Automatic dispersing device for machining process of electronic product workpieces

A process and automatic dispensing technology, which is applied to the device, spray device, coating and other directions for coating liquid on the surface, which can solve the problem of residual glue, affect the smoothness of the glue, and can not be well applied to the diameter and thickness of the coating. Different round finished parts, etc., to achieve the effect of wide application and improved gluing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

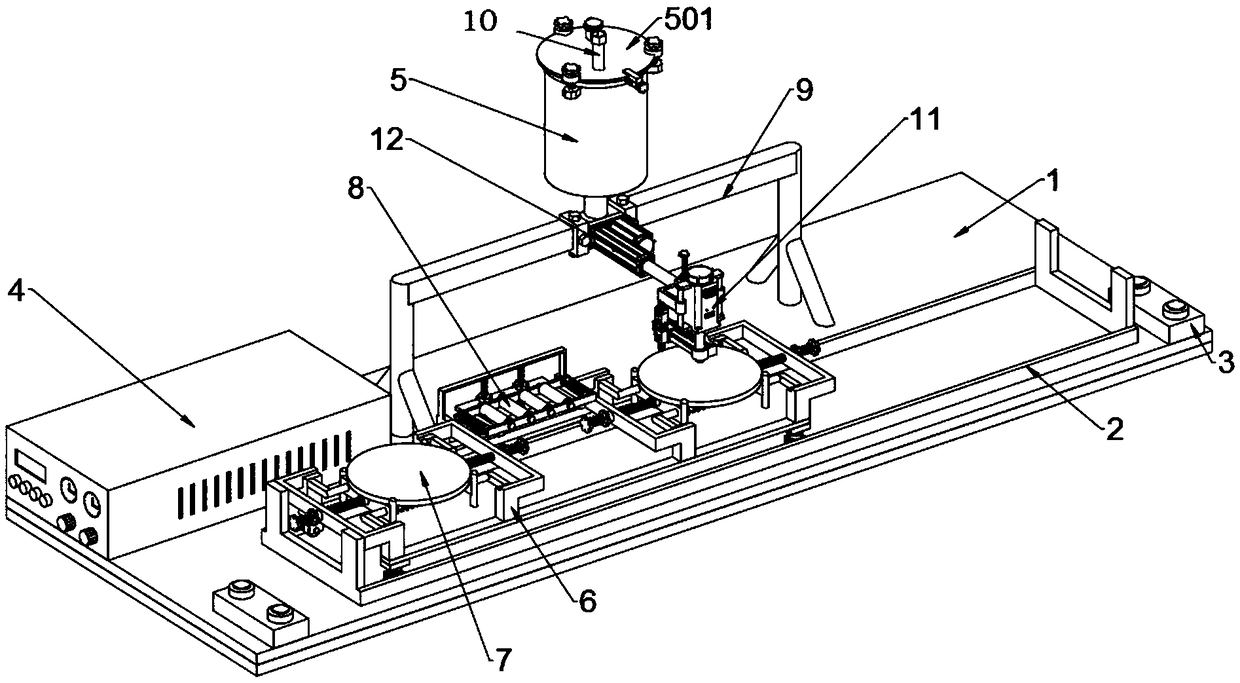

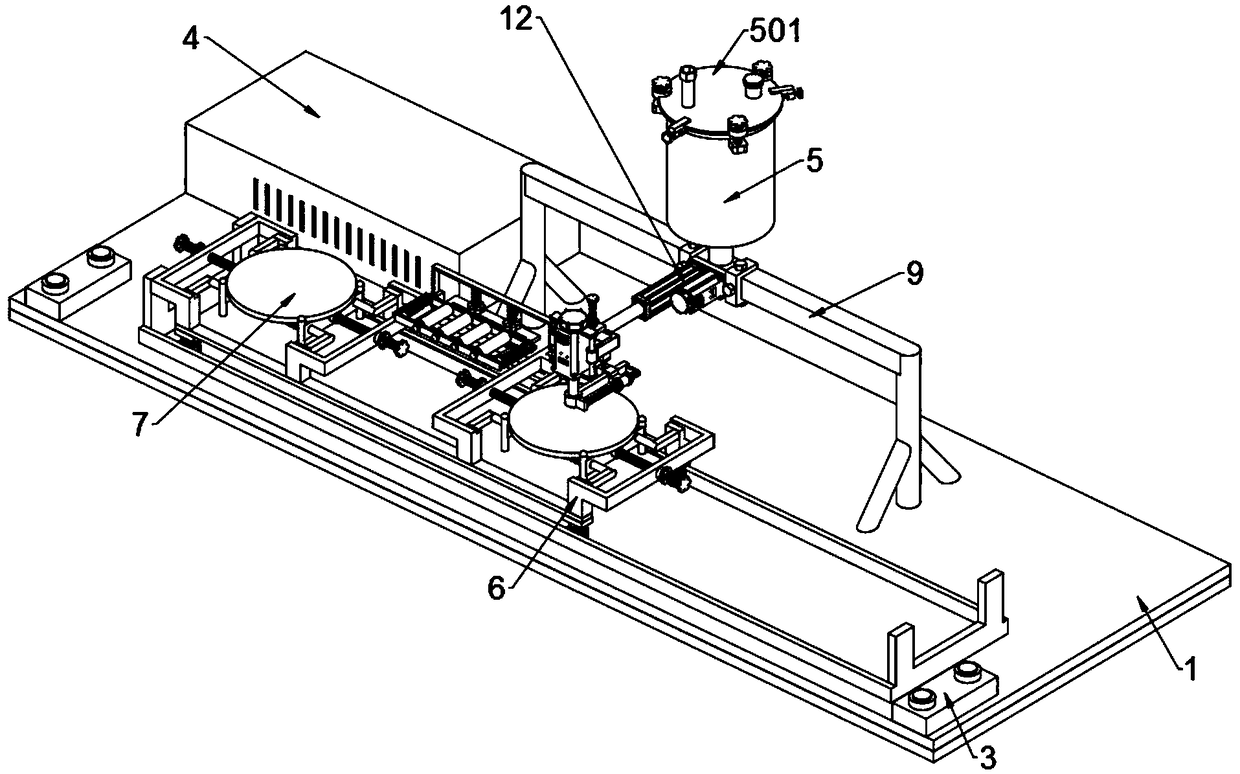

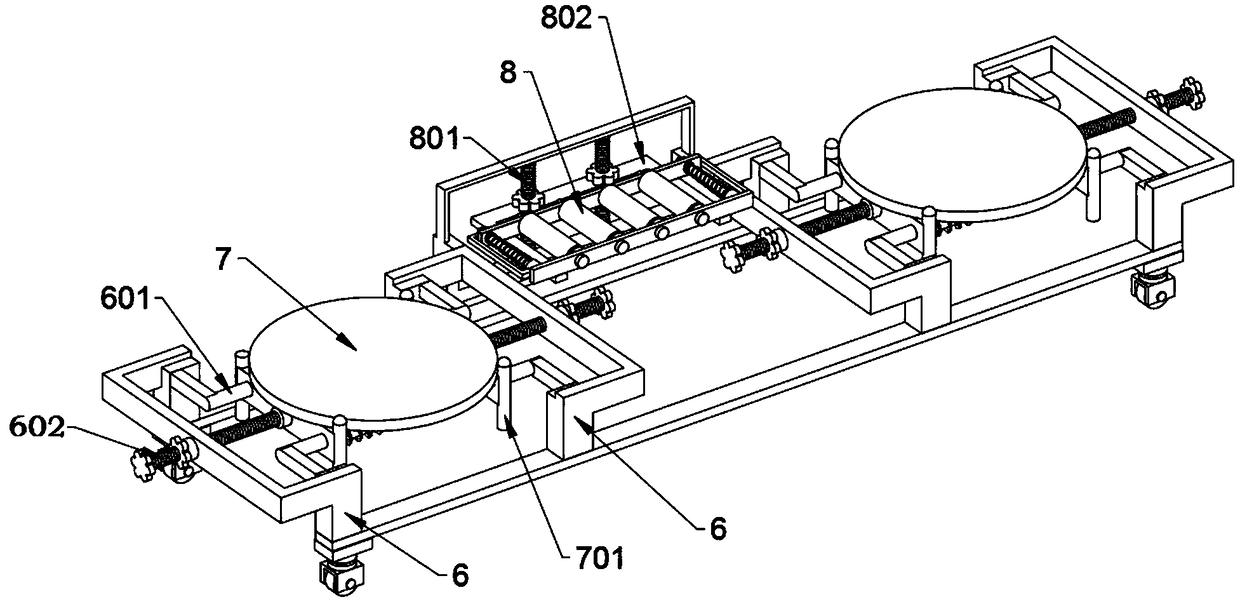

[0030] as attached figure 1 To attach Figure 8 Shown:

[0031] The invention provides an automatic glue dispensing device in the process of workpiece processing of electronic products, which includes a base plate 1, a track frame 2, a switch panel 3, an air pressure chassis 4, a glue barrel 5, a barrel cover 501, a support frame 6, a positioning polished rod 601, a top Tightening bolt 602, product part 7, limit lever 701, sponge tube 8, frame positioning strut 801, installation frame 802, sponge tube mounting frame 803, tightening rod 804, inserting rod 805, bracket 9, intake pipe 10, Servo motor 11, vertical support rod 1101, electric cylinder 12, installation frame 1201, scale support plate 13, threaded rod 1301, pneumatic rubber valve 14 and positioning screw rod 15; the middle position of the rear side of the substrate 1 is welded with a bracket 9. The center of the horizontal bar at the top of the bracket 9 supports the welding plastic bucket 5, and a bucket cover 501 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com