Ink-jet printing film and preparation method thereof

A technology of inkjet printing and film, applied in the direction of copying/marking method, printing, layered products, etc., can solve the problem of high cost, achieve the effect of enhanced coating stability, reduced cost, and uniform holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

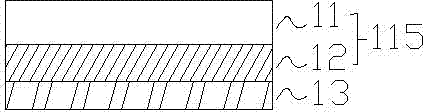

[0021] Embodiment 1: An inkjet printing film, including a substrate 13 and an ink-absorbing coating 115. The substrate 13 uses a colorless PET transparent substrate (purchased by Suzhou Zhanxingda Electronic Materials Co., Ltd.). The ink-absorbing coating 115 is divided into two layers, and each layer has holes, and the holes become larger in the direction from being away from the substrate to closer to the substrate. The hole in the layered structure 11 away from the substrate is 20-50 nm, and the hole in the layered structure 12 near the substrate is 50-100 nm.

[0022] Preparation:

[0023] S1. Preparation of ink-absorbing coating:

[0024] Ink-absorbing coating layered structure 1 coating preparation: the mass fraction of 15% porous silica (WACKER Chemie (China) Co., Ltd.) with a pore size of 20-50nm is used in a high-speed disperser at a line of 10m / s Disperse at a high speed for 1 hour to prepare a silica dispersion. The silica dispersion, polyvinyl alcohol PVA-205 (China ...

Embodiment 2

[0028] Embodiment 2: An inkjet printing film, including a substrate and an ink-absorbing coating. The substrate uses a colorless PET transparent substrate (purchased by Suzhou Zhanxingda Electronic Materials Co., Ltd.). The ink-absorbing coating is divided into four layers, and each layer has holes, and the holes become larger in the direction from being away from the substrate to closer to the substrate. The holes increase in order from the direction away from the substrate to the direction closer to the substrate, and they are 20-30nm, 30-50nm, 50-80nm, 80-100nm.

[0029] Preparation:

[0030] S1. Preparation of ink-absorbing coating:

[0031] Ink-absorbing coating layered structure 1 coating preparation: the mass fraction of 20% porous aluminum oxide with a pore size of 20-30nm (Sasol China Chemical Co., Ltd.) is used with a high-speed disperser at a line speed of 15m / s Disperse at a high speed for 2 hours to prepare an aluminum oxide dispersion. Combine aluminum oxide disper...

Embodiment 3

[0037] Embodiment 3: An inkjet printing film, including a substrate and an ink-absorbing coating. The substrate uses a colorless PET transparent substrate (purchased by Suzhou Zhanxingda Electronic Materials Co., Ltd.). The ink-absorbing coating is divided into six layers, and each layer has holes. The holes are 20-30nm, 20-30nm, 30-50nm, 50-80nm, 50-80nm, 80-100nm from the direction away from the substrate to the direction closer to the substrate.

[0038] Preparation:

[0039] S1. Preparation of ink-absorbing coating:

[0040] The coating preparation of the ink-absorbing coating layered structure 1: the mass fraction of 15% porous silica (WACKER Chemie (China) Co., Ltd.) with a pore size of 20-30nm is used in a high-speed disperser at a line of 15m / s Disperse at high speed for 2 hours to prepare a silica dispersion. The silica dispersion liquid, polyvinyl alcohol PVA-205 (China Taiwan Changchun Chemical Group), polyvinyl alcohol PVA-235 (Kuraray International Trading (Shanghai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com