Manufacturing method and system of colorful 3D objects

A manufacturing method, 3D technology, applied in the direction of 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of high production cost of molding materials, affecting the dimensional accuracy of 3D objects, and uneven surface of 3D objects, so as to improve channel utilization The effect of improving rate, improving dimensional accuracy and printing efficiency

Active Publication Date: 2017-09-15

ZHUHAI SAILNER 3D TECH CO LTD

View PDF10 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when using this method to make colored 3D objects, it is necessary to ensure that the physical properties of different materials are basically the same, such as: viscosity, shrinkage, surface tension, etc., especially strict requirements on shrinkage. Inconsistency, after photocuring, the volume of the ink droplet is different. At this time, the surface of the 3D object is uneven, which ultimately affects the dimensional accuracy of the 3D object.

Moreover, using this method to make colorful 3D objects, the production cost of molding materials is relatively high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0064] Formula Table:

[0065]

[0066] Parameters Table:

[0067]

example 2

[0069] Formula Table:

[0070]

[0071] Parameters Table:

[0072]

example 3

[0074] Formula Table:

[0075]

[0076] Parameters Table:

[0077]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Login to View More

Abstract

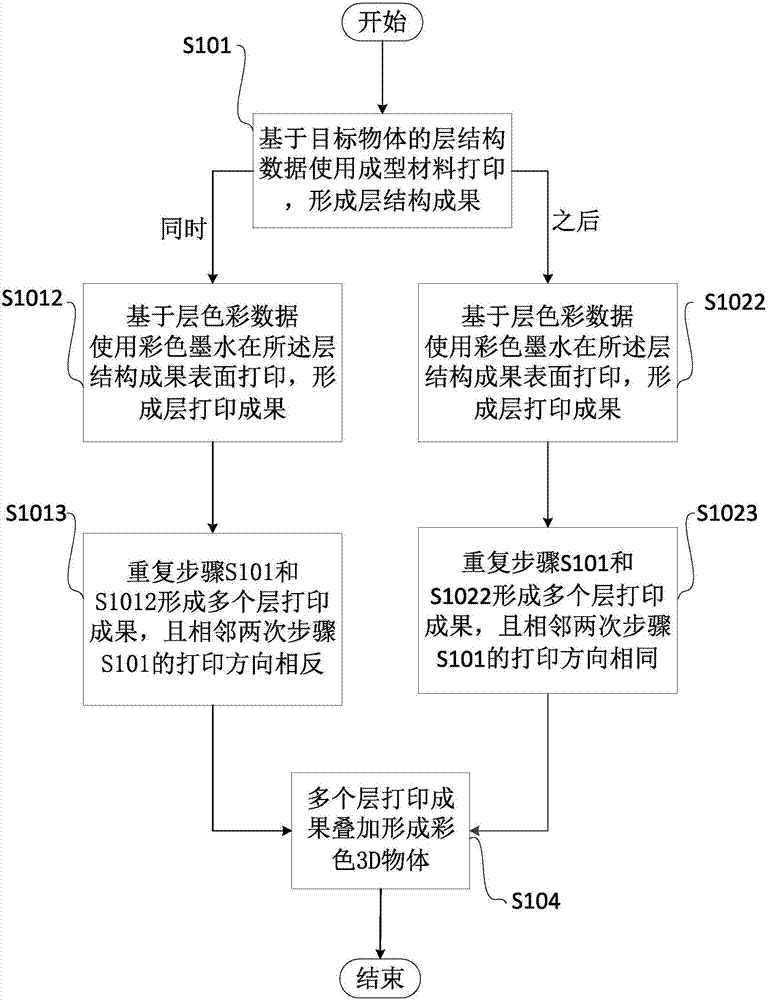

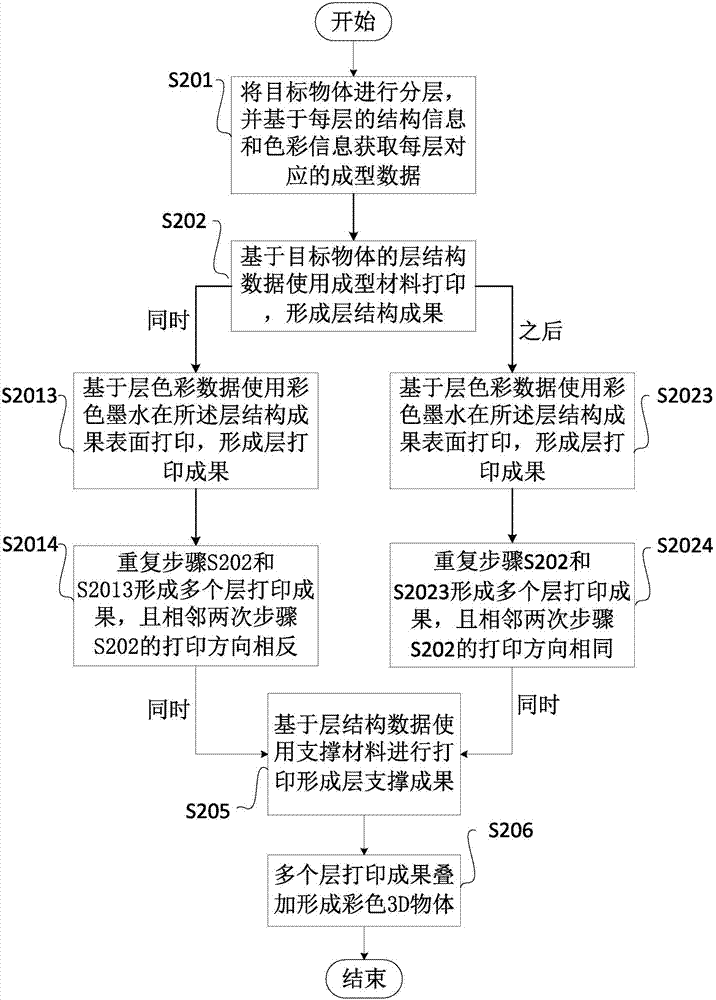

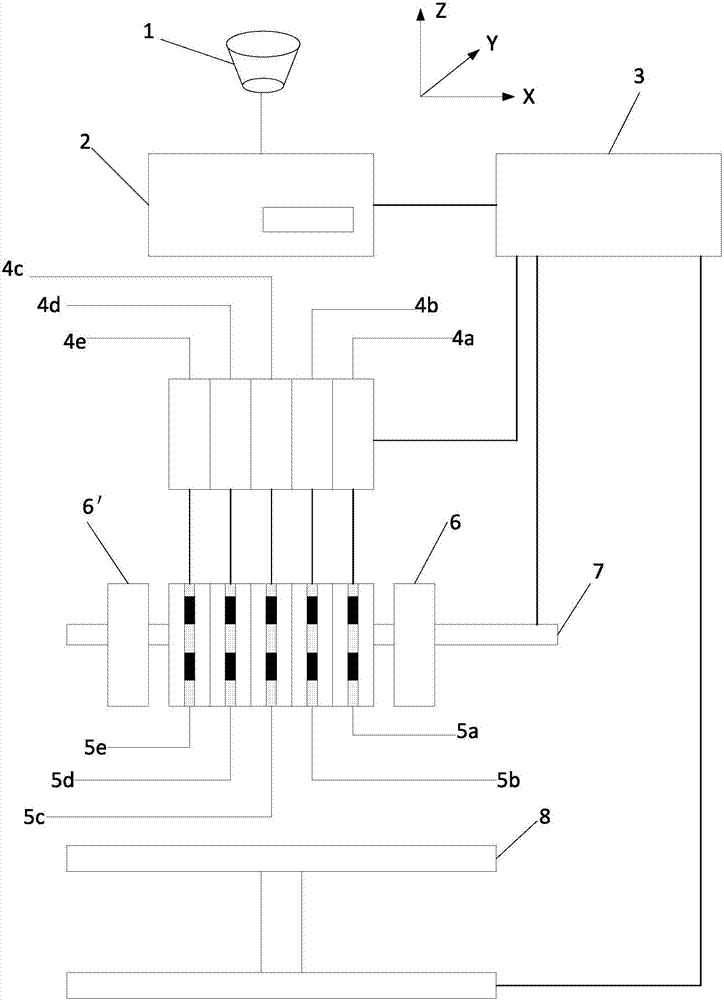

The invention provides a manufacturing method of colorful 3D objects. The manufacturing method comprises the following steps: (a) based on layer structure data of a target object, a forming material is used for printing to form a layer structure result; (b) after the step (a) or at the same time, colorful ink is used for printing on the surface of the layer structure result based on layer color data to form a layer printing result; and (c) the step (a) and the step (b) are repeated to form multiple layer printing results; and the multiple layer printing results are laminated to form a colorful 3D object; when the step (b) is executed after the step (a), the printing directions in two adjacent times of repeating the step (a) are the same; or the step (b) and the step (a) are executed at the same time, the printing directions in two adjacent times of repeating the step (a) are opposite. The invention further provides a manufacturing system for executing the manufacturing method; and the manufacturing system comprises a processing terminal, a driving controller and a printing head. The manufacturing method and the manufacturing system improve the size precision of the colorful 3D object and the printing efficiency.

Description

technical field [0001] The invention belongs to the field of rapid prototyping of 3D objects, and in particular relates to the technology of layer-by-layer superposition manufacturing of 3D objects by using an inkjet printing head, in particular to a method and system for manufacturing a colored 3D object. Background technique [0002] Rapid prototyping technology, also known as rapid prototyping technology or additive manufacturing technology, is based on the basic principles of 3D model slices, which are processed and piled up layer by layer to make 3D objects. [0003] At present, the use of rapid prototyping technology to produce 3D objects specifically includes fused deposition technology (abbreviation: FDM technology), stereolithography technology (abbreviation: SLA technology), selective laser sintering technology (abbreviation: SLS technology), laminated molding technology (abbreviation : LOM technology) or three-dimensional inkjet printing technology (abbreviation: ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C64/112B29C64/20B33Y30/00

CPCB33Y30/00

Inventor 蒋韦陈伟李嘉陈晓坤

Owner ZHUHAI SAILNER 3D TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com