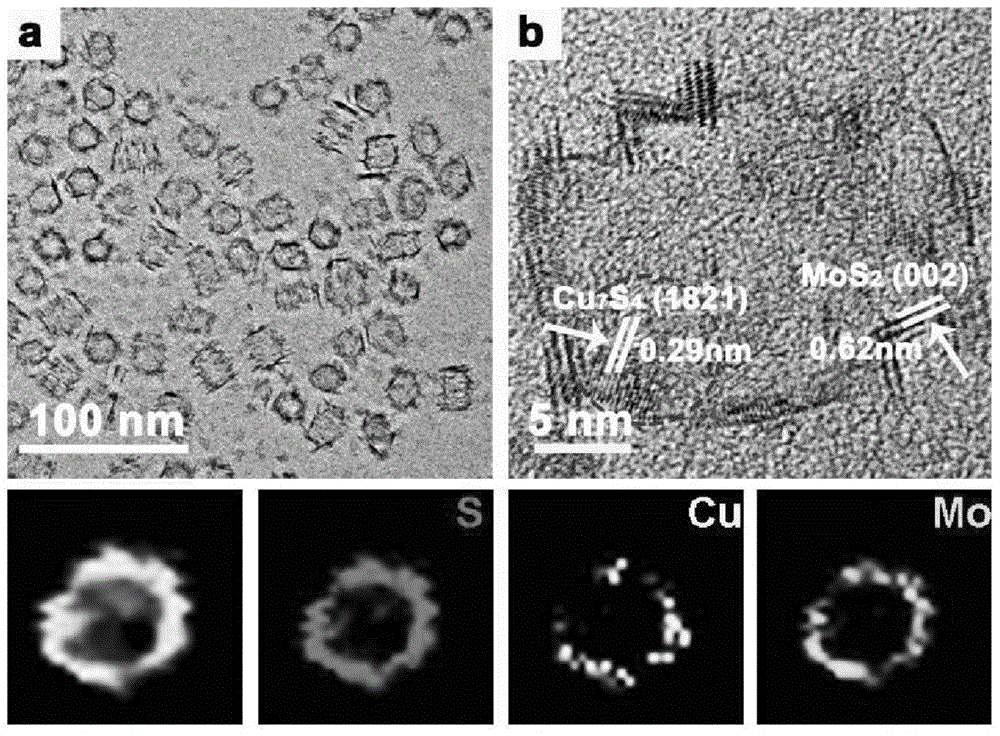

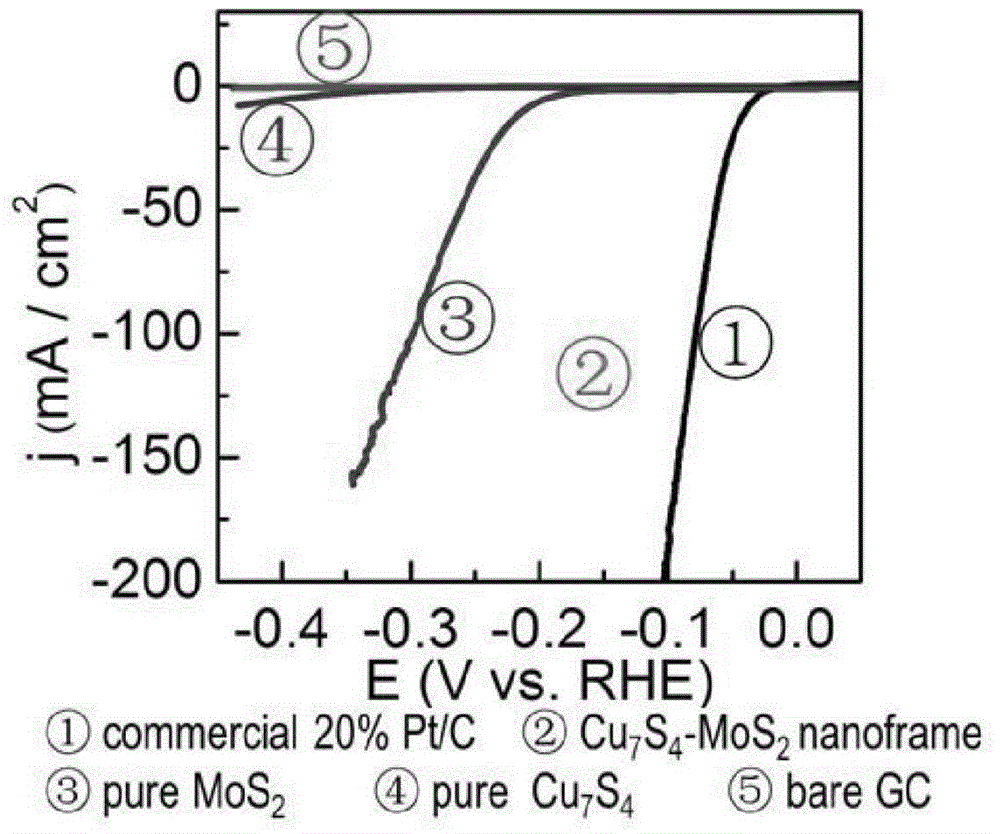

Cu7S4@MoS2 heterogeneous nanometer framework material and application thereof in producing hydrogen by catalytically electrolysing water

A nano-framework, catalytic electrolysis technology, used in electrolysis components, electrolysis process, physical/chemical process catalysts, etc., can solve the problems of poor crystallinity, poor solubility, electrochemical stability, limited practical application, etc., and achieve good crystallinity. , high stability, high activity and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] a. Stir and mix 6ml oleylamine (OAM) and 4ml octadecene (ODE), add 0.1mmol of Cu(NO 3 ) 2 ·3H 2 O and 20 mg N,N-dibutyl-dithioformic acid at 190 °C for 15 min to synthesize the resulting Cu 7 S 4 Nanoparticles are the skeleton, continue to heat and inject 0.2mmol of MoCl at 300°C 5 and 0.4mmol of S powder, keep the temperature at 300°C for 20min;

[0020] b. After the reaction is naturally cooled, take out the reaction solution and centrifuge (12000 rpm) for 10 minutes, and keep the precipitate and dissolve it with n-hexane to collect;

[0021] c. Disperse 4 mg of C powder in n-hexane, then add it to the dispersion in step b, after ultrasonication for 80 min, centrifuge (12000 rpm) for 10 min to obtain nanocrystals loaded on C powder;

[0022] d. Disperse the nanocrystals loaded on C powder into 40mL of acetic acid, stir at 70°C for 15h to remove the surface ligands, and centrifuge (12000rpm) for 15min to obtain Cu 7 S 4 MoS 2 The heterogeneous nano-skeleton mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com