Topological composite film heat sublimation transfer printing digital paper

A composite film, thermal sublimation technology, applied in papermaking, printing, paper coating and other directions, can solve the problems of complex coating process, low coating yield and other problems, improve drying speed, facilitate printing and drying, and increase ink absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

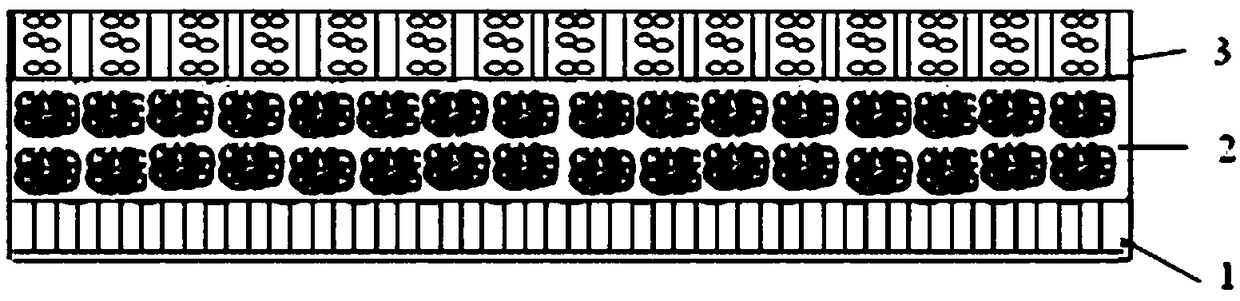

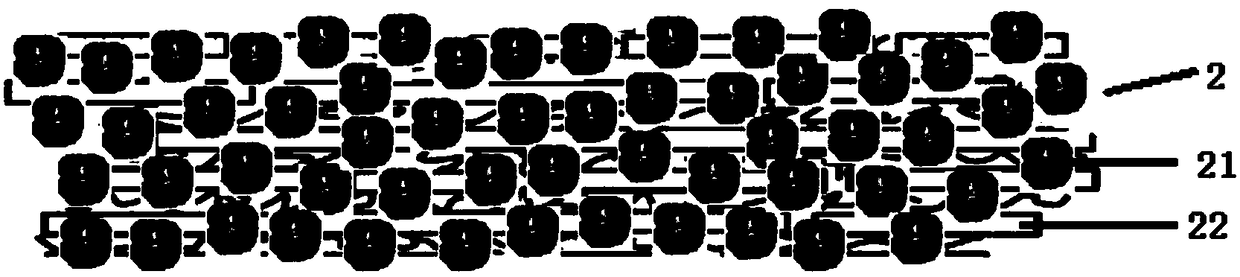

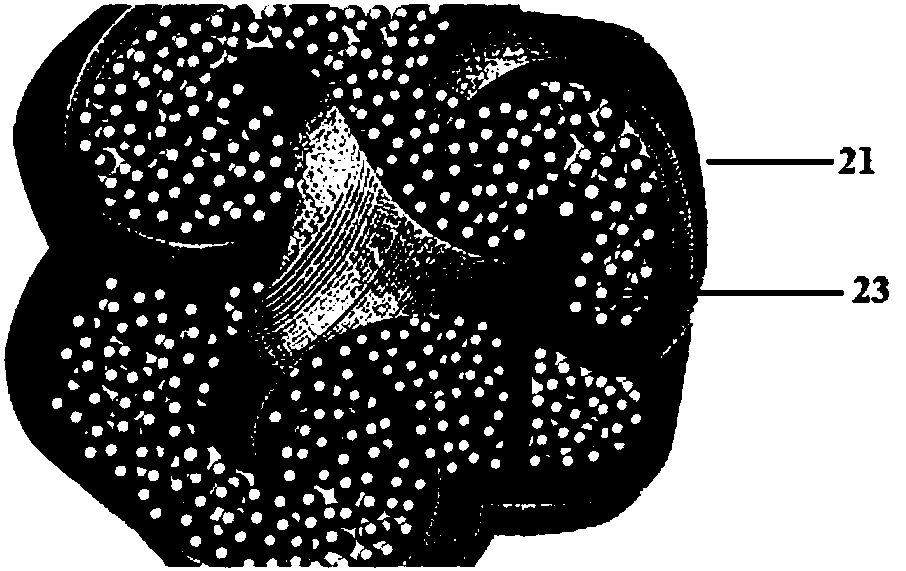

[0039] Topological composite film sublimation transfer digital paper, such as Figure 1-4 As shown, it includes substrate paper 1, topological composite film 2 and surface channel layer 3 from bottom to top, topological composite film 2 includes topological structure 21 and resin structure 22, and topological structure 21 has open channel 23; The topological composite membrane 2 is composed of a topological network resin and a porous composite. The topological composite membrane 2 is calculated by mass percentage, and the components and contents are as follows:

[0040] Topological network resin 42%;

[0041] Porous complex 58%.

[0042] The topological network resin is composed of 40% by mass of isophorone diisocyanate and triphenylmethane triisocyanate, 30% by mass of sodium carboxymethyl cellulose, and 30% by mass of an acrylic resin Interpenetrating network resin formed by cross-linking.

[0043] Wherein, the composition of isophorone diisocyanate and triphenylmethane t...

Embodiment 2

[0057] Topological composite film sublimation transfer digital paper, such as Figure 1-4 As shown, it includes substrate paper 1, topological composite film 2 and surface channel layer 3 from bottom to top, topological composite film 2 includes topological structure 21 and resin structure 22, and topological structure 21 has open channel 23; The topological composite membrane 2 is composed of a topological network resin and a porous composite. The topological composite membrane 2 is calculated by mass percentage, and the components and contents are as follows:

[0058] Topological network resin 40%;

[0059] Porous Composite 60%.

[0060] The topological network resin is composed of 30% by mass of isophorone diisocyanate and triphenylmethane triisocyanate, 40% by mass of sodium carboxymethyl cellulose, and 30% by mass of acrylic resin Interpenetrating network resin formed by cross-linking.

[0061] Wherein, the composition of isophorone diisocyanate and triphenylmethane tr...

Embodiment 3

[0073] Topological composite film sublimation transfer digital paper, such as Figure 1-4 As shown, it includes substrate paper 1, topological composite film 2 and surface channel layer 3 from bottom to top, topological composite film 2 includes topological structure 21 and resin structure 22, and topological structure 21 has open channel 23; The topological composite membrane 2 is composed of a topological network resin and a porous composite. The topological composite membrane 2 is calculated by mass percentage, and the components and contents are as follows:

[0074] Topological network resin 35%;

[0075] Porous Composite 65%.

[0076] The topological network resin is composed of 20% by mass of isophorone diisocyanate and triphenylmethane triisocyanate, 30% by mass of sodium carboxymethyl cellulose, and 50% by mass of acrylic resin Interpenetrating network resin formed by cross-linking.

[0077] Wherein, the composition of isophorone diisocyanate and triphenylmethane tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com