Aluminum foil gluing machine

A technology of aluminum foil and gluing machine, applied in the field of gluing machine, can solve the problems of low degree of automation, uneven gluing, rising defect rate of products, etc., and achieve high gluing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

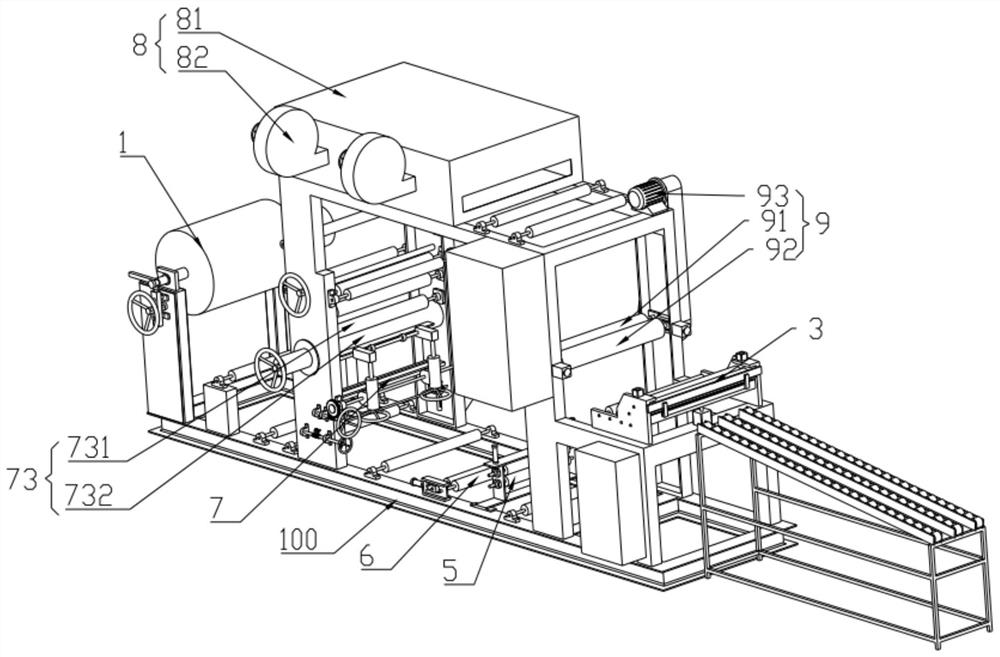

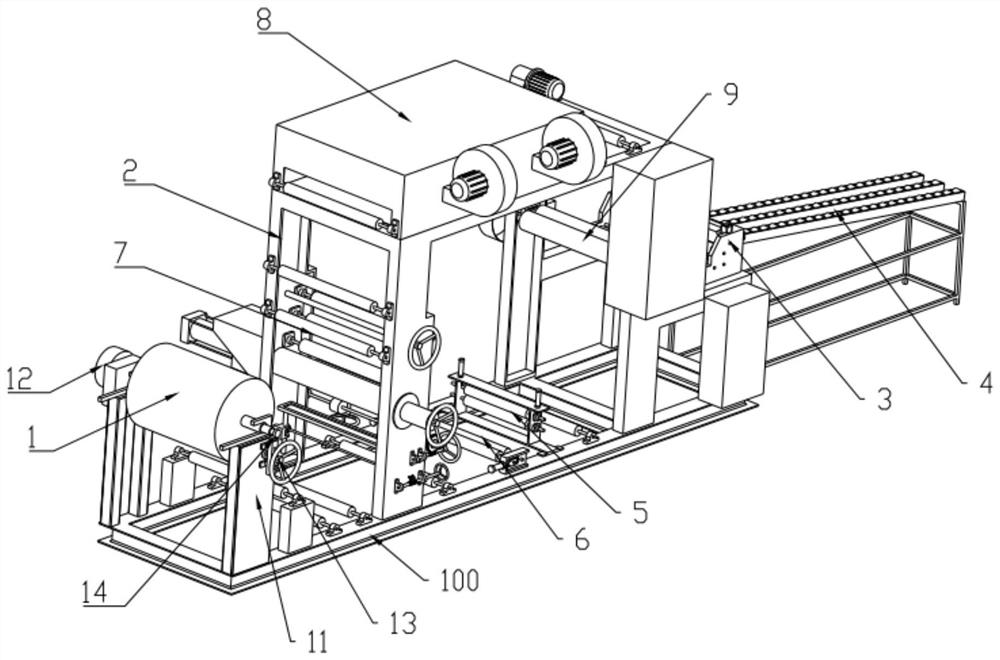

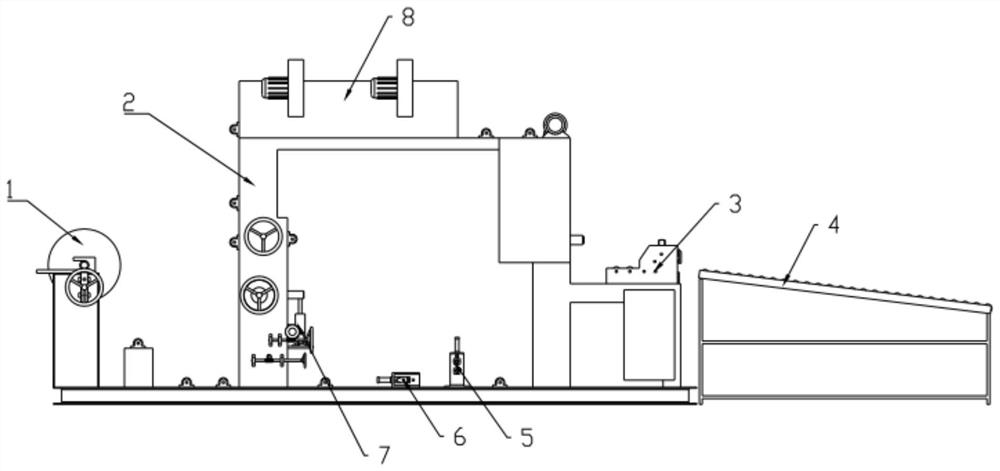

[0025] like Figure 1 to Figure 9 As shown, an aluminum foil gluing machine according to the present invention includes a frame 100, an unwinding mechanism 1 arranged on the frame 100 from left to right, a gantry frame 2, a shearing mechanism 3 and a device On the finished product discharge platform 4 on the right side of the shearing mechanism 3, a punching mechanism 5 is provided below the gantry 2 to punch holes in the aluminum foil, and a flattening mechanism 6 flattens the pinholes on the aluminum foil. The left end of frame 2 is provided with gluing mechanism 7, the top of gantry 2 is provided with air-drying mechanism 8, and the right end of gantry 2 is provided with traction mechanism 9 that pulls aluminum foil forward.

[0026] Specifically, the gluing mechanism 7 includes a glue groove 71, a glue scraping mechanism 72 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com