Device for fixed-point transferring of single-layer two-dimensional material

A two-dimensional material, single-layer technology, used in microstructure devices, processing microstructure devices, precision positioning equipment, etc., can solve the problem that the polymer layer cannot be sufficiently flat, the operation is complicated, and the transfer failure rate of the all-dry fixed-point printing method is high. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Transfer single-layer graphene on a silicon substrate to a single-layer molybdenum diselenide on a silicon substrate:

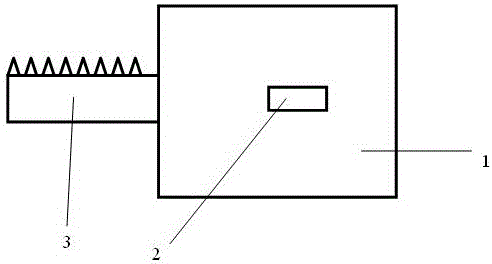

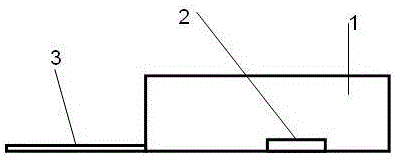

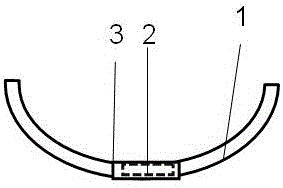

[0017] 1. Put the PDMS in the middle of the through hole 2 of the device, take the PC film to cover the PDMS and stick it on the curved glass 1.

[0018] 2. Fix the silicon substrate with single-layer graphene on the heater, raise the temperature of the heater to 80°C, adjust the focus under the microscope, and find the graphene to take pictures.

[0019] 3. Fix the device on the four-dimensional translation platform through the fixed handle 3, and press the PC film attached to the through hole 2 of the device on the found single-layer graphene by adjusting the position and angle of the translation platform .

[0020] 4. Raise the temperature of the heater to 120°C and lift up the device. Observe whether the graphene on the silicon wafer is still there, if still repeat step 3. If it is not there, it means that the graphene has stuck to the PC film a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com