Patents

Literature

35results about How to "Applicable production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

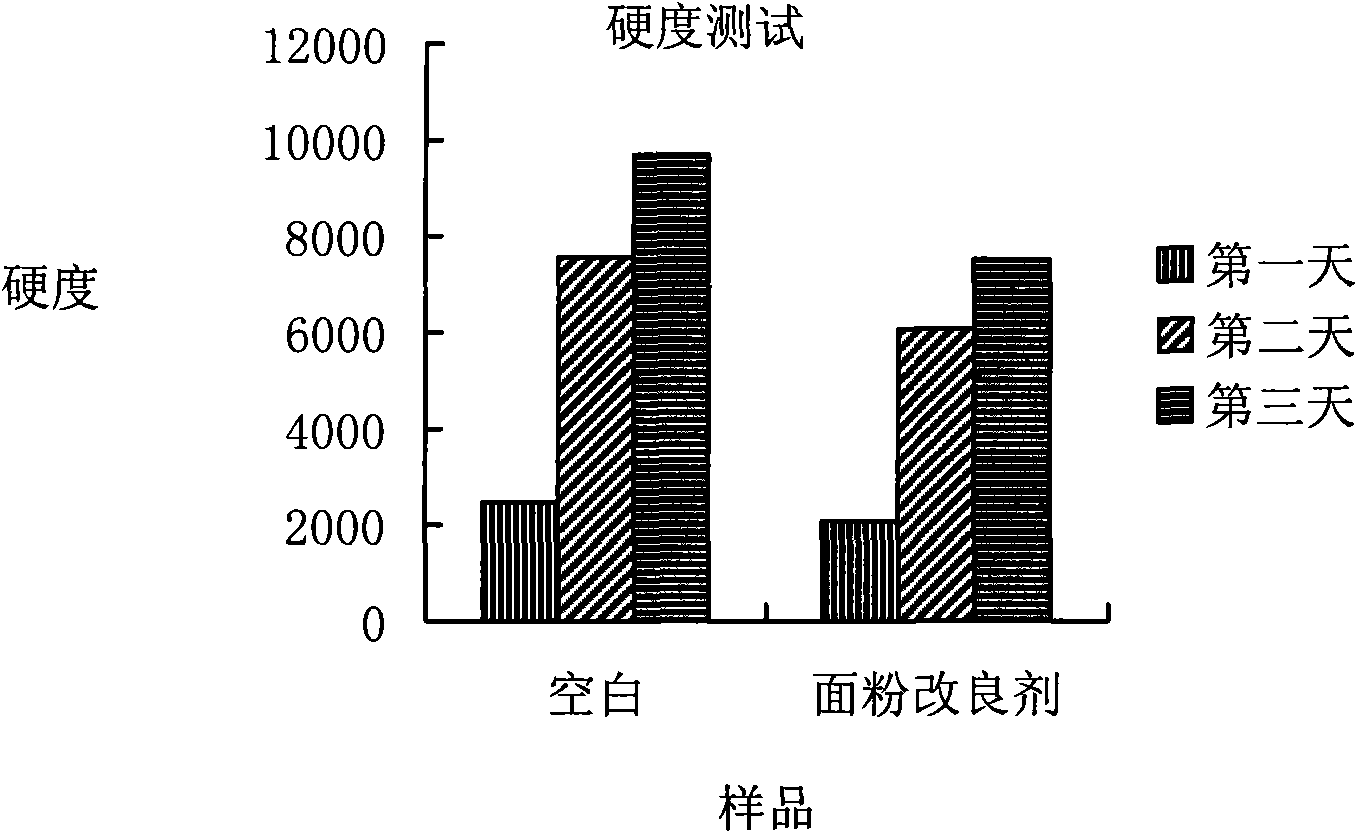

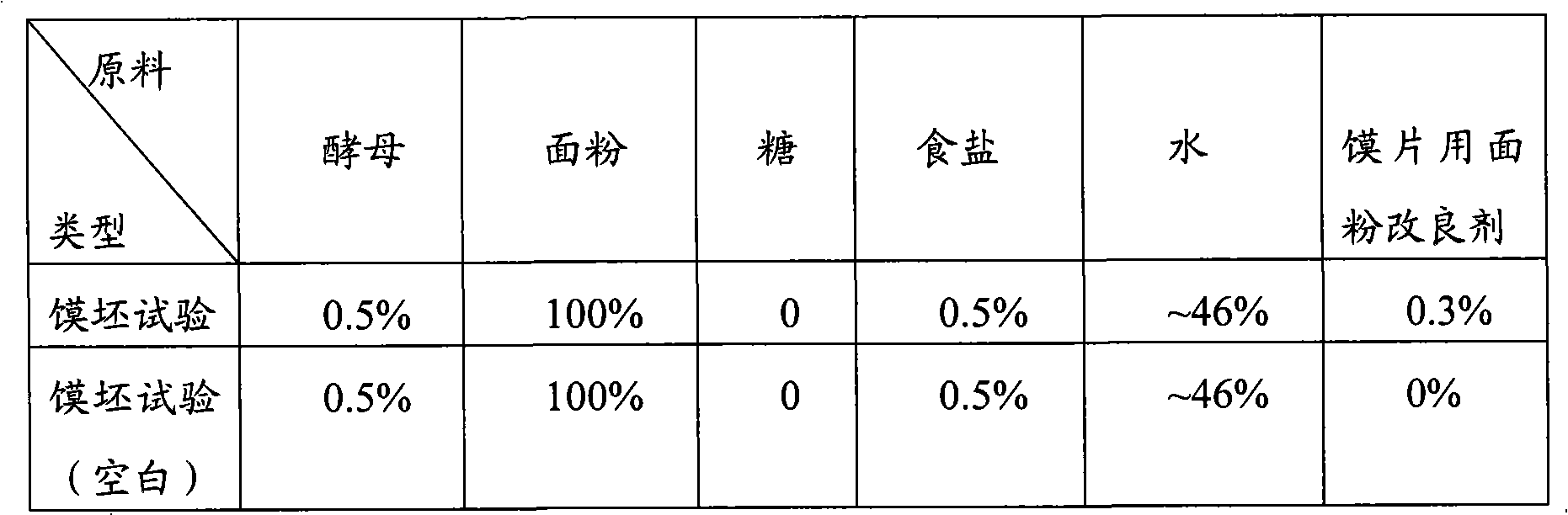

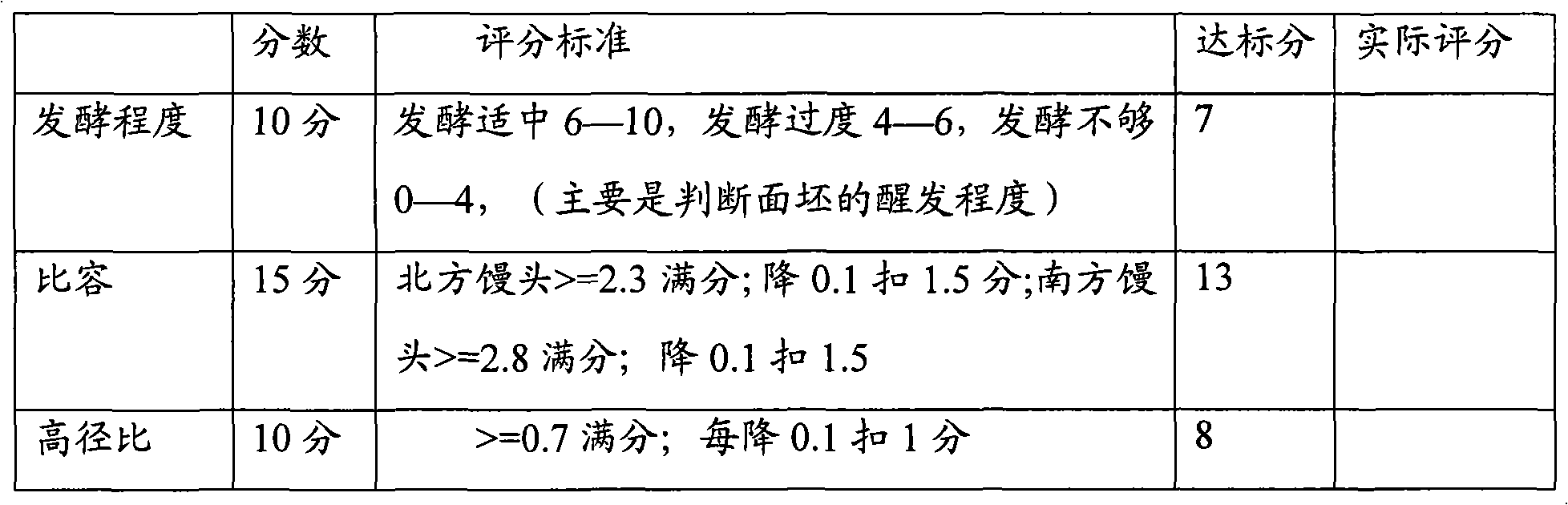

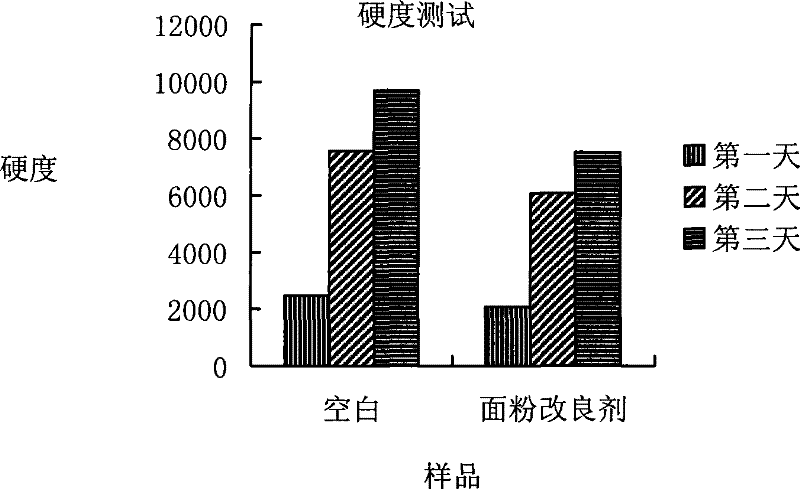

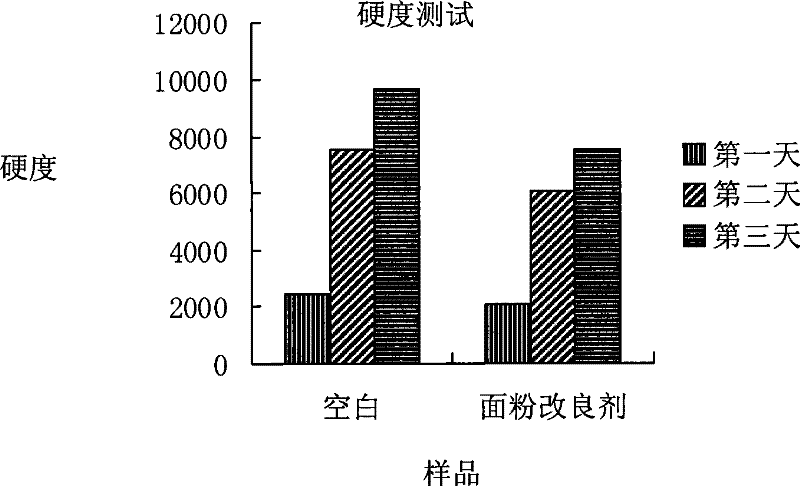

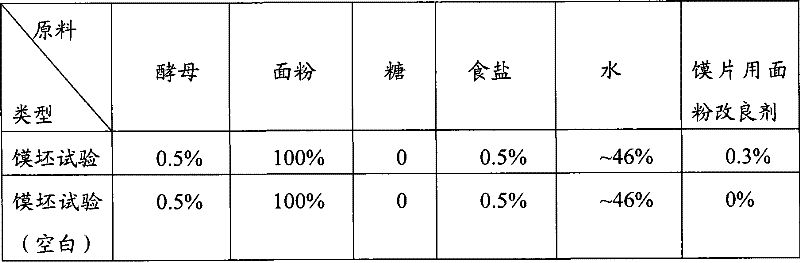

Steamed bread slice making flour modifier and use thereof

InactiveCN101664048AIncrease specific volumeImprove organizational structurePre-baking dough treatmentFood productsSteamed bread

The invention relates to a flour modifier and use thereof, in particular to a steamed bread slice making flour modifier and use thereof. The flour modifier comprises an enzyme preparation, an oxidant,an emulsifier, a swelling agent, a phosphate and starch, can be used for making wheaten food product such as steamed bread and steamed bread slices, improve the structure of steamed bread slices, make the hole in the steamed bread slices more uniform, provide the steamed bread slices with good appearance and improve the crisp degree and yield of the steamed bread slices.

Owner:ANGELYEAST CO LTD

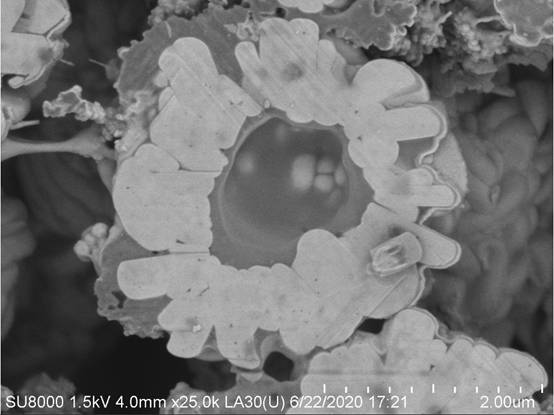

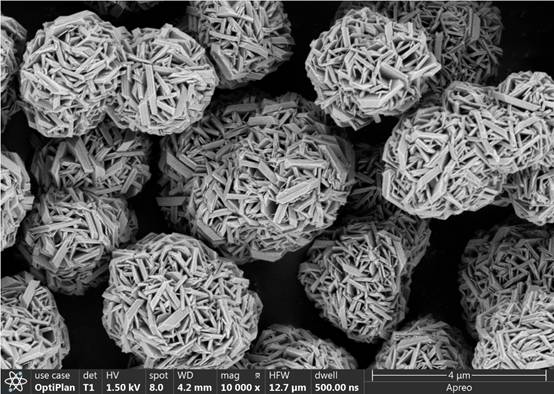

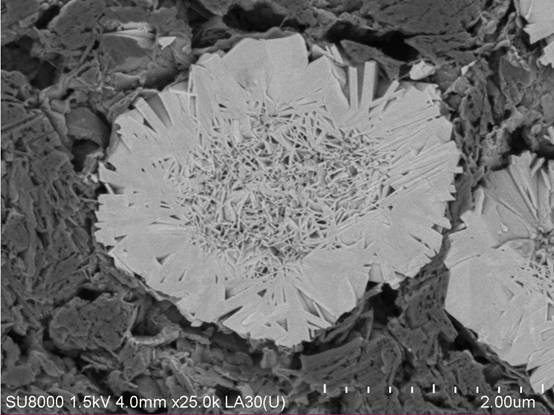

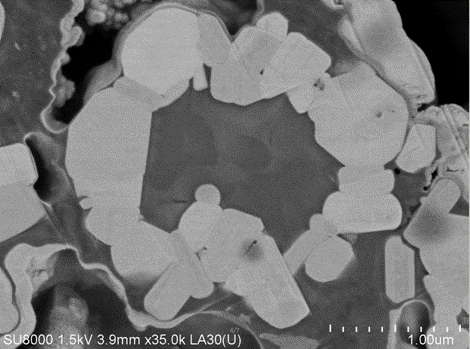

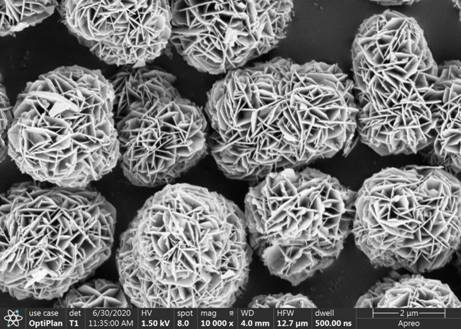

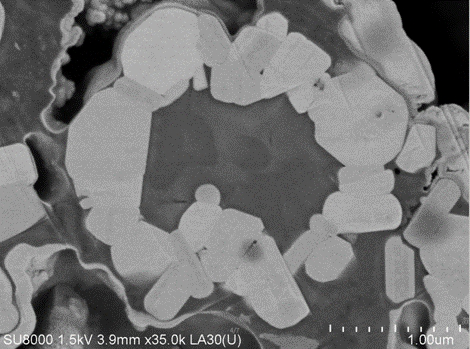

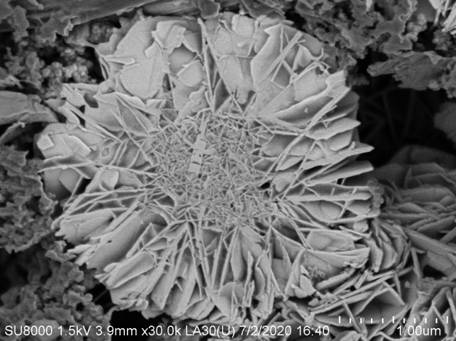

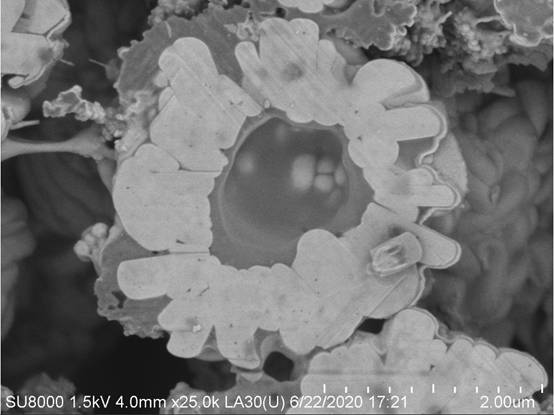

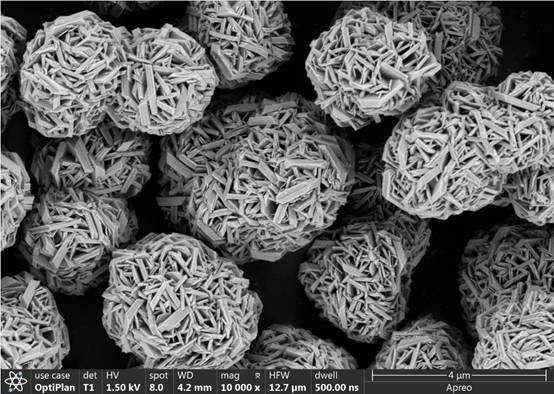

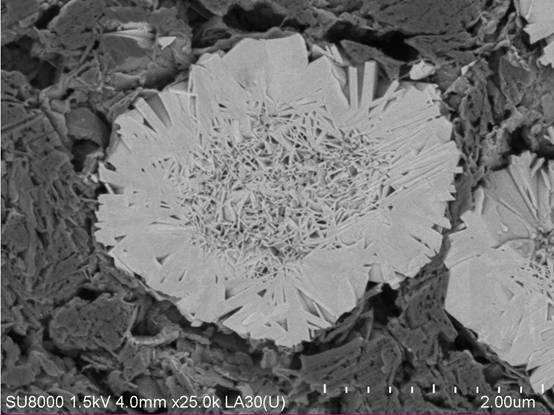

Hollow positive electrode material, precursor thereof, and preparation method of precursor

ActiveCN113247970ALow costThe core accounts for a large proportionSecondary cellsPositive electrodesPhysical chemistryLithium-ion battery

The invention belongs to the technical field of lithium ion battery materials, and particularly relates to a precursor of a hollow positive electrode material, and a preparation method of the precursor. The inner core of the precursor is provided with an inner core part and an outer shell part, the inner core part is loose, the outer shell part is compact, the high tap density is achieved, and the capacity of the hollow material can be improved on the premise that the output characteristic of the hollow material is guaranteed. According to the preparation method disclosed by the invention, the precursor of the hollow material with large core proportion, coarse primary particle size on the outer wall and fewer pores is obtained mainly by controlling the flow of the metal salt solution, the reaction time of the stage I and the reaction pH and atmosphere of the stage II. The invention also provides a hollow positive electrode material obtained by mixing and sintering the precursor and a lithium source.

Owner:JINCHI ENERGY MATERIALS CO LTD +1

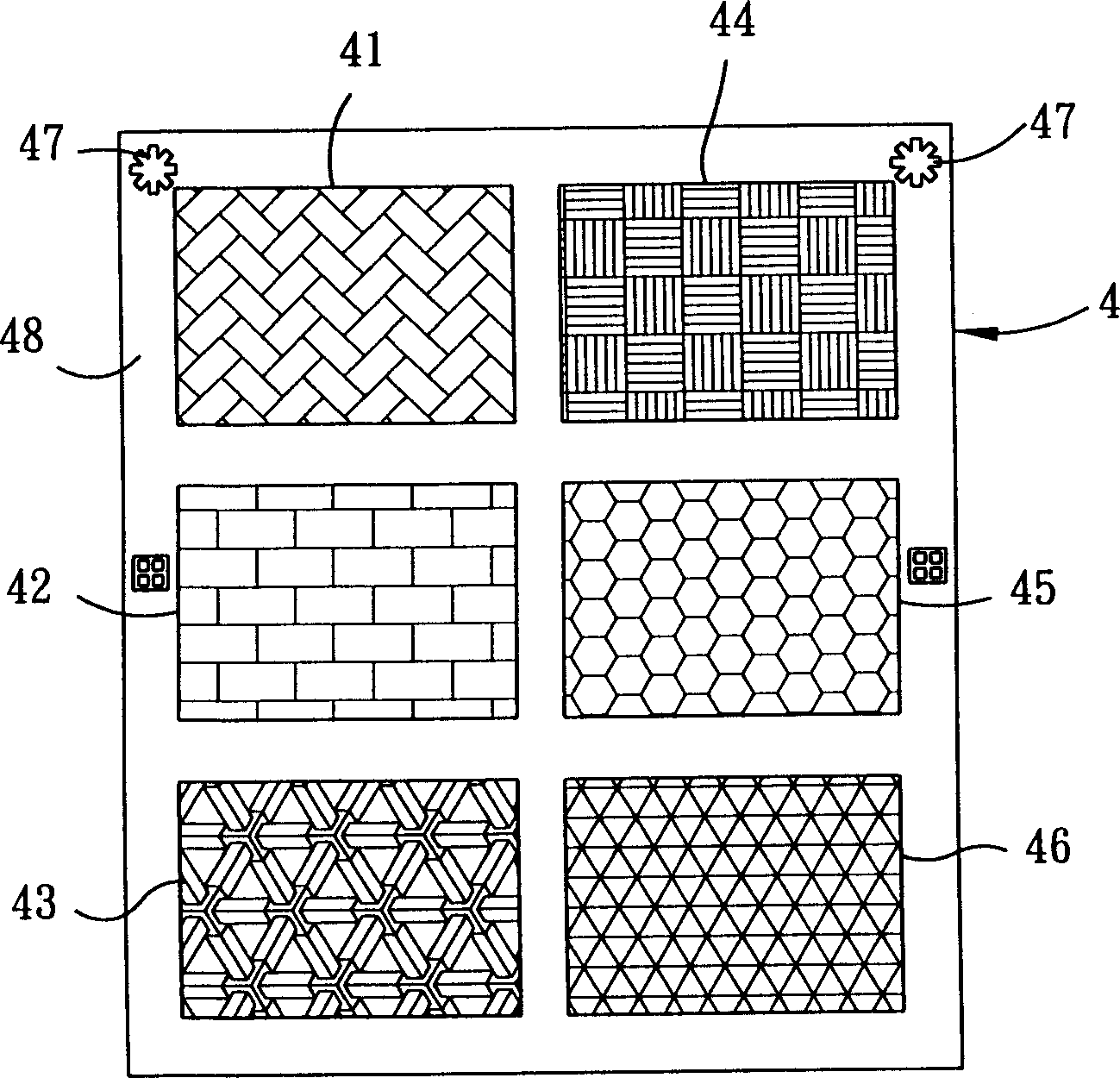

Low-resolution touch screen image defect detection method based on sparse representation

ActiveCN104200478AImprove robustnessImprove real-time performanceImage analysisCharacter and pattern recognitionPattern recognitionComputer vision

The invention discloses a low-resolution touch screen image defect detection method based on sparse representation. The method includes 1, extracting image features from a normal touch screen image training set to establish a dictionary D of normal samples; 2, performing optimization screening on the redundant dictionary D with noise features and selecting a sub-dictionary D' serving as a sparse-representation dictionary of training samples; 3, during defect detection, extracting the features of an image y to be detected, and figuring out the coefficient of the y represented through the D' in a linear manner by means of l1 norm minimization; 4, if the image y to be detected is a touch screen image without defects, allowing the coefficient represented through the D' in a linear manner to be sparse, otherwise, allowing the coefficient to be not sparse. According to the method, a redundant dictionary of over complete bases is established through the touch screen image without defects, elements in the dictionary are selected in an optimized manner to establish a redundant dictionary, and defect detection is performed on the touch screen image by means of the characteristics that the touch screen image without defects can be reconstructed through the dictionary sparse linearity but an image with defects cannot be reconstructed through the dictionary sparse linearity.

Owner:GUANGDONG UNIVERSITY OF BUSINESS STUDIES

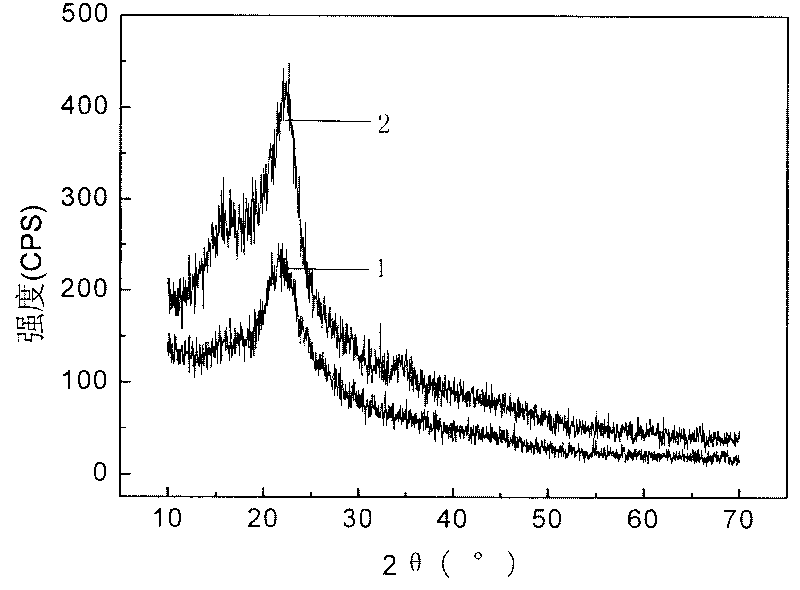

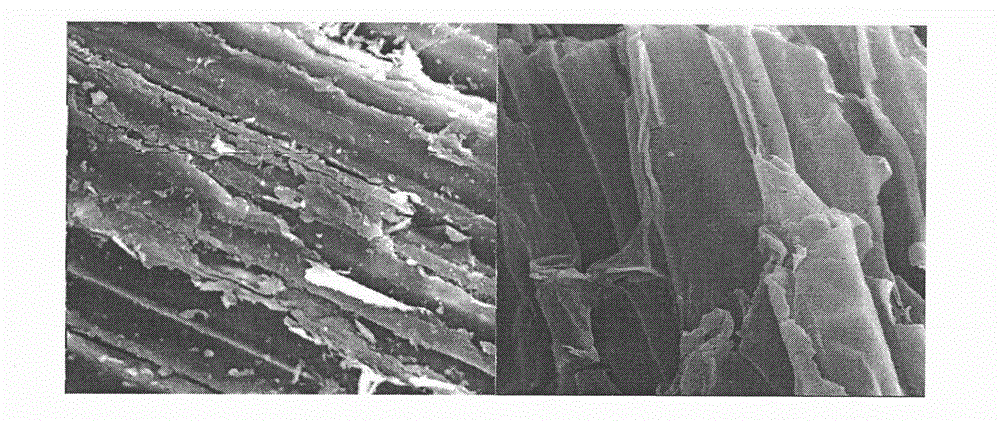

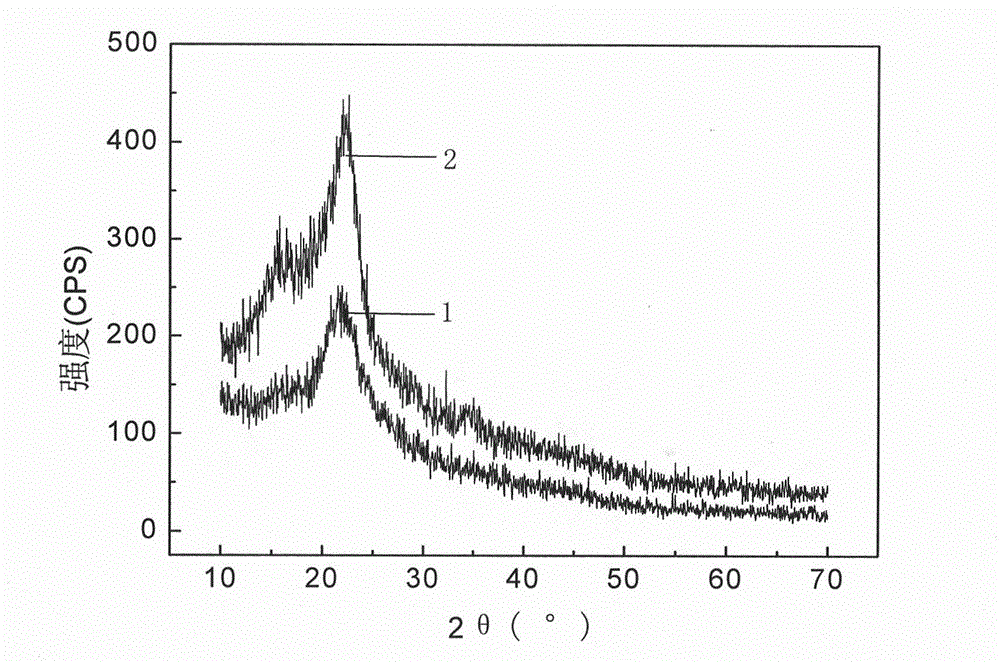

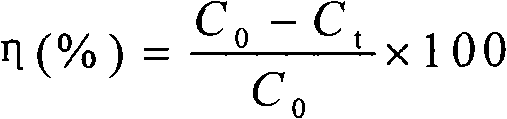

Agricultural waste anion adsorbent and application thereof

InactiveCN101693188ASimple production processApplicable production processOther chemical processesWater/sewage treatment by sorptionLiquid ratioSorbent

The invention discloses an agricultural waste anion adsorbent and an application thereof. The agricultural waste anion adsorbent is prepared by adopting wheat straws, epichlorohydrin and dimethylamine as raw materials under the condition that alkaline media exist. Under the condition of room temperature and oscillation, pH value of waste water is adjusted to be smaller than or equal to 7.0, the anion adsorbent is added, and solid-to-liquid ratio of the adsorbent to dye waste water is enabled to be larger than or equal to 0.4 g / L. Oscillation time is not less than 30 minutes, and the anion adsorbent can be separated after filtration. The method has the advantages of simple process, low cost, economical, applicable and reproducible properties and the like. The adsorbent has the characteristics of good stability, good adsorption effect, wide applicable scope and the like, and can be widely applied to anion dye waste water treatment.

Owner:SHANDONG UNIV

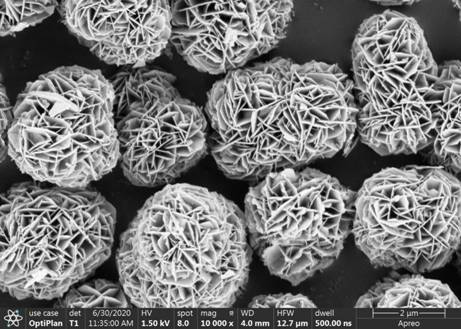

Precursor of hollow positive electrode material and preparation method thereof

ActiveCN112830527AReduce manufacturing costLarge specific surface areaCell electrodesSecondary cellsManganesePhysical chemistry

The invention belongs to the field of lithium ion battery materials, and discloses a precursor of a hollow positive electrode material and a preparation method of the precursor. The precursor synthesis process is divided into two stages, and the hollow positive electrode material precursor with narrow particle size distribution and high specific surface area is prepared by adjusting the flow and pH of the ternary metal salt solution in the reaction process of different stages. The method is simple in process, no new cost is added on the basis of an existing mainstream discontinuous method, and the method is not only suitable for manganese-containing precursors, but also suitable for manganese-free precursors such as nickel, cobalt and aluminum.

Owner:JINCHI ENERGY MATERIALS CO LTD +1

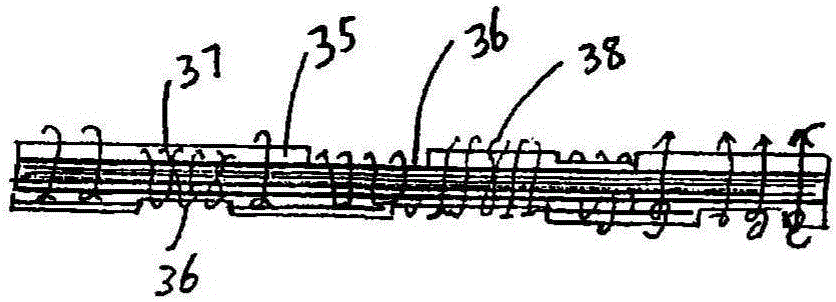

Multifunctional laser holography stamping process

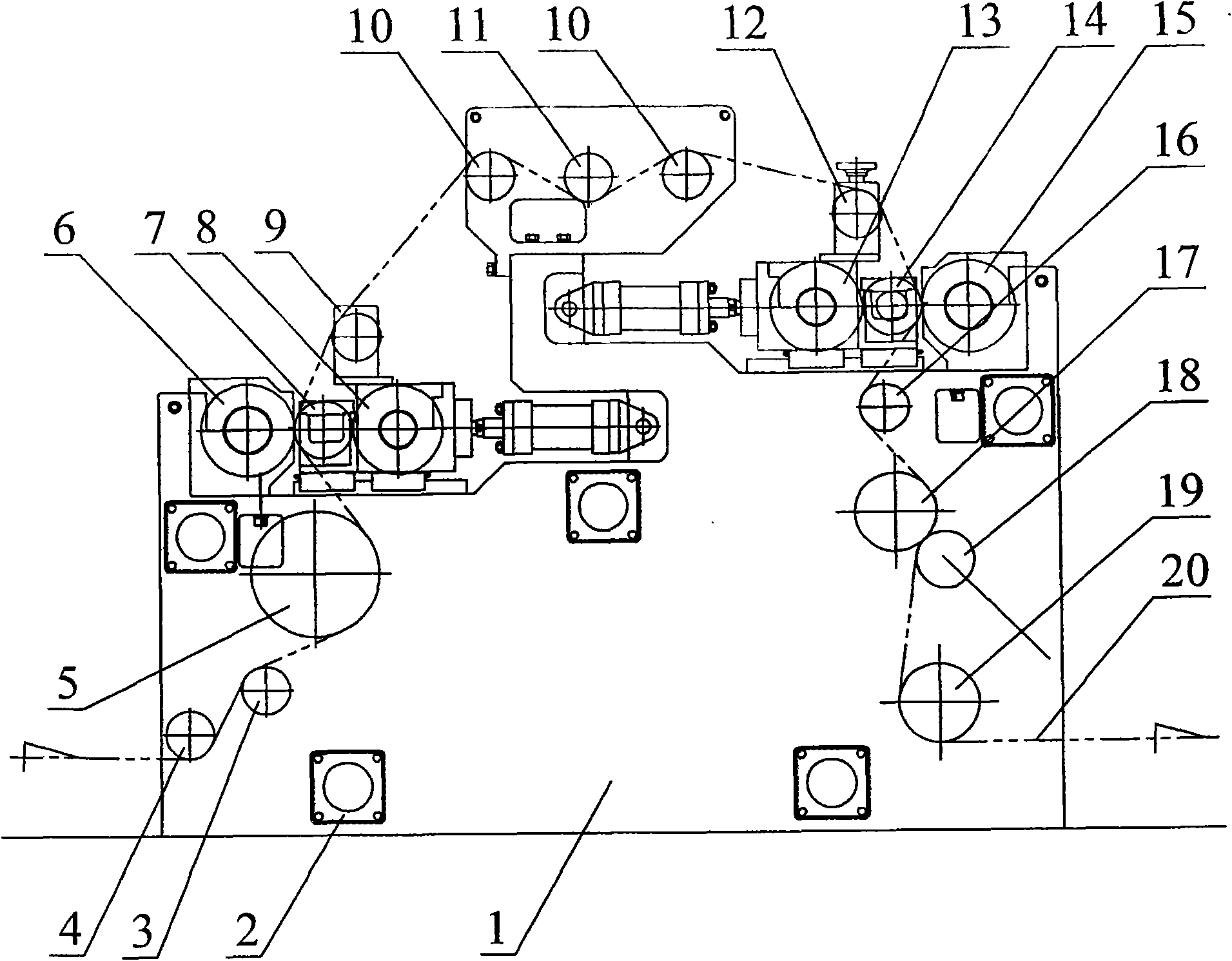

InactiveCN101579963AStrong optical effectLaser effect is goodSpecial ornamental structuresRotary pressesLaser patterningLaser holography

The invention discloses a multifunctional laser holography stamping process. The traditional laser holography compression press uses the process of single-version roller one-step embossing, which has adverse impact on subsequent laser pattern pressing due to the existing version gap. The invention mainly use a stander, a beam, a tension pulley, a stator a, a pre-heating wheel, a first stamping station, a tension-control group, a second stamping station, a stator bb, an ironing wheel, a rubber clamping wheel, a cooling wheel, a printing film, a photoelectric eye and a PLC control circuit. The invention has the beneficial effects that due to utilization of two-station stamping process, plastic film can go through laser holography embossing twice, stagger the version gap and can not be blurred; lowering the temperature requirement on wheel surface of the wheel is favor of stamped pictures and texts of the film to be more plump and saturated; more intensive optical effect is generated to achieve better laser effect; the quality of laser holography stamping on the plastic film is improved greatly.

Owner:SHANGHAI FORWARD MASCH CO LTD

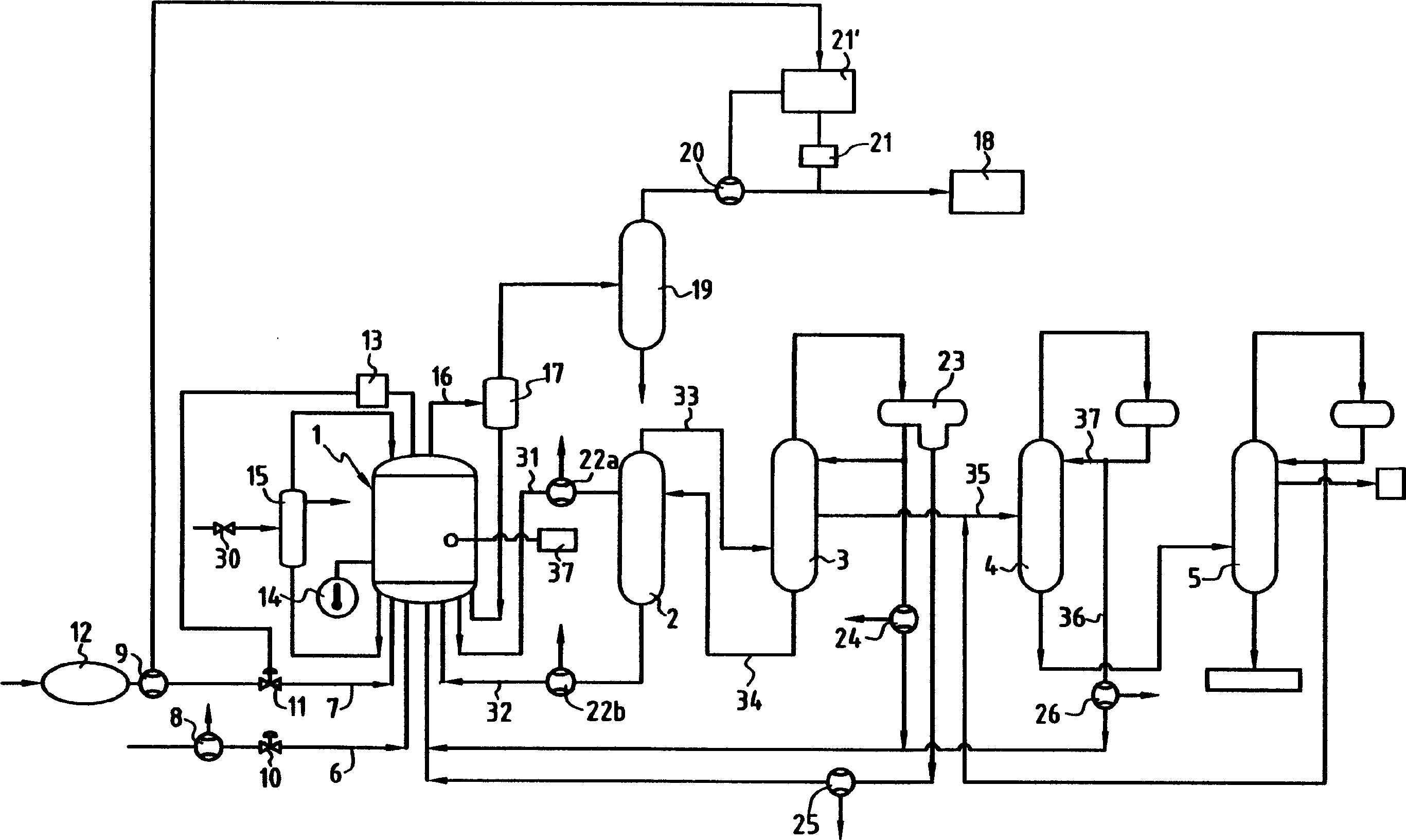

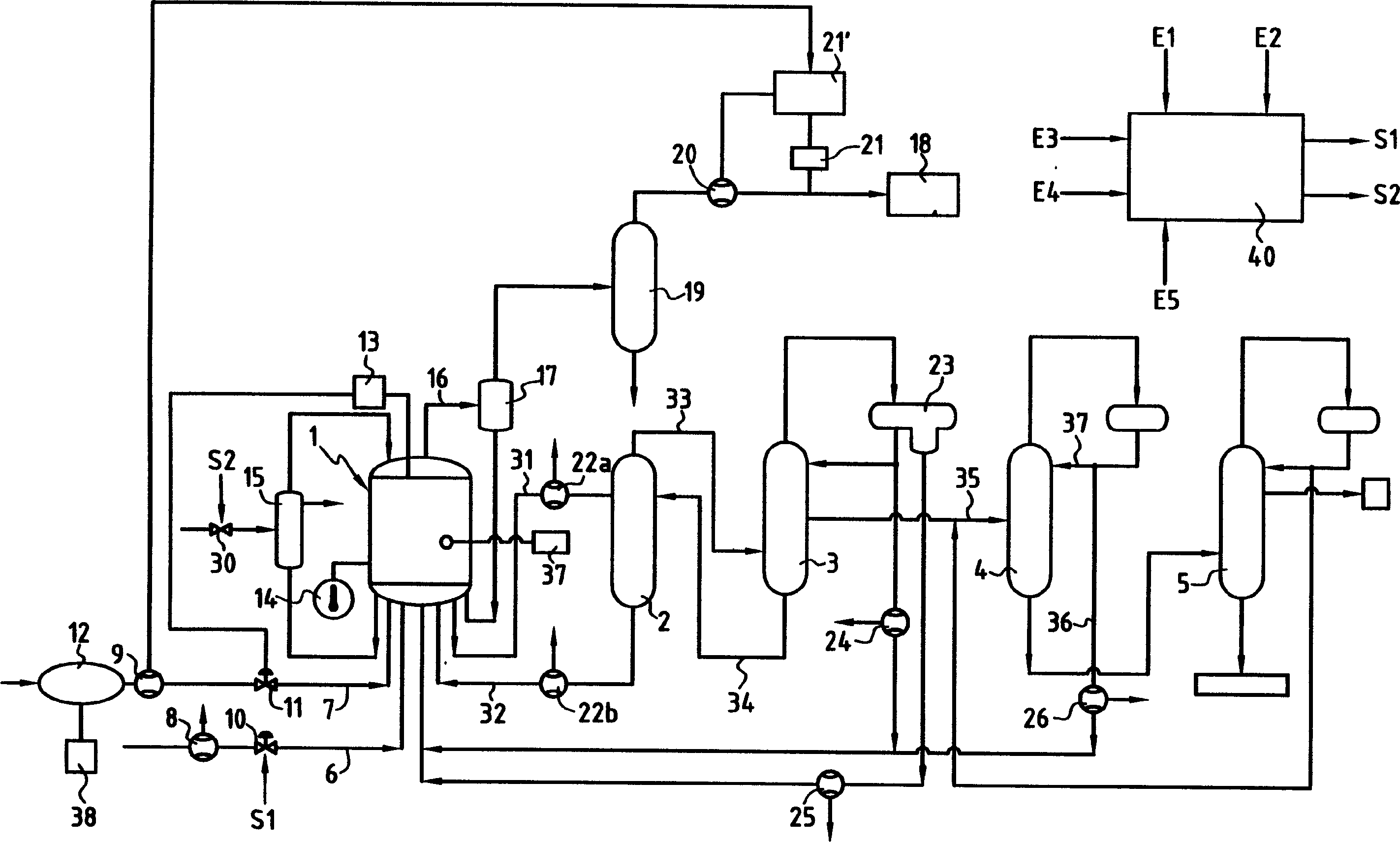

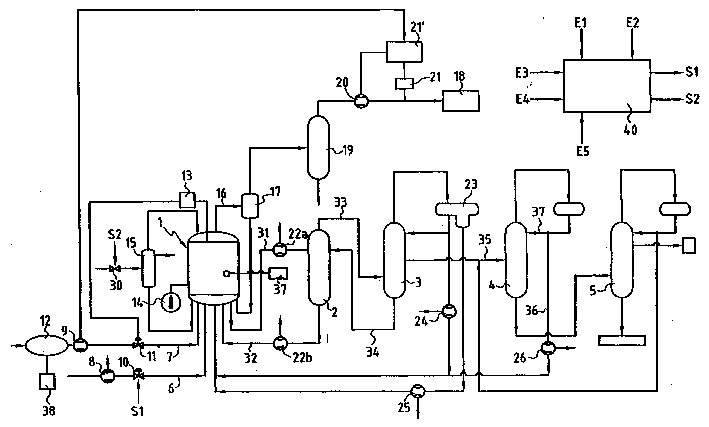

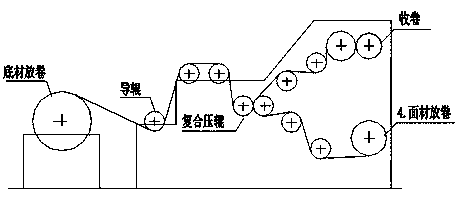

Improvement to methods for continuous production of acetic acid and/or methyl acetate

InactiveCN1538947AControl concentrationControl moisture contentOrganic compound preparationOrganic chemistry methodsAutomatic controlMethyl acetate

The invention relates to a method for the continuous preparation of acetic acid and / or methyl acetate by carbonylation using carbon monoxide, methanol or a methanol derivative that can be carbonylated, in liquid phase, in the presence of water and a catalytic system. According to the invention, in order to improve the production of acetic acid and / or methyl acetate, the temperature of the reactor and the inlet flow of methanol, or the methanol derivative that can be carbonylated, into said reactor are controlled by the inlet flow of carbon monoxide and by at least one of the parameters that define the composition of the reaction medium and / or events, said automatic control being performed preferably by means of a predictive multi-variable regulator. The inventive method is suitable for use in Monsanto-type preparation methods and low water content methods.

Owner:ACETEX CHEM

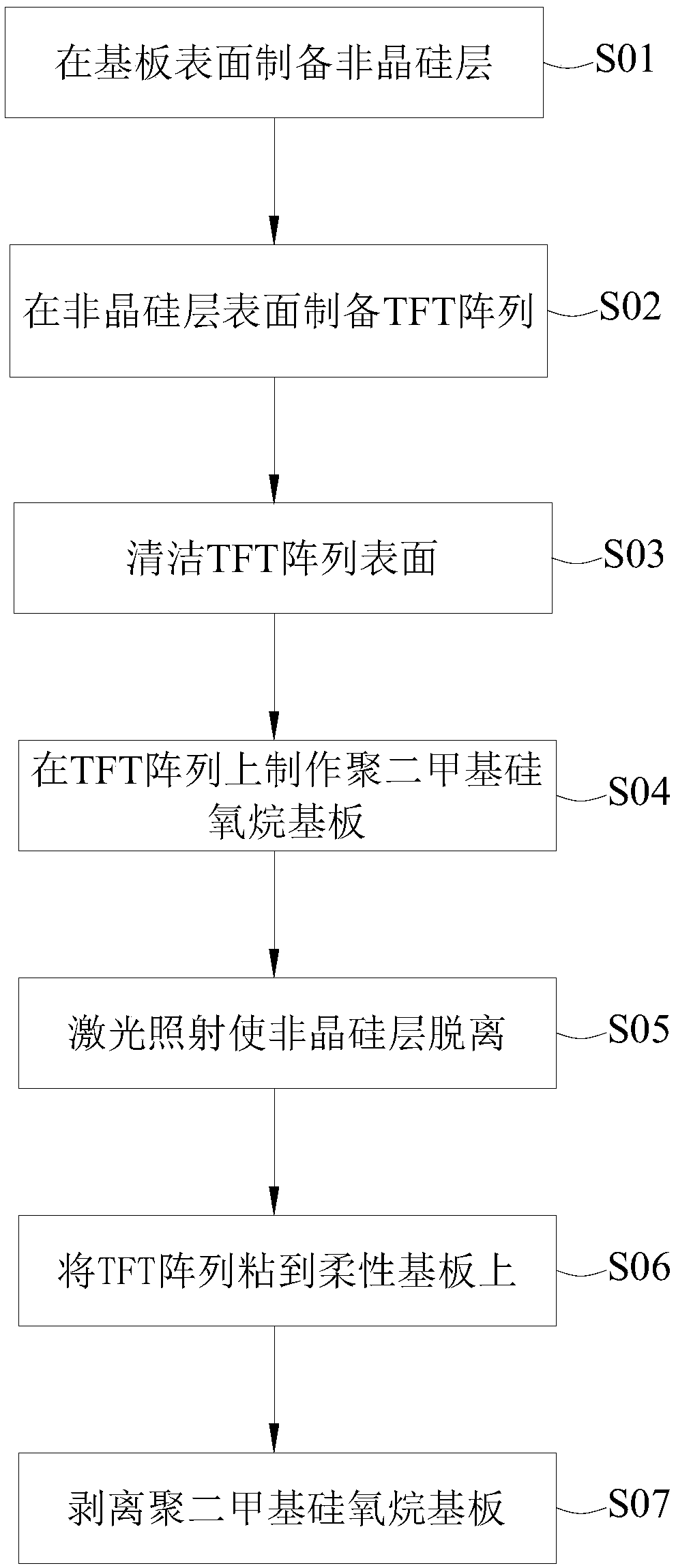

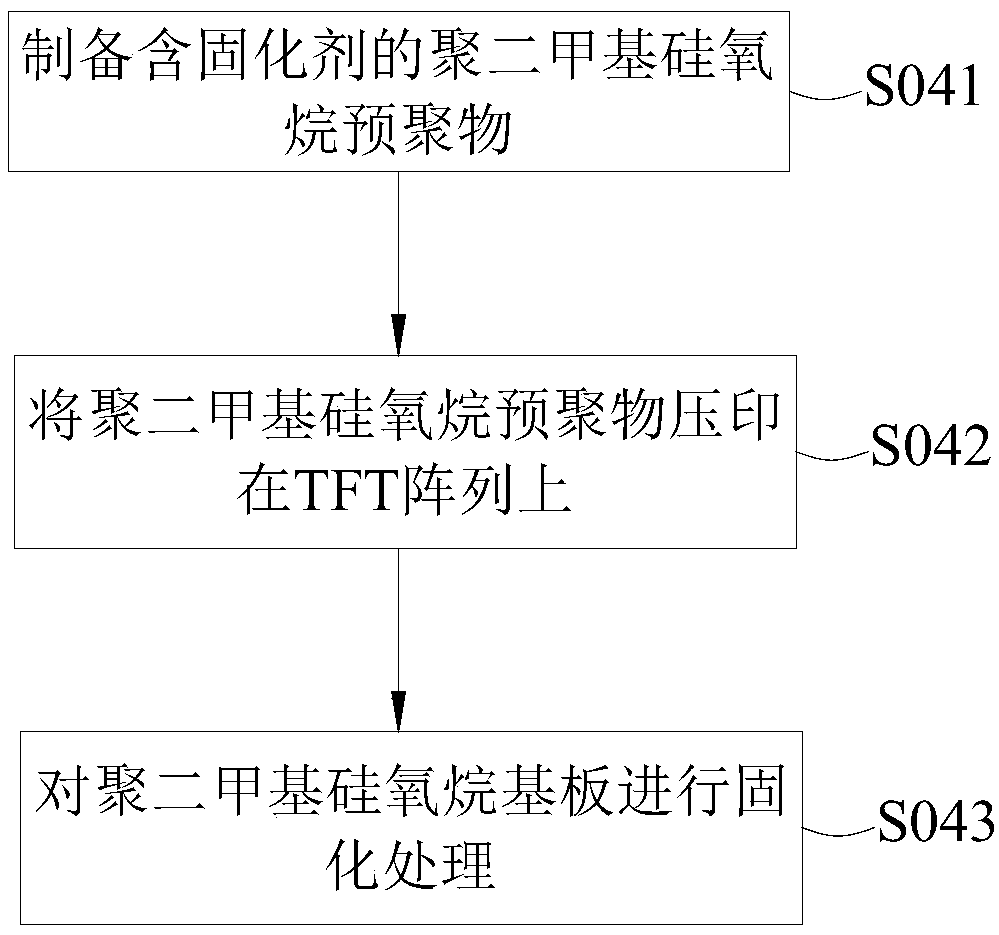

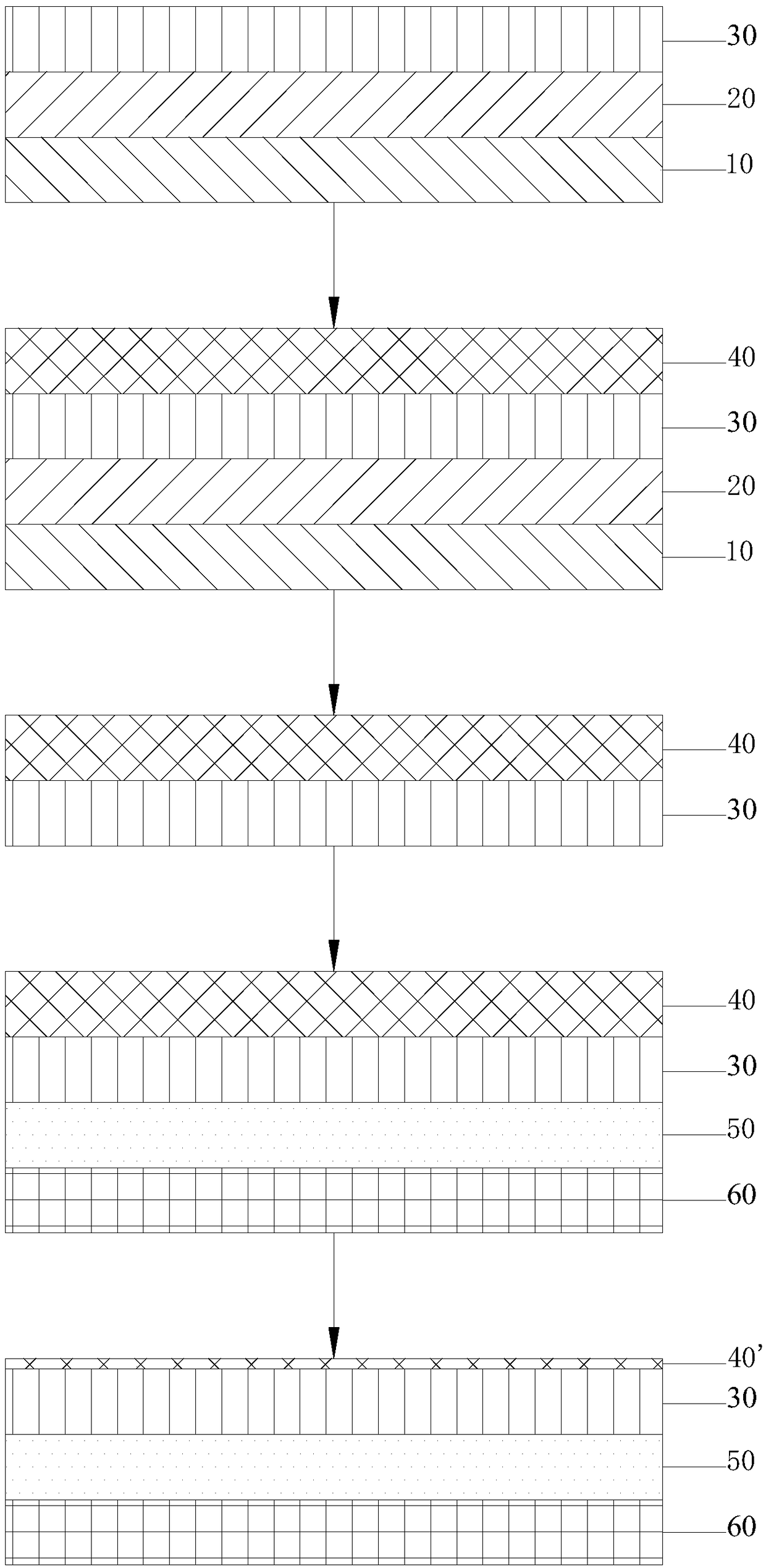

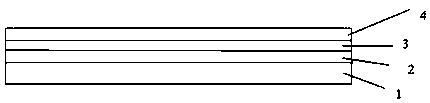

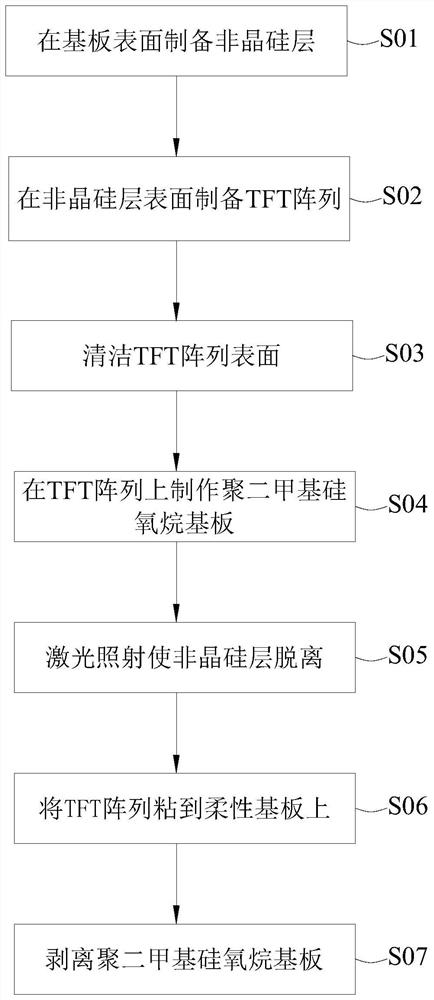

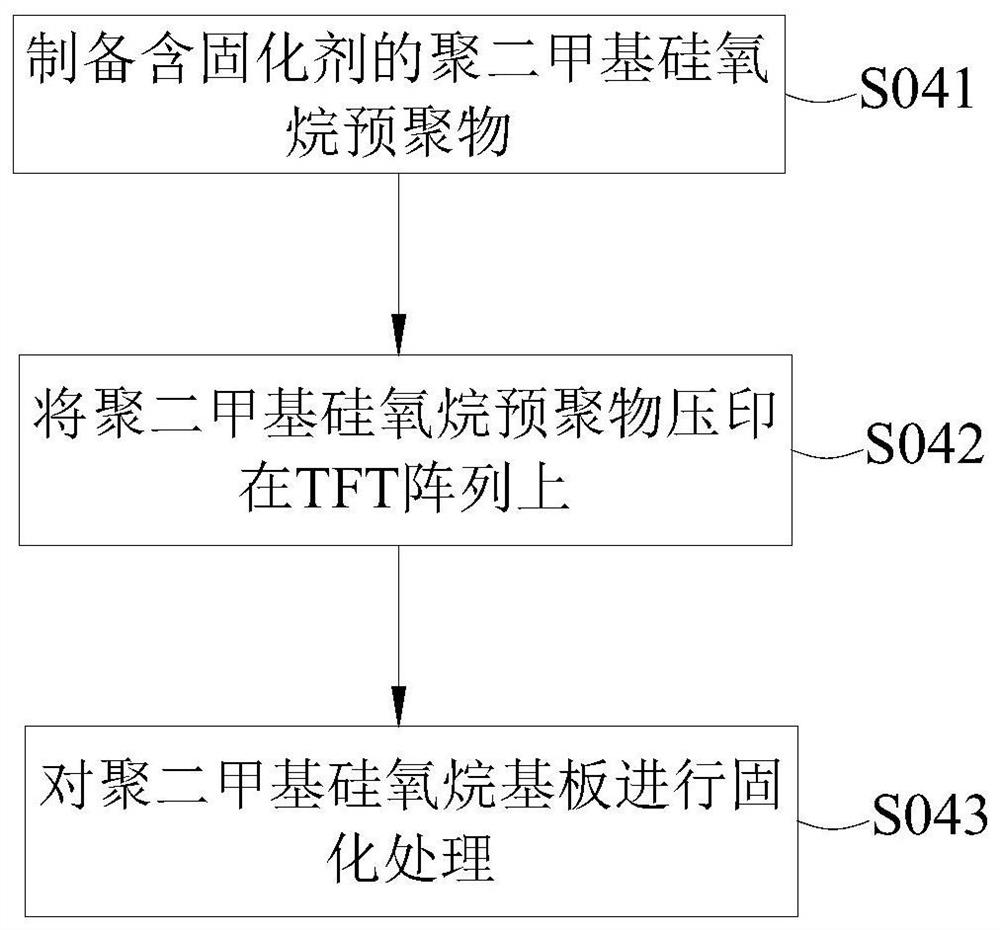

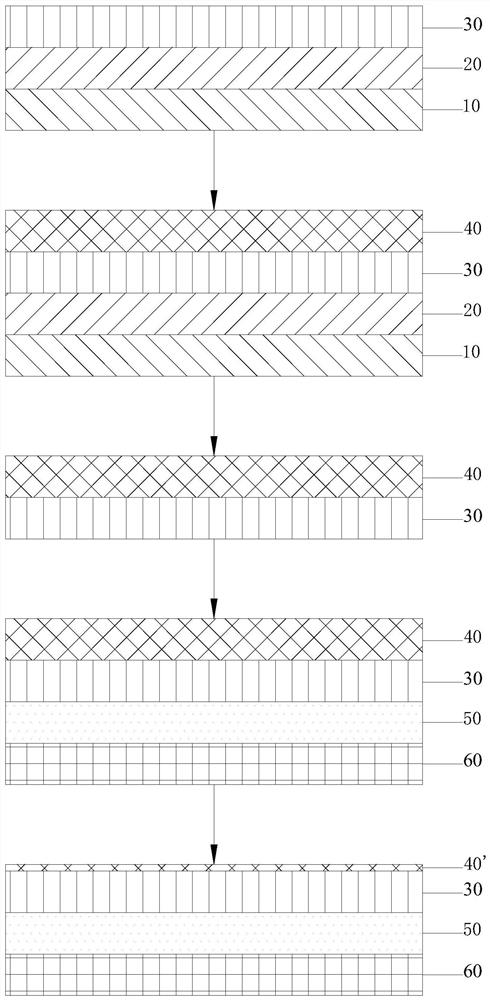

TFT array substrate of flexible liquid crystal panel and manufacturing method of TFT array substrate

ActiveCN108828863AApplicable production processEasy to makeSolid-state devicesNon-linear opticsAmorphous siliconPolydimethylsiloxane

The invention discloses a manufacturing method of a TFT array substrate of a flexible liquid crystal panel. The manufacturing method comprises the steps of preparing an amorphous silicon layer on thesurface of a substrate; preparing a TFT array on the surface of the amorphous silicon layer; cleaning the surface of the TFT array; manufacturing a polydimethylsiloxane substrate on the surface of theTFT array; using lasers to irradiate the TFT array from the back of the substrate, so that the TFT array is separated from the amorphous silicon layer; sticking and fixing the TFT array to a flexiblesubstrate; stripping the polydimethylsiloxane substrate on the TFT array in the same direction. By means of the manufacturing method, polydimethylsiloxane on the TFT array substrate is striped in thesame direction, so that polydimethylsiloxane left on the TFT array substrate can conduct alignment on liquid crystal molecules in the required direction. Manufacturing of a low-temperature alignmentlayer is not needed any more, existing manufacturing steps are simplified, the manufacturing difficulty is overcome, and the manufacturing method is suitable for a production technology of the flexible liquid crystal panel.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

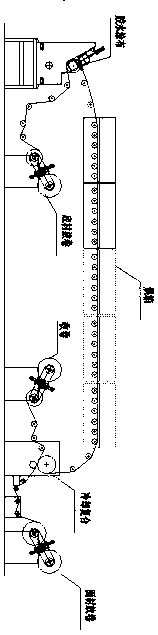

Electrostatic film product and production process thereof

InactiveCN110039870ASimple structureChange thicknessSynthetic resin layered productsLaminationBiochemical engineeringPaper sheet

The invention relates to an electrostatic film product and a production process thereof. The electrostatic film product comprises two-side offset paper, wherein a glue layer is arranged on one side ofthe two-side offset paper, a BOPP film is arranged on one side of the glue layer, and electrostatic film fabric is arranged on one side of the BOPP film; the BOPP film is placed on a winding roller on a coating machine, paper is introduced through the roller, and acrylic glue is evenly applied to the side with low surface tension of the BOPP film through a coating scraper; the BOPP film is introduced into an oven at 60-80 DEG C for 20-25 seconds by a drive guide roller, then the acrylic glue is dried and then taken out of the oven to be combined and glued with the two-side offset paper, and electrostatic film backing paper is formed; the manufactured electrostatic film backing paper is subjected to rewinding, defective products are removed, the rewound paper is arranged orderly on a special compound machine to compound the electrostatic film fabric with the BOPP film side of the electrostatic film backing paper, and then winding and packaging are performed. The product has the advantages of simple structure, high gluing speed, stable glue thickness, convenient operation and the like, production benefits can be greatly increased, and glue thickness can be adjusted.

Owner:LECCO KAIPING ADHESIVE PROD

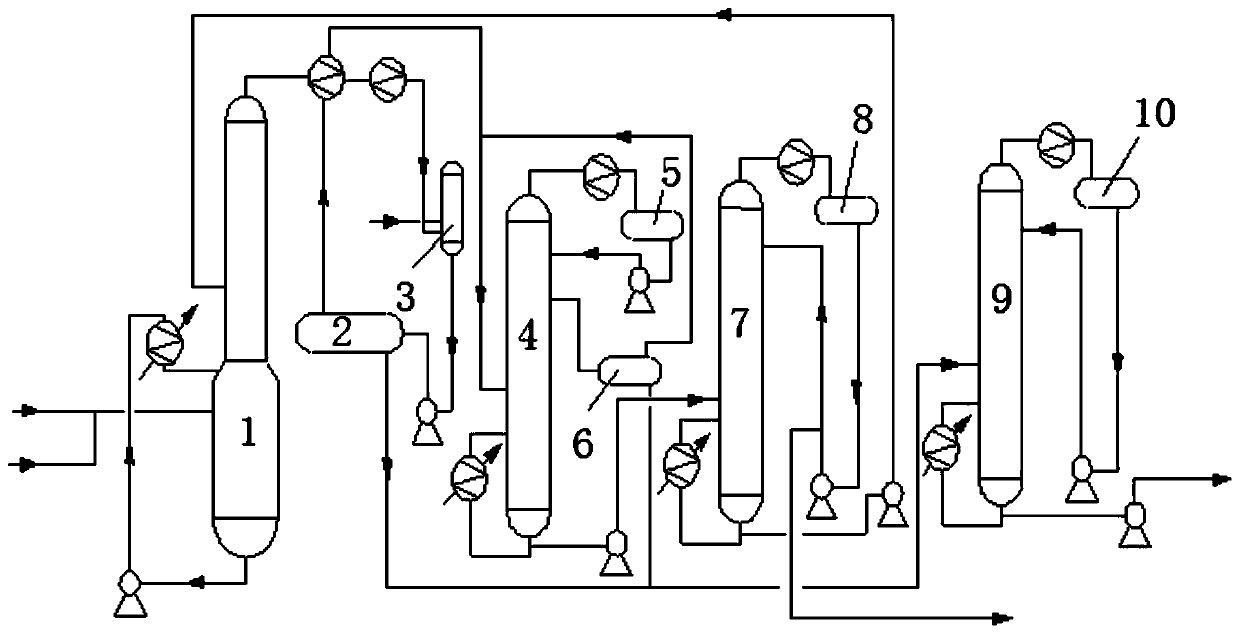

System and technology for rapid extraction of refined and pure ethyl acetate after pressurized esterification synthesis

ActiveCN109534997AHigh purityReduce driving timeOrganic compound preparationChemical industryAcetic acidWater storage

The invention discloses a system and technology for rapid extraction of refined and pure ethyl acetate after pressurized esterification synthesis. The system consists of a reactive rectification tower, a refining tower, a deacidification tower and a recovery tower, wherein the middle of the reactive rectification tower is connected to an acetic acid source and an ethanol source, the top of the reactive rectification tower is connected to the inlet of a first collection tank through a cooler, the first collection tank is also connected to a first stratification apparatus, and the top of the first stratification apparatus is communicated with the top of the reactive rectification tower and the middle of the refining tower respectively. The first stratification apparatus is communicated witha desalted water storage device, and desalted water can be supplemented into the first stratification apparatus. By supplementing desalted water into the first stratification apparatus, the substancecan serve as an extract for extraction of light components, reaction by-products and other impurities in crude ester, and also can accelerate the displacement of acetic acid in the crude ester and improve the qualified speed of products at the initial start-up stage of an ethyl acetate plant.

Owner:YANKUANG GRP CO LTD

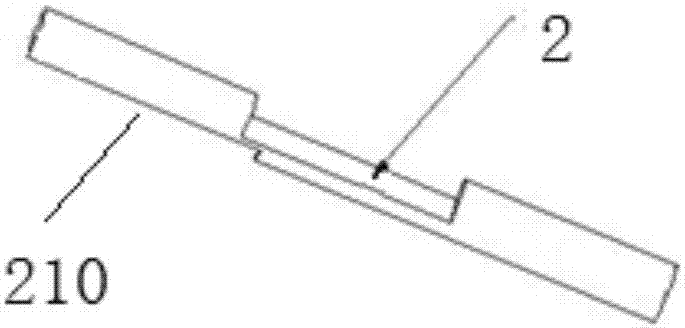

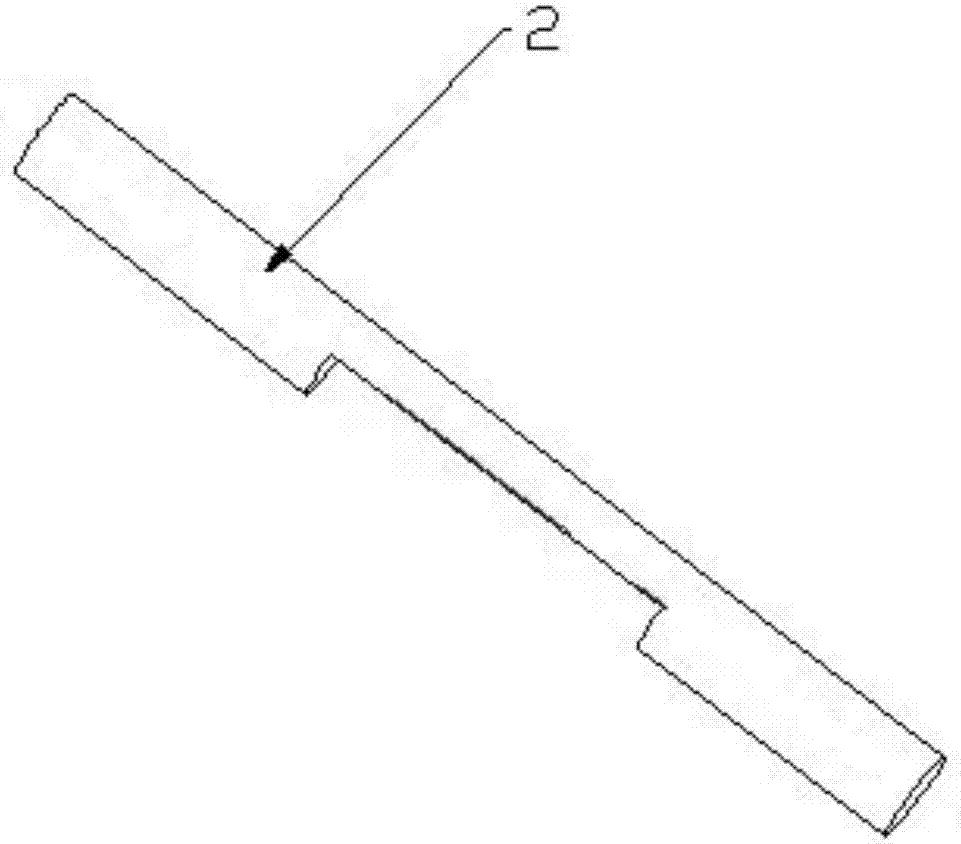

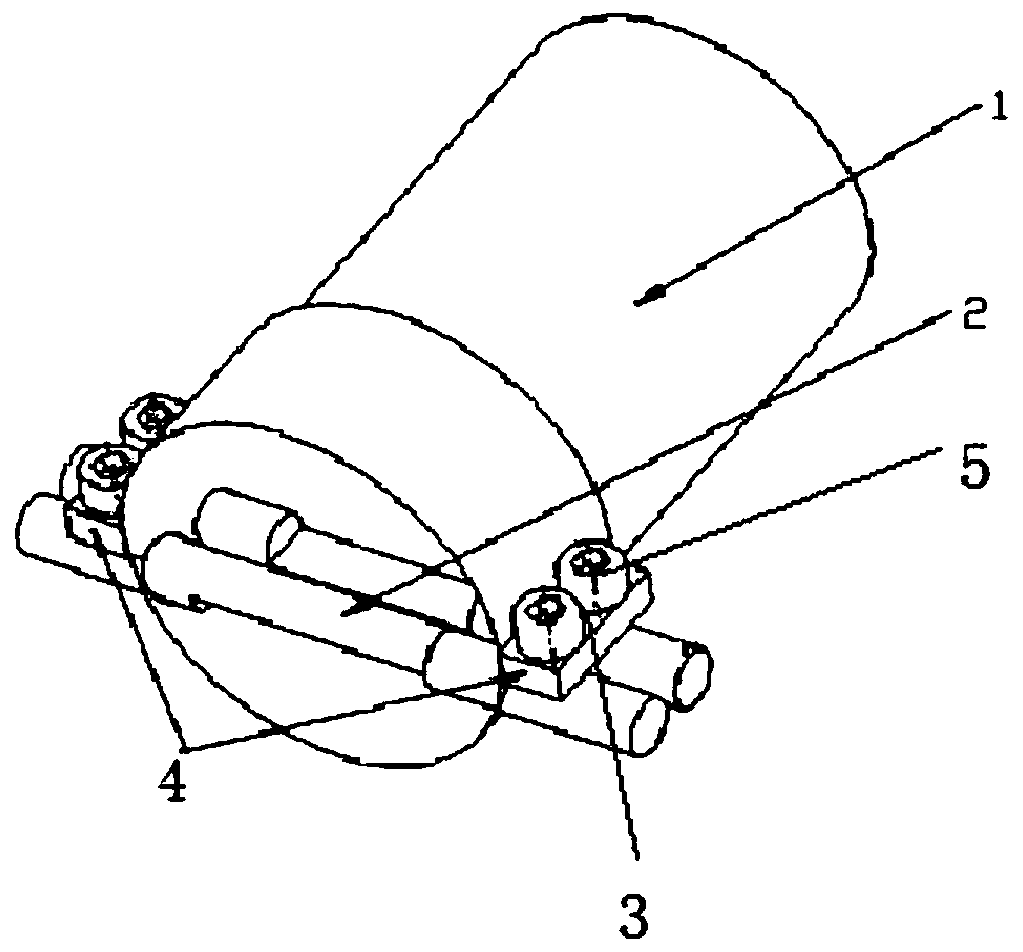

Longitudinal wrap assisting device for water-blocking tape

ActiveCN107991746AGuaranteed to be roundFormlessFibre mechanical structuresLocking mechanismWater block

The invention relates to a longitudinal wrap assisting device for a water-blocking tape. The longitudinal wrap assisting device comprises a barrel-shaped base, two water-blocking tape width regulationrods and locking mechanisms, wherein one end of the barrel-shaped base is connected with an optical cable preforming mold; the locking mechanisms are fixed on the barrel-shaped base; the two water-blocking tape width regulation rods are fixed at the other end of the barrel-shaped base sequentially in the axial direction of the barrel-shaped base through the locking mechanisms; each water-blockingtape width regulation rod is provided with an opening, the two openings are opposite in the radial direction of the barrel-shaped base, and the two openings are partially overlapped in the axial direction of the barrel-shaped base. When the longitudinal wrap assisting device for the water-blocking tape is used for cable production, roundness of a longitudinal wrap can be guaranteed, no water seepage channel is formed, and qualification rate of produced optical cables, especially GYTA53 optical cables is high.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

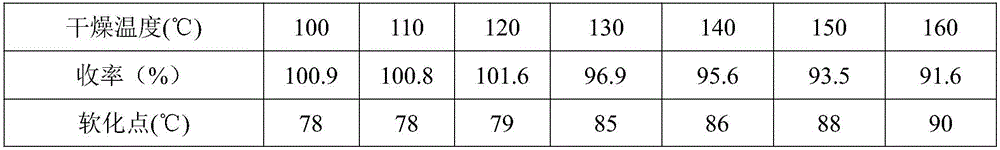

Preparation method of green high-purity thermoplastic phenolic resin

The invention discloses a preparation method of green high-purity thermoplastic phenolic resin, belonging to the technical field of phenolic resin materials. The preparation method comprises the following steps: (1) weighing phenol, aldehyde and acid catalysts; (2) heating reactants to 60-120 DEG C in a stirring state, and reacting for 1-6 hours at normal pressure and constant temperature; (3) performing normal pressure drying at 100-160 DEG C, and then pelletizing; and (4) conveying a phenolic resin particle material into a super-critical carbon dioxide extraction tower, and adding alcohol or ketone extracting agents which account for 0-20% of the mass of the resin to perform dephenolization treatment for 5-30 minutes to obtain a required product under the conditions that the extraction temperature is 31-50 DEG C, the extraction pressure is 8-20Mpa and the separation pressure is 5-7Mpa. By adopting the preparation method disclosed by the invention, free phenol can be effectively separated from the thermoplastic phenolic resin, the emission of phenolic wastewater can be reduced, the yield of the product can be improved, and the continuous production without pollution can be achieved, so that the preparation method is suitable for the production of various thermoplastic phenolic resins.

Owner:HUAINAN NORMAL UNIV

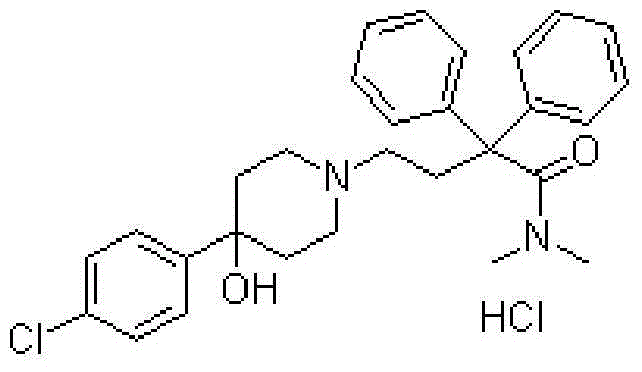

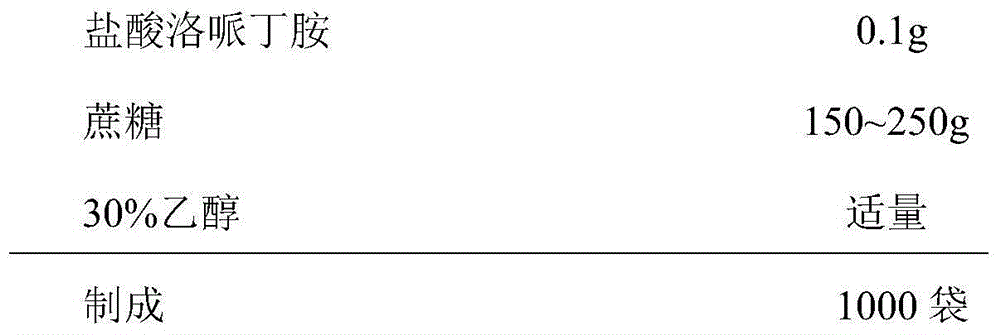

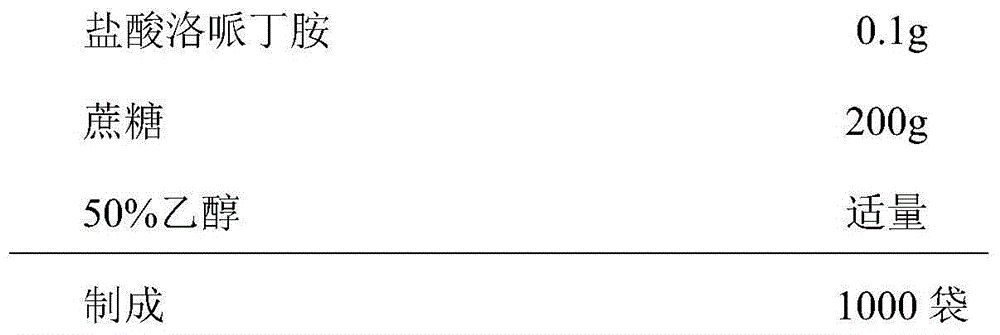

Pediatric loperamide hydrochloride granules and preparation process thereof

InactiveCN104546736AOvercome the disadvantage of uneven mixing directlyDissolution rate is fastOrganic active ingredientsDigestive systemMedical prescriptionPediatrics

The invention belongs to the technical field of medicines, and particularly relates to pediatric loperamide hydrochloride granules and a preparation process thereof. By novel formulation and process, the dissolubility and the content uniformity of the granules can be effectively improved; the quality of the granules is obviously superior to that of a foreign original product; the pediatric loperamide hydrochloride granules are suitable for industrialized production.

Owner:BEIJING KEYUAN CHUANGXIN TECH

Pull rod structure used for reaction cavity

The invention discloses a pull rod structure used for a reaction cavity. The pull rod structure comprises a pull rod, a corrugated pipe and a driving unit, one end of the pull rod is located in the reaction cavity, the other end of the pull rod is located outside the reaction cavity, the corrugated pipe is arranged at the end, located outside the reaction cavity, of the pull rod in a sleeving manner, the second end of the corrugated pipe is in sealed connection with the reaction cavity, the first end of the corrugated pipe is provided with a sealing sleeve, the sealing sleeve is arranged on the pull rod in a sleeving manner, and an annular sealing cavity is arranged between the sealing sleeve and the pull rod; the position, located in the annular sealing cavity, on the pull rod is sequentially sleeved with a first sealing ring, a first sealing pressure pad, a second sealing ring and a second sealing pressure pad, the second sealing pressure pad is close to the outer side of the sealingsleeve, and the outer sides of the pull rod and the sealing sleeve are provided with compression pieces used for compressing the second sealing pressure pad; and a driving unit is connected with thesealing sleeve and drives the sealing sleeve to drive the pull rod to do reciprocated linear motion relative to the reaction cavity. According to the pull rod structure, sealing of the pull rod is changed from sliding sealing in the prior art into static sealing of the first sealing ring and the second sealing ring, the sealing effect is good, abrasion to the sealing rings is small, and stabilityand reliability are achieved.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

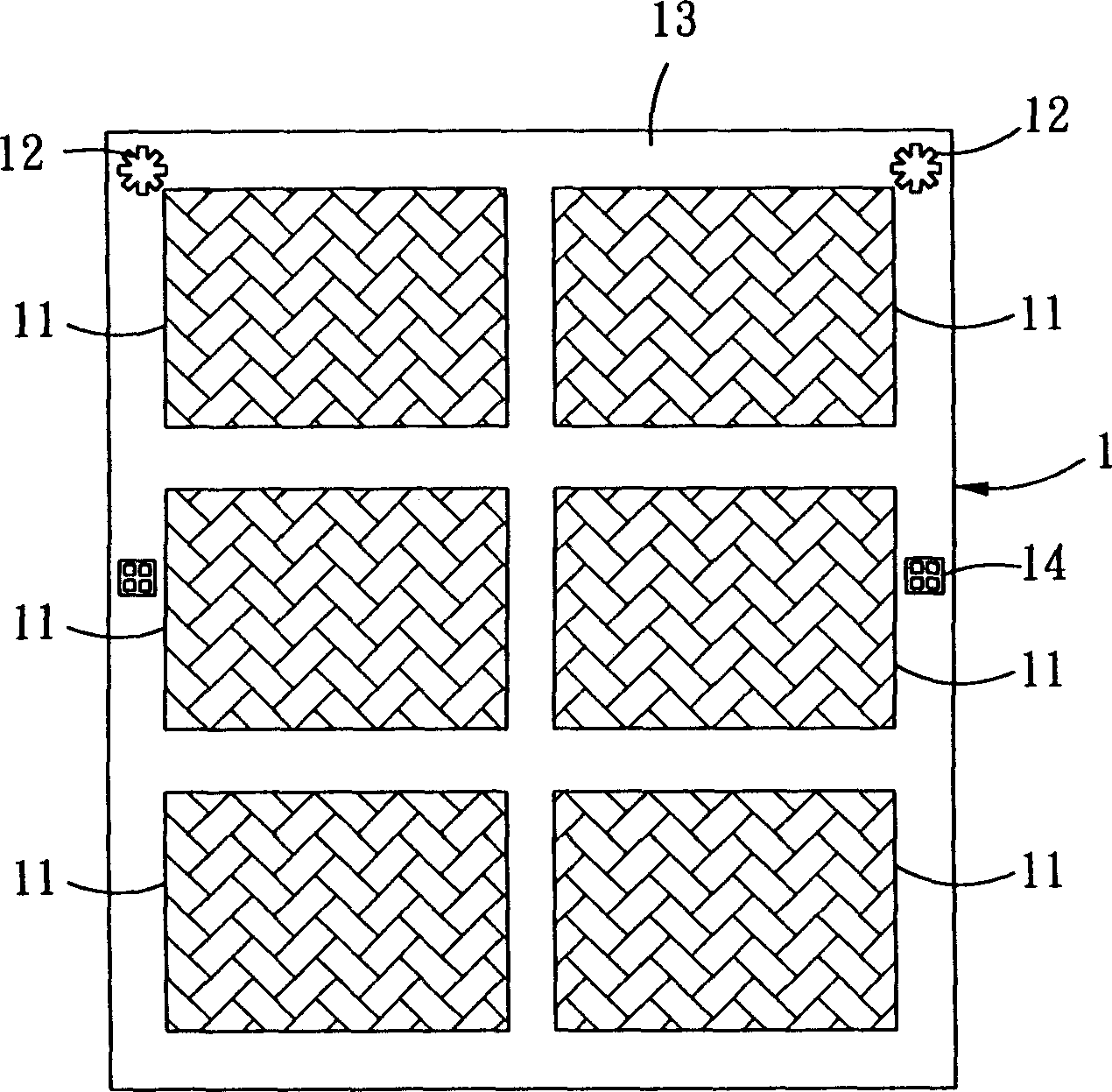

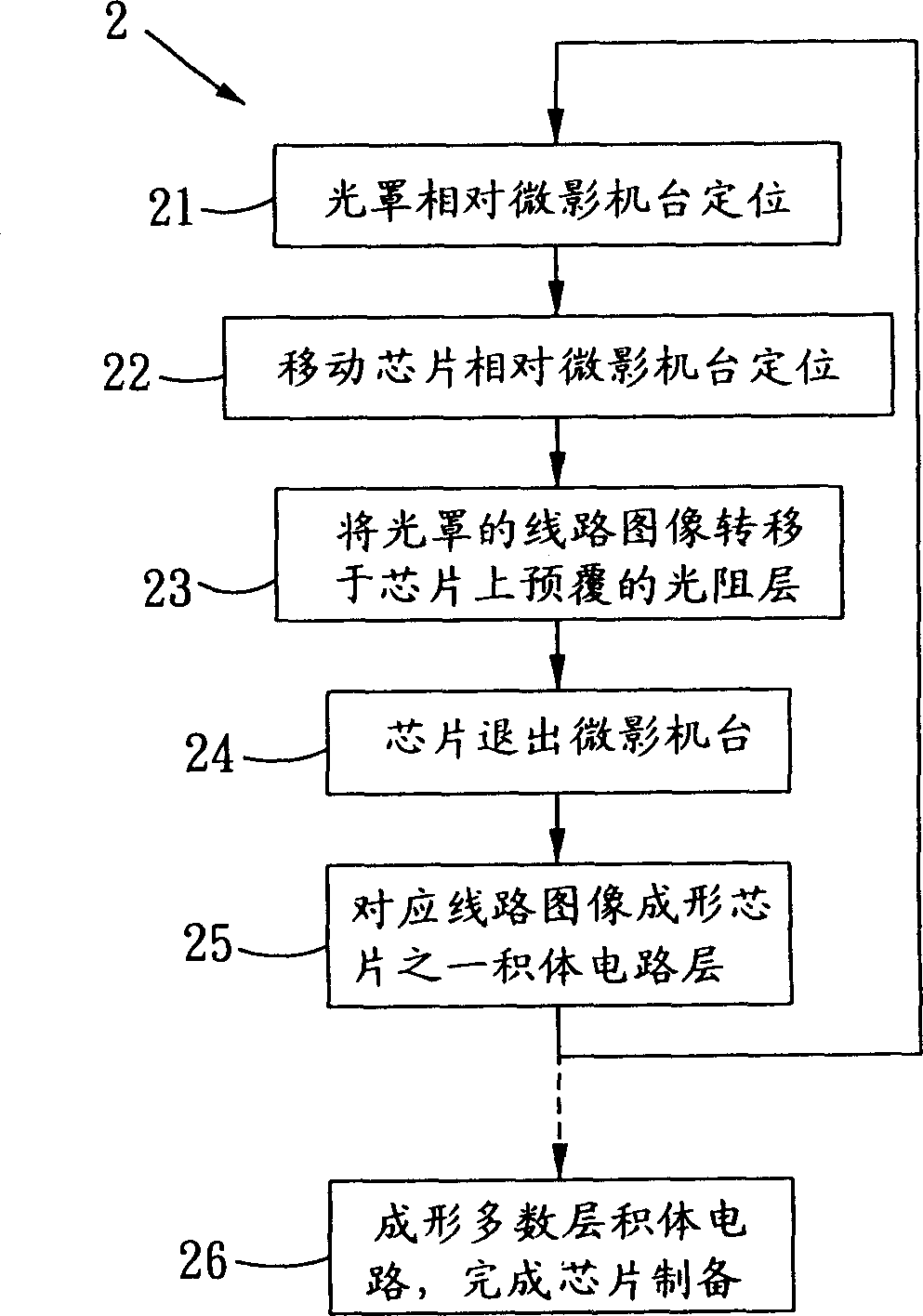

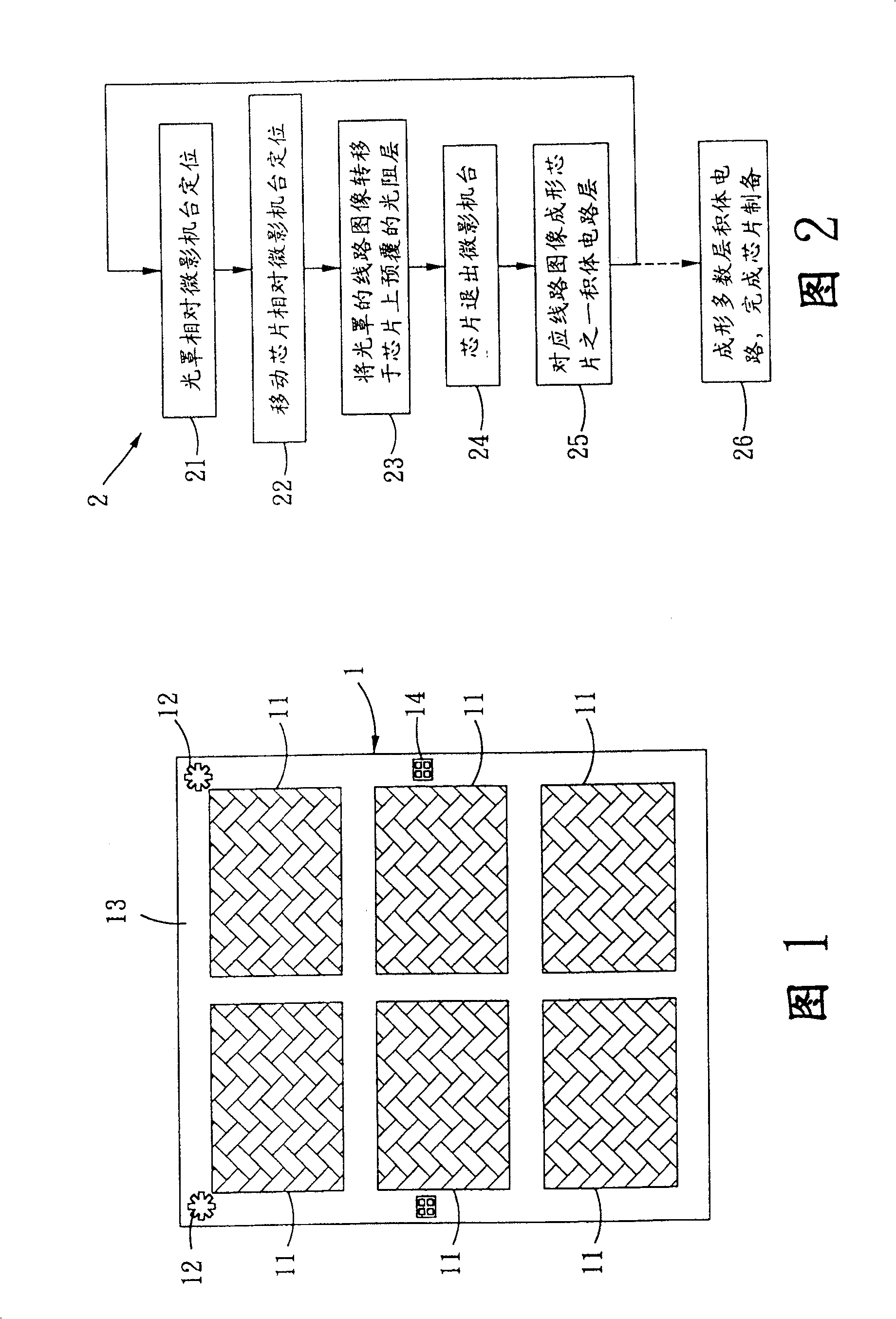

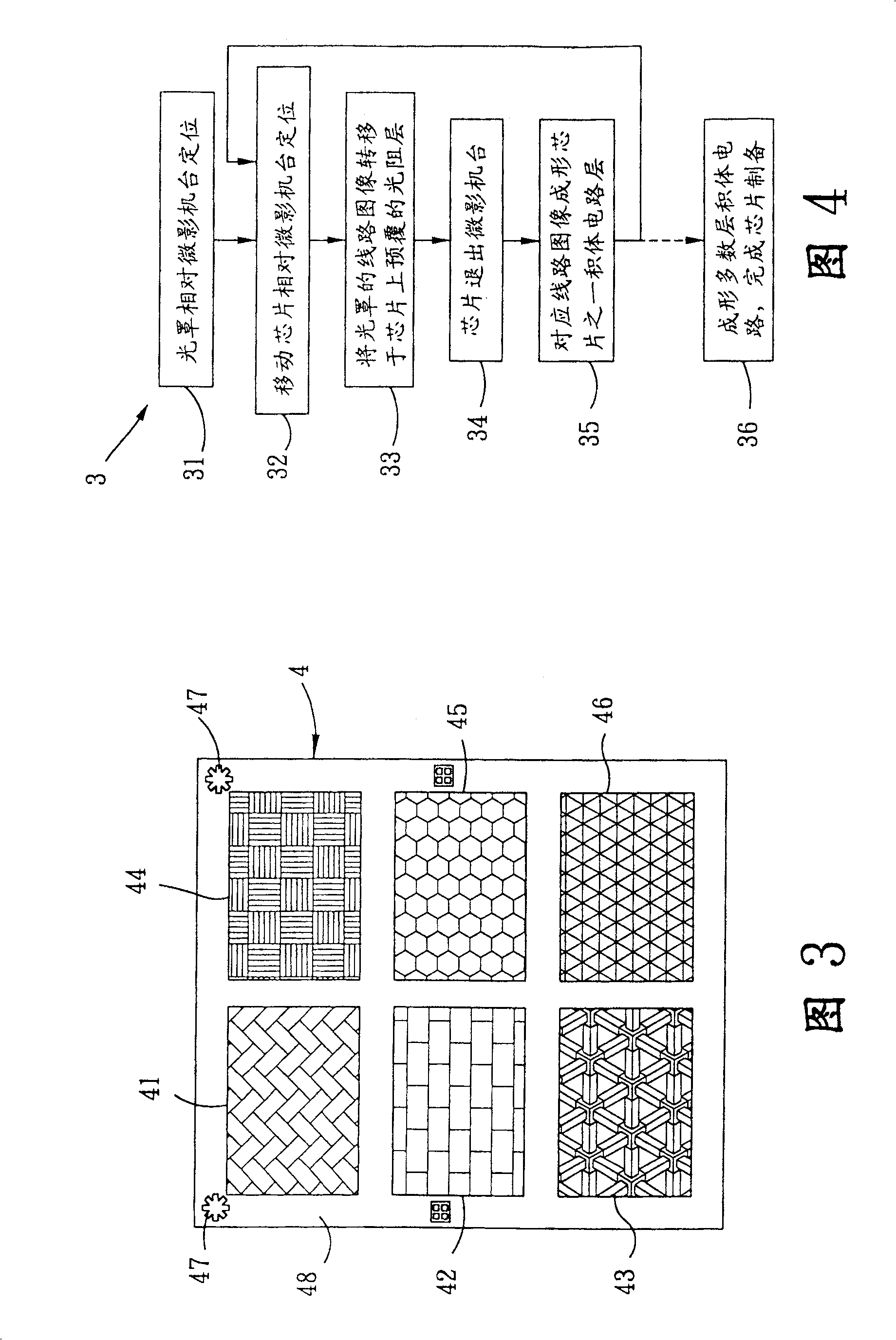

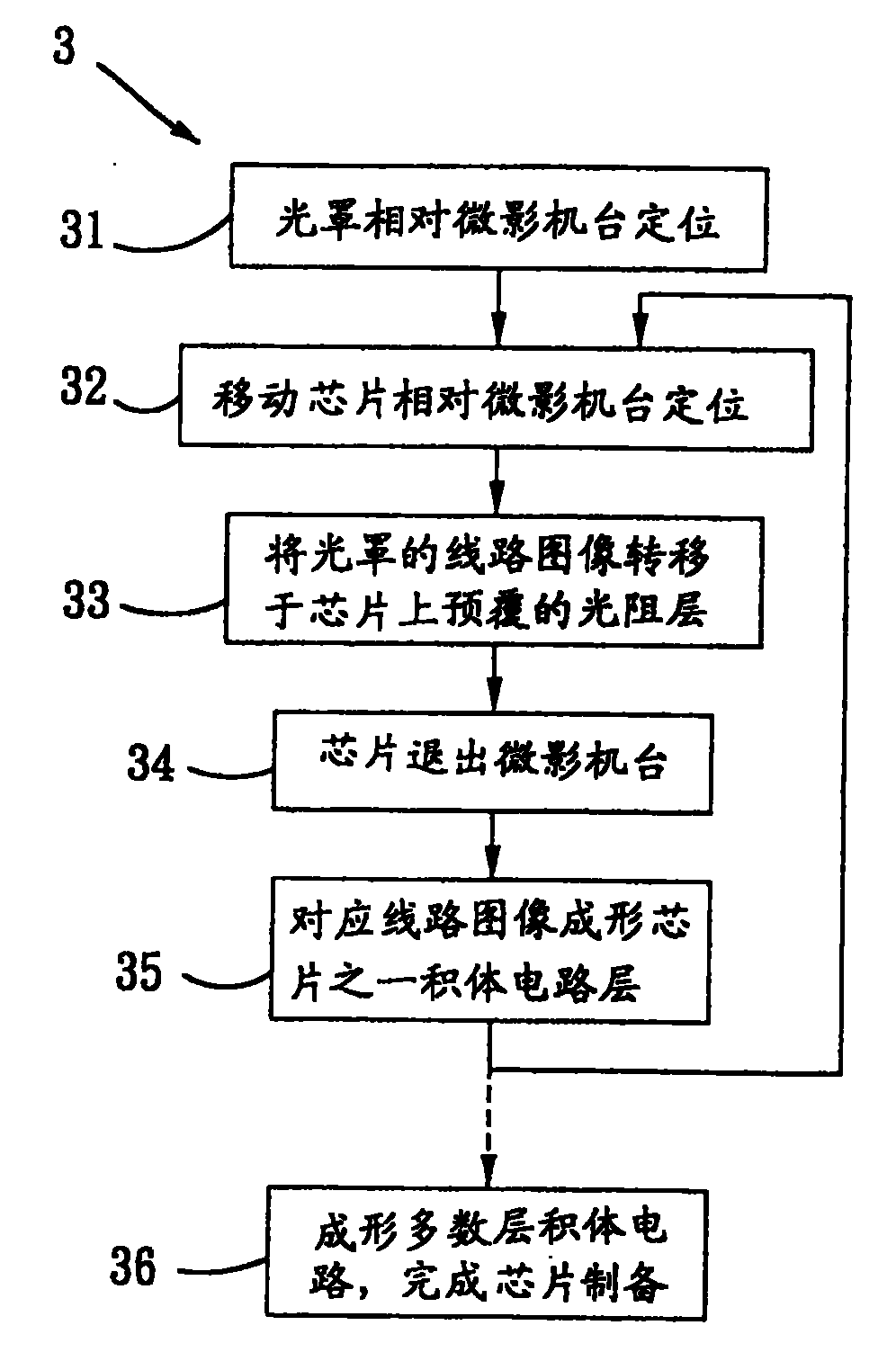

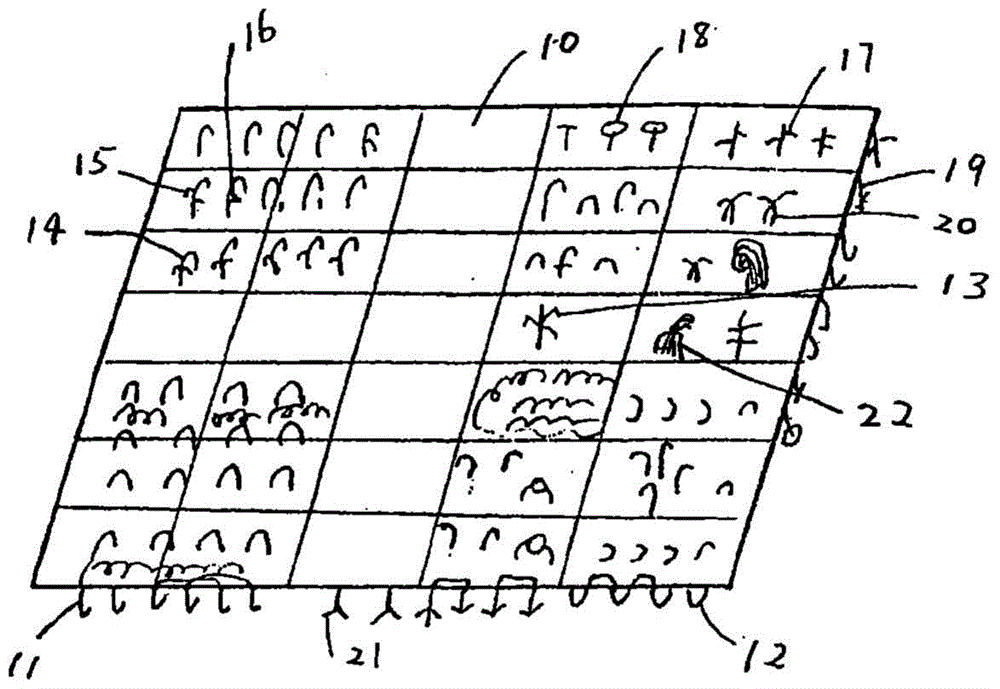

Exposure process for different levels

InactiveCN1567092AReduce in quantityReduce mistakesSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOut of phaseIntegrated circuit

It is a different-level exposure method to take multiple-level exposure to the chip with multiple integration circuit layers by a micro-image machine platform. The method are the following: A, to locate the light cover with multiple out-of-phase circuit images on the micro image machine platform; B, to locate the chip one the micro image machine platform; C, to form a integration circuit layer in the chip from a circuit image in the light cover; D, to re-locate the chip on the micro image machine and furthermore to form another integration circuit layer in the chip form the other circuit image in the cover. This invention adopts only one calibration mark on the cover to relevantly locate on the micro image machine, that is to selectively transfer the images separately on the pre-coat photoresist layer and to relevantly form at least one integration layer on the chip to lower the calibration errors of light cover.

Owner:MACRONIX INT CO LTD

A kind of precursor of hollow positive electrode material and preparation method thereof

ActiveCN112830527BReduce manufacturing costLarge specific surface areaCell electrodesSecondary cellsManganeseLithium-ion battery

The invention belongs to the field of lithium ion battery materials, and discloses a precursor of a hollow positive electrode material and a preparation method thereof. The present invention is divided into two stages in the process of synthesizing the precursor, and by adjusting the flow and pH of the ternary metal salt solution in the reaction process of different stages, a hollow type with narrow particle size distribution and high specific surface area is prepared. Precursors of cathode materials. The process of the invention is simple, there is no additional cost on the basis of the existing mainstream discontinuous method, and it is not only suitable for manganese-containing precursors, but also suitable for nickel-cobalt-aluminum and other manganese-free precursors.

Owner:JINCHI ENERGY MATERIALS CO LTD +1

Agricultural waste anion adsorbent and application thereof

InactiveCN101693188BSimple production processApplicable production processOther chemical processesWater/sewage treatment by sorptionFiltrationSorbent

The invention discloses an agricultural waste anion adsorbent and an application thereof. The agricultural waste anion adsorbent is prepared by adopting wheat straws, epichlorohydrin and dimethylamine as raw materials under the condition that alkaline media exist. Under the condition of room temperature and oscillation, pH value of waste water is adjusted to be smaller than or equal to 7.0, the anion adsorbent is added, and solid-to-liquid ratio of the adsorbent to dye waste water is enabled to be larger than or equal to 0.4 g / L. Oscillation time is not less than 30 minutes, and the anion adsorbent can be separated after filtration. The method has the advantages of simple process, low cost, economical, applicable and reproducible properties and the like. The adsorbent has the characteristics of good stability, good adsorption effect, wide applicable scope and the like, and can be widely applied to anion dye waste water treatment.

Owner:SHANDONG UNIV

Water blocking belt longitudinal package auxiliary device

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

Exposure process for different levels

InactiveCN100478782CReduce in quantityReduce mistakesSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusComputer scienceMultiple integration

Owner:MACRONIX INT CO LTD

A kind of tft array substrate of flexible liquid crystal panel and manufacturing method thereof

ActiveCN108828863BApplicable production processEasy to makeSolid-state devicesNon-linear opticsAmorphous siliconPolydimethylsiloxane

A preparation method for a TFT array substrate of a flexible liquid crystal panel, comprising: preparing an amorphous silicon layer (20) on the surface of a substrate (10) (100); preparing a TFT array (30) on the surface of the amorphous silicon layer (20) (200); cleaning the surface of the TFT array (30) (300); preparing a polydimethylsiloxane substrate (40) on the TFT array (30) (400); using lasers to irradiate, so that the amorphous silicon layer (20) is separated (500); providing a flexible substrate (60), and adhering the TFT array (30) to the flexible substrate (60) (600); and peeling off the polydimethylsiloxane substrate (40) (700).

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

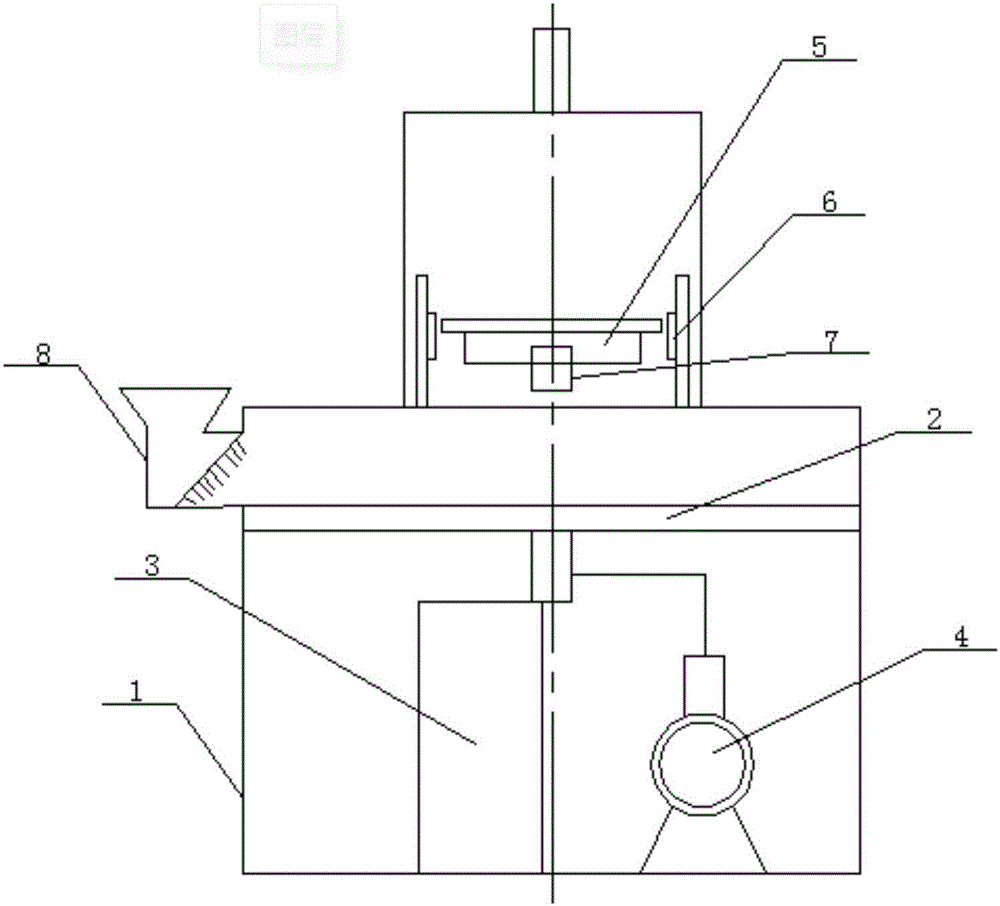

Forming machine for anti-thunder equipment

The invention provides a forming machine for anti-thunder equipment. The forming machine for the anti-thunder equipment comprises a working platform. The working platform is arranged in a machine frame, is as wide as the machine frame and can slide up and down along sliding grooves formed in the two sides of the machine frame. A pneumatic transmission device and a vacuum forming device are arranged below the working platform. The left side of the working platform is connected with a feeding port. A brush is arranged in the feeding port. A pressing device is arranged above the machine frame. Distance displaying devices are symmetrically arranged on the two sides of the pressing device, and a correcting device is arranged on the front side of the pressing device. The forming machine for the anti-thunder equipment is simple in structure, convenient to operate and suitable for the production process of the anti-thunder equipment.

Owner:XINCHANG LEIKAI TECH CO LTD

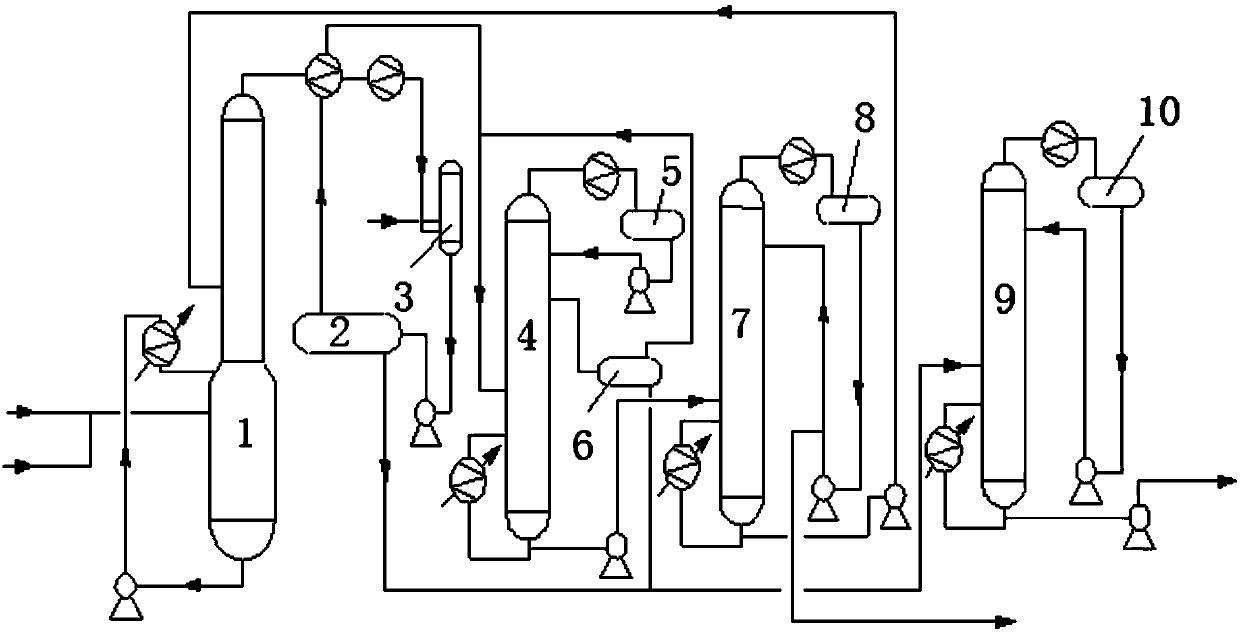

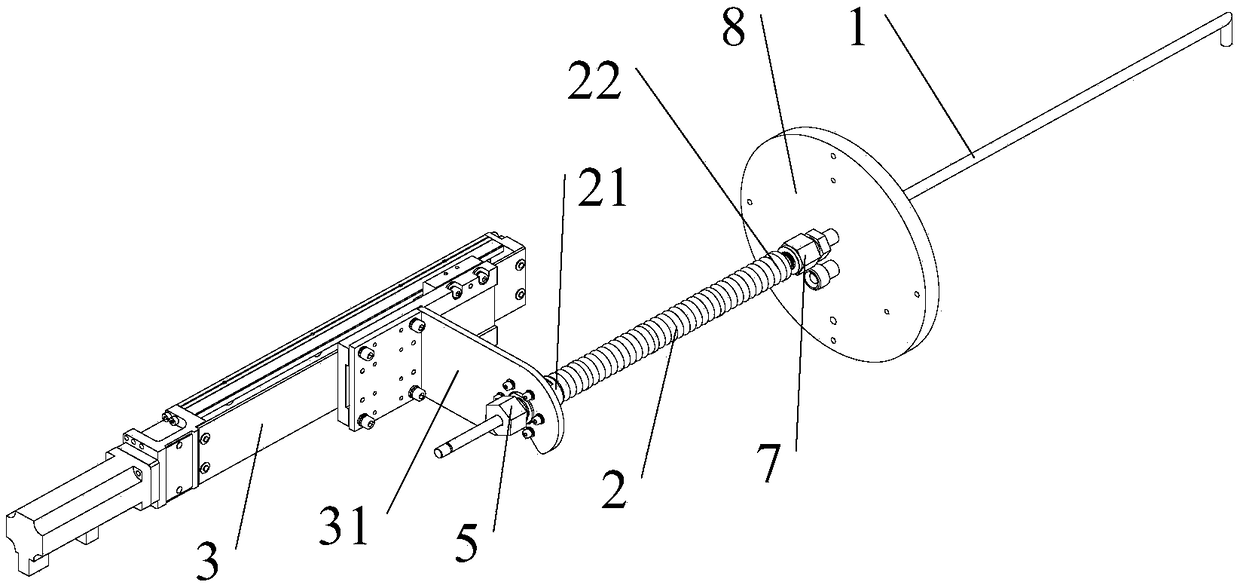

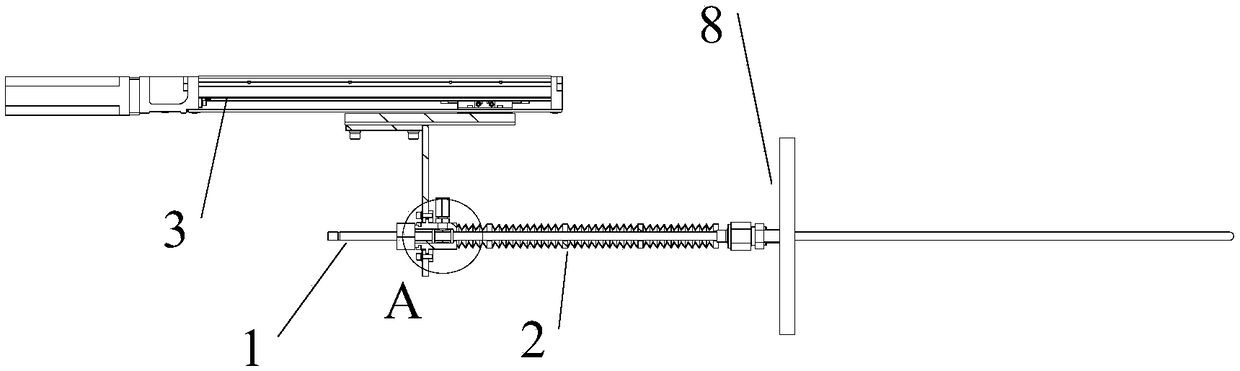

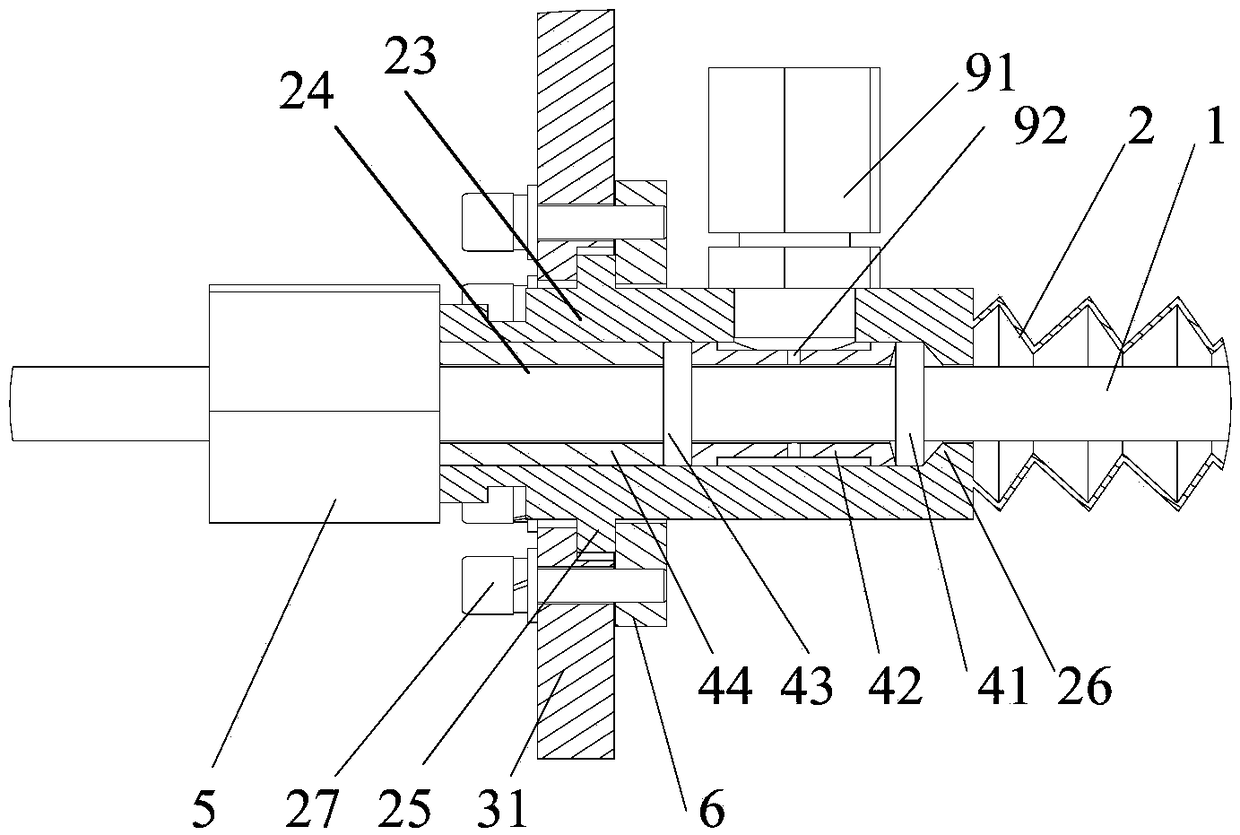

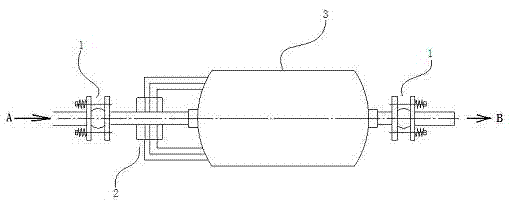

Method for allowing multiple fluid working substances to enter rotating reaction container in insoluble sulphur production

InactiveCN102874766ATroubleshooting Access to Rotary Reactor VesselsIncrease productivitySulfur preparation/purificationEconomic benefitsProcess engineering

A method for allowing multiple fluid working substances to enter a rotating reaction container in insoluble sulphur production is characterized in that according to the method, two externally-pressed spring spherical sealing swivel joints (1) are respectively mounted on pipelines at two ends of a drying pot (3); a multipass swivel joint (2) is mounted on the pipeline between one end of the drying pot (3) and one externally-pressed spring spherical sealing swivel joint (1); the path number of the multipass swivel joint depends on the kinds of the delivered fluid working substsnces; materials pass through one externally-pressed spring spherical sealing swivel joint and enter the drying pot through the pipeline, and is discharged out of the pipeline through the externally-pressed spring spherical sealing swivel joint at the other end of the drying pot; the pipeline connected with the multipass swivel joint only extends into the interlayer of the drying pot. The invention can greatly improve the production efficiency of insoluble sulphur, reduce worker labor intensity, and has very good economic benefits. The invention is suitable for production process of allowing multiple fluid working substances to enter a rotating reaction container, and especially suitable for production process of insoluble sulphur.

Owner:江西恒兴源化工有限公司

A system and process for rapidly extracting pure ethyl acetate after pressurized esterification synthesis

ActiveCN109534997BHigh purityReduce driving timeOrganic compound preparationChemical industryWater storageAcetic acid

Owner:YANKUANG GRP CO LTD

A low-resolution touch screen image defect detection method based on sparse representation

ActiveCN104200478BImprove robustnessImprove real-time performanceImage analysisCharacter and pattern recognitionImage resolutionImaging Feature

The invention discloses a low-resolution touch screen image defect detection method based on sparse representation. The method includes 1, extracting image features from a normal touch screen image training set to establish a dictionary D of normal samples; 2, performing optimization screening on the redundant dictionary D with noise features and selecting a sub-dictionary D' serving as a sparse-representation dictionary of training samples; 3, during defect detection, extracting the features of an image y to be detected, and figuring out the coefficient of the y represented through the D' in a linear manner by means of l1 norm minimization; 4, if the image y to be detected is a touch screen image without defects, allowing the coefficient represented through the D' in a linear manner to be sparse, otherwise, allowing the coefficient to be not sparse. According to the method, a redundant dictionary of over complete bases is established through the touch screen image without defects, elements in the dictionary are selected in an optimized manner to establish a redundant dictionary, and defect detection is performed on the touch screen image by means of the characteristics that the touch screen image without defects can be reconstructed through the dictionary sparse linearity but an image with defects cannot be reconstructed through the dictionary sparse linearity.

Owner:GUANGDONG UNIVERSITY OF BUSINESS STUDIES

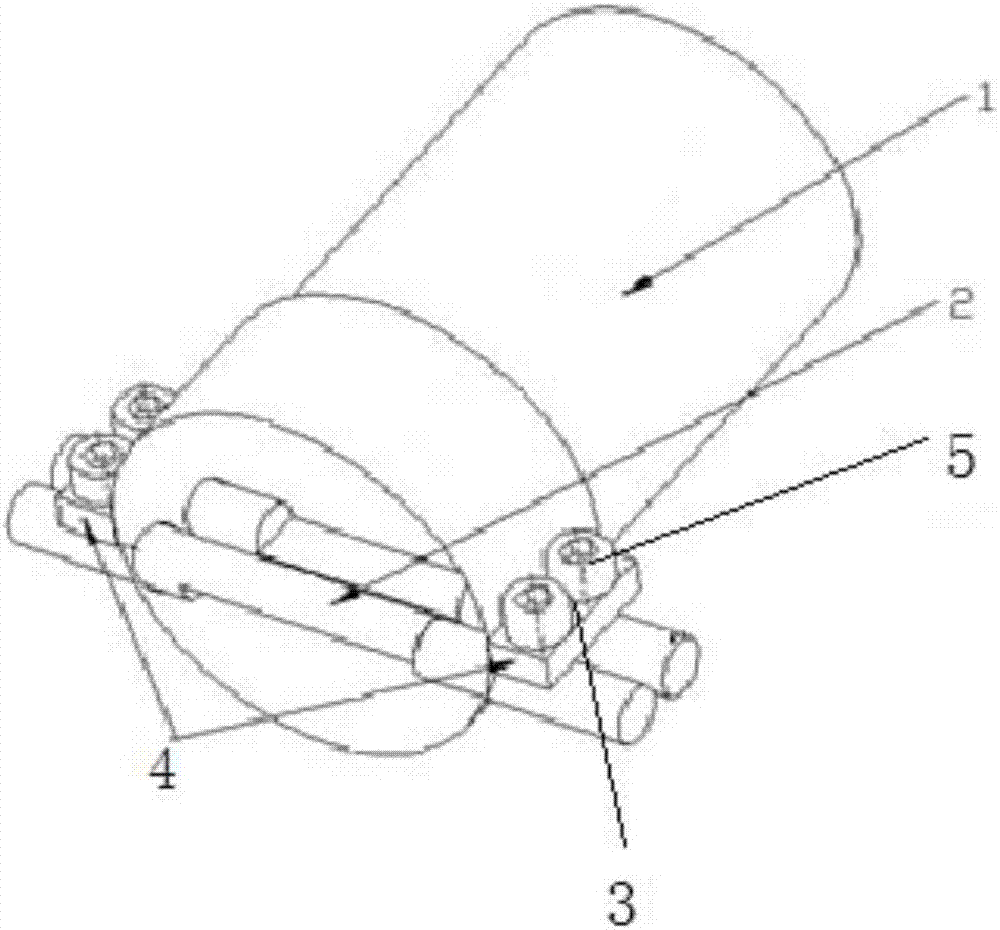

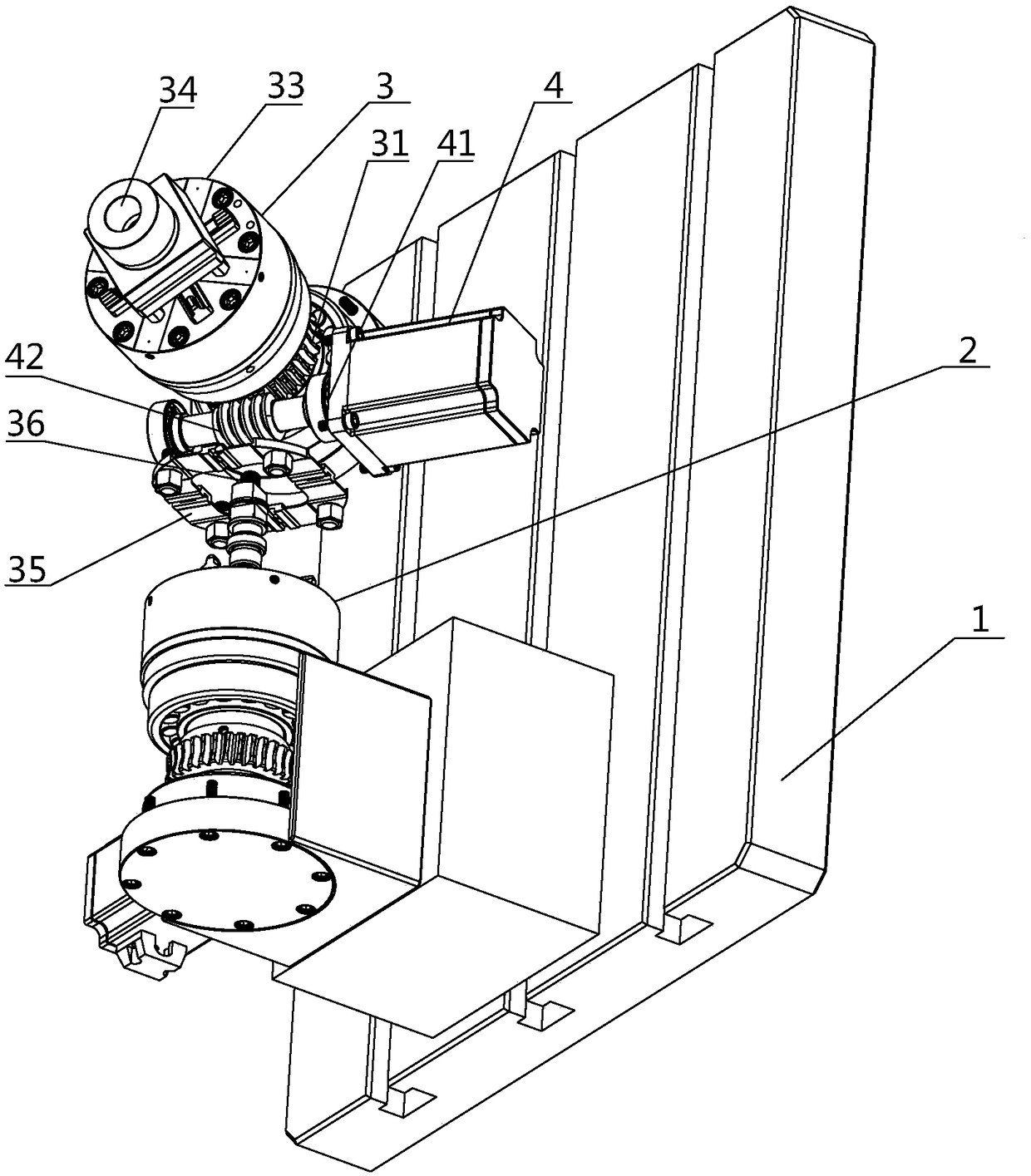

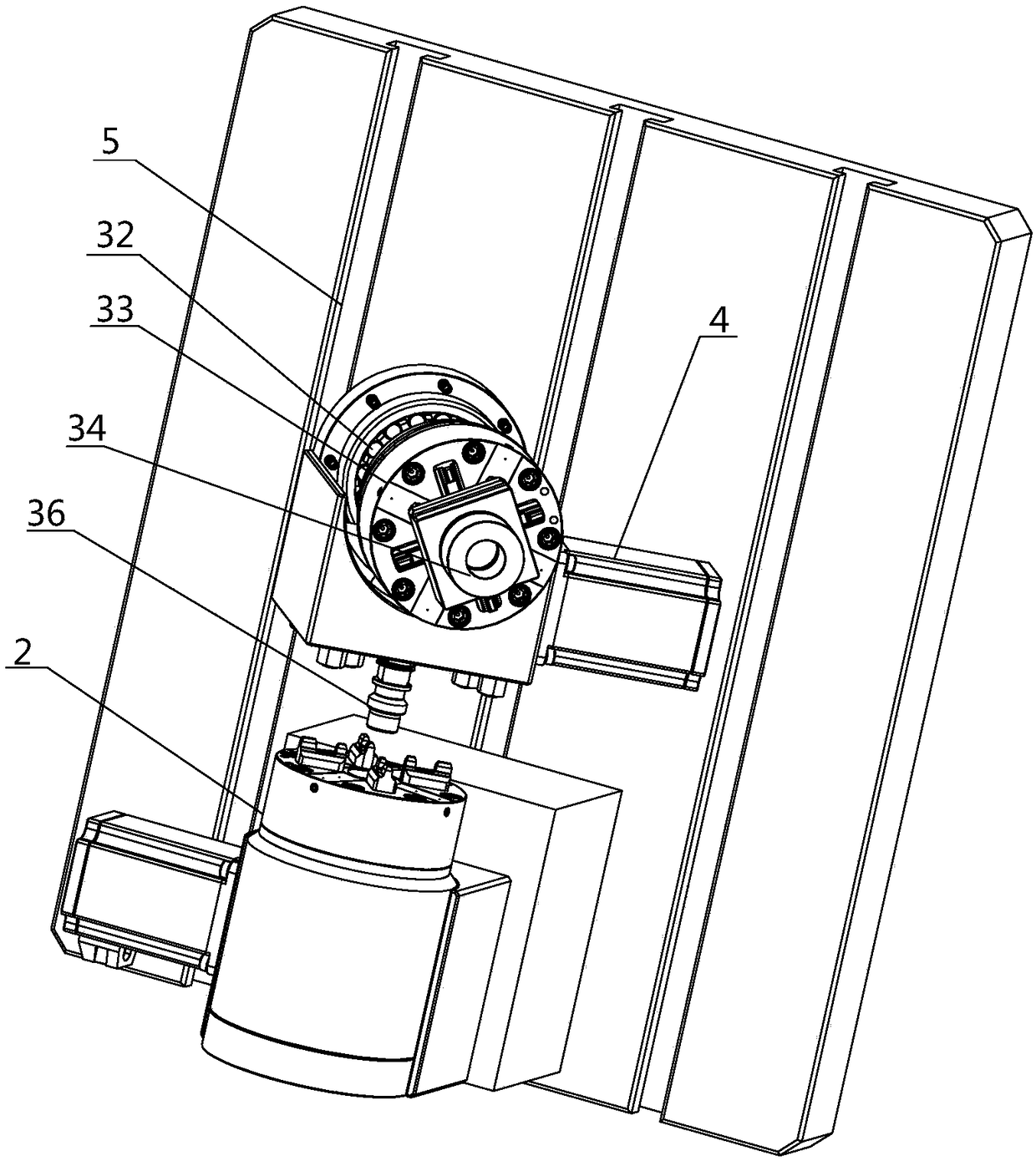

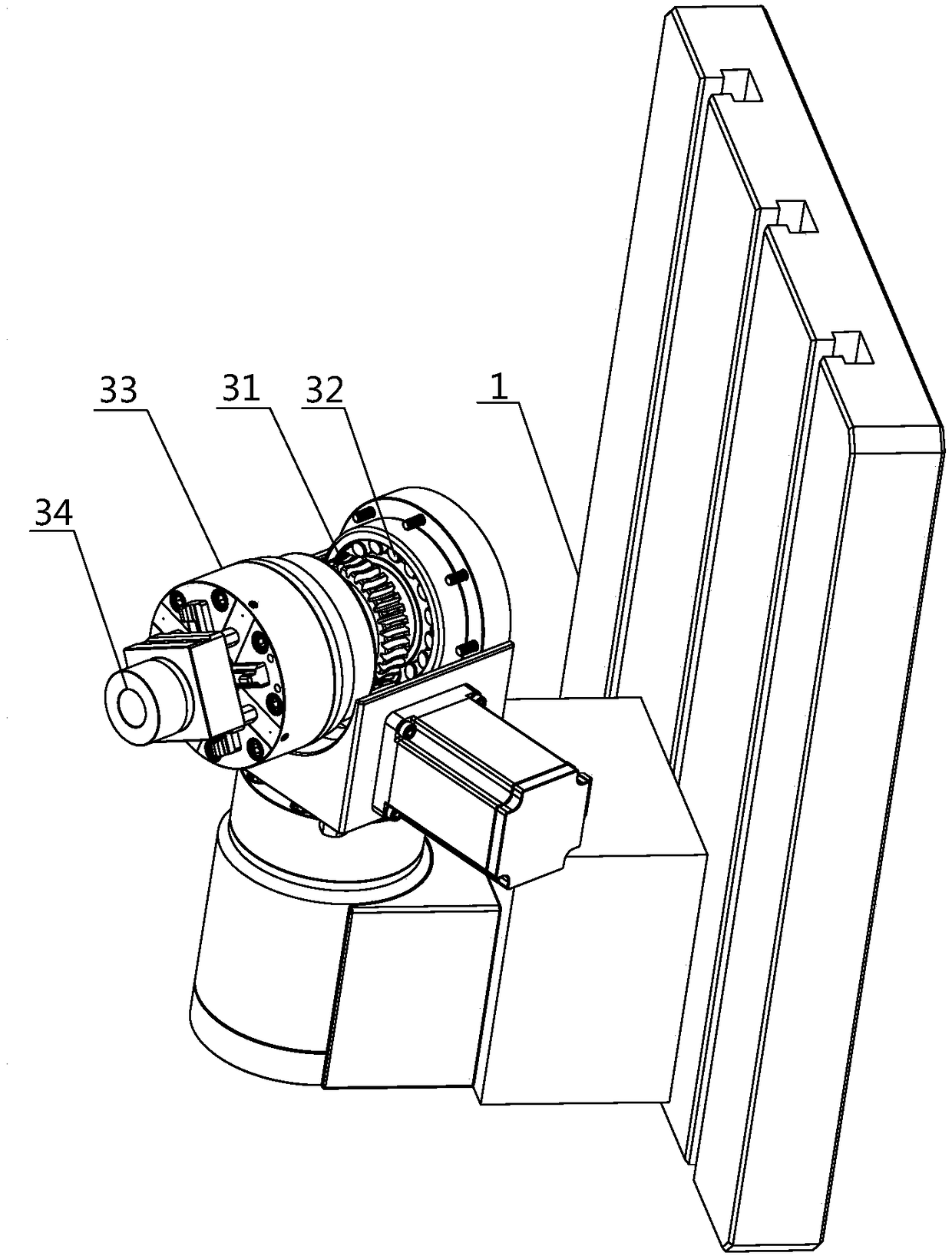

Motor drive multi-shaft combined mechanical arm system

PendingCN108161915AAvoid replacementIncrease or decrease the number of axesProgramme-controlled manipulatorBall bearingMotor drive

The invention relates to a motor drive multi-shaft combined mechanical arm system which comprises a horizontal direction one-shaft mechanical arm arranged at the top end of a vertical direction one-shaft mechanical arm. The horizontal direction one-shaft mechanical arm and the vertical direction one-shaft mechanical arm are movably connected through a rotating shaft assembly, and the horizontal direction one-shaft mechanical arm is made to rotate. The horizontal direction one-shaft mechanical arm comprises a gear outside a ball bearing and a motor driving mechanism on a mechanical arm base. The motor driving mechanism comprises a worm gear, teeth of the worm gear are engaged with wheel teeth of a gear outer ring, so that the worm gear is rotated and drives the gear, and the gear drives a rotating assembly of the horizontal direction one-shaft mechanical arm to rotate. The multiple sets of mechanical arms which can achieve multi-shaft work can be formed, one one-shaft mechanical arm isinstalled on the other one-shaft mechanical arm, one or more one-shaft mechanical arms are directly assembled according to requirements of the machining technology of a machining machine tool, the requirements for replacement of the whole mechanical arm are lowered, the shaft number of the mechanical arms can be freely increased or decreased conveniently according to different requirements, and the application range is wider.

Owner:东莞市特力精密夹具有限公司

A kind of preparation method of green high-purity thermoplastic phenolic resin

The invention discloses a preparation method of green high-purity thermoplastic phenolic resin, belonging to the technical field of phenolic resin materials. The preparation method comprises the following steps: (1) weighing phenol, aldehyde and acid catalysts; (2) heating reactants to 60-120 DEG C in a stirring state, and reacting for 1-6 hours at normal pressure and constant temperature; (3) performing normal pressure drying at 100-160 DEG C, and then pelletizing; and (4) conveying a phenolic resin particle material into a super-critical carbon dioxide extraction tower, and adding alcohol or ketone extracting agents which account for 0-20% of the mass of the resin to perform dephenolization treatment for 5-30 minutes to obtain a required product under the conditions that the extraction temperature is 31-50 DEG C, the extraction pressure is 8-20Mpa and the separation pressure is 5-7Mpa. By adopting the preparation method disclosed by the invention, free phenol can be effectively separated from the thermoplastic phenolic resin, the emission of phenolic wastewater can be reduced, the yield of the product can be improved, and the continuous production without pollution can be achieved, so that the preparation method is suitable for the production of various thermoplastic phenolic resins.

Owner:HUAINAN NORMAL UNIV

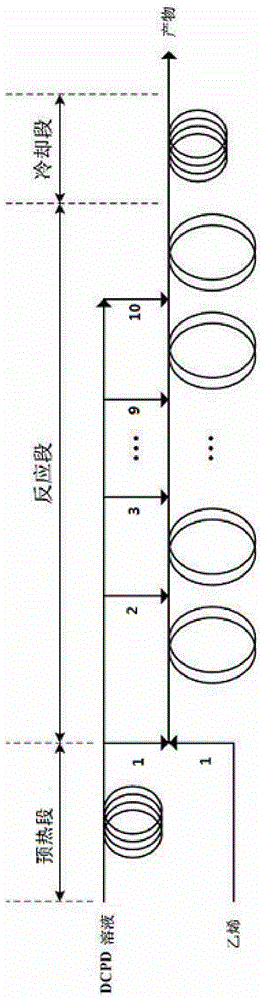

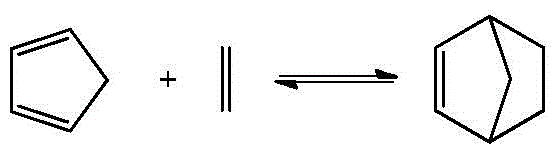

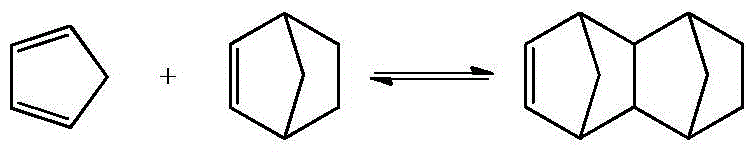

Method for synthesizing norbornene by microchannel reactor

ActiveCN104692993BImprove securityHigh synthesis efficiencyHydrocarbons from unsaturated hydrocarbon additionNorborneneReaction temperature

The invention discloses a method for synthesizing norbornene by a micro-channel reactor. The micro-channel reactor comprises a reaction section, wherein the reaction channel of the reaction section is provided with more than two feed ports arranged in the material flowing direction. The method comprises the following steps of feeding dicyclopentadiene into the reaction channel of the reaction section from one of the feed ports, feeding ethylene into the reaction channel of the reaction section from the first feed port, and controlling the reaction temperature in the reaction channel to be 180-300 degrees centigrade and the pressure to be 5-30MPa, wherein the standing time in the reaction section is 0.5-10min, and the mol ratio of ethylene and dicyclopentadiene solution is (1-10):1. Bu utilizing the method, norbornene can be synthesized safely and efficiently by the micro-channel reactor.

Owner:ZHEJIANG UNIV

A kind of hollow positive electrode material and its precursor, and preparation method

ActiveCN113247970BLow costThe core accounts for a large proportionSecondary cellsPositive electrodesPhysical chemistryLithium-ion battery

Owner:JINCHI ENERGY MATERIALS CO LTD +1

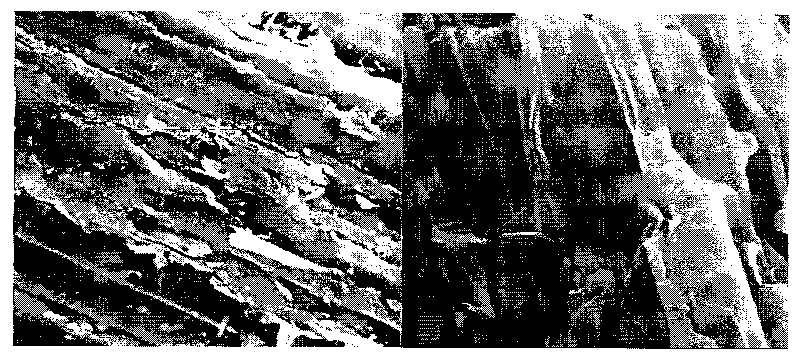

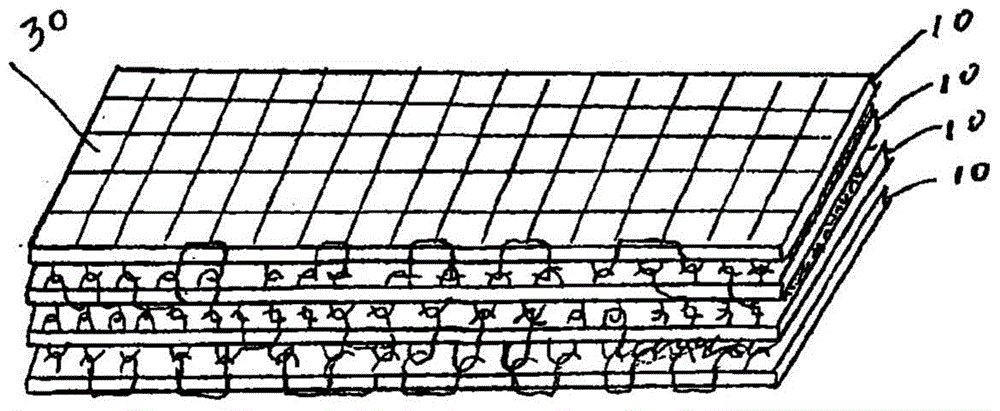

Fiber product and manufacturing method thereof

The invention discloses a fiber product which is characterized by comprising fiber bodies and connecting components arranged on the fiber bodies, wherein fiber plates, blanket products, or fiber plate-blanket product combinations are served as the fiber bodies; hook combinations or hook-loop combinations are served as the connecting components and arranged on one surface or both surfaces of the fiber plates or blanket products; the fiber bodies with the connecting components are immersed in a liquid matrix before or after being overlapped, so as to form three-dimensional fiber prepregs; and when a plurality of three-dimensional fiber prepregs are overlapped, the connecting components on the adjacent three-dimensional fiber prepregs are connected and firmly bound to form a three-dimensional composite. The invention further provides a manufacturing method of the fiber product. By adoption of the fiber product and the manufacturing method, the purpose of enhancing the mechanical strength, interlaminar strength, fatigue strength and impact strength of the three-dimensional composite can be fulfilled.

Owner:韩楠林

Steamed bread slice making flour modifier and use thereof

InactiveCN101664048BIncrease specific volumeImprove organizational structurePre-baking dough treatmentFood productsSteamed bread

The invention relates to a flour modifier and use thereof, in particular to a steamed bread slice making flour modifier and use thereof. The flour modifier comprises an enzyme preparation, an oxidant, an emulsifier, a swelling agent, a phosphate and starch, can be used for making wheaten food product such as steamed bread and steamed bread slices, improve the structure of steamed bread slices, make the hole in the steamed bread slices more uniform, provide the steamed bread slices with good appearance and improve the crisp degree and yield of the steamed bread slices.

Owner:ANGELYEAST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com