Water-based coating liquid and preparation method and application thereof

A water-based coating liquid, selected from the technology, applied in the direction of coating, paper coating, special paper, etc., can solve the problems of spots, weak wetting function, non-drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

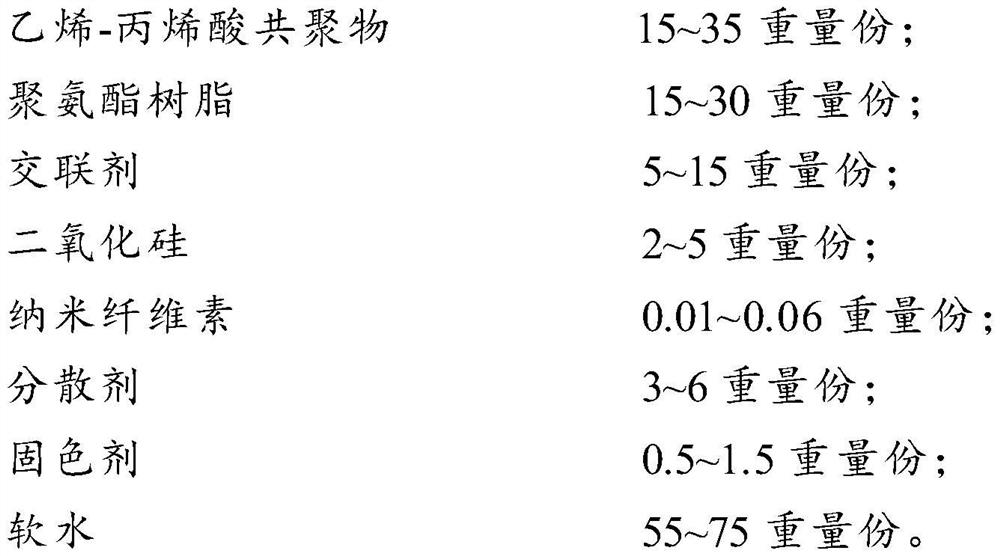

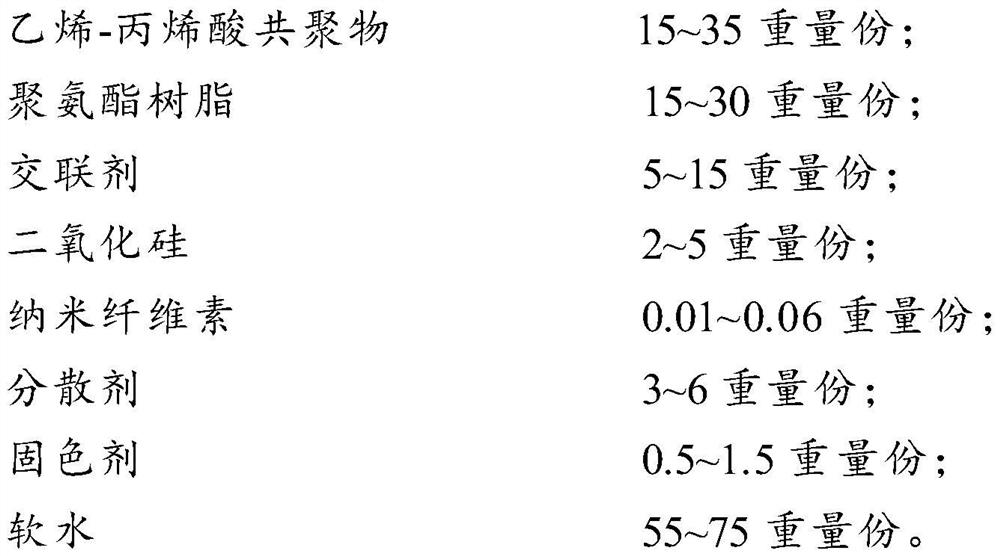

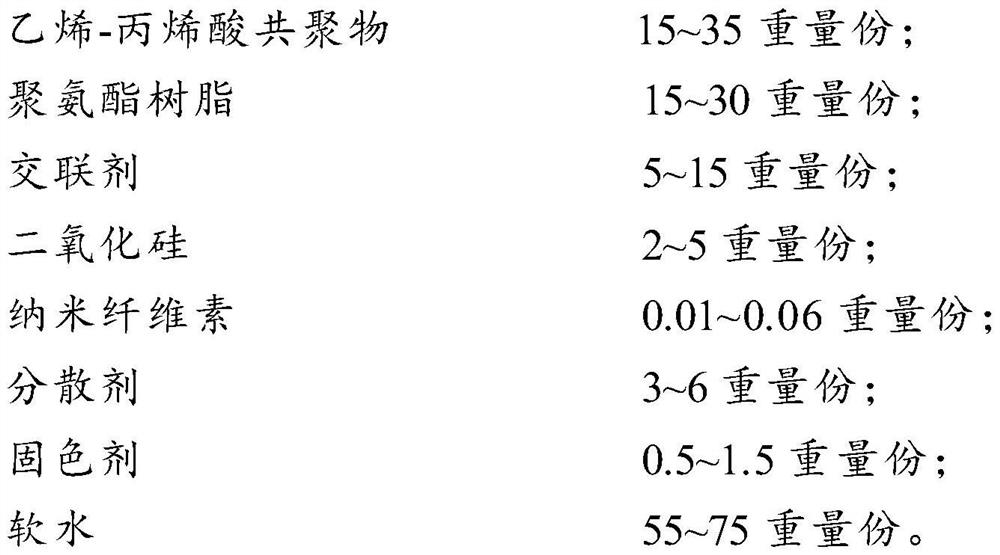

[0026] The application also provides a preparation method for an aqueous coating liquid, comprising the following steps:

[0027] According to the proportion, mix ethylene-acrylic acid copolymer, polyurethane resin and soft water, add crosslinking agent after heating, then add silicon dioxide, nanocellulose and dispersant, and obtain water-based coating liquid after standing still.

[0028] The solid content of the water-based coating liquid described in the present application is 10-20%, and the viscosity is 15-25s.

[0029] The present invention also provides a gold and silver cardboard, which is composed of a gold and silver cardboard base paper and an aqueous coating solution coated on the surface of the gold and silver cardboard base paper.

[0030] According to the present invention, specifically, an anilox roller is used to coat the aqueous coating solution on the surface of gold and silver cardboard, and the base paper of gold and silver cardboard is subjected to coron...

Embodiment 1

[0034] Mix 18 parts of ethylene-acrylic acid copolymer, 15 parts of polyurethane resin and 60 parts of soft water, start heating and stirring, stir at 100r / min, 70°C and add 5 parts of cross-linking agent at the same time, continue stirring for 5min, drop to room temperature, at room temperature Add 2 parts of silicon dioxide, 0.01 part of nanocellulose and 3 parts of dispersant in sequence, continue to stir for 20 minutes, let stand for 24 hours, add 0.5 parts of color fixing agent under stirring to obtain an aqueous coating solution, the solid content of the aqueous coating solution 10%, the viscosity is 18s, coated on gold and silver cardboard with 120 mesh anilox roller, the coating weight is 0.5g / m 2 , the sample was obtained after printing by HP Indigo, the printing appearance is good, the color is uniform, the adhesion reaches the level 1 of the standard GB / T5210-1985, and the color difference value △E is 0.42.

Embodiment 2

[0036] Mix 20 parts of ethylene-acrylic acid copolymer, 25 parts of polyurethane resin and 65 parts of soft water, start heating and stirring, stir at 100r / min, 70°C and add 10 parts of crosslinking agent at the same time, continue stirring for 5min, drop to room temperature, at room temperature Add 4 parts of silicon dioxide, 0.04 parts of nanocellulose and 5 parts of dispersant in sequence, continue to stir for 20 minutes, let stand for 24 hours, add 1 part of color fixing agent under stirring to obtain an aqueous coating solution, the solid content of the aqueous coating solution 20%, the viscosity is 23s, coated on gold and silver cardboard with 120 mesh anilox roller, the coating weight is 2g / m 2 , the sample was obtained after printing by HP Indigo, the printed appearance is full of color, the adhesion reaches the level 0 of the standard GB / T5210-1985, and the color difference value △E is 0.38.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dyne value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com