Fully-compatible ink-jet printing flame-retardant forward-blowing lamp sheet

A technology of inkjet printing and blowtorch, applied in printing, duplication/marking method, coating, etc., can solve the problems of poor light and thermal stability, decrease of light transmittance of lamp, decrease of physical and mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

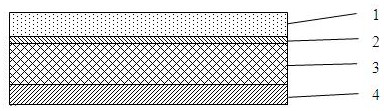

Image

Examples

Embodiment 1

[0097] Embodiment 1: A method for making a fully compatible inkjet printing flame retardant positive spray lamp sheet: firstly prepare the fully compatible inkjet printing flame retardant coating and the preparation of the back coating coating; then fully compatible inkjet printing flame retardant coating Coating production of Yanzheng blowtorch sheet.

[0098] Specifically, the coating formula of the fully compatible inkjet printing flame retardant coating is: 50 parts of flame retardant modified acrylic resin emulsion; 15 parts of ammonium polyphosphate (APP); 5 parts of melamine (MEL); 3 parts of pentaerythritol; 8 parts of aluminum; 0.5 parts of polytetrafluoroethylene emulsion (solid: 50%); 1 part of molybdenum trioxide; 0.6 parts of leveling agent; 0.3 parts of defoamer; 20 parts of water;

[0099] Its preparation method includes: step 1, flame retardant dispersion liquid grinding: fully stir ammonium polyphosphate, melamine, pentaerythritol, aluminum hydroxide and molyb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com