Method for preparing inorganic tin-based perovskite solar cell by physical vapor deposition

A physical vapor deposition, solar cell technology, used in circuits, electrical components, climate sustainability, etc., can solve the problems of difficult to control film thickness and roughness, limited use of organic flexible substrates, and expensive organic hole transport materials. To achieve the effect of easy control of morphology, reduced sensitivity and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

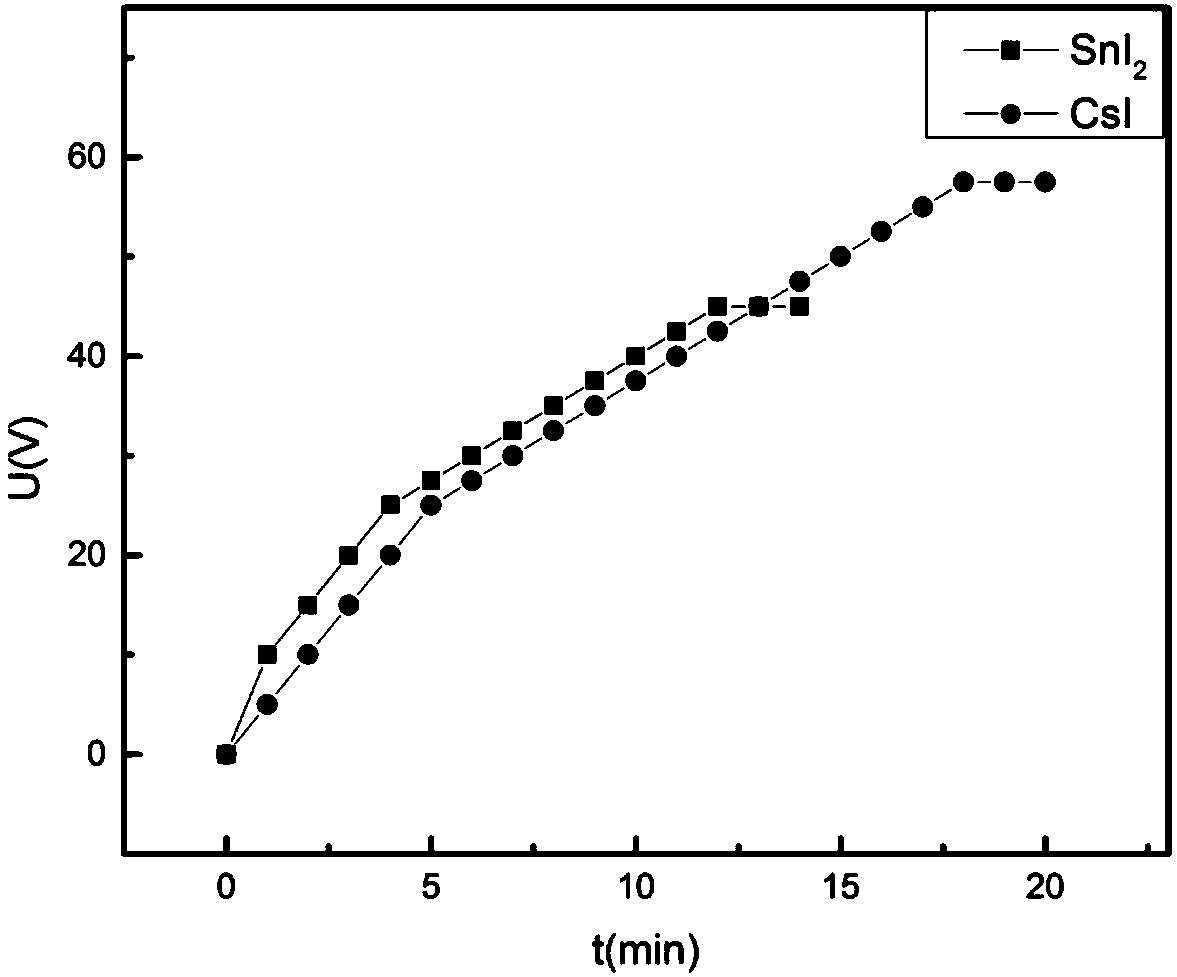

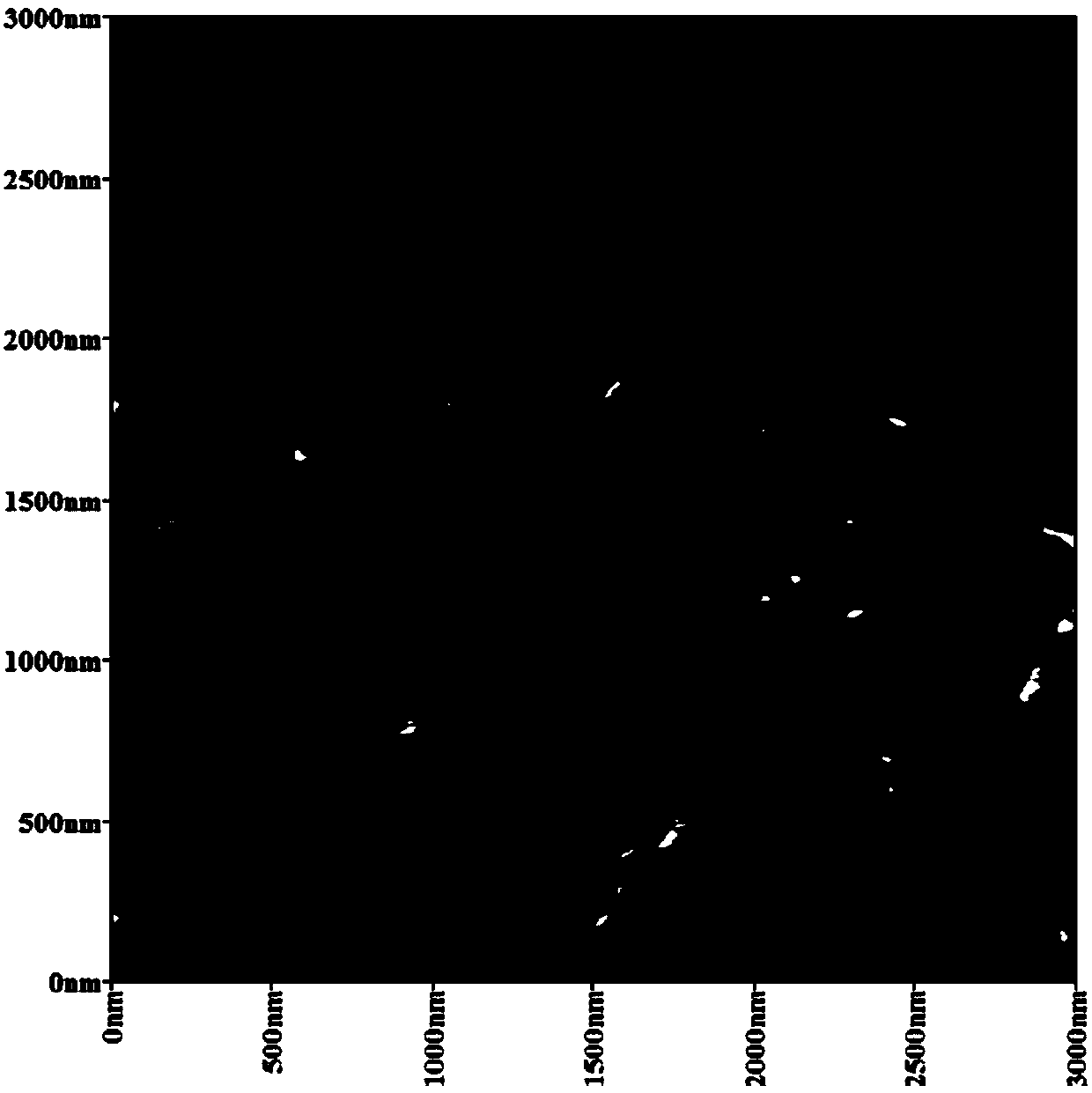

[0027] Such as figure 1 As shown, the method for preparing an inorganic tin-based perovskite solar cell by physical vapor deposition of the present invention, the inorganic tin-based perovskite solar cell consists of a flexible polyimide conductive matrix, a hole transport layer CuI, Tin-based perovskite CsSnI 3 Layer, electron transport layer ZnO, ultra-thin metal-based transparent conductive film; the preparation method includes the following steps:

[0028] 1) Clean the substrate; use a flexible polyimide conductive substrate as the substrate, and then use acetone, ethanol, and deionized water in an ultrasonic cleaner to clean for more than 15 minutes, and then dry it with nitrogen; in order to measure the thickness of the film, dry it Mark the flexible polyimide conductive substrate with a marker;

[0029] 2) Prepare the hole transport layer CuI by radio frequency magnetron sputtering method on the flexible polyimide conductive substrate treated in step 1);

[0030] 3) Prepare t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com