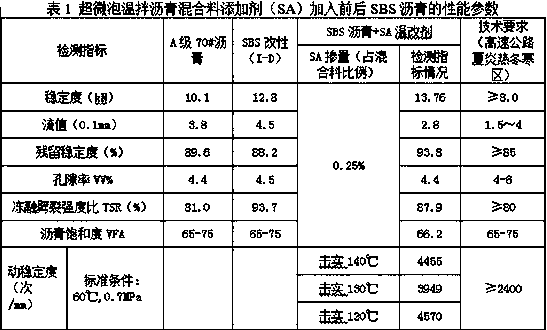

Ultra-microbubble additive for warm mix asphalt mixture as well as preparation and application methods of additive

An asphalt mixture and additive technology, applied in the field of composite materials in the field of road engineering, can solve the problems of exhaust gas and dust emission, asphalt aging, etc., and achieve the effect of reducing energy and pollutant emissions, reducing compaction temperature and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

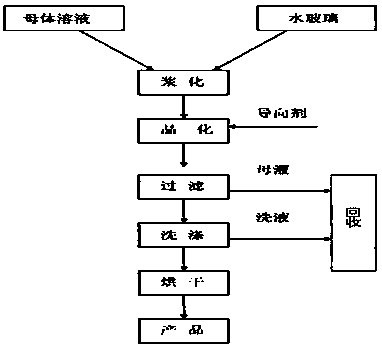

Method used

Image

Examples

Embodiment 1

[0026] (1) Mix bauxite, sodium carbonate and lime with a mass ratio of 1:1:2 to obtain a mixture, sinter at 1200°C to make clinker, and then use an alkali solution with a mass concentration of 2% to dissolve the clinker Metal oxide, and add the purifying agent of 50g / L to obtain parent solution;

[0027] The mass ratio of described lye and mixed material is 1:1;

[0028] (2) Add the matrix solution and water glass to the reaction vessel synchronously, adjust the reaction temperature to 50°C, stir at a rate of 300 rpm, and stir for 45 minutes to form gel; the mass ratio of the amount of water glass added to the mixed material is 1 :3;

[0029] (3) Add an adhesive and a directing agent to the glue described in step (2), and put it in a constant temperature water bath at 68°C for 2.5 hours to crystallize it;

[0030] (4) Liquid-solid separation, washing, dilute drying at 180°C for 30 minutes, grinding, and adding a dispersant; the prepared ultra-microbubble warm mix asphalt mix...

Embodiment 2

[0033] (1) Mix bentonite, sodium carbonate and lime with a mass ratio of 1:1:2 to obtain a mixed material, sinter at 1300°C to make clinker, and then use an alkali solution with a mass concentration of 2% to dissolve the metal oxide in the clinker Thing, and the purifying agent that adds 50g / L obtains parent solution;

[0034] The mass ratio of described lye and mixed material is 1:1;

[0035] (2) Add the matrix solution and water glass to the reaction vessel synchronously, adjust the reaction temperature to 40°C, stir at a rate of 300rpm, and stir for 35 minutes to form a gel; the mass ratio of the amount of water glass added to the mixed material is 1 :5;

[0036] (3) Add an adhesive and a directing agent to the glue described in step (2), and put it in a constant temperature water bath at 70°C for 2 hours to crystallize it;

[0037] (4) Liquid-solid separation, washing, dilute drying at 180°C for 30 minutes, grinding, and adding a dispersant to obtain an additive for supe...

Embodiment 3

[0040] (1) Mix kaolin, sodium carbonate and lime with a mass ratio of 1:1:2 to obtain a mixed material, sinter at 1250°C to make clinker, and then use an alkali solution with a mass concentration of 2% to dissolve the metal oxide in the clinker Thing, and the purifying agent that adds 50g / L obtains parent solution;

[0041] The mass ratio of described lye and mixed material is 1:1;

[0042] (2) Add the matrix solution and water glass to the reaction vessel synchronously, adjust the reaction temperature to 60°C, stir at a rate of 300 rpm, and stir for 50 minutes to form a gel; the mass ratio of the amount of water glass added to the mixed material is 1 :1;

[0043] (3) Add an adhesive and a directing agent to the glue described in step (2), and put it in a constant temperature water bath at 60°C for 3 hours to crystallize it;

[0044] (4) Liquid-solid separation, washing, dilute drying at 180°C for 30 minutes, grinding, and adding a dispersant to obtain an additive for superm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com