A kind of matte antistatic spray paint and preparation method thereof

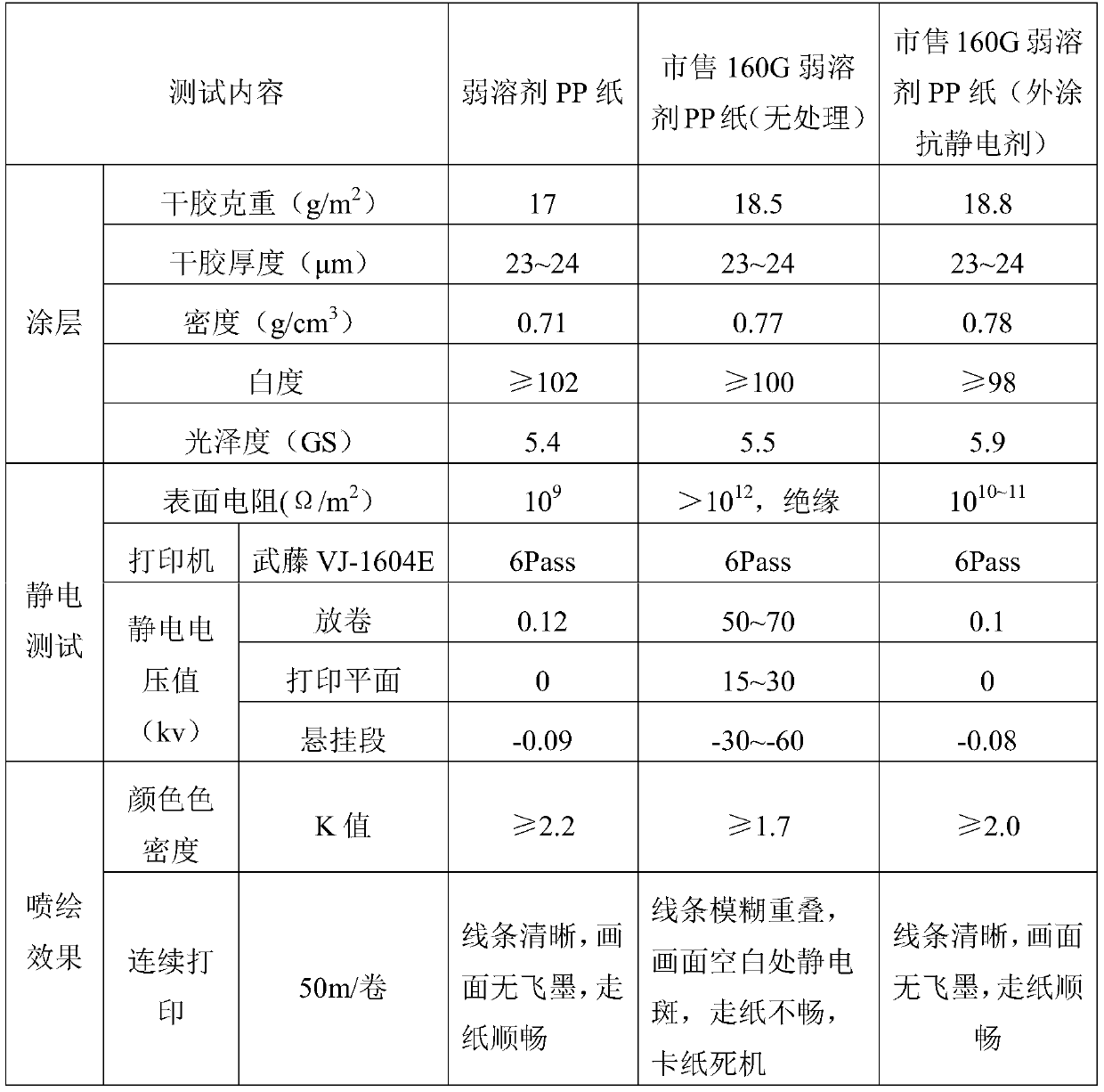

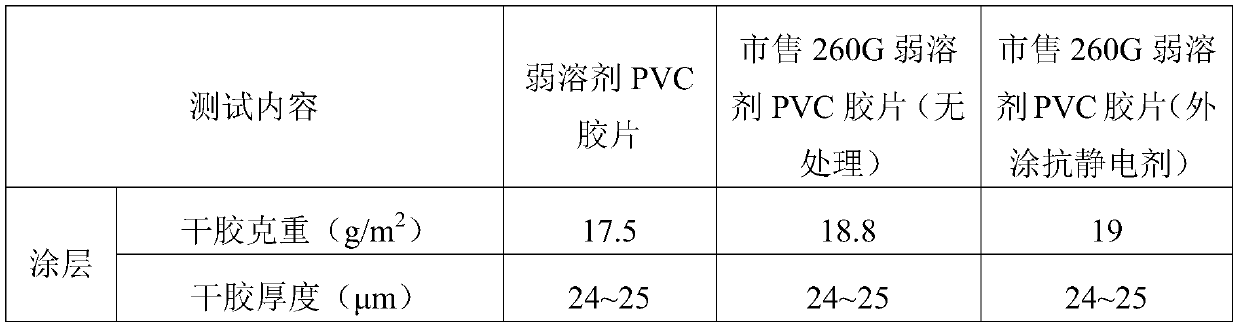

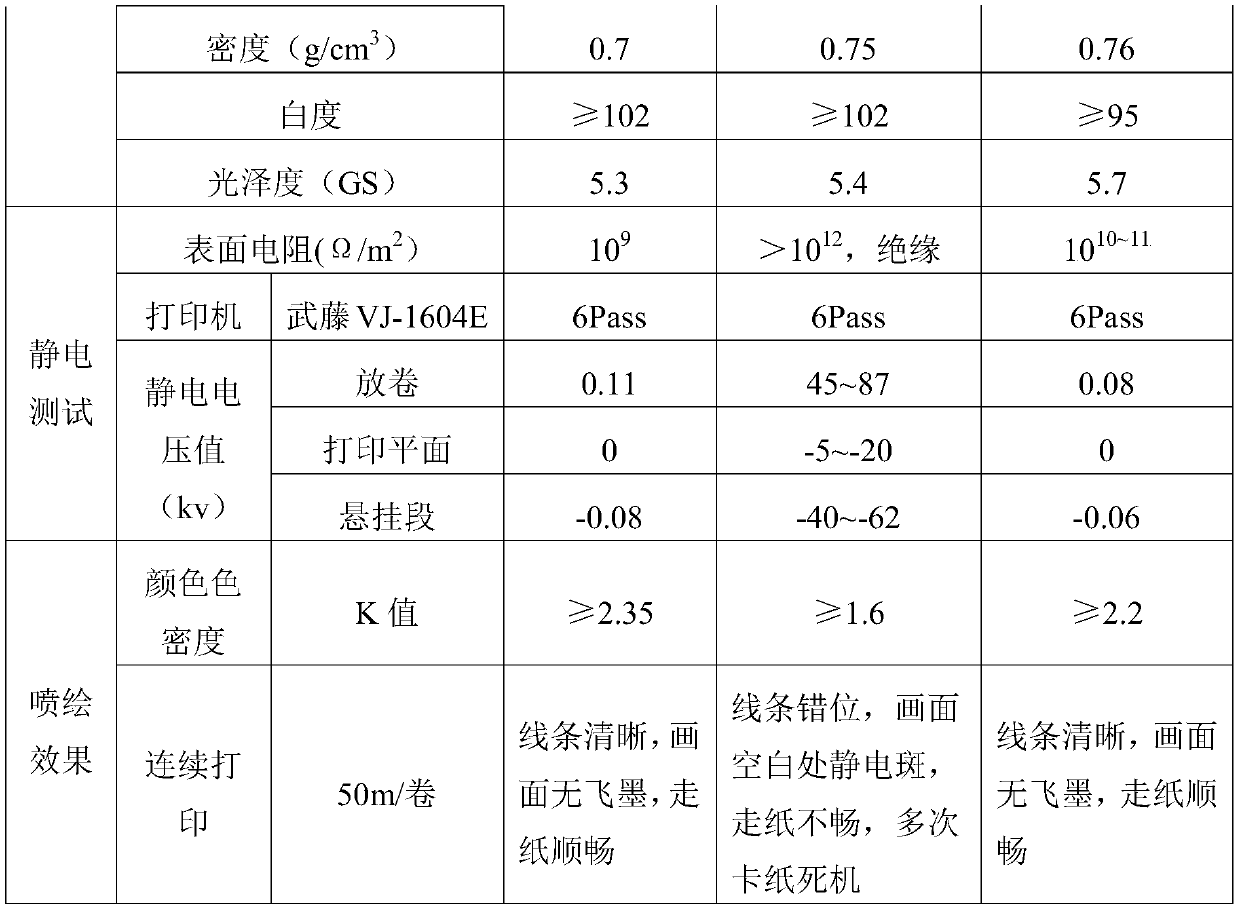

An antistatic and antistatic agent technology, applied in conductive coatings, coatings, etc., can solve problems such as increased operational complexity, yellowing and fading of coatings, lack of static electricity, etc., to achieve clear printing lines without offset, coating The effect of good whiteness and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Matte antistatic spray paint, its raw materials are: 24 parts of pure acrylic emulsion, 20 parts of styrene-acrylic emulsion, 8 parts of polyvinyl alcohol glue (prepared by 10 parts of polyvinyl alcohol colloids and 90 parts of deionized water), 6 parts of matte Light powder, 4 parts of antistatic agent solution (prepared by dissolving 40 parts of antistatic agent in 60 parts of deionized water), 2.2 parts of kaolin, 0.1 part of dispersant, 0.32 part of whitening agent, 0.34 part of defoamer, 0.56 Part conductive agent, 0.48 part wetting agent and 34 parts deionized water.

[0044] Follow the steps below to prepare spray paint:

[0045] 1. Prepare the antistatic agent solution: weigh the antistatic agent and seal it for use. Add the weighed deionized water into the stirring pot, start the stirrer at a speed of 300r / min, and start the heater to set the heating temperature at 60°C. After the water temperature reaches 60°C, slowly add the antistatic agent, stir for 10 min...

Embodiment 2

[0049] Matte antistatic inkjet paint, its raw materials are: 21 parts of pure acrylic emulsion, 22 parts of styrene-acrylic emulsion, 10 parts of polyvinyl alcohol glue (prepared by 5 parts of polyvinyl alcohol colloids and 95 parts of deionized water), 5 parts of matte Light powder, 4 parts of antistatic agent solution (prepared by dissolving 40 parts of antistatic agent in 60 parts of deionized water), 2 parts of kaolin, 0.2 part of dispersant, 0.5 part of whitening agent, 0.3 part of defoamer, 0.6 Part conductive agent, 0.5 part wetting agent and 36 parts deionized water.

[0050] Follow the steps below to prepare spray paint:

[0051] 1. Prepare the antistatic agent solution: weigh the antistatic agent and seal it for use. Add the weighed deionized water into the stirring pot, start the stirrer at a speed of 500r / min, and start the heater to set the heating temperature to 65°C. After the water temperature reaches 65°C, slowly add the antistatic agent, stir for 15 minutes ...

Embodiment 3

[0055] Matte antistatic inkjet paint, its raw materials are: 30 parts of pure acrylic emulsion, 16 parts of styrene-acrylic emulsion, 5 parts of polyvinyl alcohol glue (prepared by 20 parts of polyvinyl alcohol colloids and 80 parts of deionized water), 3 parts of matte Light powder, 3 parts of antistatic agent solution (prepared by dissolving 50 parts of antistatic agent in 50 parts of deionized water), 1 part of kaolin, 0.15 parts of dispersant, 0.4 parts of whitening agent, 0.4 parts of defoamer, 0.8 Part conductive agent, 0.4 part wetting agent and 30 parts deionized water.

[0056] Follow the steps below to prepare spray paint:

[0057] 1. Prepare the antistatic agent solution: weigh the antistatic agent and seal it for use. Add the weighed deionized water into the stirring pot, start the stirrer at a speed of 400r / min, and start the heater to set the heating temperature to 55°C. After the water temperature reaches 55°C, slowly add the antistatic agent, stir for 8 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com