Patents

Literature

53results about How to "Uniform hole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

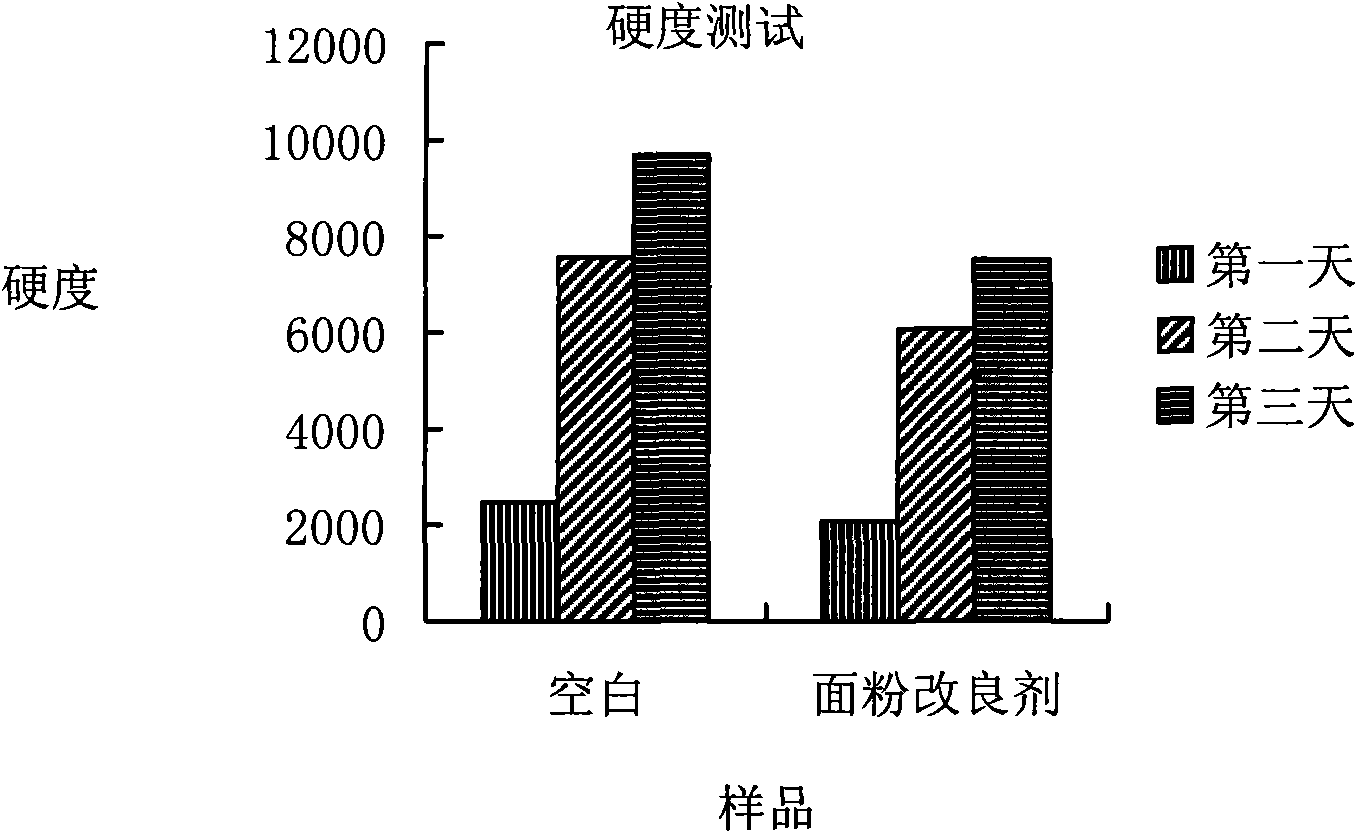

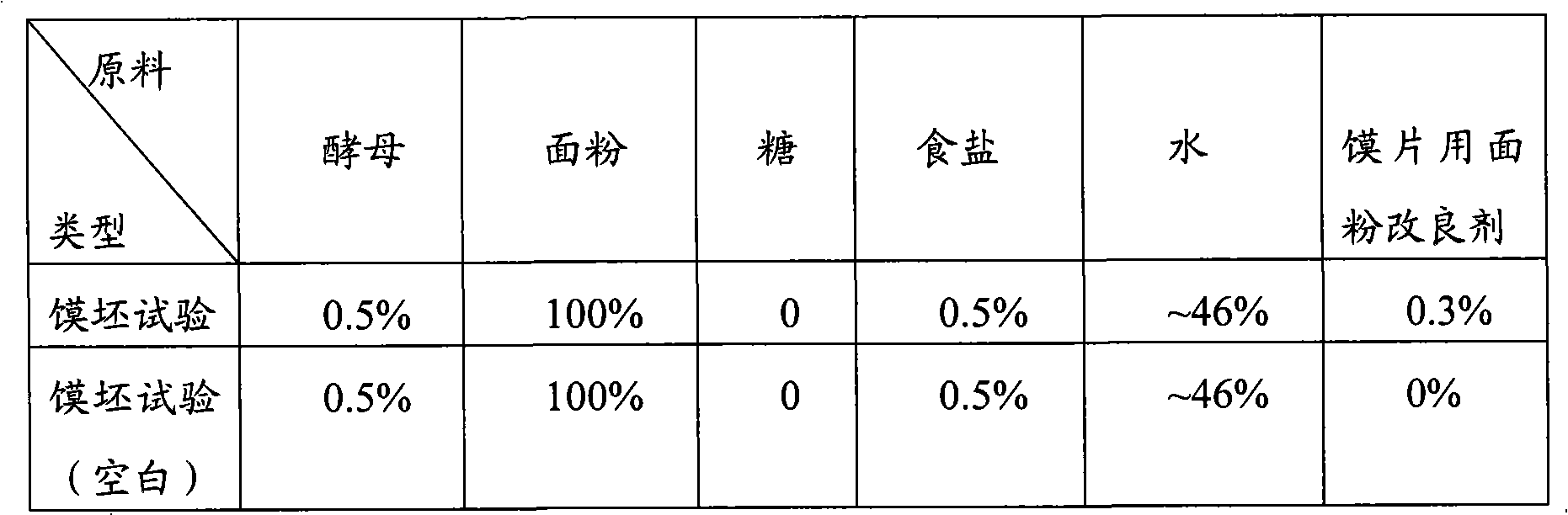

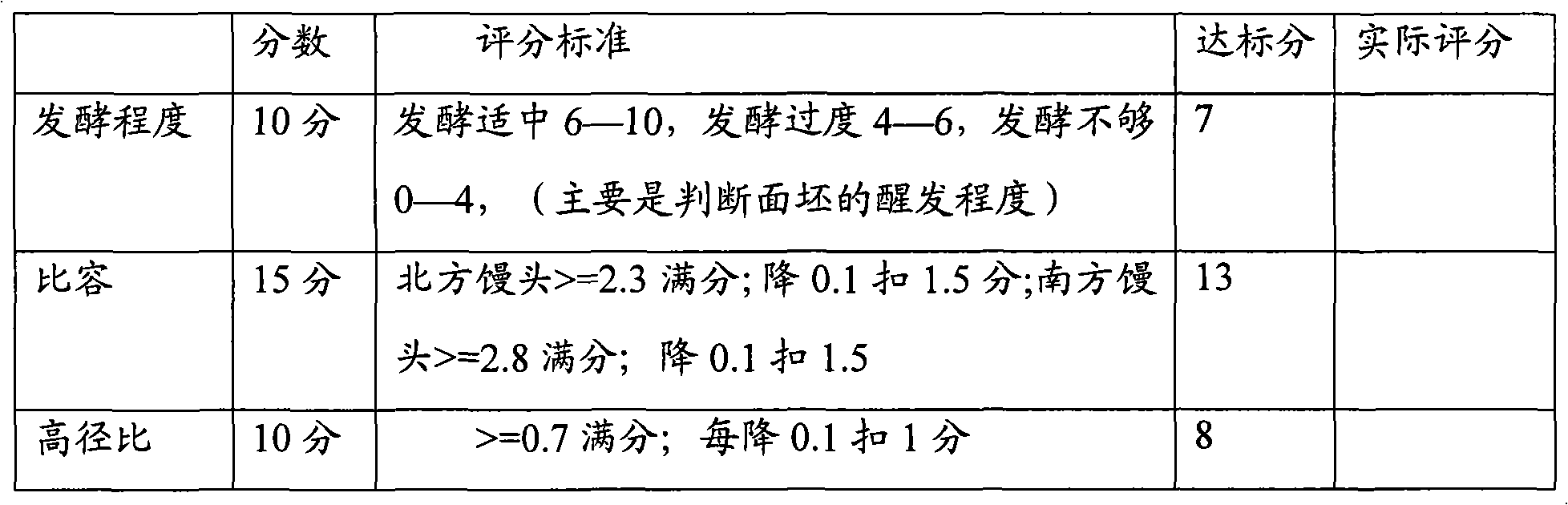

Steamed bread slice making flour modifier and use thereof

InactiveCN101664048AIncrease specific volumeImprove organizational structurePre-baking dough treatmentFood productsSteamed bread

The invention relates to a flour modifier and use thereof, in particular to a steamed bread slice making flour modifier and use thereof. The flour modifier comprises an enzyme preparation, an oxidant,an emulsifier, a swelling agent, a phosphate and starch, can be used for making wheaten food product such as steamed bread and steamed bread slices, improve the structure of steamed bread slices, make the hole in the steamed bread slices more uniform, provide the steamed bread slices with good appearance and improve the crisp degree and yield of the steamed bread slices.

Owner:ANGELYEAST CO LTD

Hole sealing moisture-proof anticorrosive composite coating material and its prepn process

The pore sealing moisture-proof anticorrosive composite coating material includes pore sealing material and moisture-proof anticorrosive material. The pore sealing material includes gel with high solid phase content as the basic phase and filler(s) in the amount of 10-100 % of the solid phase component. The moisture-proof anticorrosive material is sol, hydrophobic organic matter or their mixture. The pore sealing moisture-proof anticorrosive composite coating material is prepared through the four steps of preparing pore sealing material, preparing moisture-proof anticorrosive material, preparing pore sealing coating and preparing moisture-proof anticorrosive coating. The pore sealing moisture-proof anticorrosive composite coating material has excellent water permeation arresting performance, high hydrophobicity and high corrosion resistance.

Owner:WUHAN UNIV OF TECH

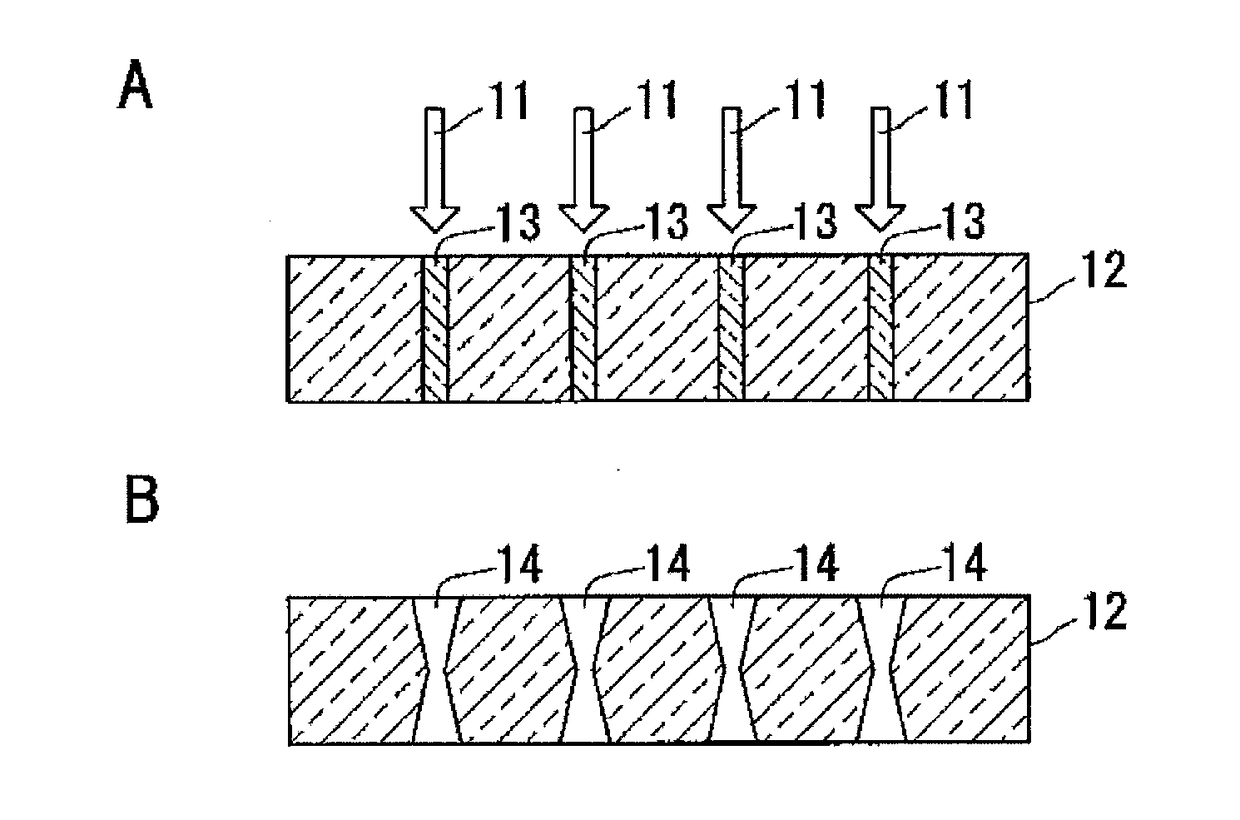

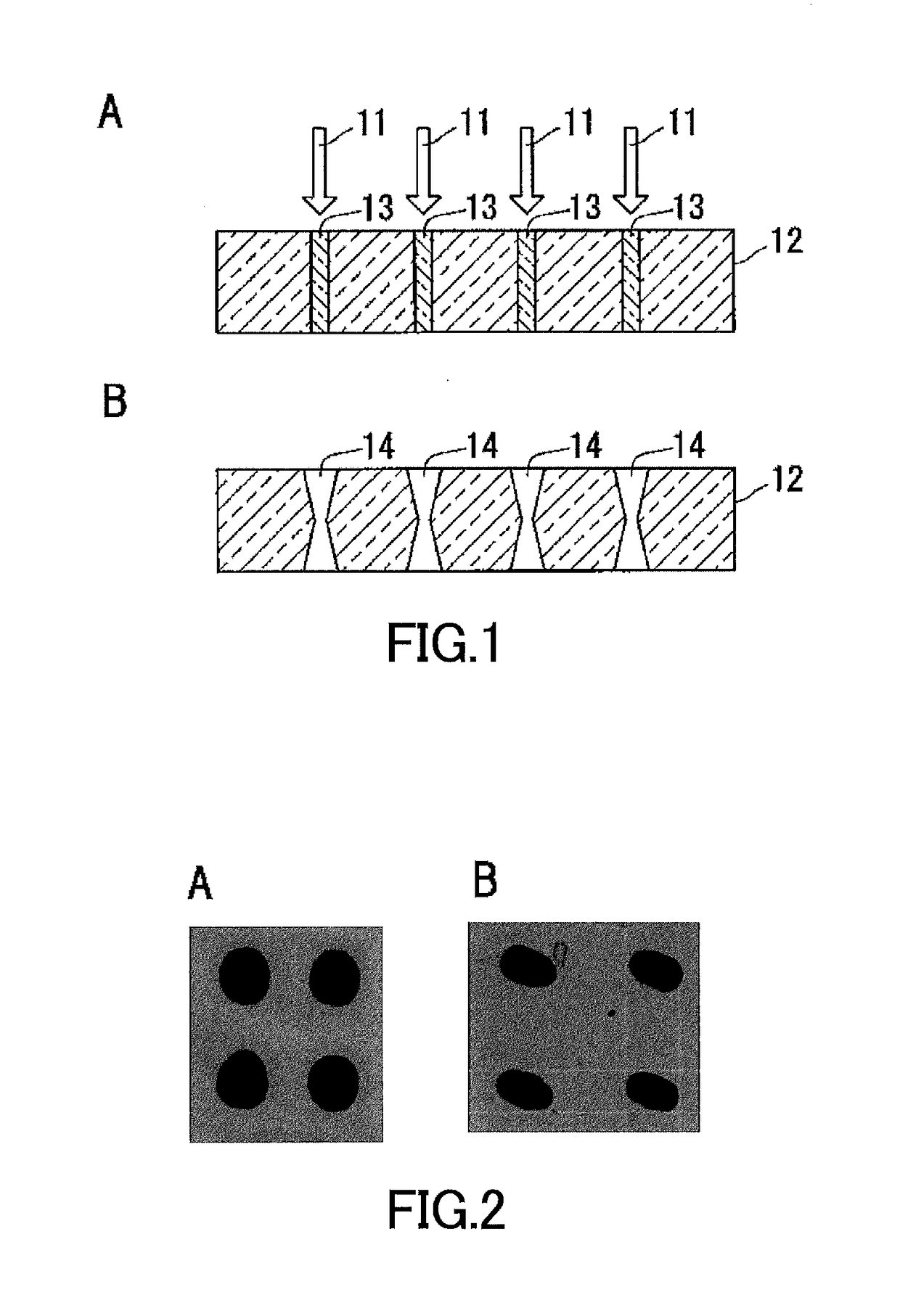

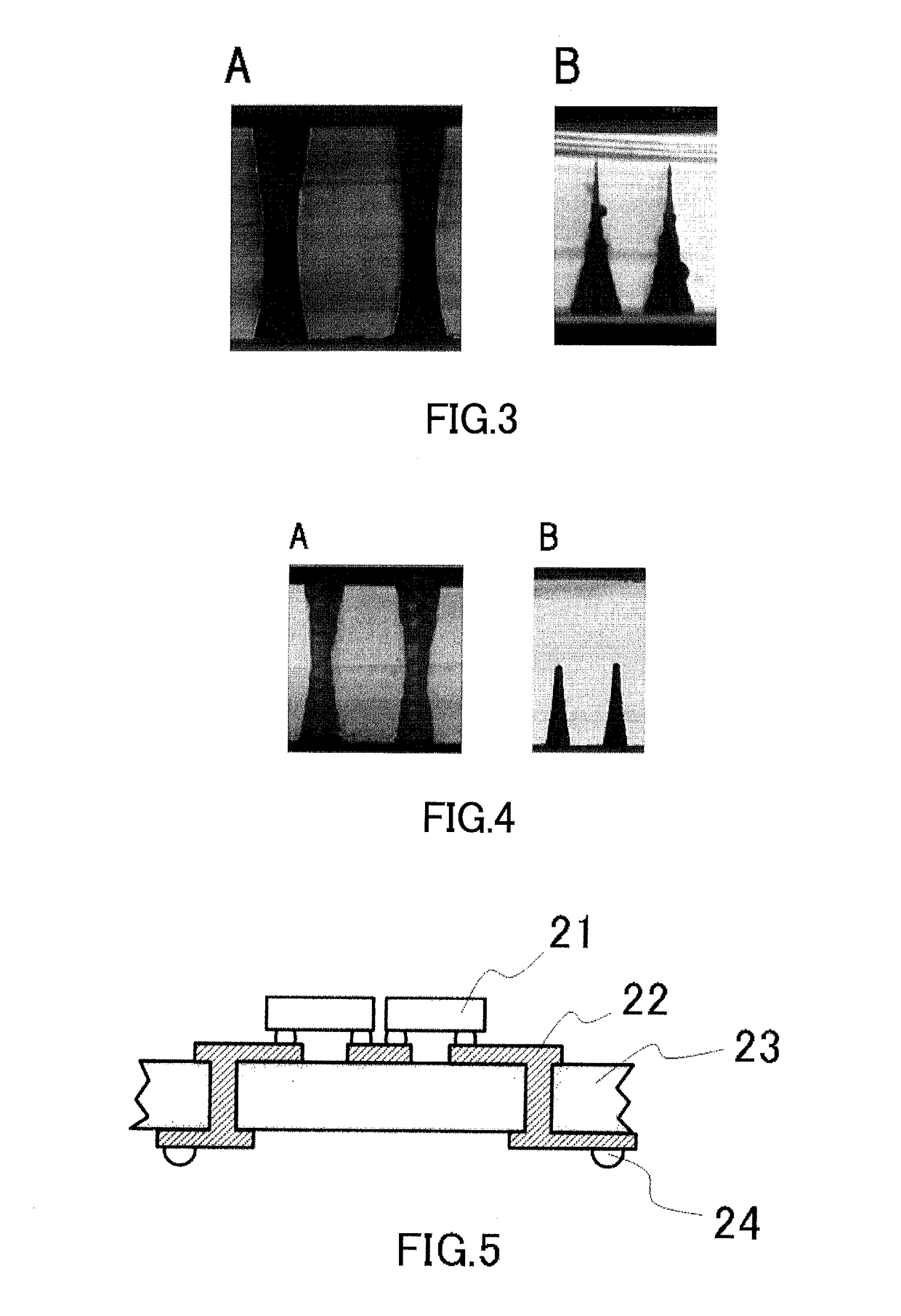

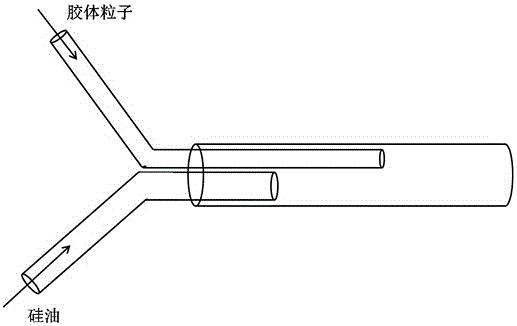

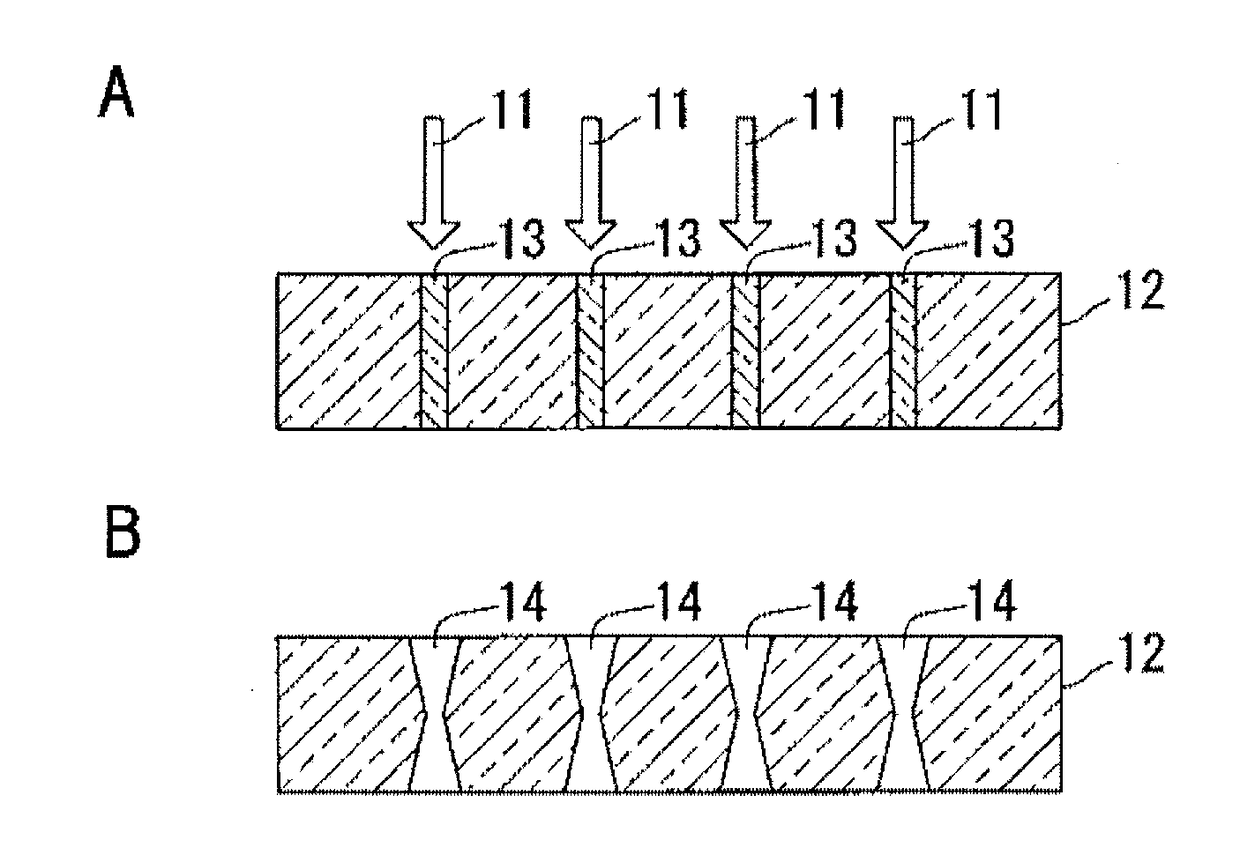

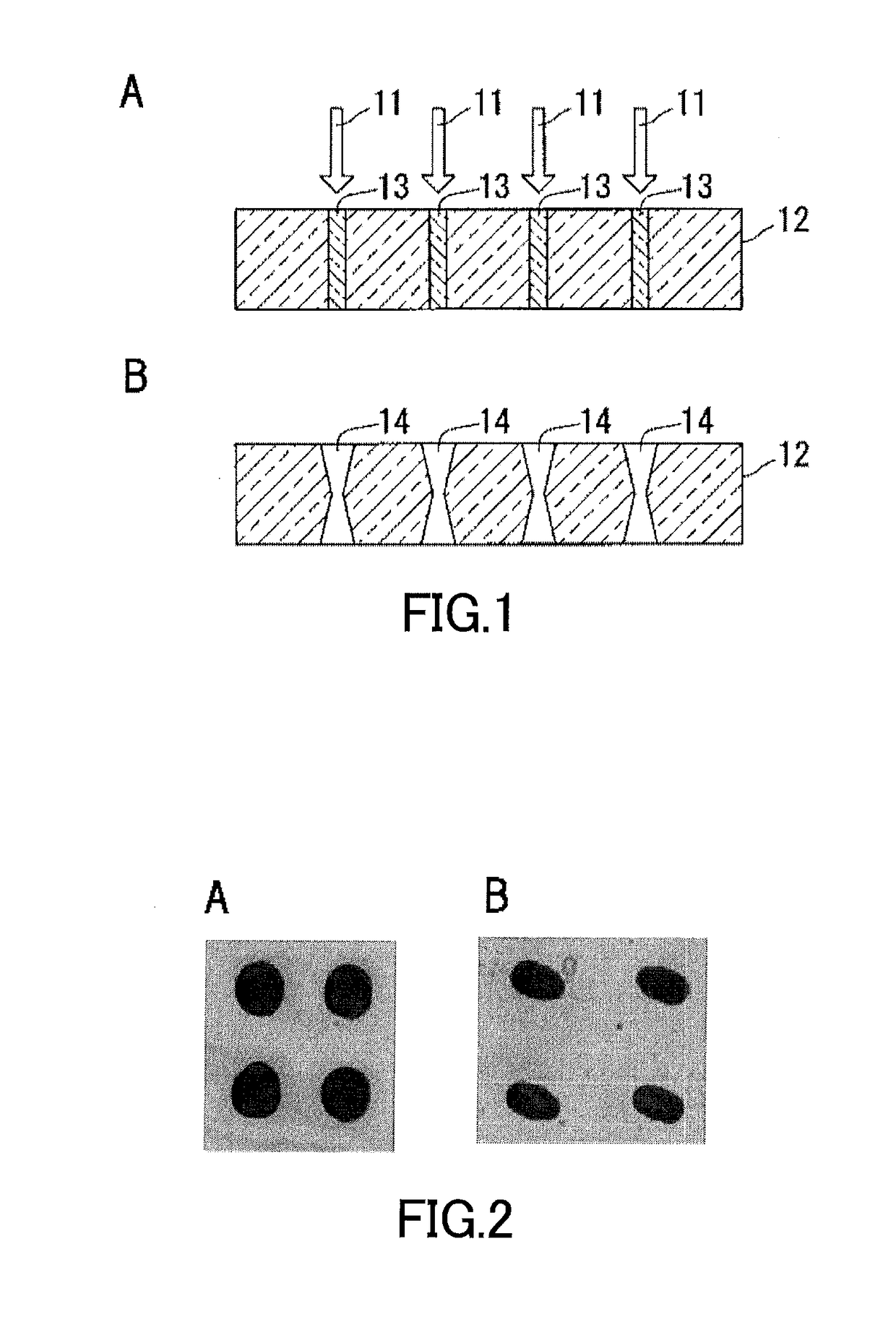

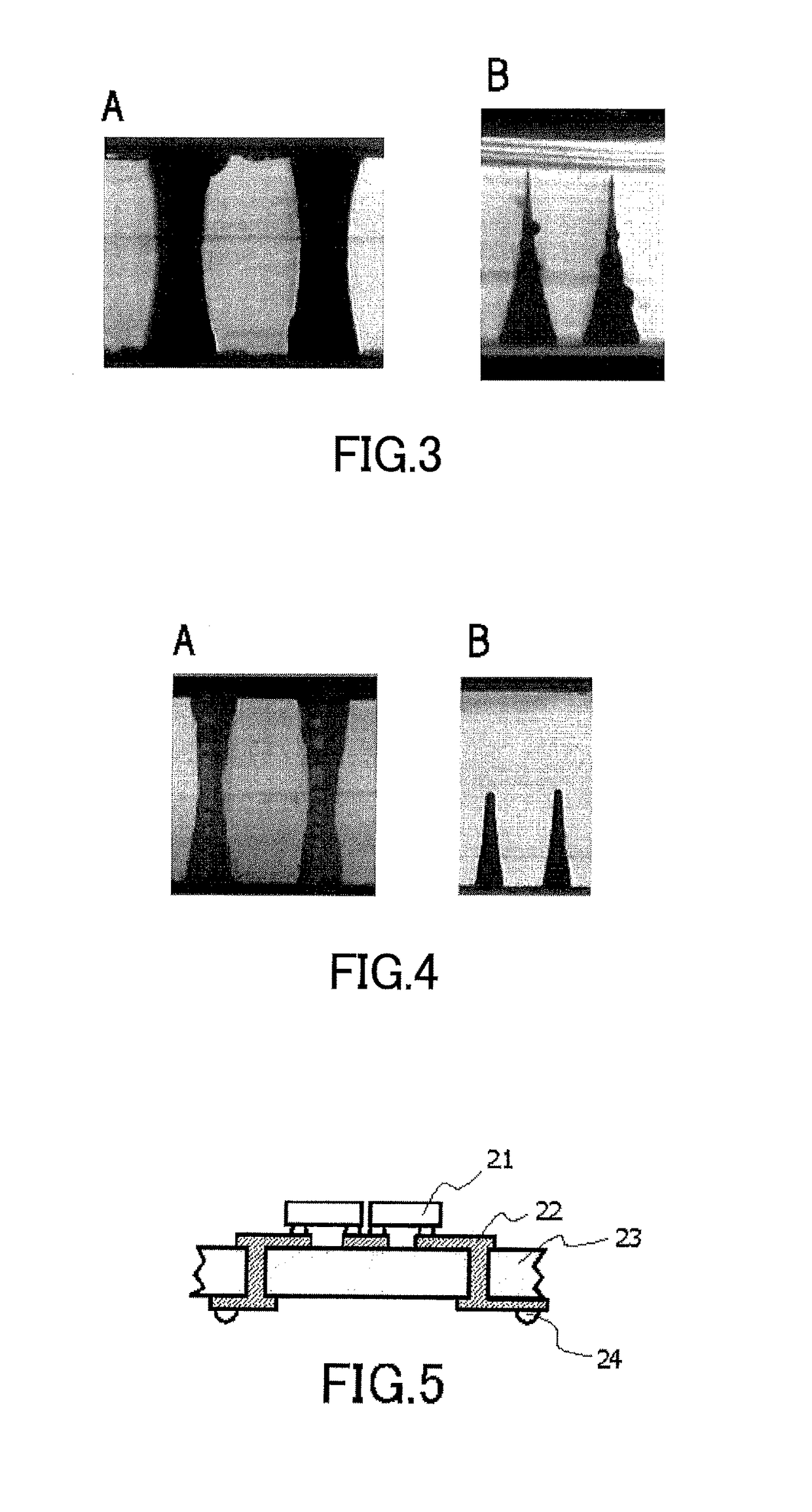

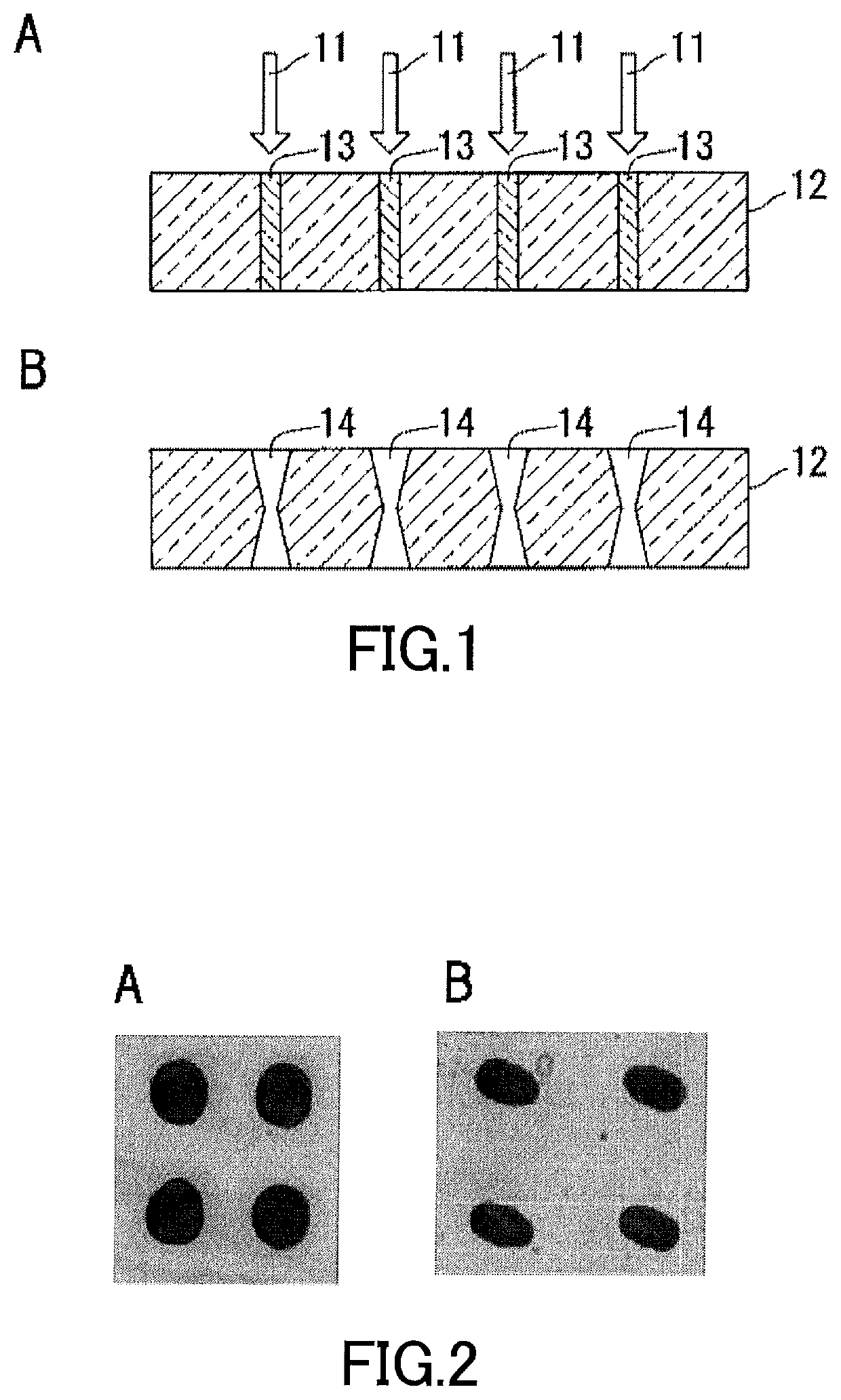

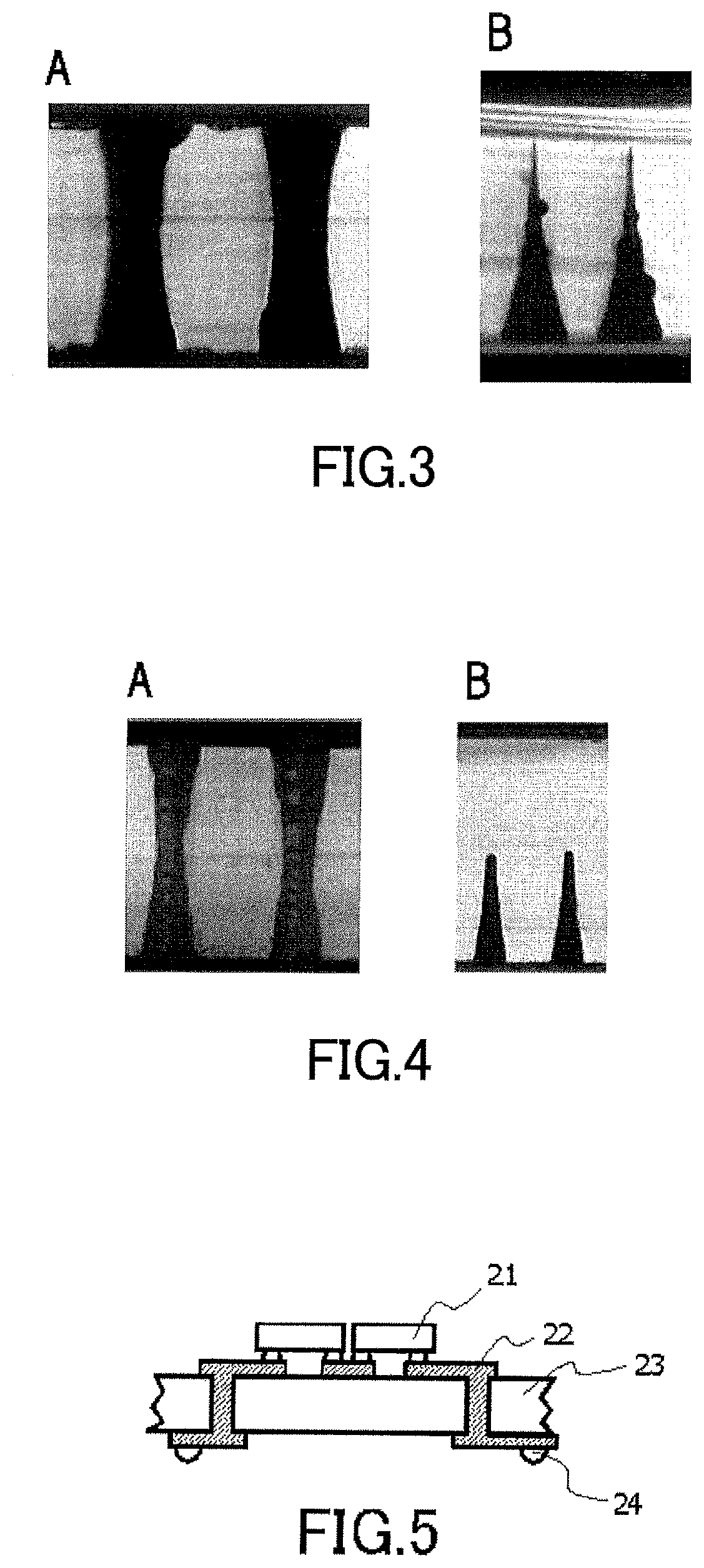

Glass for laser processing and method for producing perforated glass using same

ActiveUS20180022634A1Uniform holeEliminate needGlass severing apparatusWelding/soldering/cutting articlesLaser processingUltraviolet

The present invention provides a glass composition that allows holes with a circular contour and a smooth inner wall to be formed by a collective micro-hole-forming process using a combination of modified portion formation by ultraviolet laser irradiation and etching, the glass composition being adapted for practical continuous production. The present invention relates to a glass for laser processing, the glass having a glass composition including, in mol %: 45.0%≦SiO2≦70.0%; 2.0%≦B2O3≦20.0%; 3.0%≦Al2O3≦20.0%; 0.1%≦CuO≦2.0%; 0%≦TiO2≦15.0%; and 0%≦ZnO≦9.0%, wherein a relationship of 0≦Li2O+Na2O+K2O<2.0% is satisfied.

Owner:NIPPON SHEET GLASS CO LTD

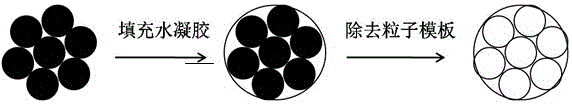

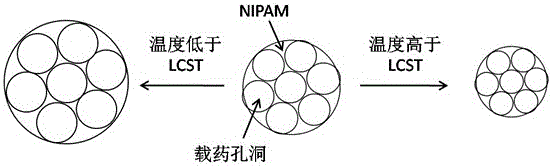

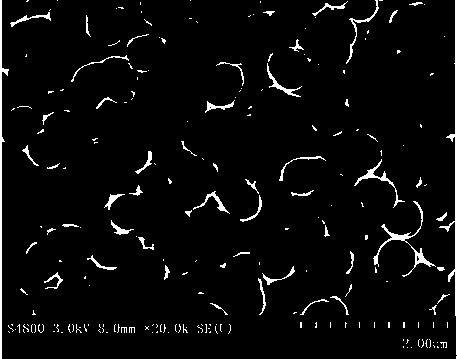

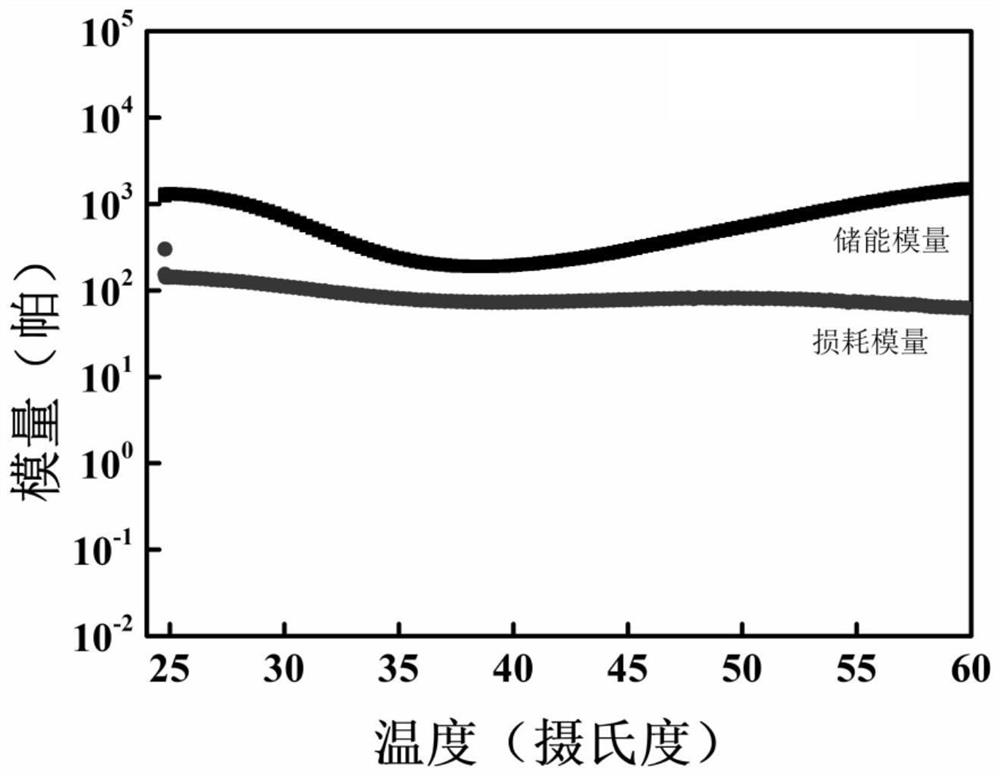

Thermo-sensitive coding microsphere carrier for drug controlled release and preparation method of microsphere carrier

InactiveCN106214644AAchieve controlled releaseHelp monitorAerosol deliveryOintment deliveryControlled releaseMedicine

The invention discloses a thermo-sensitive coding microsphere carrier for drug controlled release and a preparation method of the microsphere carrier. The carrier is a hydrogel microsphere with an inverse opal structure. The main component of the microsphere is poly(N-isopropylacrylamide), which has a three-dimensional ordered nanometer porous structure for carrying multiple protein or polypeptide medicines. Contraction and expansion of nanometer holes can be controlled through temperature regulation, so that drug controlled release is achieved. The inverse opal hydrogel microsphere is prepared by taking a colloidal crystal microsphere as a template. The carrier is simple in preparation method, low in cost and convenient for large-scale production. The prepared coding carrier is non-toxic and is good in biocompatibility and controllability.

Owner:SOUTHEAST UNIV

Glass for laser processing and method for producing perforated glass using same

ActiveUS20180029924A1Uniform holeEliminate needGlass severing apparatusWelding/soldering/cutting articlesContinuous productionOxide

The present invention provides a glass composition that allows holes with a circular contour and a smooth inner wall to be formed by a collective micro-hole-forming process using a combination of modified portion formation by ultraviolet laser irradiation and etching, the glass composition being adapted for practical continuous production. The present invention relates to a glass for laser processing, the glass including a metal oxide serving as a coloring component, the glass having a glass composition including, in mol %: 45.0%≦SiO2≦68.0%; 2.0%≦B2O3≦20.0%; 3.0%≦Al2O3≦20.0%; 0.1%≦TiO2≦5.0%; and 0%≦ZnO≦9.0%, wherein a relationship of 0≦Li2O+Na2O+K2O<2.0% is satisfied.

Owner:NIPPON SHEET GLASS CO LTD

Polycrystal black silicon texturing process

ActiveCN108193281AGood lookingBlurred appearancePolycrystalline material growthAfter-treatment detailsMicro nanoSilver particles

The invention discloses a polycrystal black silicon texturing process. The polycrystal black silicon texturing process includes the following steps that 1), a polycrystalline silicon wafer is polishedthrough polishing liquid; 2), the polished silicone wafer is hole-dug through hole-digging treating liquid, and nano-holes are prepared in the surface of the silicone wafer; 3), the hole-dug siliconewafer is de-silverized, and silver particles on the silicone wafer are removed; 4), the de-silverized silicone wafer is chambered through chambering treating liquid, and micro-nano holes are preparedin the surface of the silicone wafer. According to the polycrystal black silicon texturing process, by means of control over the three key steps of polishing, hole-digging and chambering, the whole black silicone texturing process is controllable, polycrystal black silicon with the good appearance and high efficiency can be prepared, and the prepared polycrystal black silicon is fuzzy in appearance and is provided with uniform holes.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

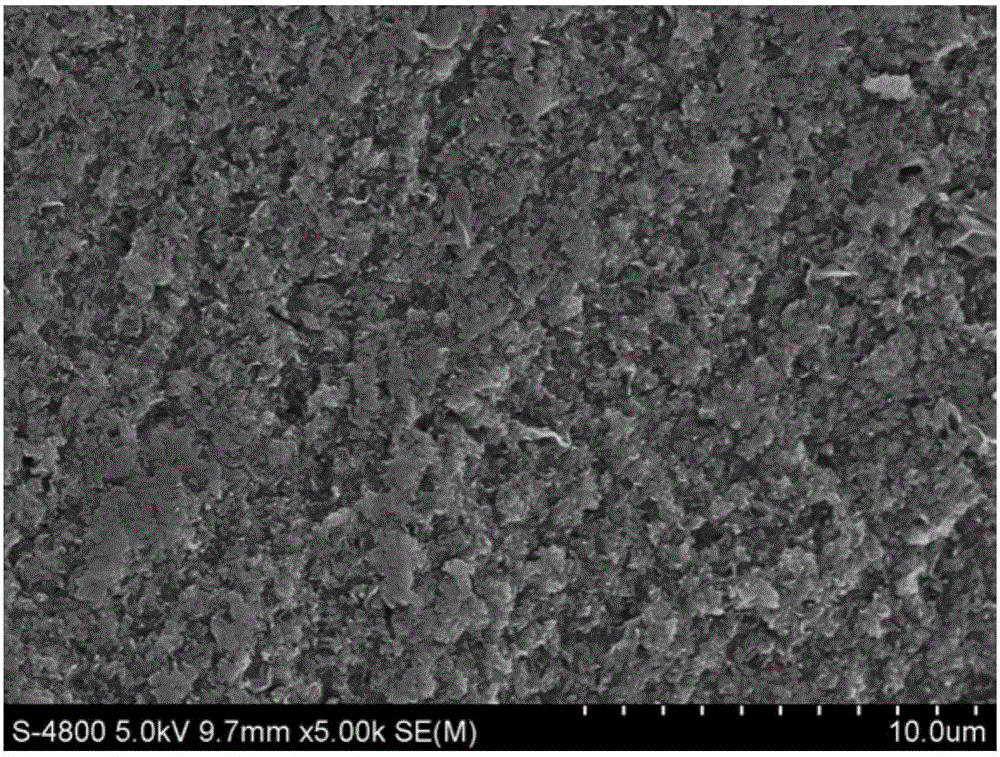

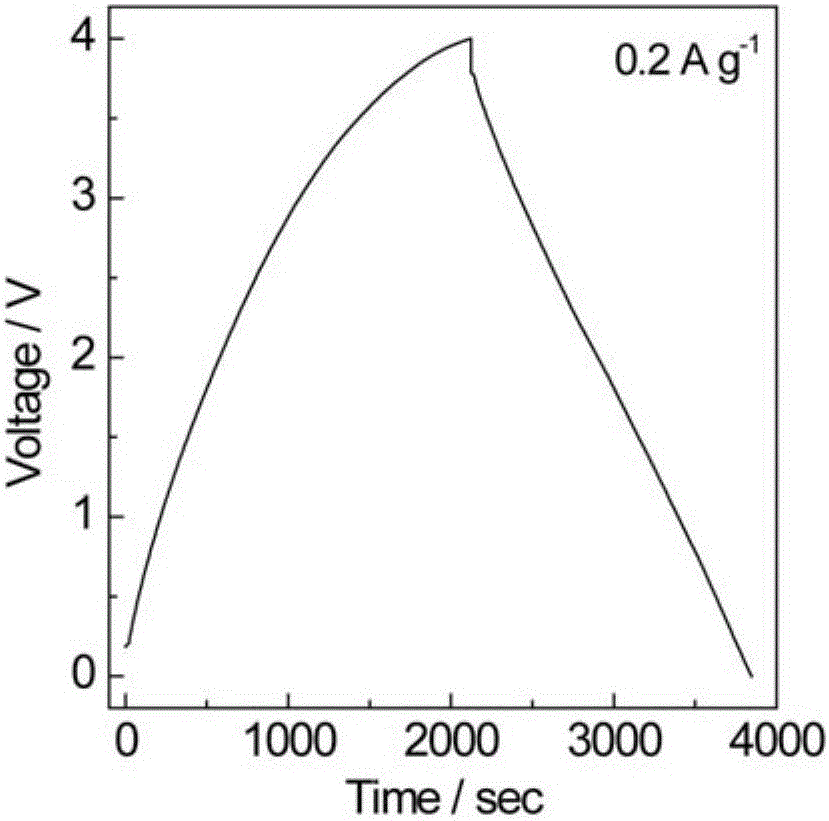

Preparation method of graphene-based thick and dense electrode

ActiveCN105869924AHigh yieldUniform holeHybrid capacitor electrodesHybrid/EDL manufacturePorous grapheneHigh volume manufacturing

The invention discloses a preparation method of a graphene-based thick and dense electrode. The method comprises the following steps of preparation of graphene hydrogel, compounding of graphene and a salt component, aerogenesis and removal of the salt component and preparation of the graphene-based thick and dense electrode. According to the method, a three-dimensional porous graphene block material is prepared according to the pore-forming effect of aerogenesis salt on a graphene network in the heating process. Compared with other pore-forming methods, the aerogenesis salt does not etch graphene in the heating process, the yield of the graphene is high, and the method is suitable for batch production of the porous graphene material; gas generated after heating is removed, and therefore the obtained graphene has few impurities and is high in purity; a small quantity of remaining impurities occupy pores of the graphene, and a secondary pore-forming effect is achieved on the graphene network after washing. The graphene is of a three-dimensional formed block structure and can be directly applied to an electrode material, the electrode has large thickness and density, and the processing step of preparing the electrode from powdery graphene is avoided.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Low-thermal conductivity composite foam material and preparation method thereof

The invention discloses a low-thermal conductivity composite foam material, which is prepared by the following steps: uniformly mixing resin, hollow microspheres, thermal expansion microspheres, a curing agent, an accelerant, a coupling agent, a toughening agent and a flame retardant in proportion, and filling a mold with the mixed slurry for molding and curing to obtain a resin-based foam matrix;and uniformly mixing a silicon source, ethanol, water and a catalyst to obtain silica sol, impregnating the resin-based foam matrix with the silica sol, and carrying out gelatinization treatment, aging and drying to obtain the low-thermal conductivity composite foam material. By adding the hollow microspheres, the problems that traditional aerogel is low in mechanical strength and poor in toughness are solved, the operability of the aerogel serving as a thermal insulation material in construction application is improved, and the mechanical properties of the aerogel material are greatly improved. The prepared low-thermal conductivity composite foam material has good heat insulation and sound insulation characteristics and mechanical properties, is simple in forming process and convenient to operate, and can be widely applied to the requirements of industries, buildings and aerospace for heat insulation and heat preservation components.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

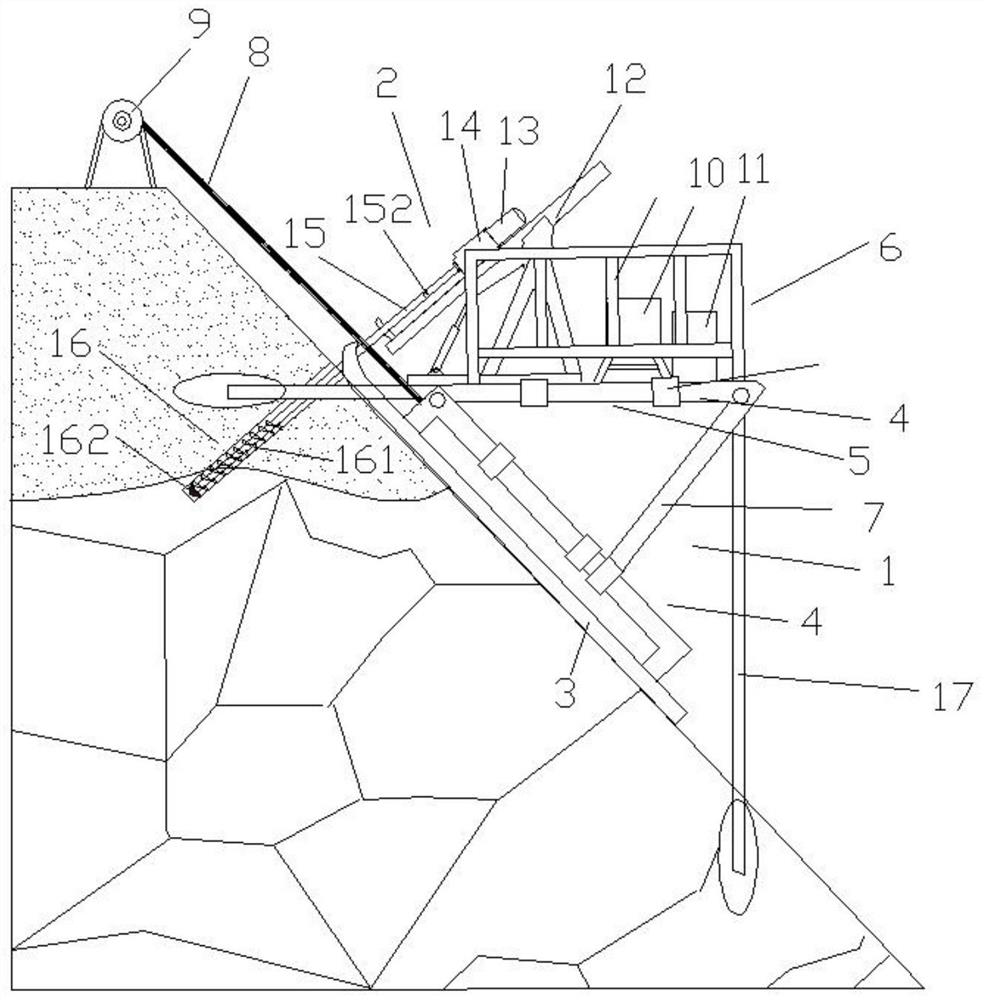

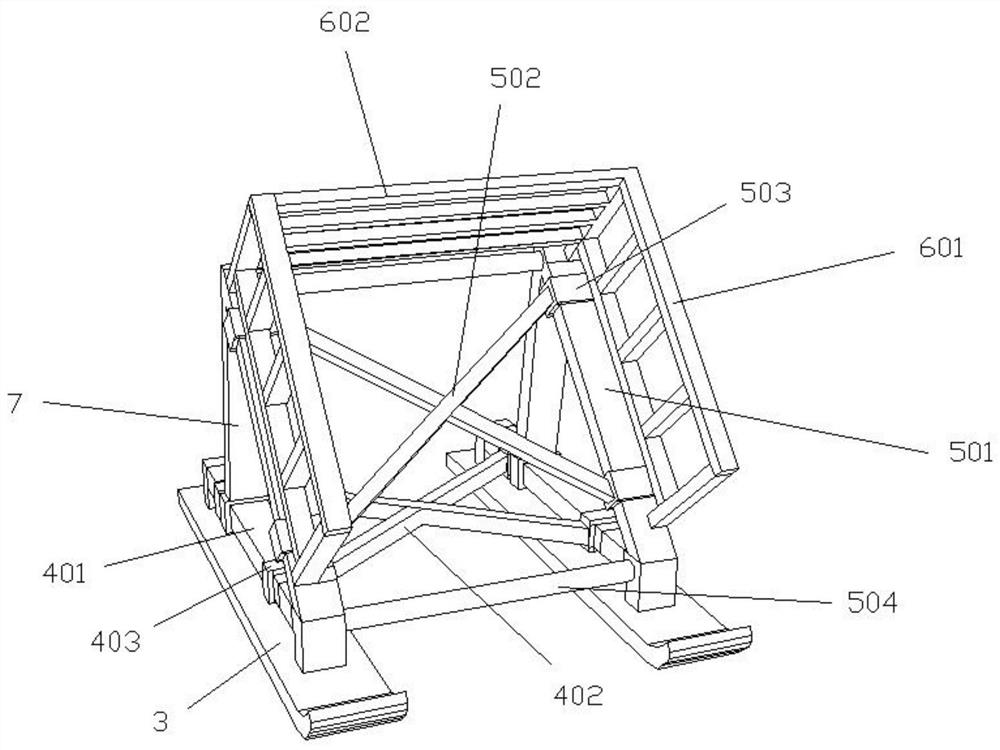

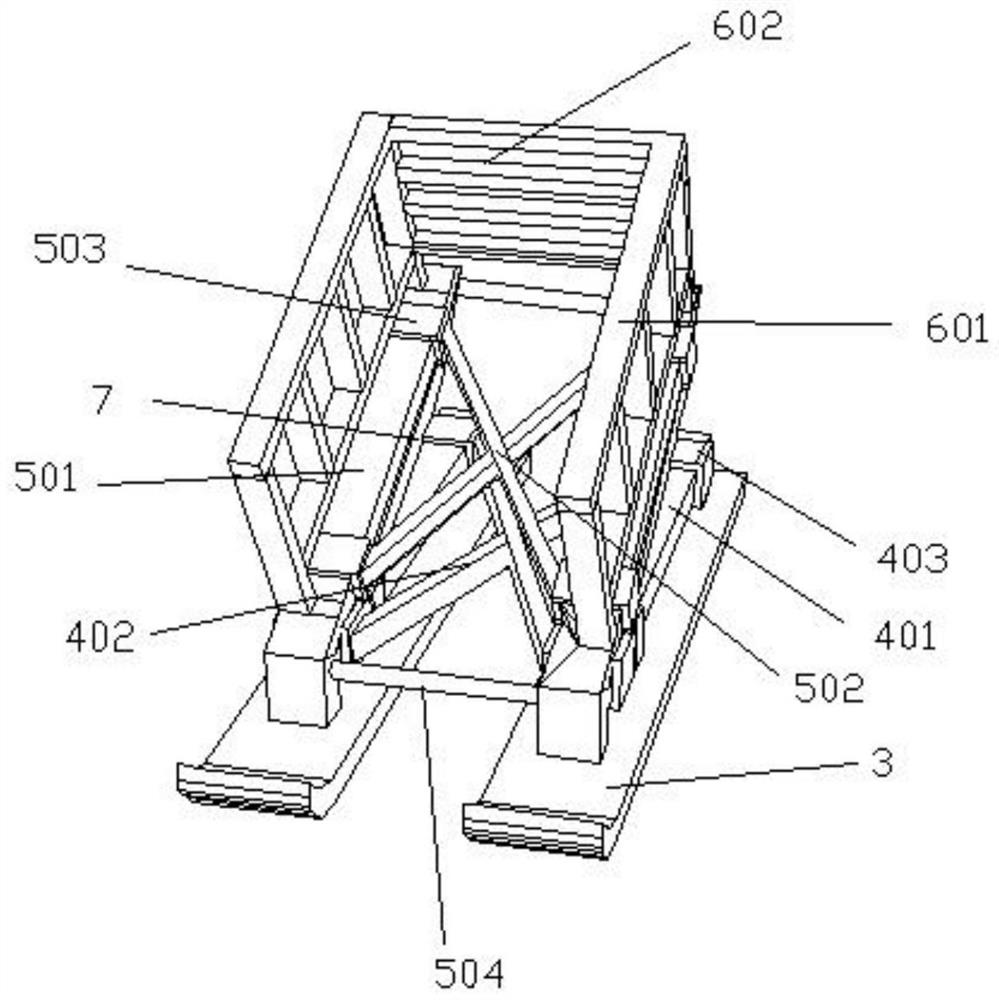

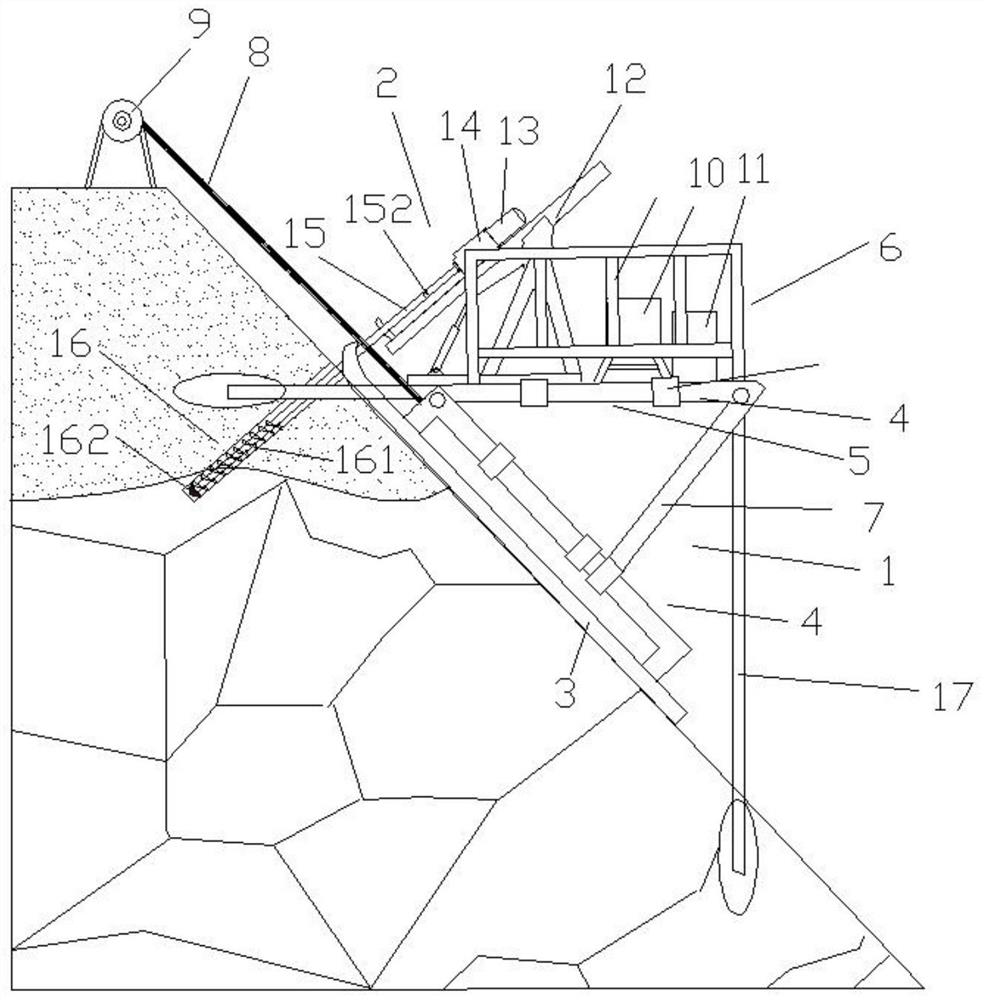

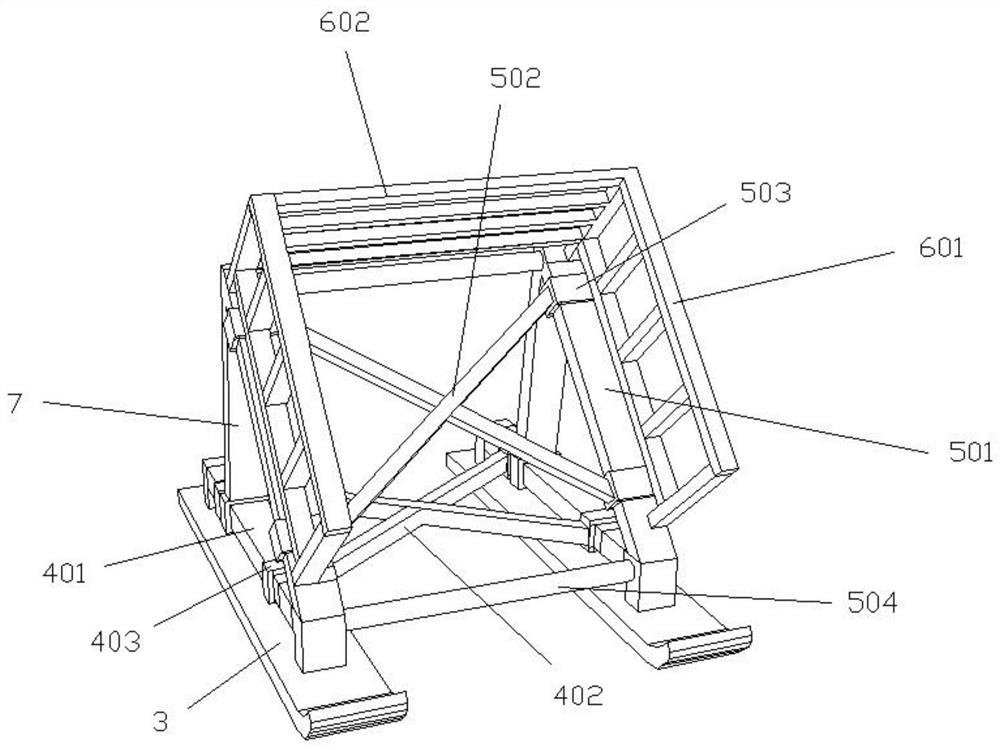

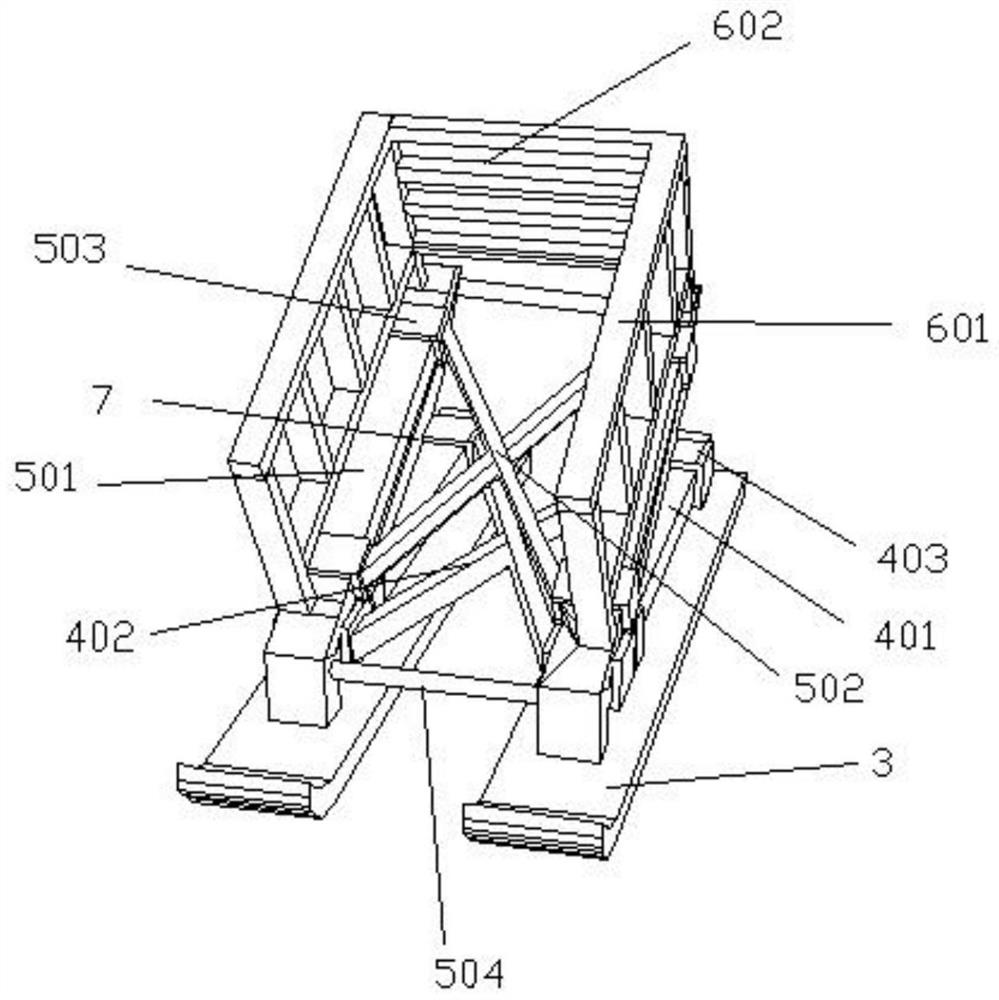

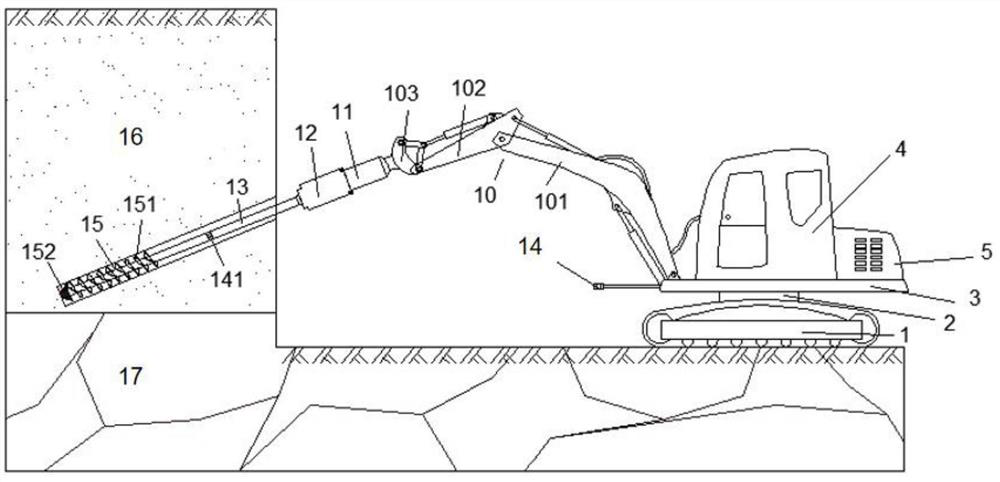

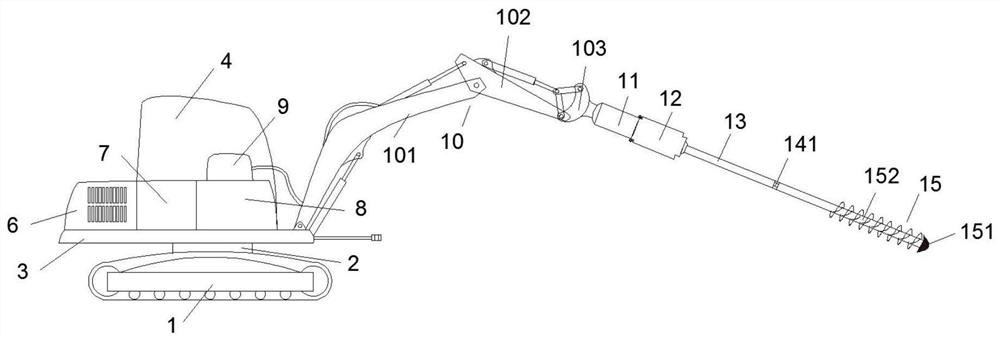

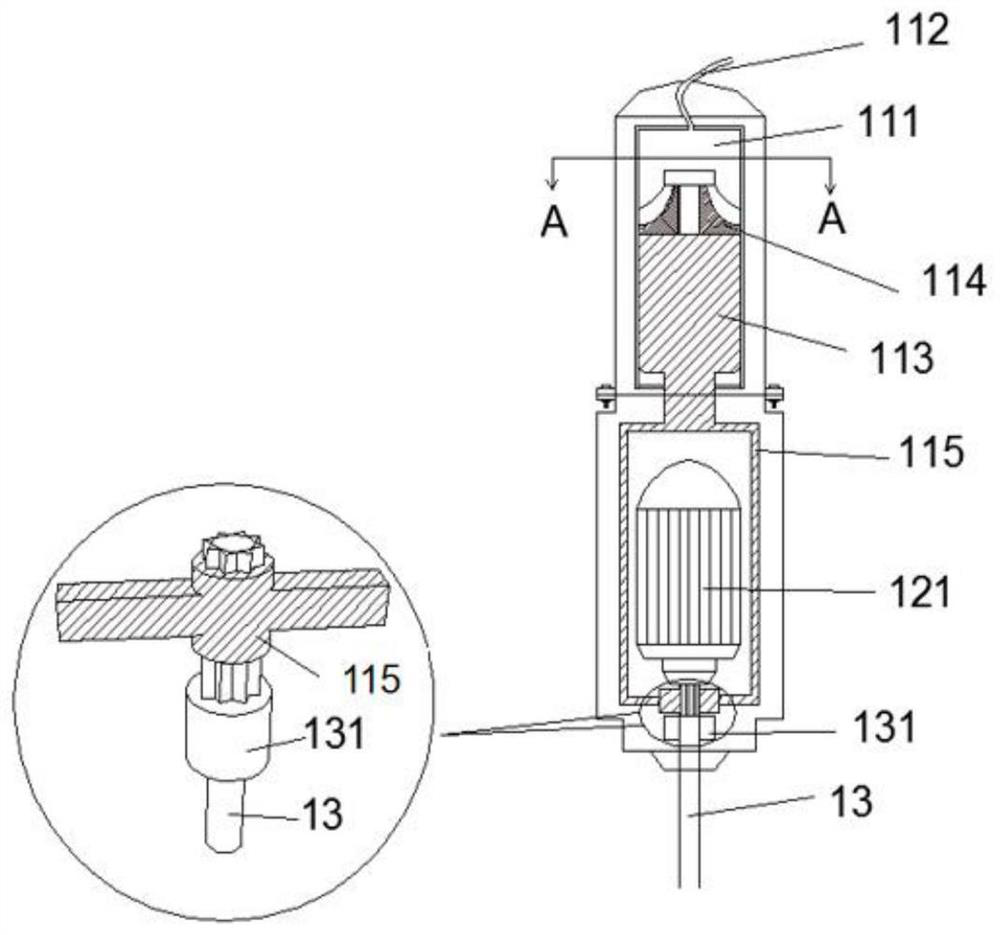

Construction method of drilling device for complex high and steep side slope

The invention discloses a construction method of a drilling device for a complex high and steep side slope. The drilling device comprises a drilling machine support, a drilling machine base and a drilling machine; the drilling machine support comprises a sliding plate, a chassis is arranged on the sliding plate, the front end of the chassis is hinged to the front end of a platform, a supporting component is hinged to the platform and connected with a chassis fastener, and the width of the chassis and the width of the platform are adjustable; and the drilling machine comprises a power distribution system, an air compression system, a gear, a rock drilling component, a soil drilling component, a drill rod and a drill bit. The construction method comprises the following steps of 1, pulling the drilling machine support to a specified position; 2, unfolding and locking the support; 3, adjusting the angle between the chassis and the platform; 4, mounting the drilling machine; and 5, startingdrilling. The device solves the problem that it is difficult to drill in the complex high and steep side slope, can adapt to various rock-soil body stratums, can cope with complex slope surface conditions such as concavo-convex surfaces and flourishing forests, is flexible in action and safe and reliable in performance, and can fully cope with existing complex high and steep side slope reinforcement engineering.

Owner:DALIAN UNIV OF TECH

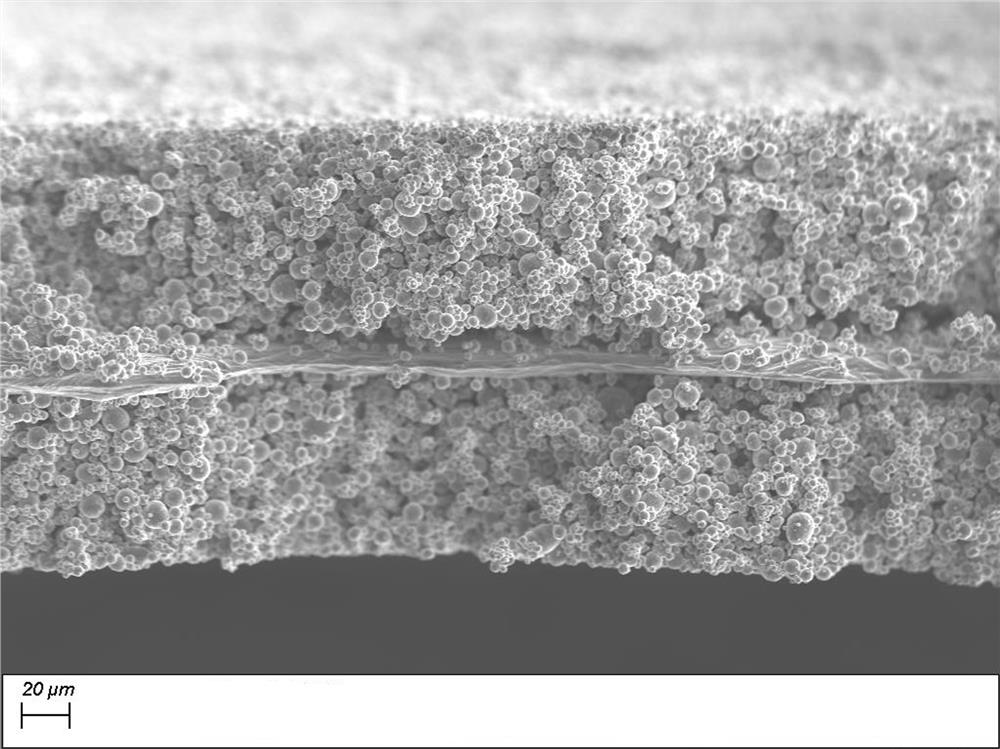

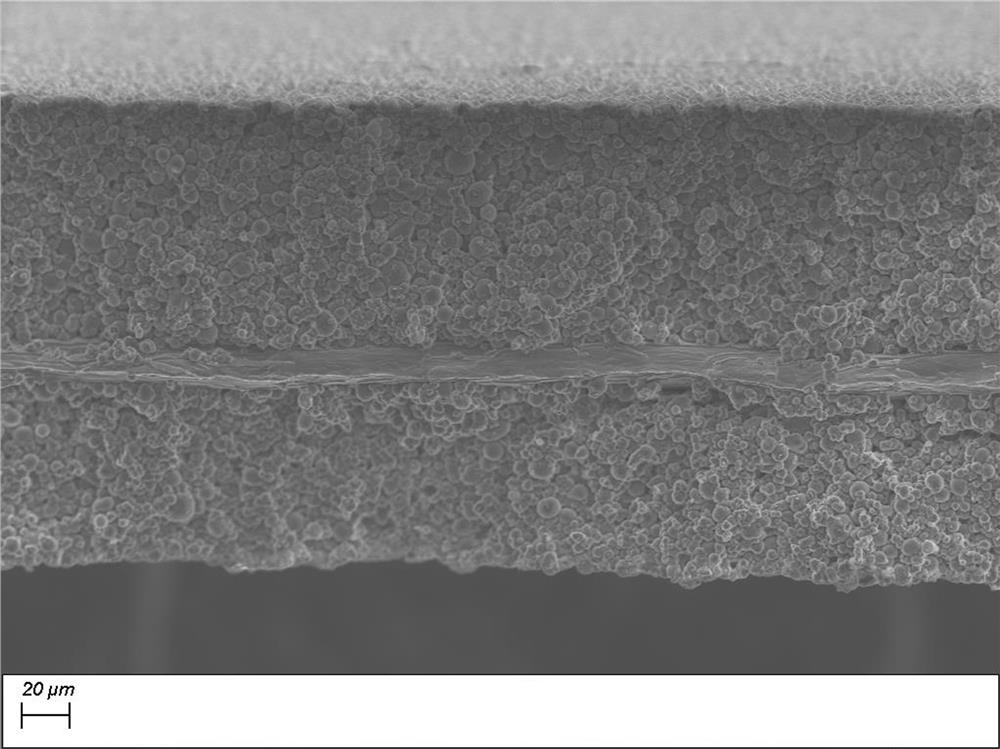

Manufacturing method of powder sintered anode foil and anode foil

The invention provides a preparation method of a sintered anode foil for an aluminum electrolytic capacitor. The preparation method comprises the following steps: S1, preparing aluminum powder slurry;s2, making the uniformly mixed slurry into a film on a substrate and curing the film; s3, degreasing the substrate obtained in the S2; s4, sintering the substrate obtained in the S3; and S5, formingthe substrate obtained in the step S4. According to the method for sintering the anode foil, it can be guaranteed that degreasing is clean and complete, the state in the sintering process is stable, overburning is avoided, and holes are uniform after sintering.

Owner:CENT SOUTH UNIV

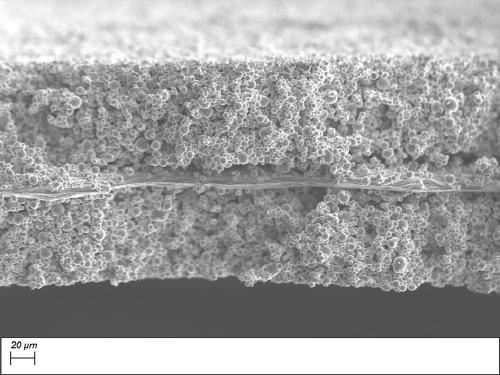

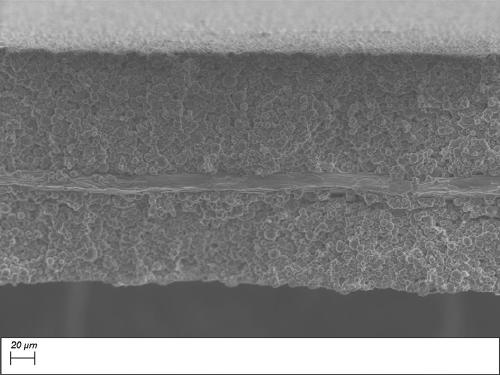

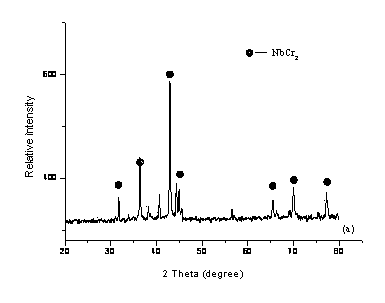

Method for preparing and synthesizing NbCr2 intermetallic compound porous material through reaction of Cr powder and Nb powder

The invention discloses a method for preparing and synthesizing an NbCr2 intermetallic compound porous material through a reaction of Cr powder and Nb powder. The method comprises the steps as follows: 1), the Cr powder and the Nb powder which have the atomic percent of 2:1 and a grinding ball are placed into a ball grinding tank, the tank is sealed, and ball grinding is performed; 2), a proper quantity of a binding agent is added into the fully-mixed powder, and the mixture is pressed into sheet briquettes after uniform mixing; and 3), briquette-pressing is performed, a sectional type sintering process is adopted, and sintering is performed in a vacuum sintering furnace, so that the Cr powder and the Nb powder have a reaction fully, so that the intermetallic compound NbCr2 is formed. According to the method, the Laves-phase NbCr2 intermetallic compound porous material is synthesized, and the porosity of the synthesized porous material reaches 35%-55%.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for preparing foam glass with high foaming rate by utilizing lead-free high-barium abandoned lamp tube

InactiveCN106630649AHigh foaming rateUniform pore sizeGlass shaping apparatusCalcium carbonateBall mill

The invention discloses a method for preparing foam glass with a high foaming rate by utilizing a lead-free high-barium abandoned lamp tube and belongs to the field of foam glass. The method comprises the following steps: carrying out ball milling on the lead-free high-barium abandoned lamp tube to form a glass powder raw material; feeding foaming agents, namely manganese dioxide and calcium carbonate, a fluxing agent, namely sodium fluorosilicate, and a stabilizer, namely sodium phosphate into a ball mill to be subjected to ball milling; feeding mixture obtained through ball milling into a high-temperature-resistant mould, preheating for 15-20 minutes at the temperature of 400-430 DEG C, then heating up to 800-820 DEG C, and carrying out heat preservation for 20-30 minutes; then cooling to 500-550 DEG C, annealing, and carrying out heat preservation for 35-40 minutes; and finally carrying out furnace cooling to room temperature. The prepared foam glass is uniform in pore diameter, closed pores are formed mainly, the average pore diameter reaches about 4.2mm, the density is 0.58g / cm<3>, the compressive strength is 3.78MPa, the performance is excellent, and the application standard of the foam glass can be met.

Owner:YANGZHOU UNIV

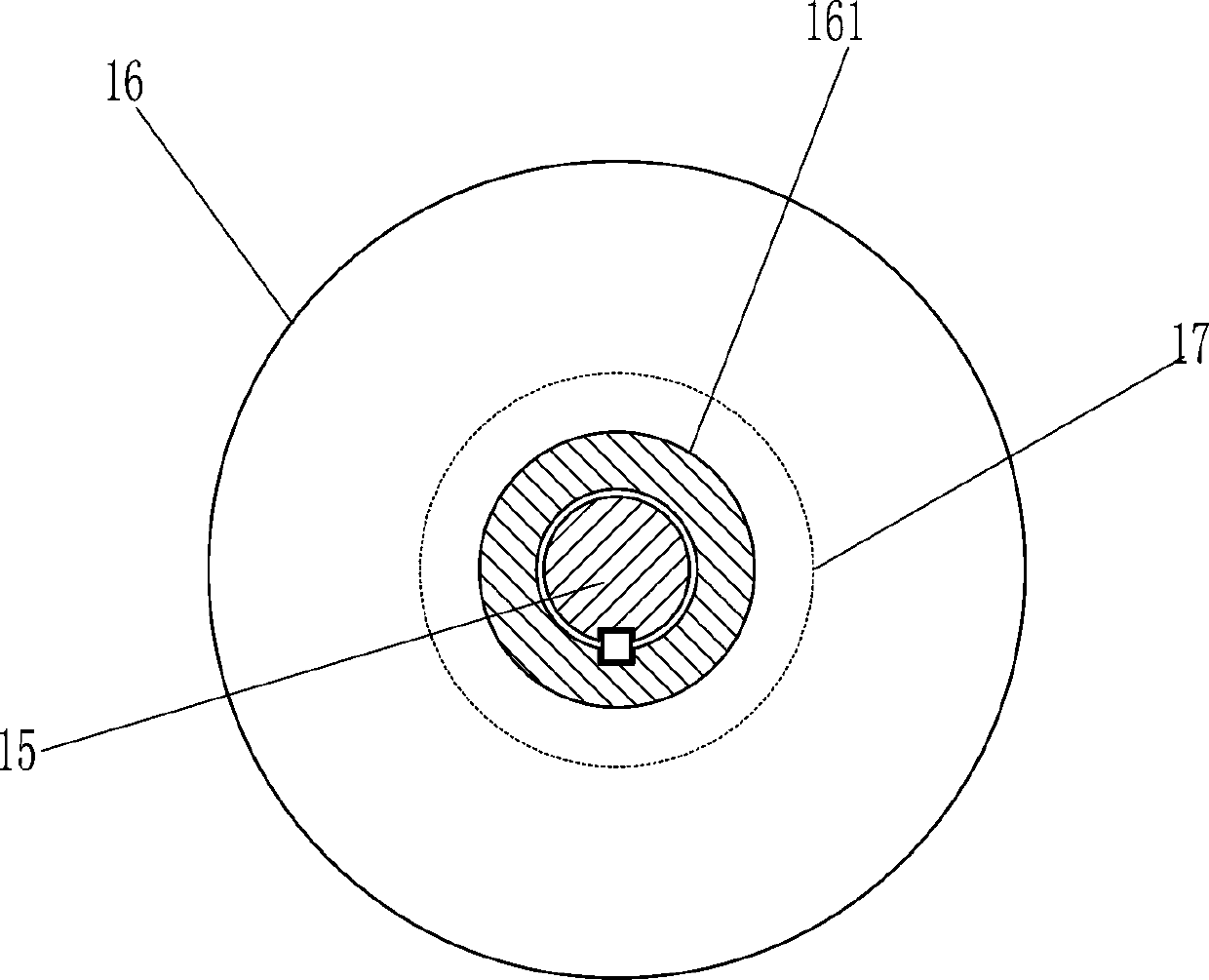

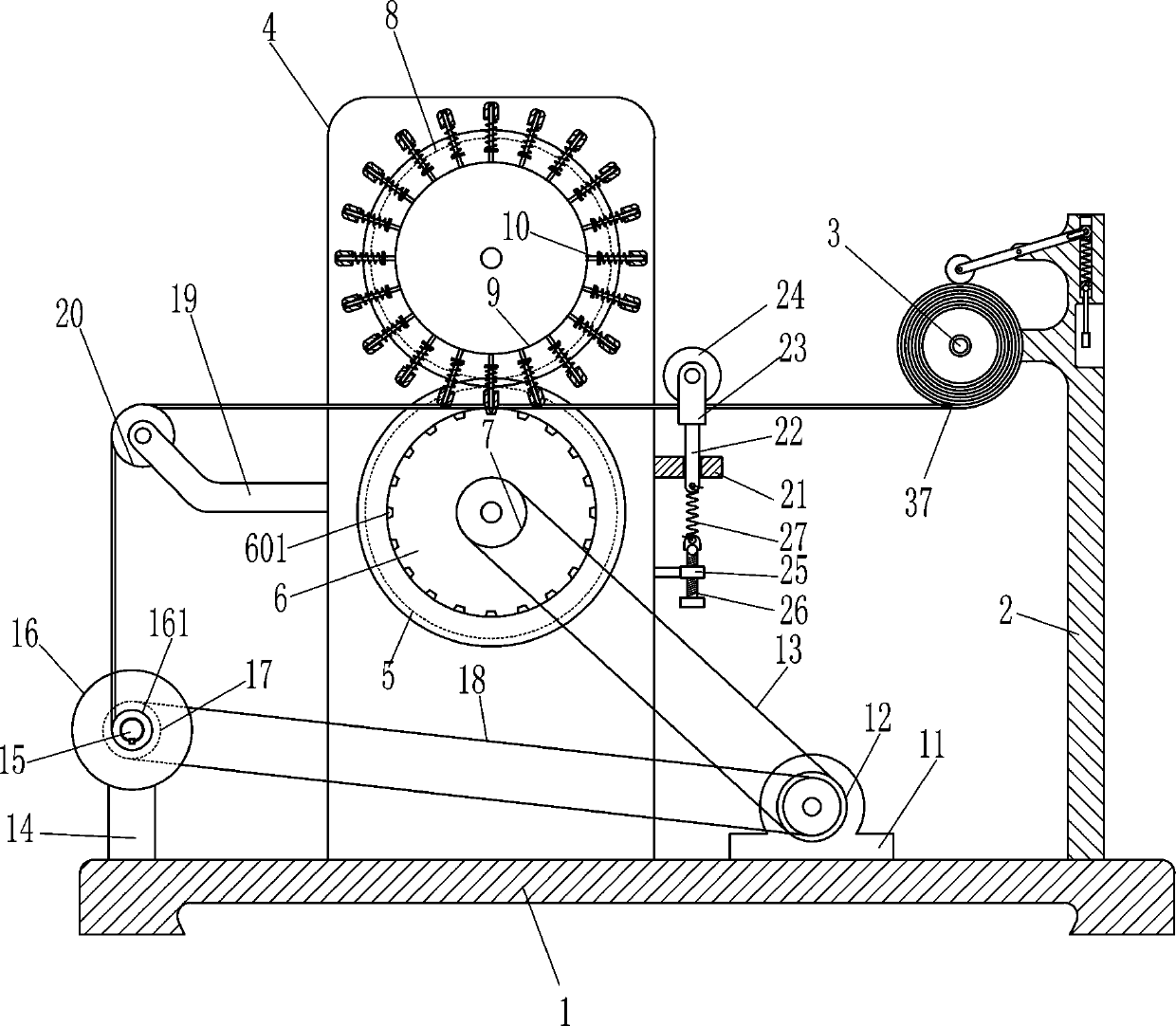

Water spraying belt punching machine

The invention relates to a punching machine, in particular to a water spraying belt punching machine. According to the water spraying belt punching machine, punching is more uniform, a water belt canbe compressed, and the water spraying belt can be tensioned. According to the technical implementation scheme, the water spraying belt punching machine comprises a base, a first rack, a first rotatingrod, a mounting plate, a first gear, a first disc, a first belt wheel, a second gear, a second disc, a needle rod and the like; the top of the base is sequentially provided with a second rack, the mounting plate, a motor and the first rack from left to right; the first rotating rod is rotatably arranged on the upper part of the left side of the first rack; the water belt is wound on the first rotating rod; and the first gear and the second gear are rotatably arranged on the front side of the mounting plate. The water spraying belt punching machine is provided with a first screw rod, a U-shaped seat and a second idler wheel, people rotate the first screw rod to enable the U-shaped seat and the second idler wheel to move up and down so as to adjust the tightness of the water belt, and thusthe situation that the needle rod is missed when the water belt is too loose or too tight, and then the punching quality is affected can be prevented.

Owner:山东爱舒乐卫生用品有限责任公司

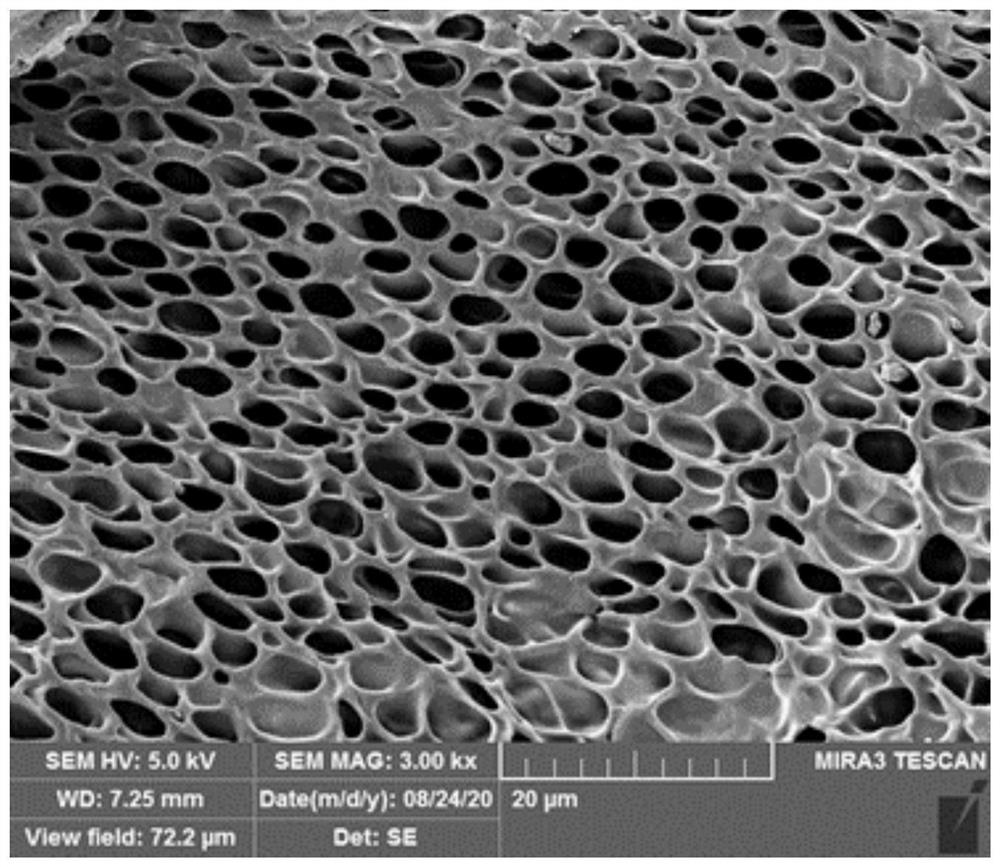

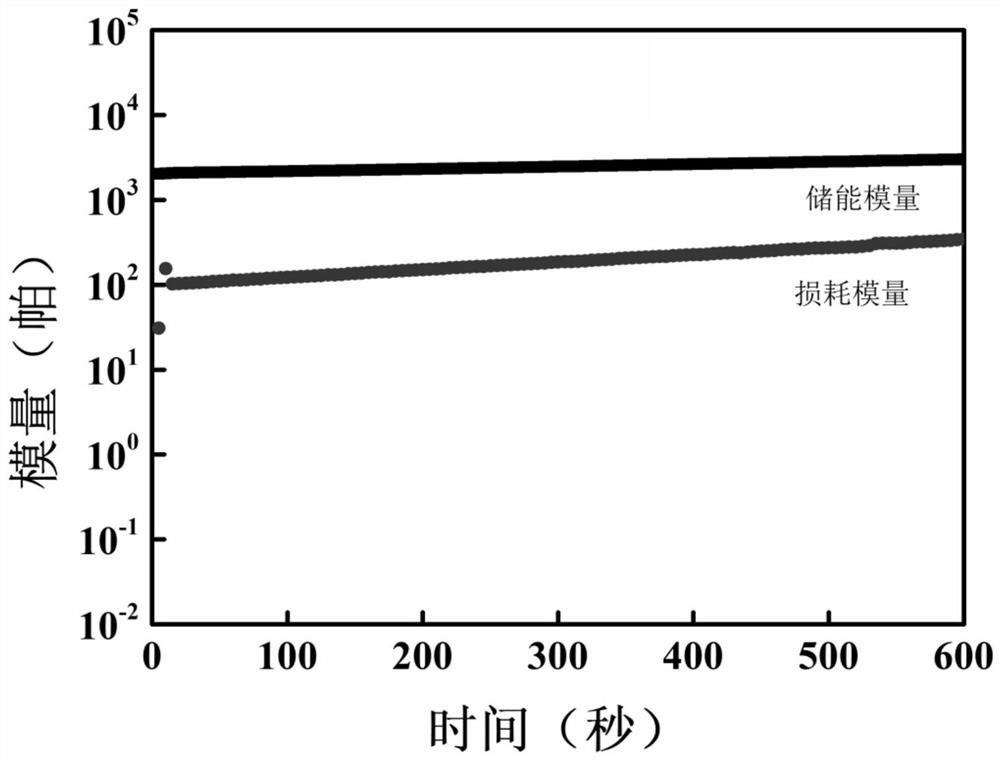

Injectable hydrogel as well as preparation method and application thereof

ActiveCN113416326AImprove adhesionControllable 3D mesh structureSurgical adhesivesAerosol deliveryGlutaminasePolyphenol

The invention relates to injectable hydrogel as well as a preparation method and application thereof. The injectable hydrogel is obtained by taking gelatin and tannic acid as raw materials and carrying out chemical crosslinking under the catalysis of transglutaminase. Gelatin molecular chains in the injectable hydrogel form a network structure under the action of amido bonds, polyphenol hydroxyl groups of the tannic acid and amino groups on the gelatin chains have hydrogen-bond interaction, the polyphenol hydroxyl groups of the tannic acid can be spontaneously complexed under an alkaline condition, and finally the injectable hydrogel is endowed with excellent adhesion performance; the material and tissues are adhered, the performance of the material is promoted, the injectability of the material is improved, the gelling time is shortened, the clinical operation is easy, and the mechanical property is improved. The hydrogel material can realize adhesion and efficient retention of defective tissues, is suitable for filling various irregular-shaped defects, can efficiently promote the performance of the material to play, and realizes repair of the defective tissues.

Owner:SHENZHEN PEOPLES HOSPITAL

Glass for laser processing and method for producing perforated glass using same

ActiveUS10717670B2Uniform holeEliminate needGlass severing apparatusWelding/soldering/cutting articlesLaser processingUltraviolet laser light

The present invention provides a glass composition that allows holes with a circular contour and a smooth inner wall to be formed by a collective micro-hole-forming process using a combination of modified portion formation by ultraviolet laser irradiation and etching, the glass composition being adapted for practical continuous production. The present invention relates to a glass for laser processing, the glass including a metal oxide serving as a coloring component, the glass having a glass composition including, in mol %: 45.0%≤SiO2≤68.0%; 2.0%≤B2O3≤20.0%; 3.0%≤Al2O3≤20.0%; 0.1%≤TiO2≤5.0%; and 0%≤ZnO≤9.0%, wherein a relationship of 0≤Li2O+Na2O+K2O<2.0% is satisfied.

Owner:NIPPON SHEET GLASS CO LTD

Preparation method of recyclable flocculating agent

ActiveCN112500633AMolecular chain stretching stability is goodImprove stabilityWater/sewage treatment by flocculation/precipitationCelluloseGlycidyl methacrylate

The invention discloses a preparation method of a recyclable flocculant, and the method comprises the following steps: selecting an ethylene vinyl acetate copolymer with VA content of 5-8% as a structural matrix of the flocculant, carrying out graft modification on hydroxy propyl cellulose and N-succinyl chitosan by glycidyl methacrylate and acrylic acid to obtain the recyclable flocculant, adopting N-methoxy-N-methyl acetamide as a structure modifier, and adopting a foaming process to prepare the recyclable flocculant. The flocculant prepared by the invention overcomes the problems of insufficient flocculation capacity and difficulty in recovery treatment of the existing flocculant, shows higher flocculation capacity, can be recovered, avoids secondary pollution, and can be widely used inthe treatment process of blue-green algae water.

Owner:SHANGHAI SHANHENG ECOLOGICAL TECH CO LTD

Preparation process of macroporous sodium polyacrylate embolization microspheres

PendingCN114470308AUniform polymerizationIntragranular microporous channels are goodSurgical adhesivesTissue regenerationMicrosphereIon exchange

The invention discloses a preparation process of macroporous sodium polyacrylate embolism microspheres, and relates to the technical field of medical instruments, the macroporous sodium polyacrylate embolism microspheres are subjected to suspension polymerization by taking a dispersing agent and water as continuous phases and taking a monomer acrylate compound, a cross-linking agent polyolefine compound, a pore-foaming agent and an initiator as dispersion phases, and the macroporous sodium polyacrylate embolism microspheres are obtained. And carrying out a hydrolysis process to obtain the macroporous sodium polyacrylate embolization microspheres. The prepared macroporous sodium polyacrylate embolization microspheres have high elasticity and large drug loading capacity. According to the invention, a suspension polymerization process is adopted for the first time, and the obtained macroporous microspheres have better intragranular microporous channels, are convenient for intragranular diffusion of molecules, have better ion exchange kinetics performance, are more suitable for medium-molecular chemotherapeutic drugs to quickly enter the microporous channels and exchange of functional groups, and greatly improve the drug loading capacity; the macroporous microspheres are more uniform in polymerization, and have higher strength and better elasticity compared with the macroporous microspheres.

Owner:苏州森康微球医疗科技有限公司

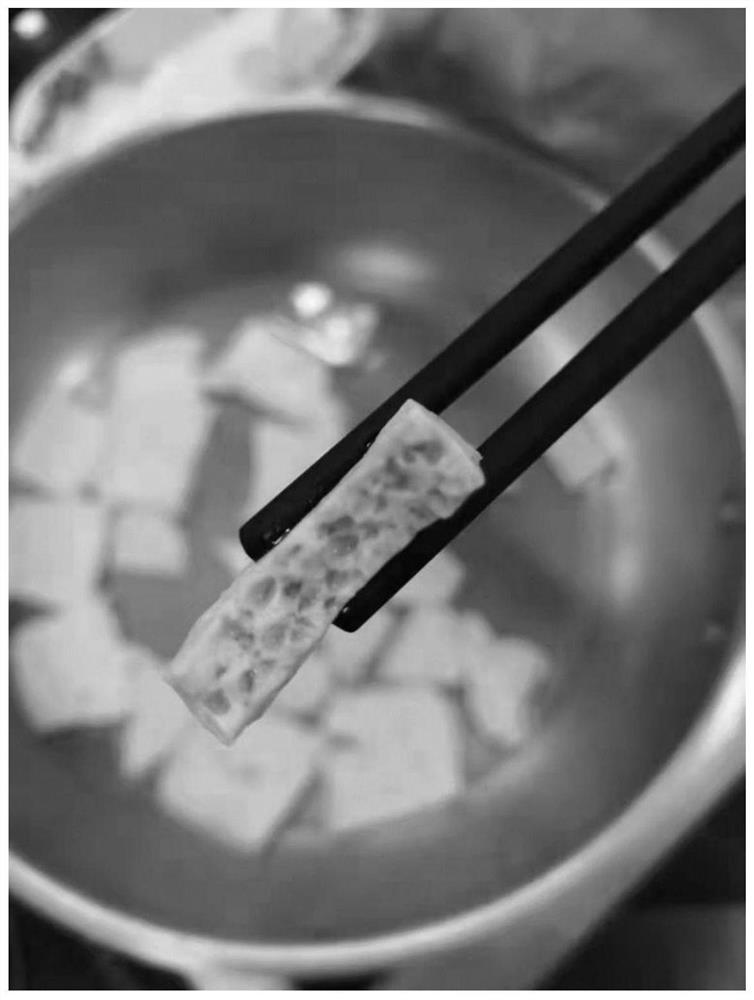

Method for preparing cooked bean curd with uniform pores

PendingCN111820289AIncrease elasticityImprove toughnessCheese manufactureEngineeringOrganic chemistry

The invention discloses a method for preparing cooked bean curd with uniform pores from soybeans as a raw material. The method comprises the following steps of peeling, soaking, primary grinding, secondary grinding, pulp filtering, pulp mixing, pulp boiling, primary brine adding and pulp curdling, secondary brine adding and pulp curdling, pressing, cutting, and packaging and sterilizing. The beancurd prepared by the method is fine and smooth in taste, free of beany flavor, and strong in bean fragrance, and the cooked bean curd has the uniform pores and is more tasty.

Owner:内蒙古西贝餐饮集团有限公司

Construction method of a drilling device for complex high and steep slopes

The invention discloses a construction method of a drilling device for complex high and steep slopes. The drilling device comprises a drilling machine support, a drilling machine base and a drilling machine. The drilling machine bracket includes a slide plate, on which there is a chassis, the front end of the chassis is hingedly connected with the front end of the platform, the supporting member is hingedly connected with the platform, and connected with the chassis fastener, and the width of the chassis and the platform can be adjusted; the drilling machine includes a power distribution system , air pressure system, gears, rock drilling components, soil drilling components, drill pipes and drill bits; construction methods include: 1) Pull the drilling machine bracket to the designated position; 2) Expand the bracket and lock it; 3) Adjust the chassis and platform Angle; 4) Install the drilling machine; 5) Start drilling. The invention solves the problem of difficult drilling of complex high and steep slopes, can be adapted to various rock and soil strata, and can deal with complex slope conditions such as unevenness and lush forests. It is flexible in action, safe and reliable in performance, and can fully cope with existing Reinforcement works for complex high and steep slopes.

Owner:DALIAN UNIV OF TECH

A kind of manufacturing method of powder sintered anode foil and anode foil

The invention provides a method for preparing sintered anode foil for aluminum electrolytic capacitors, comprising the following steps: S1: configuring aluminum powder slurry; S2: forming a film from the uniformly mixed slurry on a substrate and curing it; S3: obtaining S2 Degreasing the substrate; S4: sintering the substrate obtained in S3; S5: forming the substrate obtained in S4. The method for sintering the anode foil provided by the invention can ensure that the degreasing is clean and complete, the state of the sintering process is stable without burning, and the pores are uniform after sintering.

Owner:CENT SOUTH UNIV

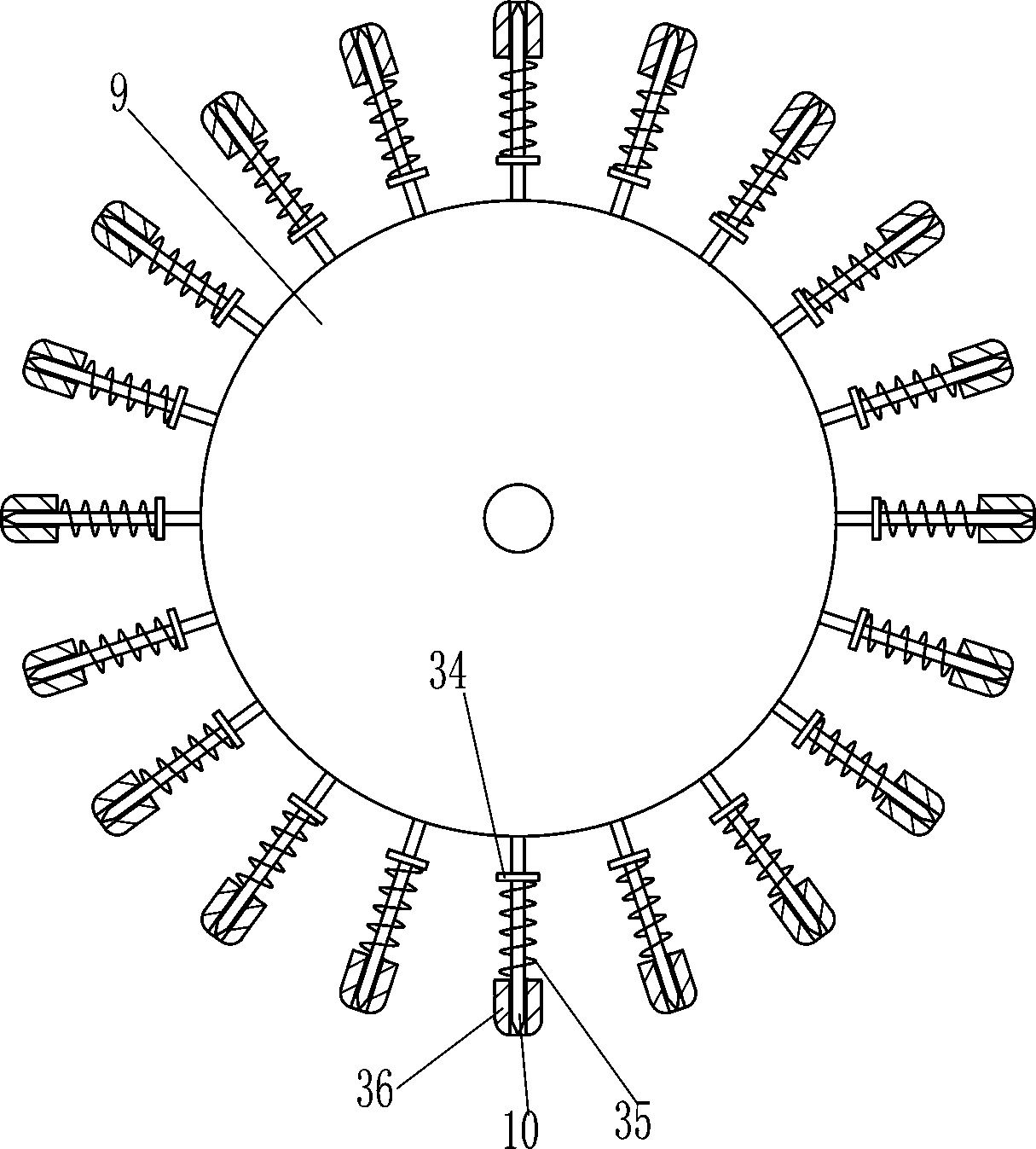

Novel seedling raising disc seeding device

InactiveCN101796902ASimple structureLow costSeed depositing seeder partsFertiliser equipmentsGear wheelEngineering

The invention provides a novel seedling raising disc seeding device, which relates to the field of agricultural production machinery. The novel seedling raising disc seeding device consists of a seed box (1), gears (2), a seed distributing shaft (3), a shaft sleeve (4) and a handle (5), wherein the seed distributing shaft (3) is arranged at the lower end of the seed box (1), the shaft sleeve (4) is arranged at the outer side of the seed distributing shaft (3), the gears (2) are arranged at both ends of the seed distributing shaft (3), and the handle (5) is fixed on the seed box (1). The invention has the advantages of simple structure, low cost, small size, convenient operation and the like, can realize the whole disc seedling, and has the characteristics of few hollow pit amount, uniform pits and stains and high work efficiency.

Owner:海安县农作物栽培技术指导站

Construction method of spiral impact drilling device suitable for rock and soil

ActiveCN112502610APrecise control of drilling angleAccurate control of drilling inclinationDrill bitsDrilling rodsAir compressionGear wheel

The invention discloses a construction method of a spiral impact drilling device suitable for rock and soil. The drilling device comprises a drilling machine system and a drilling machine support, wherein the drilling machine support comprises a walking chassis mechanism, a rotating mechanism is arranged on the chassis mechanism, a working platform is arranged on the rotating mechanism, a drivingand operating room is arranged on the working platform, a movable arm is arranged at the front end of the working platform, and the front end of the movable arm is connected with the drilling system;and the drilling system comprises a power distribution system, an air compression system, a rock drilling component, a soil drilling component, a gear, a drill rod and a drill bit. The construction method comprises the steps of enabling the drilling machine support to travel to a designated position; installing a drilling system; adjusting the initial height and the drilling angle of the drill bit; and starting drilling. According to the construction method, the problem that drilling equipment cannot be suitable for different soil layers can be solved, and the method can adapt to different stratum conditions since the drilling angle can be accurately controlled and high maneuverability is achieved; moreover, the method is environmentally-friendly and can save energy and reduce noise; and in addition, the drill bit is firm and reliable, and therefore the method is suitable for slope and foundation pit supporting engineering.

Owner:DALIAN UNIV OF TECH

Foam glass used for continuous furnace thermal insulation layer, and preparation method thereof

InactiveCN108863027AExcellent performanceGuaranteed foam rateGlass shaping apparatusTrisodium phosphateSodium phosphates

The invention discloses a preparation method for foam glass used for a continuous furnace thermal insulation layer. The preparation method comprises the following steps: S1: sending raw material wasteglass, 0.5-1wt% of foaming agent calcium carbonate, 5-7wt% of fluxing agent sodium fluosilicate and 6-7wt% of stabilizer sodium phosphate into a planetary ball mill to be grinded to obtain mixed materials; S2: sending the grinded mixed materials into a high temperature resistant die, preheating at the temperature of 450DEG C for 25-30min, raising the temperature to 850-860DEG C to be foamed, keeping the temperature for 40-45min, cooling to 520-530DEG C to be annealed, keeping the temperature for 50-60min, finally, cooling to the room temperature along with the furnace, and thus obtaining thefoam glass. The prepared foam glass has even aperture, most holes are closed holes, average aperture is about 1.5mm, density is 0.88g / cm<3>, compressive strength is 5.78Mpa, a heat conductivity coefficient is 0.168W / m<2>.K, each piece of performance is excellent, and the use requirement of the foam glass can be met.

Owner:TONGFU HEAT TREATMENT KUNSHAN

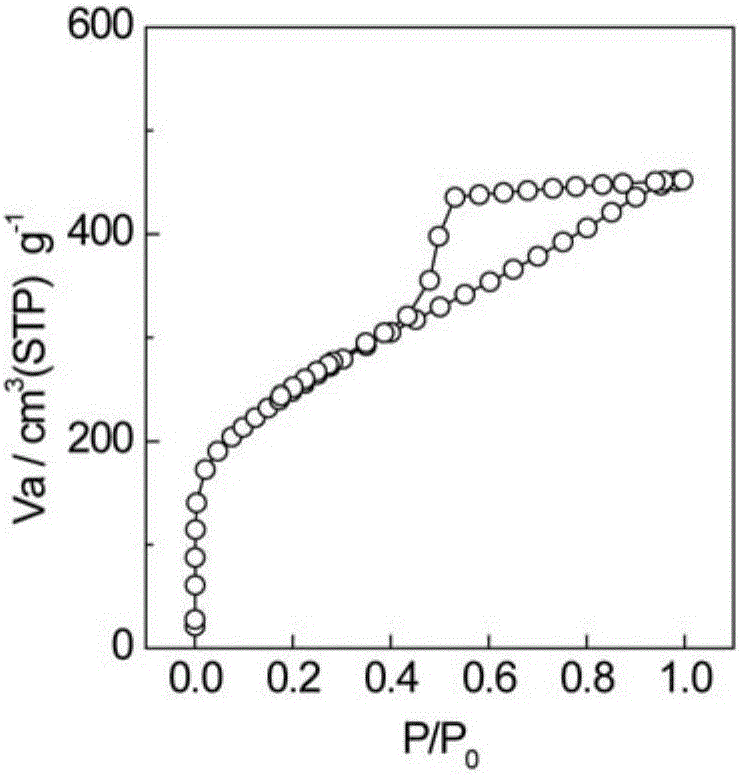

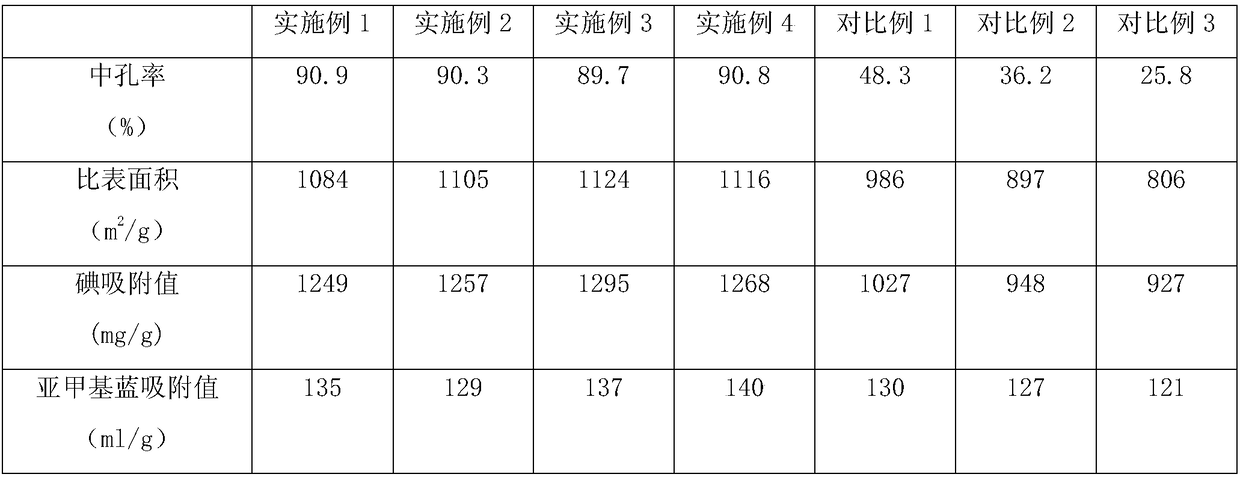

A kind of preparation method of mesoporous carbon material

ActiveCN107055503BEasy to integrateHigh porosityCarbon preparation/purificationPorosityActivated carbon

The invention provides a preparation method of a mesoporous carbon material and belongs to the field of material production. The mesoporous carbon material is mainly prepared from activated carbon. The preparation method comprises the following steps: mixing and immersing a pore forming agent prepared by mixing activated carbon with polyvinyl alcohol, polyethylene glycol, polyvinylpyrrolidone and ethanol under an ultrasonic vibrating condition; drying the mixture and carbonizing the dried mixture in a carbonizing furnace for 3-6 hours; then immersing the obtained substance in a nitric acid solution for 5-6 hours; and after drying and crushing the substance, treating the substance for 30-35 minutes at 900-950 DEG C under nitrogen protection to obtain the mesoporous carbon material. The mesoporous carbon material is high in porosity, has a relatively high specific surface area, has a good adsorption action and is safe in preparation method.

Owner:江苏丽鑫实业有限公司

Nutrient bread made of fermented mung bean dregs or filtered fermented soybean dregs and making method of nutrient bread

InactiveCN104351294AImprove nutritional qualityPromote absorptionDough treatmentPre-baking dough treatmentFermentationOrganoleptic

The invention discloses nutrient bread made of fermented mung bean dregs or filtered fermented soybean dregs and a making method of the nutrient bread. The nutrient bread is made of fermented mung bean dregs or filtered fermented soybean dregs which account for 10-40% of the weight of wheat flour. The water content of the fermented mung bean dregs or the filtered fermented soybean dregs is less than 20% or is 50-120%, and the fermented mung bean dregs or the filtered fermented soybean dregs are made by fermenting a finely selected mung bean raw material by using a fermentation process. The nutrition quality of the nutrient bread can be improved, and the nutrient bread is convenient to absorb. The sensory quality of bread is improved, the bread is relatively soft and floppy, the internal texture is light green, and uniform pores are formed. The water retention property of the bread is improved. In addition to mung beans, representative raw materials such as green tea powder and red rice powder can be also added, so that the bread further has a dietary therapy healthcare function.

Owner:王小亮

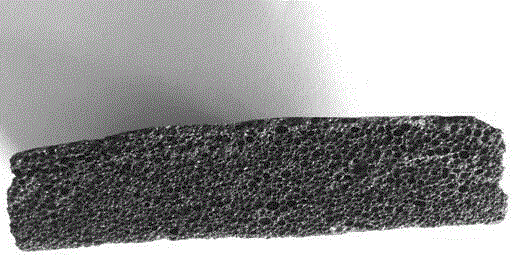

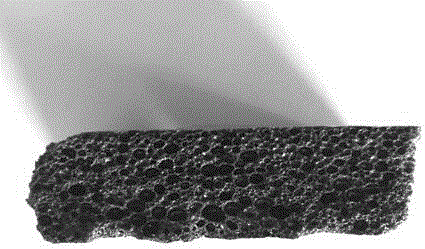

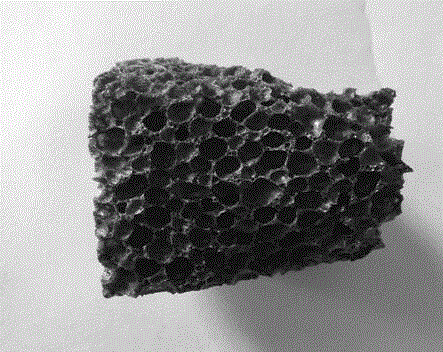

Foam metal processing technology

The invention discloses a foam metal processing technology. The foam metal processing technology comprises the steps that an aqueous solution of anionic surfactants, nano conductive carbon slurry andan electroplating solution C are prepared, and a non-metallic insulating foam sponge is cleaned by the aqueous solution containing the anionic surfactants; the cleaned and dried foam sponge is drawn to a material holding groove containing the nano conductive carbon slurry for walk-dipping, then the foam sponge is drawn to a double-roll machine for extrusion, and the extruded dipped foam sponge isdrawn to a hot air drying device for walk-drying; and the dried dipped foam sponge is put into electroplating equipment for electroplating required metal. The foam metal processing technology has a simple preparation process and low processing cost, and the prepared foam metal has higher porosity, more uniform holes, more obvious three-dimensional network structure and lower cost.

Owner:烟台东方新程科技有限公司

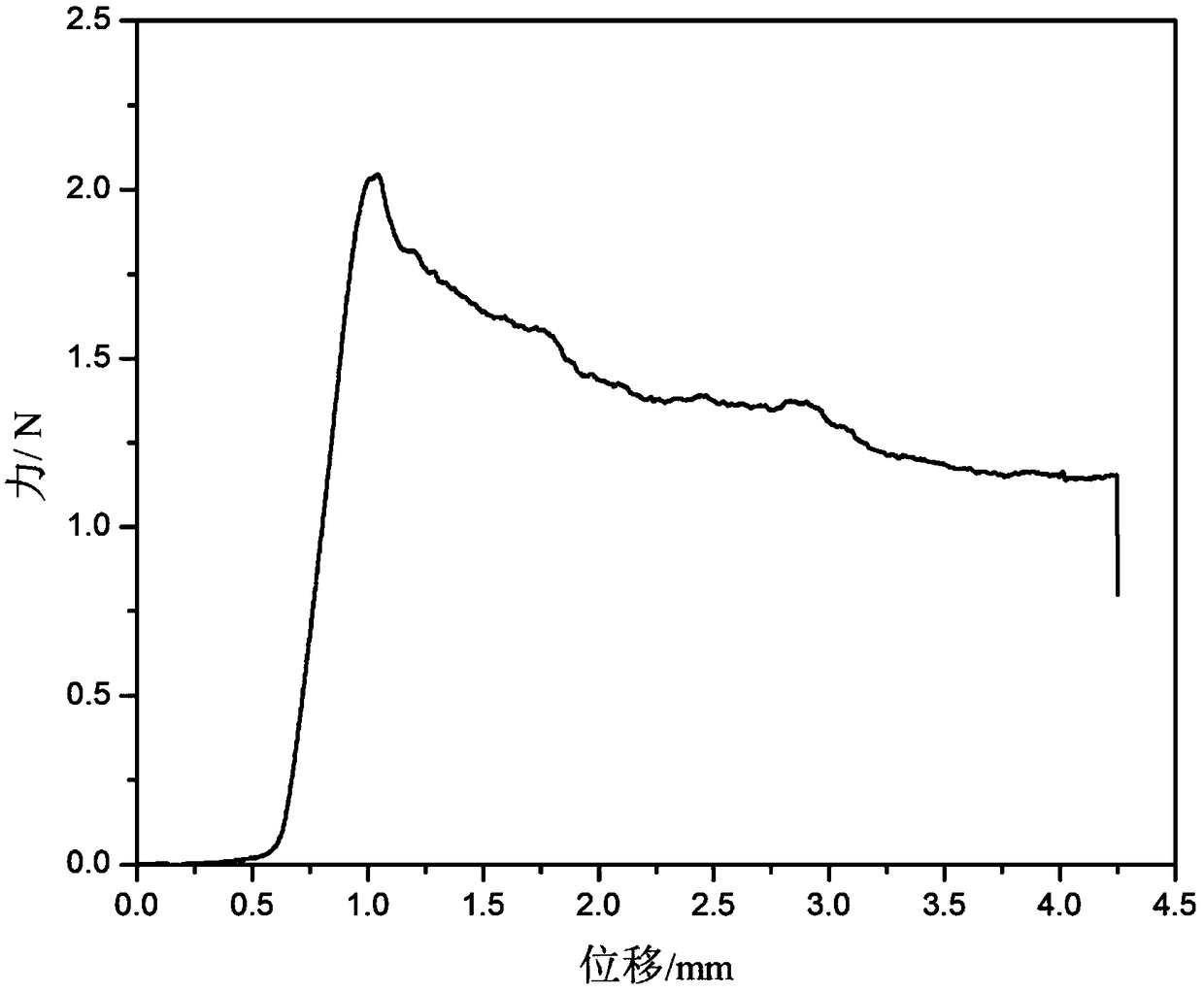

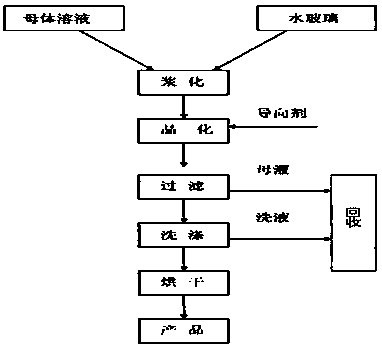

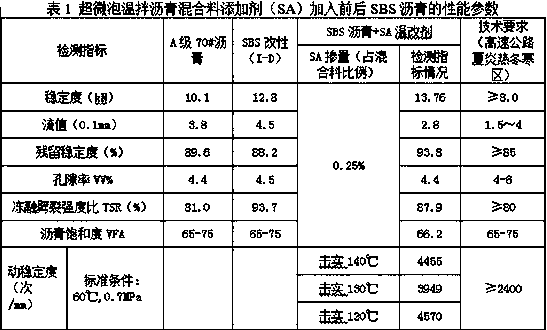

Ultra-microbubble additive for warm mix asphalt mixture as well as preparation and application methods of additive

ActiveCN109970384AGood crystallinityUniform holeClimate change adaptationBuilding insulationsSodium carbonateEnvironmentally friendly

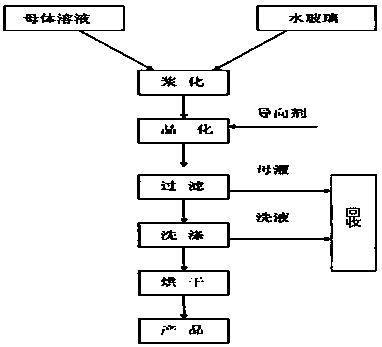

The invention relates to an ultra-microbubble additive for a warm mix asphalt mixture. A preparation method of the additive comprises the following steps: mixing natural minerals, sodium carbonate andlime, performing sintering, dissolving out metal oxides by using an alkali solution, adding a purification agent to obtain a mother solution, synchronously adding the mother solution and water glassinto a reaction vessel, performing slurrying under stirring to form gel, adding an adhesive and a guiding agent, performing thermostatic waterbath for crystallization, performing liquid-solid separation, performing washing, performing drying, performing grinding, and adding a dispersing agent. The finished product provided by the invention has good crystallinity, uniform pores and a low price, thecompaction temperature can be significantly reduced when the addition amount is 0.25 wt%, the road performance of the asphalt mixture is improved, and the additive is high-efficiency and environmentally friendly, and has the effects of modification and reducing warm-mix temperature.

Owner:张燕军

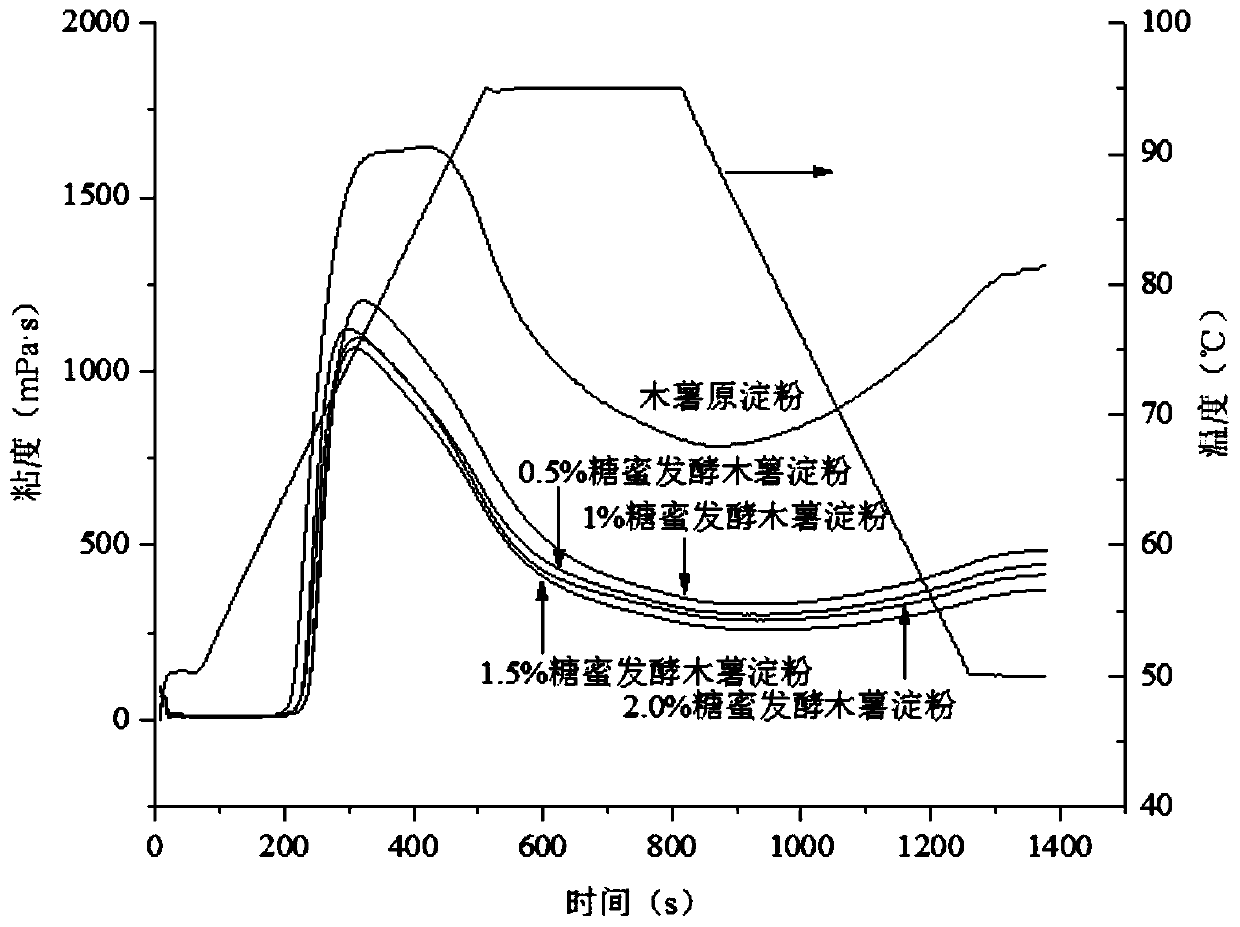

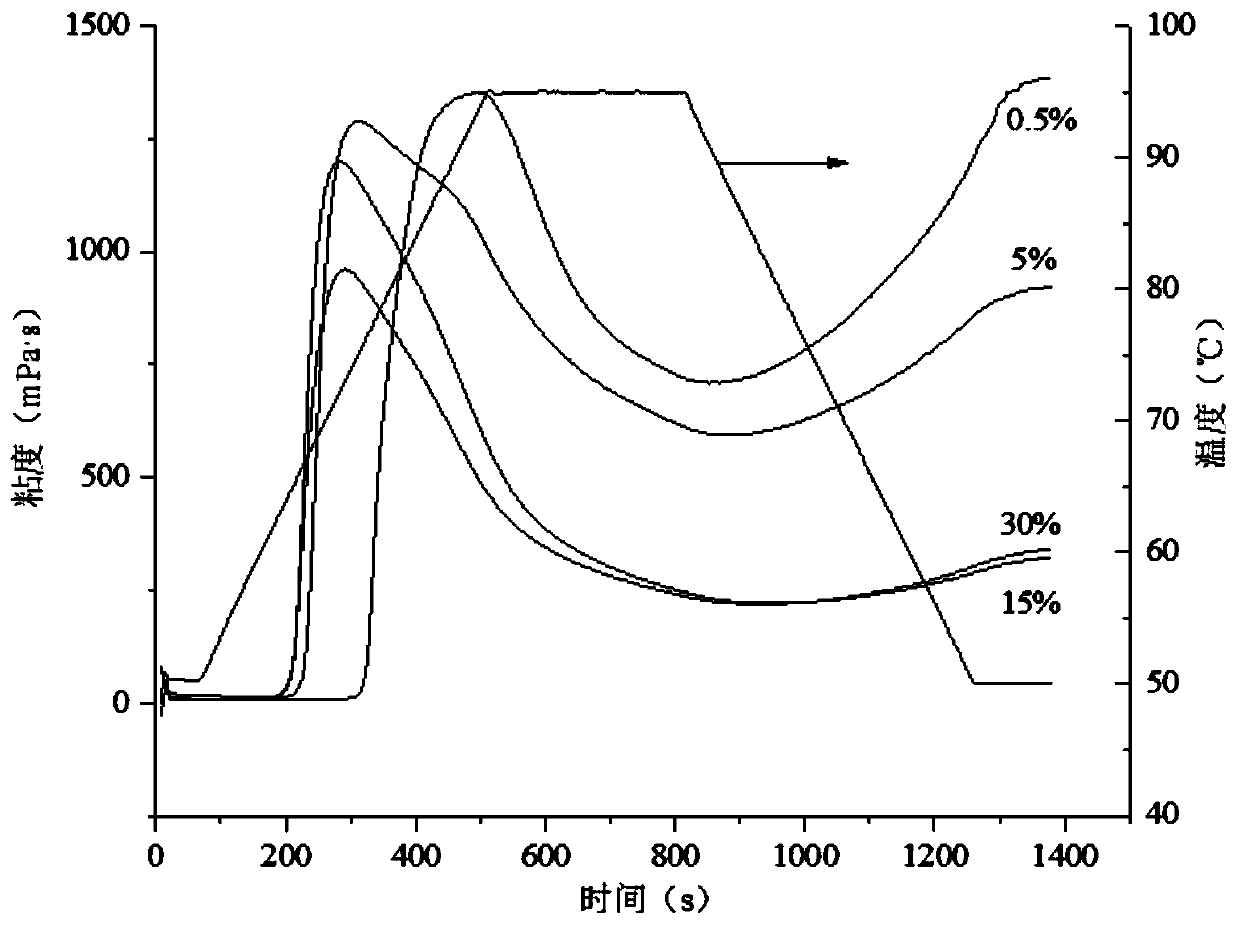

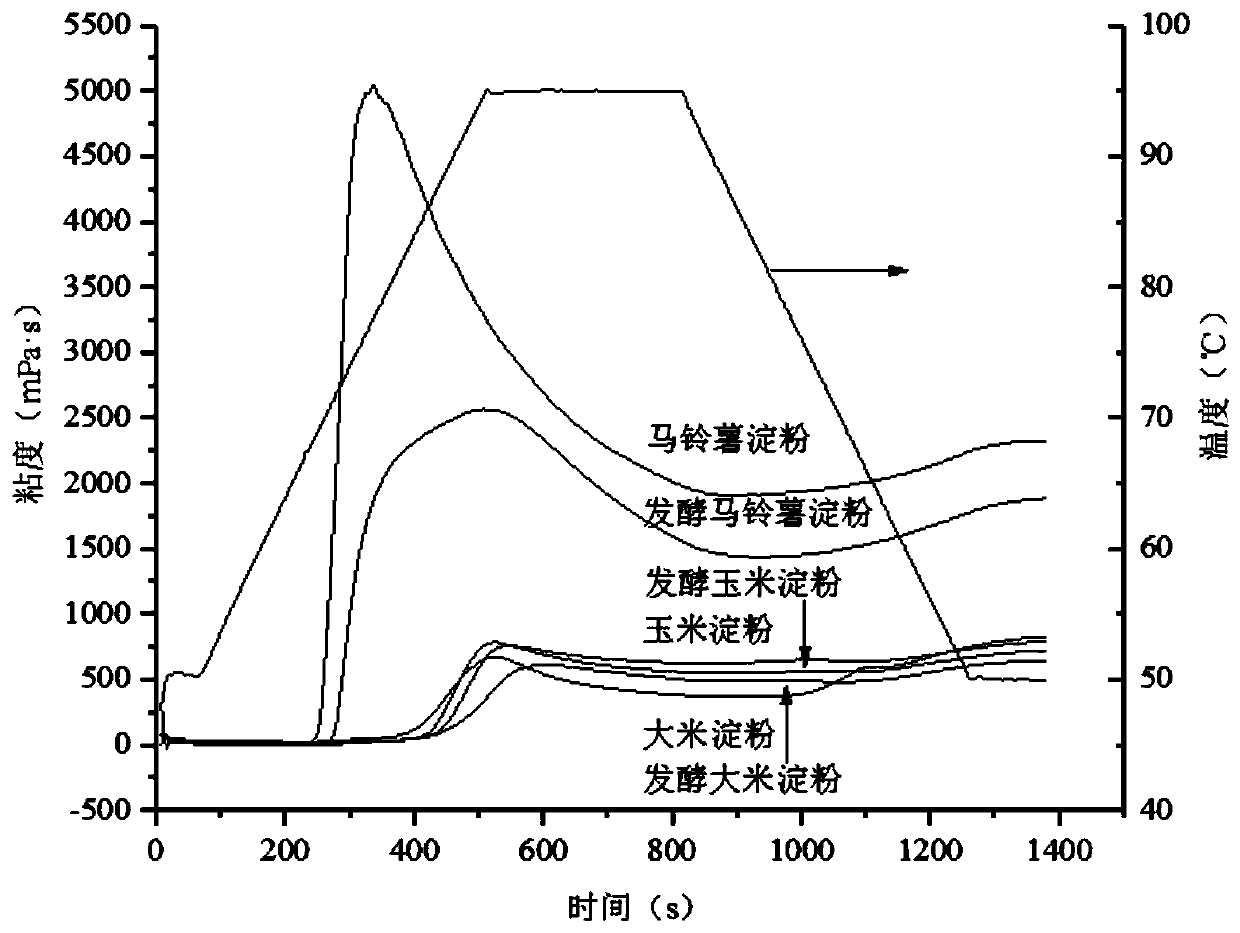

Production technology and application of fermented tapioca starch for baking

ActiveCN110029137AElimination of Mixed Toxin HazardsShorten the production cycleDough treatmentMicroorganism based processesCooking & bakingCarbon source

The present invention discloses a production technology and an application of fermented tapioca starch for baking, and belongs to the field of starch deep processing and food processing and production. The disclosed production method of the fermented tapioca starch for baking is simple in steps and greatly shortens the process cycle; tapioca starch is used as a main raw material, a specific amountof carbon source and a specific bacterium strain are added, and cooperation of fermenting, illumination, etc. is used to improve the structure of the starch. The addition of the fermented tapioca starch increases the volume of gluten-free mochi bread, increases pores of the bread, and improves the texture and mouthfeel of the bread.

Owner:JIANGNAN UNIV

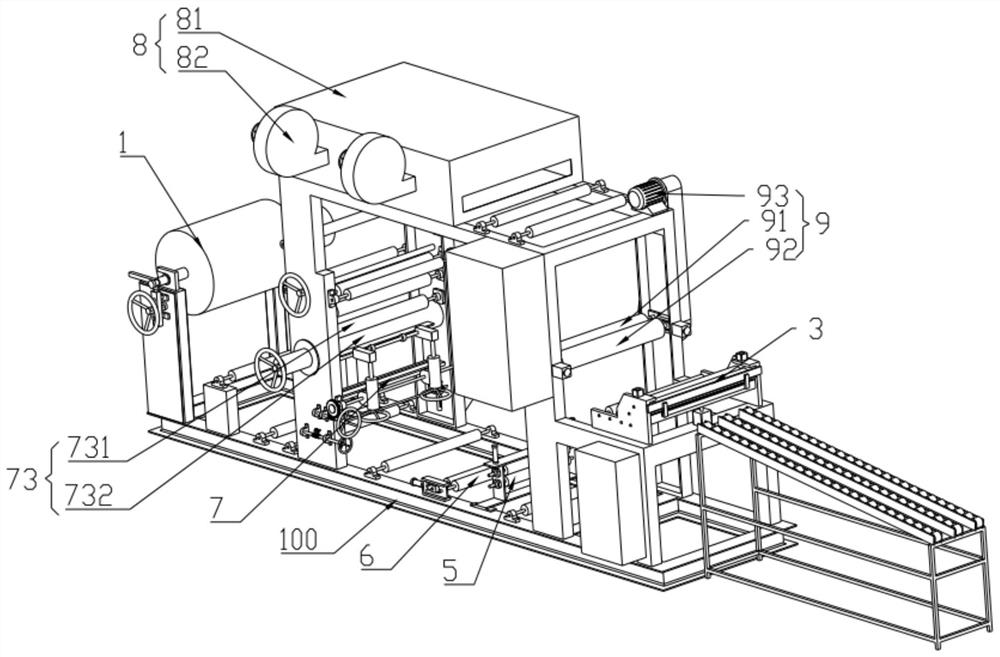

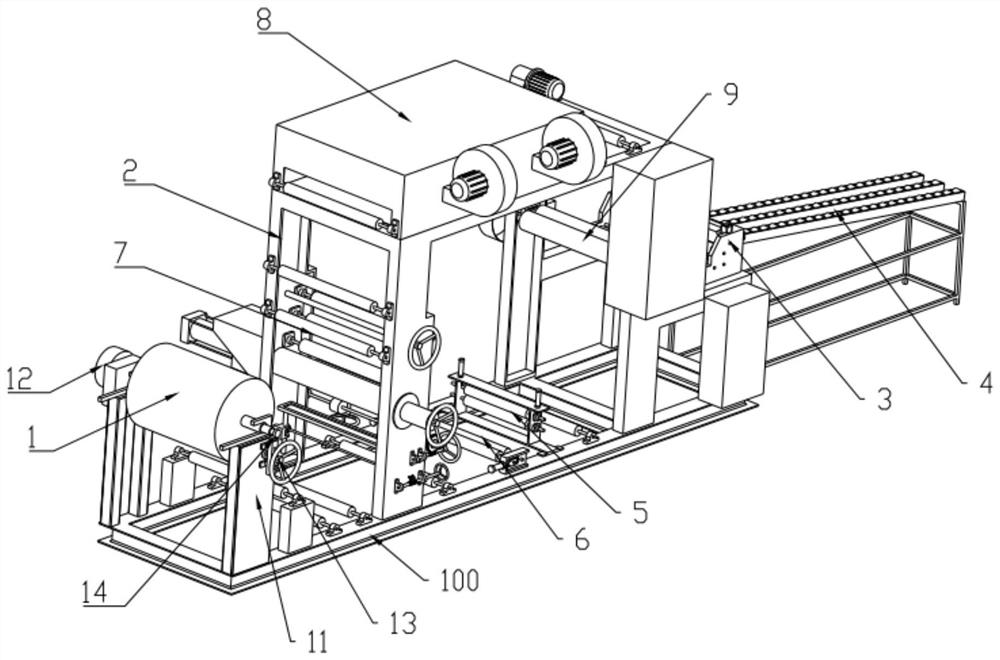

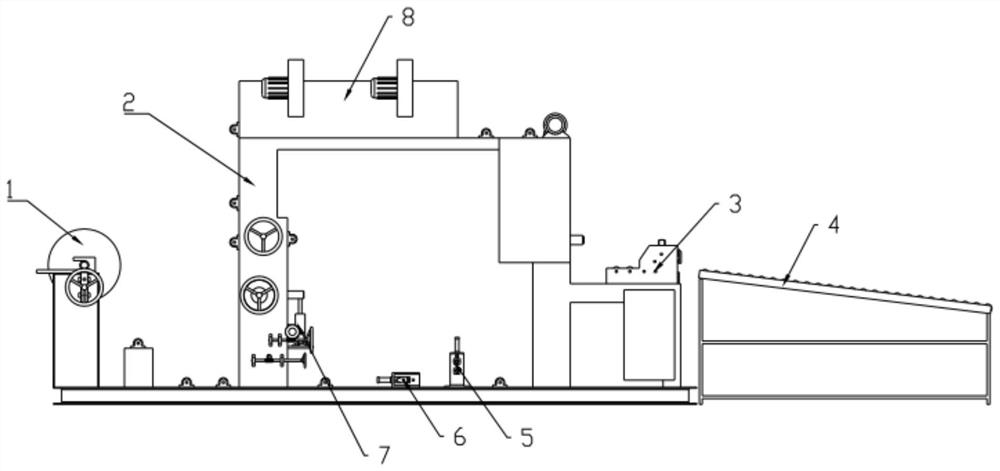

Aluminum foil gluing machine

PendingCN112691853AImprove gluing efficiencyEasy to storeLiquid surface applicatorsLamination ancillary operationsPunchingAluminum foil

The invention provides an aluminum foil gluing machine. The machine comprises a rack, an unwinding mechanism, a portal frame, a shearing mechanism and a finished product discharging table, the unwinding mechanism, the portal frame and the shearing mechanism are arranged on the rack from left to right, the finished product discharging table is arranged on the right side of the shearing mechanism, a punching mechanism and a fattening mechanism are arranged below the portal frame, the punching mechanism is used for punching aluminum foil, and the flattening mechanism is used for flattening pinholes in the aluminum foil, the gluing mechanism is arranged at the left end of the portal frame, an air drying mechanism is arranged above the portal frame, a traction mechanism for pulling the aluminum foil to move forwards is arranged at the right end of the portal frame, the aluminum foil is led out of the unwinding mechanism, enters the punching mechanism through a guide roller to be punched, enters the flattening mechanism to flatten the pinholes after being punched, and then enters the gluing mechanism to be glued, after gluing, air drying is conducted through the air drying mechanism, and after air drying, the aluminum foil enters the shearing mechanism through the traction mechanism to be cut off and enters the finished product discharging table after being cut off. According to the machine, continuous operation of punching, flattening, gluing, drying and shearing is achieved, the gluing efficiency is high, and the gluing effect is good.

Owner:佛山市盈研新材料科技有限公司

Preparation method of light refractory plate

The invention discloses a preparation method of a light refractory plate, belonging to the field of the refractory material. The preparation method comprises the following steps: using talcum powder, bauxite powder and clay powder as main raw materials to mix evenly in advance, then adding expansion glazed hollow beads to mix evenly, placing the final mixture in a mixer, adding water to stir, shaping, drying, and firing at 1400-1600 DEG C. The added glazed hollow beads can meet the refractory requirement and also effectively achieve the aim of reducing the weight. The method can be widely used in the fields such as architecture, metallurgy and chemical engineering.

Owner:BEIJING UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com