Process method for producing sharp-edge integrated lampshade and lampshade made by using same

A production process, an integrated technology, applied in the direction of lampshade, lighting device parts, lighting devices, etc., can solve the problems of high machining surface and precision requirements, high cost, degumming and other problems of parts, and achieve uniform light transmission and dimensional stability. , overall clean and tidy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

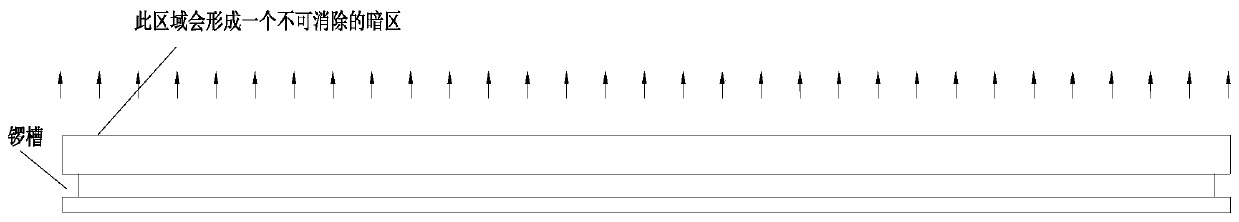

Problems solved by technology

Method used

Image

Examples

Embodiment 1

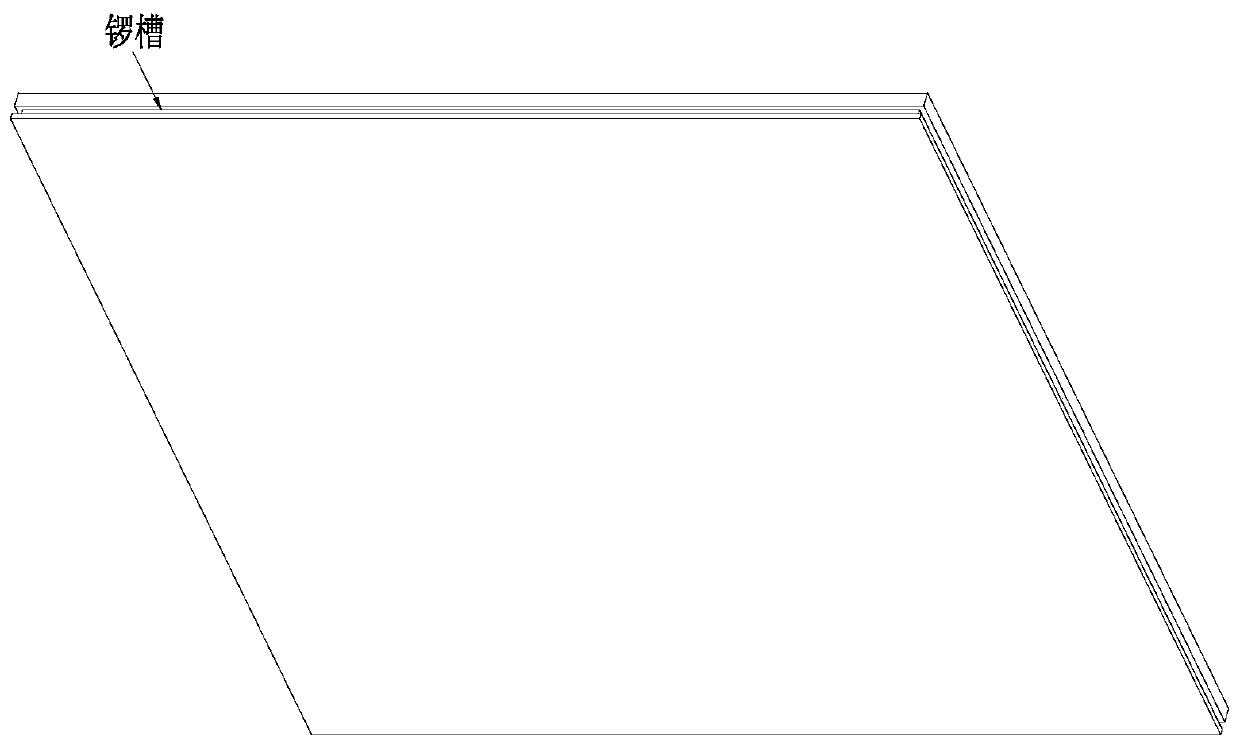

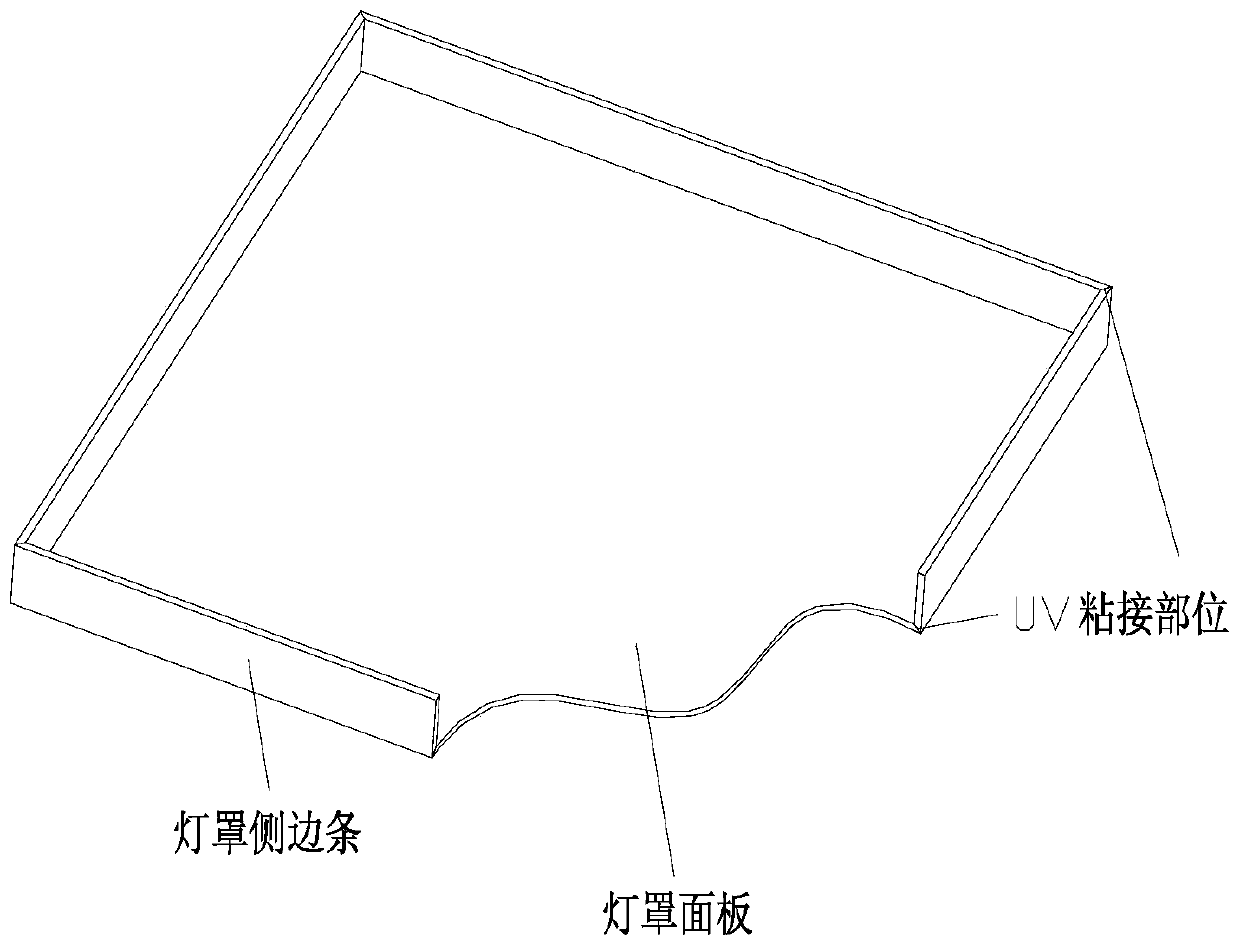

[0065] This embodiment is a production process of a sharp-edged right-angle integrated lampshade, which has the following steps for the side butt joint structure and its sealing process,

[0066] Step one:

[0067] 1.1. Cut PS or PMMA or PC plastic plate with CNC engraving machine or punch out a rectangular blank 1 with a precision mold. The blank 1 is filled with a diffusing agent inside, which can be used as a diffusion plate for light diffusion; in this embodiment The blank material 1 is a blank material with a size of 0.6m*1.2m, and the thickness of the blank material 1 can be 1-4mm, which is 4mm in this embodiment;

[0068] 1.2, please refer to Figure 5 with Image 6 As shown, there is a 30mm*32mm square notch 2 at the four corners of the blank 1 (the size of the notch can be adjusted according to the height of the lampshade and the installation range, the size here is only an example), and the two walls of the notch 2 are kept straight. The sides are at right angles,...

Embodiment 2

[0087] This embodiment is a production process of a sharp-edged right-angle integrated lampshade, which has the following steps for the 45° bevel joint and seam sealing process,

[0088] Step one:

[0089] 1.1. Cut PS or PMMA or PC plastic sheet with CNC engraving machine or punch it into a square blank 1. The blank 1 is filled with a diffusing agent, which can be used as a diffusion plate for light diffusion; the blank in this embodiment Material 1 is a blank material with a size of 0.6m*0.6m, and the thickness of blank material 1 is 1-3mm, which is 3mm in this embodiment;

[0090] 1.2, please refer to Figure 14 with Figure 15 As shown, there is a square notch 20 of 28mm*28mm in the four corners of the blank 1 (the size of the notch can be adjusted according to the height of the lampshade and the installation range, the size here is only as an example), and the wall 200 of the square notch 20 is milled out at 45° For chamfering, the blank 1 part between adjacent square g...

Embodiment 3

[0105] This embodiment is a production process of a sharp-edged and right-angled integrated hexagonal lampshade, which has the following steps for the 60° bevel butt joint and seam sealing process,

[0106] Step one:

[0107] 1.1. Cut the PS or PMMA or PC plastic board with a CNC engraving machine or punch it into a hexagonal blank 1. The blank 1 is filled with a diffusing agent and can be used as a diffusion plate for light diffusion; this implementation The blank material 1 in the example is a blank material with a size of 0.8m*0.8m, and the thickness of the blank material 1 is 1-4mm, and 2mm is selected in this embodiment;

[0108] 1.2, please refer to Figure 21 As shown, there is a triangular notch 600 of 25mm*25mm in the corner of the blank 1 (the size of the notch can be adjusted according to the height of the lampshade and the installation range, the size here is only an example), and the wall of the triangular notch 600 is milled out 60° For chamfering, the blank 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com