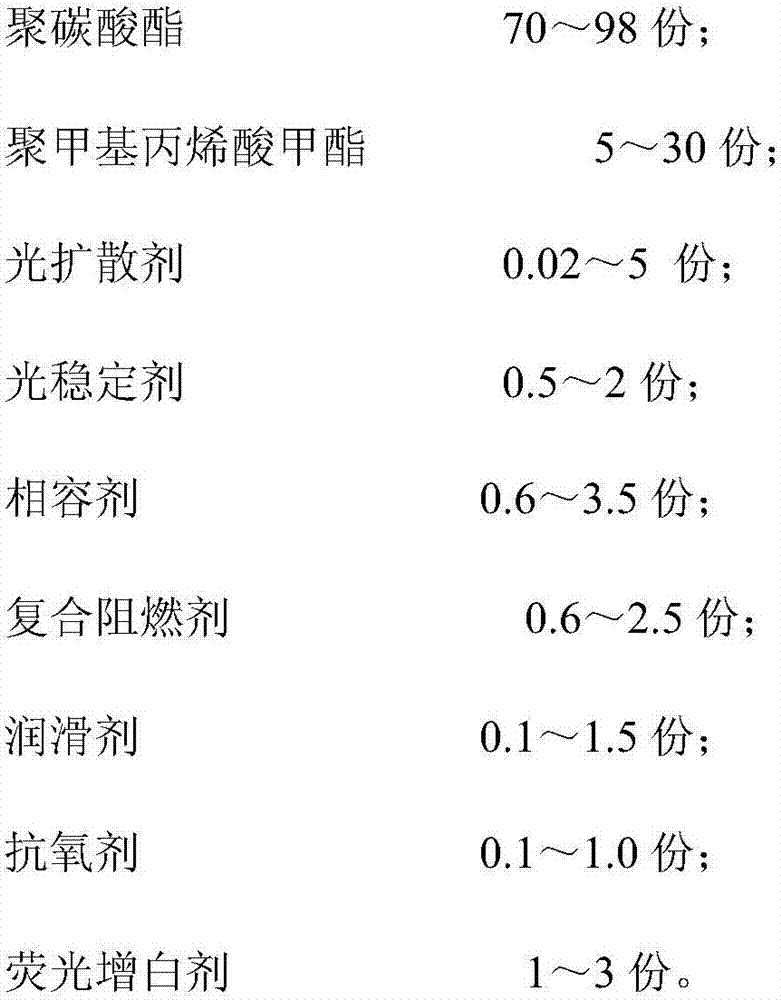

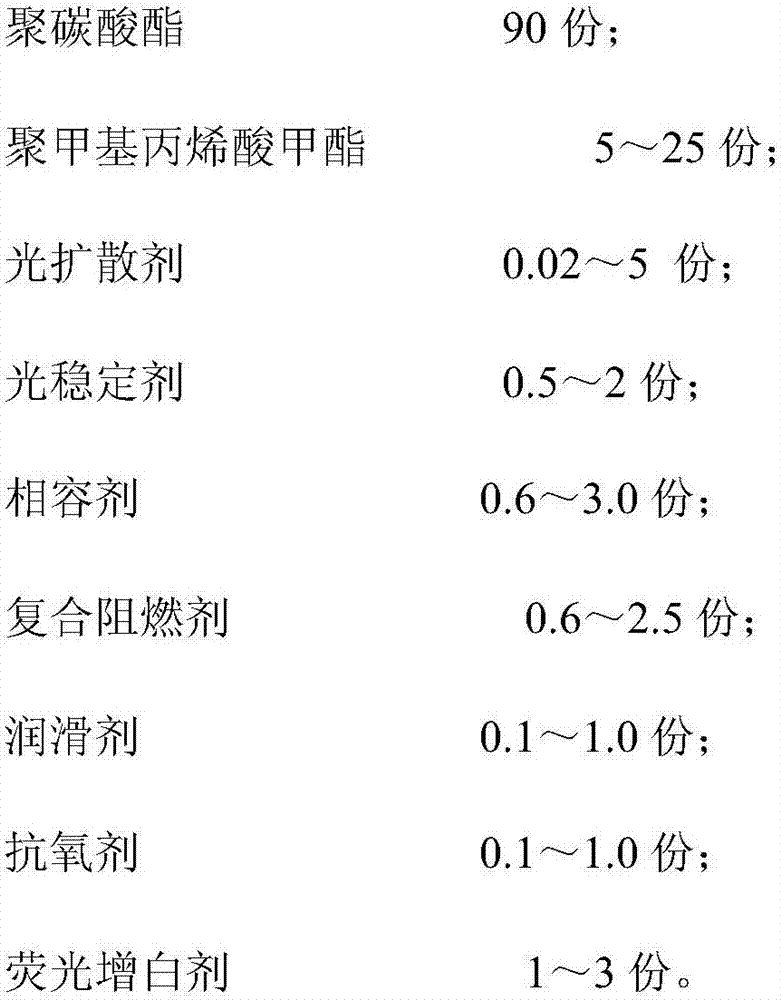

Method used

Image

Examples

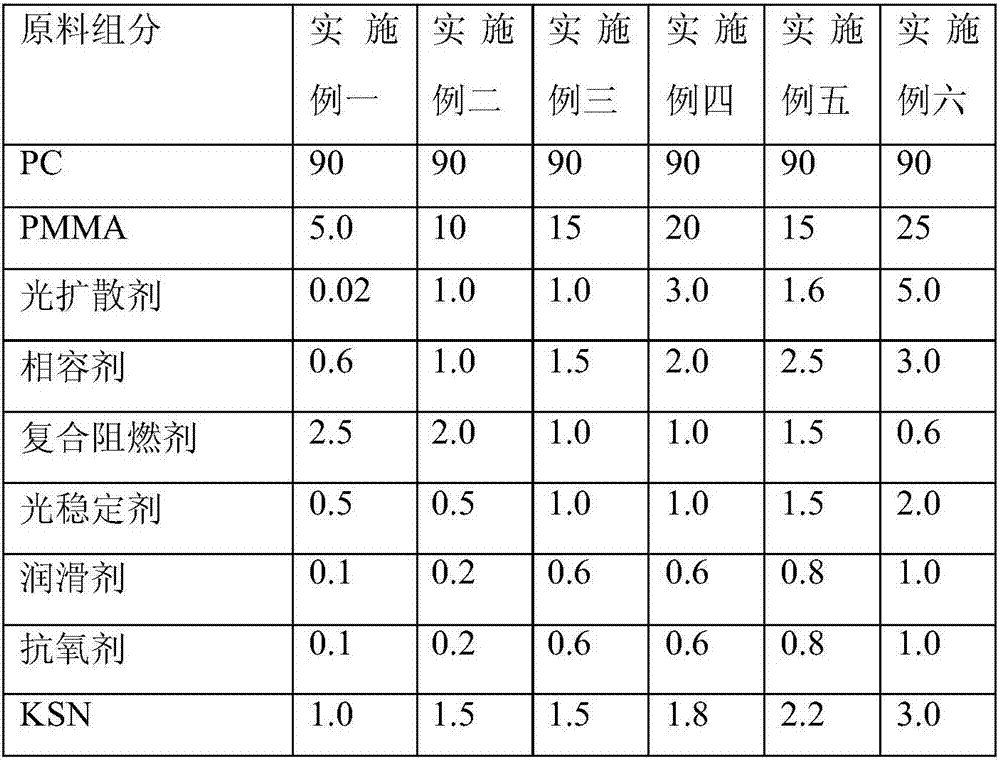

Embodiment 1

[0047] PC 90 copies;

[0048] 5 parts of PMMA;

[0049] 0.02 part of light diffusing agent, which is formed by blending acrylate light diffusing agent and silicone light diffusing agent according to the mass ratio of 1:2;

[0050] 0.6 parts of compatibilizer;

[0051] 0.5 part of light stabilizer;

[0052] 2.5 parts of composite flame retardant, which is composed of organosilicon flame retardant and sulfonate flame retardant, the weight ratio of organosilicon flame retardant and sulfonate flame retardant is 20:1;

[0053] 0.1 parts of lubricant;

[0054] 0.1 part of antioxidant, which is a mixture of hindered phenolic antioxidant 1010, phosphite antioxidant S9228 and PEPQ in a weight ratio of 1:2;

[0055] KSN 1.0 copies.

Embodiment 2

[0057] PC 90 copies;

[0058] 10 copies of PMMA;

[0059] 1.0 parts of light diffusing agent, which is formed by the combination of acrylate light diffusing agent and silicone light diffusing agent according to the mass ratio of 1:2;

[0060] 0.5 part of light stabilizer;

[0061] 1.0 parts of compatibilizer;

[0062] 2.0 parts of composite flame retardants, which are compounded by organosilicon flame retardants and sulfonate flame retardants, and the weight ratio of organosilicon flame retardants and sulfonate flame retardants is 20:1;

[0063] 0.2 parts of lubricant;

[0064] 0.2 parts of antioxidant, which is a compound of hindered phenolic antioxidant 1010, phosphite antioxidant S9228 and PEPQ in a weight ratio of 1:2;

[0065] KSN 1.5 parts.

Embodiment 3

[0067] PC 90 copies;

[0068] 15 copies of PMMA;

[0069] 2.0 parts of light diffusing agent, which is made of acrylate light diffusing agent and silicone light diffusing agent according to the mass ratio of 1:2; 1.0 parts of light stabilizer;

[0070] 1.5 parts of compatibilizer;

[0071] 1.0 parts of composite flame retardant, which is composed of organosilicon flame retardant and sulfonate flame retardant, the weight ratio of organosilicon flame retardant and sulfonate flame retardant is 20:1;

[0072] 0.6 parts of lubricant;

[0073] 0.6 parts of antioxidant, which is a compound of hindered phenolic antioxidant 1010, phosphite antioxidant S9228 and PEPQ in a weight ratio of 1:2;

[0074] KSN 1.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com